Your Premier Tablet Disintegration Tester Manufacturer

- Adjustable Test Time

- Overheating Protection

- Real-Time Display Of Time And Temperature

Disintegration Tester

Allpack disintegration testers are a special test instrument for controlling the quality of solid preparation drugs. The instrument is suitable for testing time limit of disintegration solid preparations such as tablets, sugar-coated tablets, film-coated tablets, enteric coated tablets, extract tablets and capsules. It is a kind of drug disintegration measuring instrument with advanced level.All the disintegration testers are built-in user right management, audit trail, data management system with high precision integrated circuit design that ensures measurement accuracy.With high definition touch screen with simple interface, the disintegration testers have minimal operational mode. And all disintegration testers have high precision real time constant temperature control and fault prompt function.

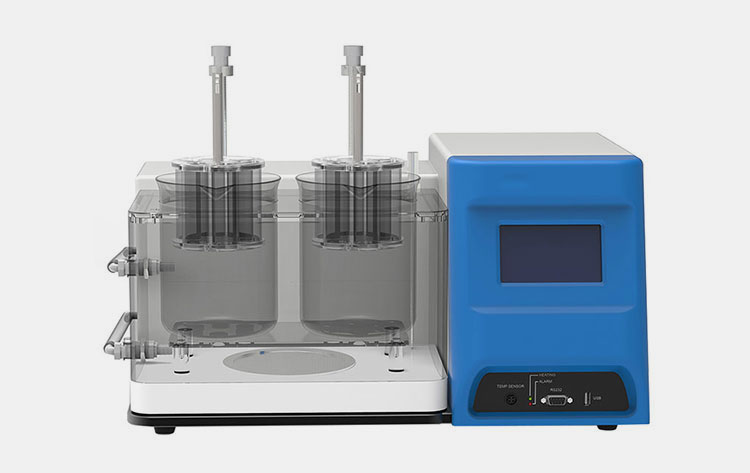

Allpack Disintegration Tester

APK-3D Laboratory Tablet Disintegration Tester Apparatus Tablet Disintegration Time Limit Tester

Allpack APK-3D Laboratory tablet disintegration tester is a new type of apparatus designed in accordance with the requirements of the Chinese Pharmacopoeia. It adopts international advanced design concept and manufacturing technology. Its shape is smooth and beautiful, compact and stable, and it is highly reliable and easy to operate. Etc. This disintegration tester is widely used in pharmaceutical factories, medical research, teaching and research and drug inspection departments.

Adjustable test time

Real-time display of time and temperature

Overheating protection

APK-2D Intelligent Tablet Disintegration Tester Time Limit And Dissolution Rate Testing

Allpack APK-2D Laboratory tablet disintegration tester is a drug test instrument to test the disintegration time limit of tablets, capsules and pills in accordance with Chinese Pharmacopoeia.With three-basket working position system measures disintegration time limit. 3 sets of baskets, which can realize 3-way independent operation to be controlled independently. With electronic temperature sensor can display and monitor various points in water bath case and the temperature in the beaker. High-precision digital electronic sensor is adopted to ensure the high precision and high accuracy of water bath temperature without the need for calibration.

Smart, automatic control, automatic detection, automatic diagnosis and automatic alarm

Automatic temperature control and high temperature control precision.

Automatic time control and automatic timing shutdown

The Buyer's Guide

Disintegration Tester: The Complete Buying Guide In 2025

Are you involved in quality control? Do you need to comply with strict regulations for product testing? Then there is equipment for you- Disintegration tester.

Pharmaceutical and other medical care industries rely on accuracy testing performance because failure to do so would result in severe health outcomes for the patient. Therefore, many quality control procedures have been adopted in the healthcare sector with one of them being the disintegration test.

This critical quality control test is performed by a disintegration test that records and analyses disintegration behavior in real-time. Do you want to obtain efficient outcomes from this equipment?

If yes, here is a complete buying guide for you. It will discuss different facets of disintegration tester and will aid you in capitalizing on your product quality and accuracy. Let’s explore together.

1.What is Meant by Disintegration Tester?

Allpack Disintegration Tester

The main job of the disintegration tester is to determine the rate at which the sample entirely breaks down into smaller fragments inside the medium. It is an instrument engineered for precise calculation of the disintegration time of different dosage forms. It detects the disintegration ability of a sample from its fabricated state to tiny, loose, free-flowing particles.

For the sake of simplicity, the disintegration tester measures whether the sample fragments into powdery forms or stays as a solid mass.

For medication ingredients to be able to successfully absorb into the human circulation and deliver their desired effects, they should crumble into the gastrointestinal tract and dissolve in the gastrointestinal fluids. This feat of fragmentation is evaluated by a disintegration tester.

2.Why Disintegration Tester is Popular in Manufacturing Sectors?

Disintegration tester is exceedingly renowned in the medication manufacturing sector because of its ability to determine the disintegration profile of a sample and it is effective in maintaining regulatory compliance and supports the creation of competent drugs. Let’s detail some reasons that contribute to the popularity of disintegration testers.

Role in Quality Control

Role in Quality Control- Picture Courtesy: Tecnalia

Since the disintegration tester accesses the ability of solid oral dosage to break within the specific time frame, it attains uniformity in the drug release and guarantees every batch in the products has the required quality standard. This leads to safer medication and a reduction in product recall.

Measures Drug Bioavailability

Measures Drug Bioavailability- Picture Courtesy: Total Laboratory Services

Disintegration tester also has a role in measuring drug bioavailability because it detects the rate of disintegration that leads to drug absorption in the bloodstream. It measures the time after which the drug is accessible to the body for absorption. Measuring bioavailability is vital in boosting medication effects.

Regulates Manufacturing Process Control

Regulates Manufacturing Process Control

This device is routinely employed in the research and development sector to access the uniformity of formulation, which is essential in determining the process parameters- compression force and granulation- for the production of optimized products that have a desired disintegration rate.

Versatility

Versatility- Picture Courtesy: Tablet-Tester

One of the significant reasons for using a disintegration tester is its versatility. It is used for testing a variety of dosage forms because it can measure diverse disintegration profiles. This adaptability makes it an essential device in the pharmaceutical sector.

Stimulation of In-Vivo Behavior

Stimulation of In-Vivo Behavior- Picture Courtesy: QbD Group

The disintegration tester is essential in mirroring the conditions in the gastric tract, helps predict the performance and behavior of dosage form in the body, and allows manufacturers to access the functioning of dosage form without carrying out mass-scale in-vivo studies.

Product Stability

Product Stability

Disintegration tester also carries out stability studies and aids in evaluating the stability of the product over time. The stability of dosage form is the indicator of its shelf-life and product quality because changes in the environment have a significant effect on medication fragmentation and release.

3.Where is Disintegration Tester Found?

A disintegration tester is a valuable device, majorly seen in industries and research centers, where testing of different dosage forms is compulsory. Some of the important areas where disintegration tester has found its use are:

Pharmaceutical Manufacturing

Pharmaceutical Manufacturing- Picture Courtesy: Advanced Technology Services

A disintegration tester is one of the most significant equipment for quality control in the pharmaceutical businesses. It evaluates the disintegration accuracy of solid dosage and allows pharmaceuticals to meet the pharmacopeial standards. This device is found in batch testing and quality control laboratories in the pharmaceutical sector.

Research and Development Sector

Research and Development Sector

It is very pivotal to optimize drug formulation because it impacts the safety of patients. Proper disintegration affects bioavailability and therapeutic efficacy. Therefore, the research and development sector utilize disintegration tester to aid researchers in estimating the pharmacokinetic properties of formulations.

Regulatory Laboratories

Regulatory Laboratories- Picture Courtesy: TempGenius

Regulatory organizations such as the FDA or EMA and other local health groups use a disintegration tester to check product compliance with pharmacopeial regulations. Their job is to test products independently to ensure that pharmaceuticals have the required disintegration profile.

Clinical Center

Clinical Center

Various tests are performed in clinical and bioequivalence centers to compare the disintegration rates of several generic and branded medications. For this, disintegration tester is routinely used in these study centers and verifies that generic formulations have similar disintegration time to their branded counterparts.

Nutraceutical Businesses

Nutraceutical Businesses

Various nutraceuticals must have a comparable disintegration rate to that of pharmaceutical products. Thus, nutraceutical industries use a disintegration tester to study the breakdown rate of dietary supplements and ensure that they break accurately in vivo.

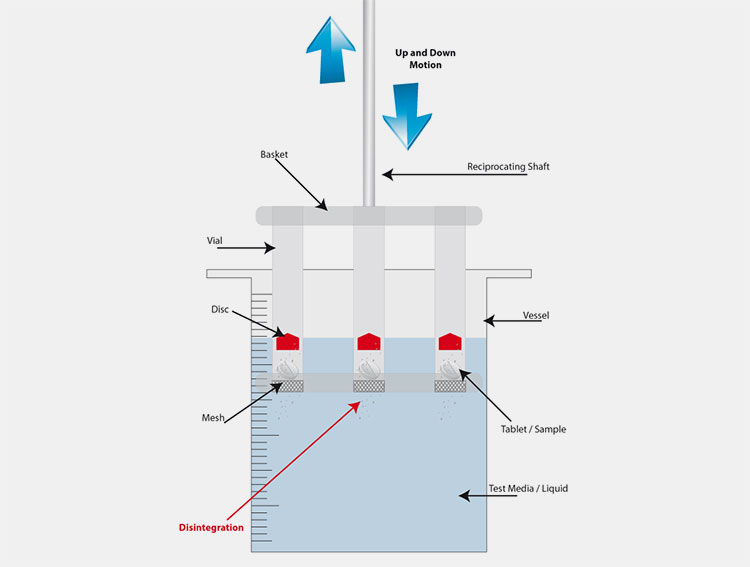

4.What is the Structural Design of Disintegration Tester?

Understanding the basic parts of a disintegration tester aids in assessing its work efficiency. So, for your ease, we are explaining the structural design of a disintegration tester and its basic parts in detail.

Structural Design of Disintegration Tester

| Machine Cover | It is a protective covering that shields the internal components from environmental agents and other accidents. It is essential to keep the machine safe and extend its shelf-life. |

| Temperature Probe | It is a vital part of the disintegration tester and allows accurate monitoring of the temperature of the liquid medium. It ensures maintenance of consistent (37°C0 temperature for accurate testing. |

| Vessel | Stimulated gastric fluid (SGF) and oral solid dosage are loaded in the vessel. The dosage forms are placed in a basket assembly within the vessel, which ensures complete submergence in the SGF. Glass vessels and stainless-steel vessels are most common because of their transparency and durability, respectively. |

| Water Bath | This part has significance in the disintegration tester and ensures that the temperature of the machine is at the required limit. It is heated to 37°C to imitate the physiological temperature. Baskets are also submerged in the water bath. |

| Reciprocating Arm | It is a cylinder that has up-and-down linear movement, essential for inducing gastrointestinal tract environment in the test baskets. It mimics the action of the digestive tract by its agitation. It helps in the fragmentation of solid dosage. |

| Display Screen | It offers real-time information to the operator and is equipped with a touchscreen interface. This aids in quick programming inputs and stores pre-set program options for rapid operativity of the machine. |

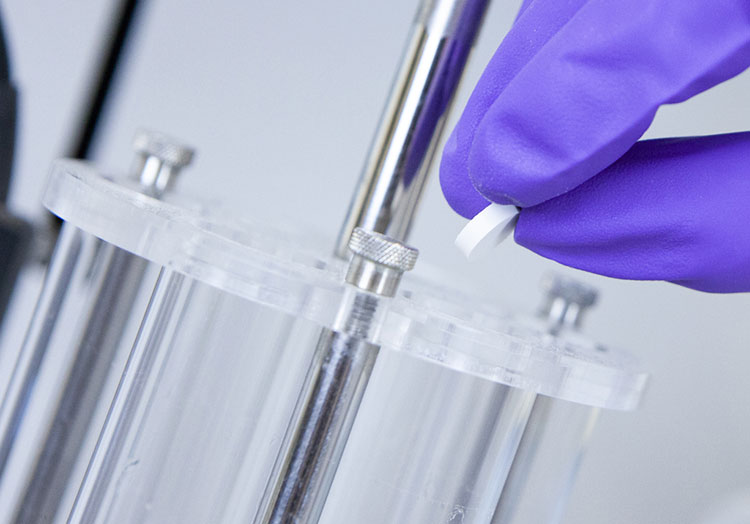

| Basket-Rack Assembly | This component has major importance in the disintegration tester, as it holds the dosage forms during analytical procedures. It is immersed in the liquid medium and make sure dosage forms are consistently subjected to the test medium. It avoids the floating of samples and allows movement of the medium. It has about 6-12 cylindrical tubes or baskets. These tubes are mounted on the rack, which keeps them oriented in the vertical direction. |

| Basket Cover | For the absolute security of solid dosage, the basket covers are used in the basket-rack assembly. This part keeps the pharmaceuticals in place and retains them inside the basket. |

| Plastic Disc | It is present within the basket-rack assembly, above the dosage form and its function is to gradually apply light downward force so that pharmaceuticals stay immersed in the liquid or SGF medium. |

5.How Does Disintegration Tester Work?

The disintegration tester has a special place in the manufacturing sector because of its smooth and efficient working performance. It is an innovative instrument comprising different parts that work in synchronicity to ensure accurate test results. Let’s explore the working of a disintegration tester:

Preparation

Preparation- Picture Courtesy: Merlin Powder Characterisation

First, the program parameters are set on the display panel, for instance, time, temperature, agitation speed, volume, etc. The solid dosage for testing is loaded in the cylindrical baskets present in the basket-rack assembly. The disintegration medium is heated to about 37°C to imitate body temperature. The medium is then loaded in the vessels, which are encased by the water bath.

Immersion

Immersion- Picture Courtesy: SOTAX

In the next step, the basket-rack assembly having oral solid dosage is put into the medium, in such a way that it is fully immersed in the latter. Afterward, the perforated discs are put over the dosage forms to make sure they stay under the water.

Agitation

Agitation- Picture Courtesy: Justdial

After the submergence of the complete basket-rack assembly, the reciprocating arm lifts and drops down in the basket for about 15 minutes, the friction and mechanical forces created by the movement of the reciprocating arm help in the disintegration of the sample.

Disintegration and Observation

Disintegration and Observation- Picture Courtesy: Pharmaceutical Network

The samples immersed in the disintegrating medium break apart into tiny fragments by constant agitation and test medium subjection. As soon as 15 minutes have passed, the agitating arm is stopped and lifted upward and is inspected. If there are fragments on the mesh, it means the test has failed.

However, the test is successful if samples are completely disintegrated, meaning there are no residues seen in the basket, except for fragments like insoluble shell coats. If the disintegration time is within the desired range, it means that the product fulfills the quality standards.

6.What Product Types are Tested by Disintegration Tester?

The disintegration tester tests a wide range of product types. Here is a list of products accessed by the disintegration tester:

Tablets

Tablets- Picture Courtesy: Cleveland Clinic

It is a widely prescribed solid dosage form and is prepared by compression of active ingredients and excipients. There are a variety of tablets evaluated by the disintegration tester like coated tablets, uncoated pills, effervescent tablet types, chewable, delayed, and extended-release tablets. This device also detects the disintegration profile of buccal and sublingual tablets.

Capsules

Capsules

These dosage forms contain encapsulated ingredients like powders, granules, pellets, tablets, and liquids surrounded by a shell covering. This covering is manufactured from gelatin or plant-based materials like cellulose. A disintegration tester is utilized to test the disintegration rates of a variety of capsules, such as hard gelatin, soft gelatin, starch capsules, and HPMC capsules.

Suppositories

Suppositories-Picture Courtesy: Love Wellness

These solid dosage forms are typically manufactured for administration into the body cavities, for instance, rectum or vagina. It is used for treating local infections and disorders. Since they dissolve at the human physiological temperature, therefore, disintegration tester estimates their breakdown rate under a simulated physiological environment.

Pellets and Granules

Pellets and Granules

Some kinds of granules and pellets, particularly those created for immediate release are tested by a disintegration tester. This instrument determines how rapidly they fragment when exposed to stimulated digestive tract conditions.

Pessaries

Pessaries- Picture Courtesy: Natura Sophia Herbs

They are administered into the body areas like the vagina, where they deliver their effects by melting in the vaginal environment. Hence, a disintegration tester is usually utilized for measuring their correct disintegration time under suitable physiological conditions.

7.Can the Disintegration Tester Handle Multiple Samples at the Same Time?

Processing of Multiple Samples by Disintegration Tester- Picture Courtesy: DKSH

Pharmaceutical sectors and research clinics are required to test samples at faster rates to minimize downtimes. Therefore, they want to use versatile devices that can process multiple samples in one go. So, a disintegration tester is designed for handling multiple samples in one cycle.

In general, the standard type of disintegration testers can deal with 6-12 capsules or other solid dosage types at the same time. This results in efficient testing performance and allows research to compare numerous samples under the same conditions.

However, it should be mentioned number of samples handled by a disintegration tester typically depends upon its specific model and design.

8.How Do You Ensure Proper Maintenance of Disintegration Tester?

Good maintenance and cleaning practices always produce optimized results, maximize work efficiency, and prolong the lifetime of the instrument. Therefore, manufacturers and researchers pay special attention to the maintenance and cleaning aspects of disintegration tester. We have penned some appropriate tips for you to get better outcomes from this machine:

Routine Cleaning

Routine Cleaning- Picture Courtesy: Charles Ischi AG

It is important to remember that basket-rack assembly is the chief component of the disintegration tester. Therefore, it is advised to stick to a proper and thorough cleaning schedule for attaining error-free results. Baskets, beakers, water baths, and vessels should be removed from the machine and carefully cleaned with mild detergent to discard residues from earlier testing and avert mineral buildup.

Calibration

Calibration- Picture Courtesy: Charles Ischi AG

The performance of the disintegration tester is dependent upon the temperature probe, time mechanism, and agitation speed. So, it is a must to perform calibration of a temperature sensor, timer, and agitation speed through a standard thermometer, stopwatch, tachometer, or other suitable devices, respectively.

Inspection

Inspection of Disintegration Tester- Picture Courtesy: ERWEKA

You must inspect baskets, plastics, vessels, and beakers for any evident damage, for instance, cracking, deformation, scratching, or break lines to avoid inaccuracy in the test results. Also, make sure the basket-rack arrangement is properly aligned and fitted in place to prevent inconsistent agitation.

9.What Pharmacopeial Standards Does Disintegration Tester Comply?

Pharmacopeial Standards- Picture Courtesy: Platinum Diagnostics

A disintegration tester must conform to different pharmacopeial standards for safeguarding the quality, accuracy, effectiveness, and safety of the pharmaceuticals. A few significant pharmacopeial standards that disintegration testers comply with are discussed below:

| United States Pharmacopeia (USP)

|

It is the most comprehensive resource for medication quality standards across the globe. It is dedicated to improving the quality guidelines of active ingredients, excipients, chemicals, and biologics. It aids in boosting confidence and trust in drug treatments. USP standards include requirements for the disintegration tester like test conditions, number of samples, apparatus, and disintegration time. |

| European Pharmacopoeia (Ph. Eur.)

|

It is the main source of executive quality standards of therapeutics and their drug components in Europe. It consists of compendium information on the systematic and accessible composition of medications and different tests conducted on them. Ph. Eur. includes guidelines on apparatus and breakdown duration of different dosages during testing in disintegration tester. |

| British Pharmacopoeia (BP)

|

It is the official pharmacopeia of the United Kingdom. It is a set of information on qualitative and quantitative aspects of dosage forms. It comprehensively describes testing instructions on medicinal compounds and sets disintegration time limits, apparatus type, and testing conditions for the disintegration tester. |

| Japanese Pharmacopoeia (JP)

|

It is an official publication in Japan that specifies guidelines on assays, classification, purity of medicinal products, standard test procedures, and their testing apparatus. It details instructions on the calibration of the disintegration tester, its testing apparatus (basket), test media, and system requirements. |

10.What are Common Troubleshooting Issues with Disintegration Tester?

Nowadays, a disintegration tester is a noteworthy instrument in quality control processes because of its easy setup and convenience. It comes with a plethora of benefits but it also has some problems that are easily tackled. For your learning, we are presenting some basic problems and their solutions:

Inconsistency in Temperature Control

Inconsistency in Temperature Control- Picture Courtesy: Merlin Powder Characterisation

Sometimes, there are fluctuations in the temperature because the water bath cannot maintain a stable temperature. Also, temperatures go above and below 37°C.

Possible Solutions

Proper calibration of the temperature sensor can resolve this issue. Temperature deviations can be the result of poor functioning of heating elements, so ensure that they are working correctly. Check and clean the water bath so that it is free of dust, debris, or mineral accumulation. Verify the display screen reading using a separate thermometer to check if there is a problem with the display screen.

Inaccurate Agitation Speed

Inaccurate Agitation Speed- Picture Courtesy: Scientz

It is observed that there is incorrect movement of the basket-rack assembly in terms of its frequency and amplitude. This issue is due to several reasons like incorrect programming of agitation speed, malfunctioning in the drive units, and poor maintenance of the machine.

Possible Solutions

To solve this issue, it is advised to match the agitation speed with the speed specified in the test protocols. Also check the moving components for example, the drive system for damage, and ensure they are working flawlessly. Routine maintenance is necessary for keeping the agitation system in good condition.

Floating Samples

Floating Samples- Picture Courtesy: ALSIN

There comes a time when dosage forms are observed floating around or moving out of the basket during test settings. There could be numerous causes of this problem like incorrect placement of perforated discs. Improper alignment of baskets could contribute to this problem. There is an incompatibility between basket arrangement and samples.

Possible Solutions

This issue is resolved by following these recommendations, such as checking the positioning of the plastic discs in the basket and ensuring they are damage-free. Also, verify the alignment of baskets in the test medium and tight fitting of samples inside the baskets. Moreover, use right-type baskets and discs for particular dosage forms.

Incorrect Disintegration Time

Incorrect Disintegration Time- Picture Courtesy: Lorderan

The tested disintegration time is incorrect or inconsistent with other readings. Multiple factors lead to this issue, such as there is an error in comprehending pharmacopeial protocols. The timing mechanism and sensors are poorly calibrated or have malfunctioning issues.

Possible Solutions

It is suggested to properly follow test protocols and pharmacopeial guidelines. Check the wear and tear and calibration of the timing unit and other sensors. Correctly preparing and loading the samples into the basket arrangement solves this defect.

11.How to Buy a Suitable Disintegration Tester for Production?

When you are planning to buy a disintegration tester for manufacturing and research needs, we suggest having an insight into below mentioned essential points to get maximum efficiency and optimized results.

Types of Dosage Form

Types of Dosage Forms

It is a fundamental factor you must consider because identifying the types of samples- like uncoated, coated, effervescent, and other tablets and capsules- you will be processing is a great approach to choosing a disintegration tester. This is due to some models of disintegration testers that can handle only specific types of products.

Size of Processing

Size of Processing- Picture Courtesy: Disi-AutoSense

The processing volume is another significant factor that you should take into account when going out for purchase. Generally, the standard models of disintegration testers can process an average of 12 samples concurrently. For higher production volume, you will be required to select units with higher throughput.

Media Flexibility

Media Flexibility- Picture Courtesy: MedicalExpo

You must know that certain media are compatible with specific types of products. Therefore, to achieve versatility in product processing, it is important to choose a machine that can handle diverse kinds of media like water, simulated gastric fluid, saliva, and others.

Automation Characteristics

Automation Characteristics- Picture Courtesy: Pharma Test

Your disintegration tester should have advanced automation and software components that should not need much processing time. Therefore, always remember this argument when choosing this device as automated temperature control, sample placement, test recordings, etc. reduce valuable time and resources.

Calibration and Validation Service

Calibration and Validation Service- Picture Courtesy: Testo

It is integral to have calibration and validation service when buying the disintegration tester. Reputable manufacturers include starting calibration and validation of instruments as a part of services and this saves buyers from going out in the market for calibrating machines, which takes much effort and money.

Conclusion

This detailed article about a disintegration tester offers you a definitive opportunity to select a suitable device for testing and accessing the disintegration phenomenon of different samples in a simulated environment, which ensures the safety, excellence, and superior therapeutic effect of the solid dosage forms. This stringently regulated device is unquestionably a first-class approach to attaining maximum test accuracy and decisive outcomes. If you want the latest and unmatched disintegration tester or purchase-related details, then, without wasting time, contact us now and speak to our sales representatives.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours