Sugar Coating In Pharma:How To Make Your Tablets Better

What would be your choice when it comes to selecting regular and coated tablets? It would be a vibrant and easy-consuming coated formulation. Worldwide, the coated dosage form is always considered a preferred choice due to several reasons. That’s why sugar coating in pharma is hooked to high demand among pharmaceutical manufacturing companies. In this article, ‘Sugar coating in pharma: how to make your tablets better’ you will explore proficient tips and techniques involved in bringing the process with achievable goals.

Let’s get started it!

1.What is sugar coating?

Sugar coating- Picture Courtesy: Silverson machines

Sugar coating is the process utilized in the preparation of solid pharmaceutical dosage form which is applied over the surface of tablets in the form of the sugary layer to get several health-related benefits. Moreover, along with physiological effects, sugar coating is done to protect the medicine in many ways that range from protection of active to physiological effects.

The sugar coating is prepared by combining various substances that are potentially not harmful though exert inter effects and is prepared in the form of a thick solution, or a suspension that is applied with the help of a coating pan.

2.Why sugar coating in pharma is required?

Sugar coating in pharma is a traditional and popular method for applying coating on various solid dosage forms. Did you know that this is the most frequent method and has higher demand than other modes? There are certain reasons for this; we have explained them below:

A Better Taste

Good taste- Picture Courtesy: Banagel

The clear benefit of sugar coating in pharma is an improved taste. It is mainly prepared from the combination of various excipients and active ingredients. Absolutely, their taste is not good and not everyone can accept it. Therefore, a layer of sugar coat is applied over the outer surface of the drug to make it patient-compliant and easy to digest for everyone as it is not bitter anymore.

Look Glossy and Good

Good appearance

A smooth layer of sugar coat makes your drugs look nice. It directly gives a sophisticated finish and a good external appearance that offers good vibes when patients take it in. Moreover, your medicine looks appealing and easy to identify in terms of external looks and taste.

Protecting Your Medicine

Medicine safety- Picture Courtesy: Pharma Machinery

Choco beans are almost safe when coated with a layer of solution in this way your medicine is promisingly safe when encountering sugar coating. It acts as an external barrier against light, moisture, temperatures, and other unwanted contaminant. Yes, side by side, it protects to enhance unwanted bitter impressions too and makes the tablet more palatable when you’re taking it. However, it can act as an insulator that masks chemical effects on your taste buds as well as making medicine more protected.

Controlled Releasing

Controlled release- Picture Courtesy: Labor Przedsiębiorstw

Some tablets are designed to release at specific locations inside your body and at a specific time pace. For that, the sugar-coating layer plays a significant role.

For that, coating is done to regulate the kinetic of medicine or can alter the rate of releasing medicine.

Inexpensive way of Coating

Economical way of coating- Picture Courtesy: Liaoyang Bright Shin

Applying a sugar coat over the medicines is comparatively the most economical method than another mode of coating. Whether it is concerning the equipment or utilization of materials; this is a pretty low-cost application with abundant benefits.

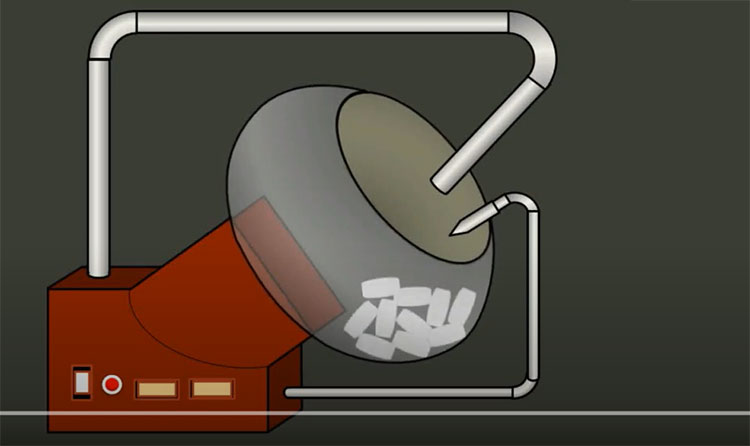

3.How to do sugar coating in pharma: how to make your tablets better?

Stages of sugar coating- Picture Courtesy: The medicine maker

The process of sugar coating in pharma is considered a simple method that is composed of multiple steps. The purpose behind every step is to coat the tablet properly with specific ingredients; let’s see them one by one. Do you know how sugar coating is taking place? When a tablet is sugar-coated, the multiple layers make an ultimate increase in weight which is up to 30 to 50% of total tablet weight. Let's see the steps of the process of sugar coating.

Sealing or Water Proofing

Sealing

To protect the tablets from the penetration of water and moisture, sealing is done. It makes the tablet strong and stable from external factors. Therefore, sealing is applied that is mostly prepared with either

This process is also known as waterproofing. Previously, shellac, which is a natural polymer used as a sealant. However, it is not used and replaced by CAP and PVAP. The reason behind its replacement is polymerization problems. When you need to apply sealing, the tablet core must be dried so the coating can be fixed properly.

The sealants are actually insoluble polymers means they act as a barrier to humidity and water content which is why it is known as water-proof coating.

Although, it is essential to optimize the whole process which mainly depends upon the tablet’s porosity and batch size. Therefore, shellac is meant for mainly enteric coating applications as it helps in extended-release tablet matrix upon ingestion.

The common Sealant used for Sealing are, Cellulose Acetate Phthalate or CAP, Polyvinyl-acetate Phthalate or PVAP, Hydroxypropyl Cellulose, Hydroxypropyl Methylcellulose (HPMC), Or Zein known as Corn Protein Derivative.

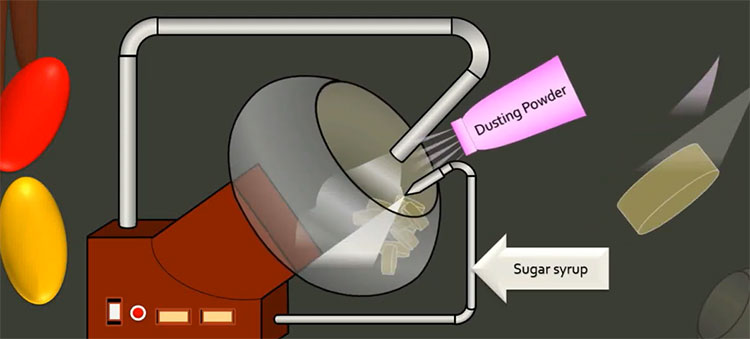

Subcoating

Sub-coating

This is known as the major step involved in sugar coating that possibly increases the weight up to 50% of the entire sugar coating. It is a kind of sandwich between a layer of gum layer and dusting powder. The primary purpose of subcoating is to laminate the tablet and mask imperfections of tablets. So, it ensures smoothness all around the tablet and makes an excellent shape with round shapes. The subcoating is mainly achieved by lamination and suspension procedures.

Now you should know that the shape of the tablet is very important. Tablets with fewer edges or corners will be capable of picking up maximum and effective coating materials. If it is not fully covered with coating material, then there are more chances of twinning which is a coating problem where tablets stick to one another.

There are two important procedures used for sub-coating:

Lamination

Here, the gum-based formulation is prepared and coated over the tablet bed. Once it is distributed uniformly all over the tablets, then it is followed by dusting powder. The purpose of using dusting powder is to reduce the stickiness of the sub-coating layer with drying. This procedure is repeated till you get a desirable result. You should take care to keep a balance between gum-based solution and dusting powder to achieve excellent subcoating.

Suspension

In the suspension, lamination solution or gum-based solution is incorporated with dry powder and applied over the tablet bed with air drying.

The drying powder material is suspended in solution. The suspension process is a comparatively easier method than lamination it requires high skills to manage the gum solution application, and the concentration of dusting powder to be applied over it. However, in suspension, there’s no need for such formalities, you just need to apply the solution coat.

Therefore, suspension reduces the complexities of the process, and you can achieve satisfactory outcomes without requiring high technicalities.

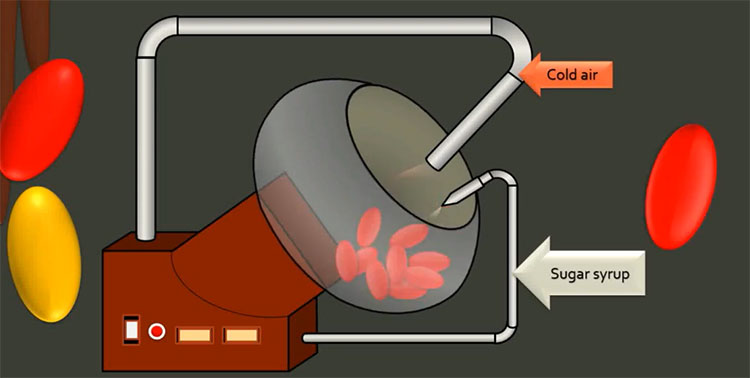

Smoothing

Smoothing

In subcoating step, there are still some irregularities left over the tablet surface. However, you can notice them clearly, to give more perfection and smoothening to the tablets smoothing or grossing is done. It is applied over the sub-coating layer and increases the bulk mass of the tablet up to the size of pre-determined measurements of the tablet.

In this process, you use sugar syrups which is almost composed of 60 to 70% of sugary content. This means it is a simple sugar solution. Also, there are constituents you can add to improve the smoothing such as starch, opacifiers, gelatin, etc.

In this smoothing, many manufacturers incorporate a small concentration of colorant to form a good base for further steps of coloring the tablet.

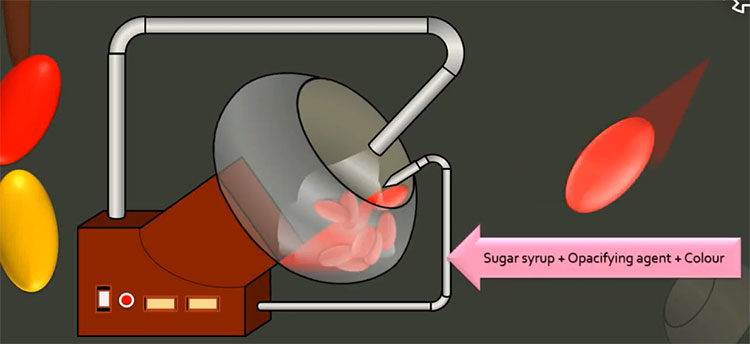

Color Coating

Color coating

This is an essential step of sugar coating that is followed once you’ve satisfactorily achieved other steps of coating such as sealing, sub-coating, and smoothing. You can count it as a final processing of sugar coating.

Here, your primary aim is to improve the color and aesthetics of the tablets for that along with sugar syrup you add coloring agents. It is mainly dissolved in the sugar syrup and applied over the tablet surface to achieve a dispersed layer all over it.

There is water soluble, and water insoluble dyes used for coating. For water soluble dyes there might be associated discoloration problems whereas water insoluble dyes are considered as suitable as it does not hook to discoloration issues and maintains batch to batch uniformity.

However, soluble dyes are a conventional way of color coating but require much technical skills to maintain uniformities in every batch. However, in case of any mishandling may result in tablet mottling.

Therefore, water insoluble offers you various benefits such as no risk of color migration, shortening of coating time, and rare chances of mottling.

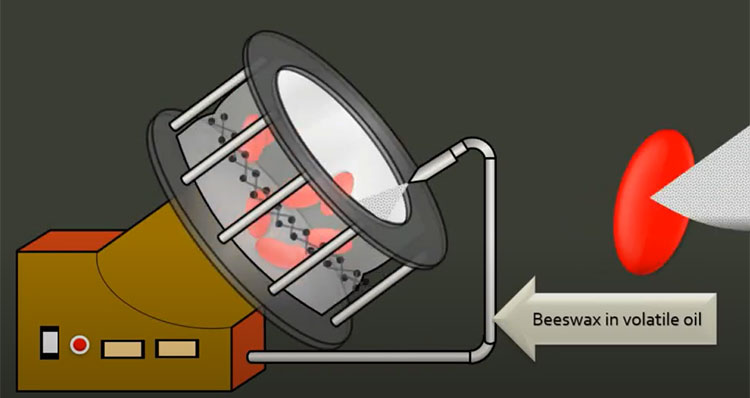

Polishing or Glossing

Polishing

Generally, sugar coated tablets are dull in color if polishing is not done. To make them shiny and glossy, the polishing is done. Therefore, it ensures to production of final elegance to your tablets. Polishing is mainly done by using various waxes sprayed on a tablet bed along with air to make them dry simultaneously.

It is commonly recommended to air dry tablets overnight before it is subjected to the polishing process. By this, you will be pretty sure that tablets are ready for polishing and on a fully dried surface. If your tablets are holding moisture content, then it would make polishing challenging and may result in blooming after some time.

Printing

Printing- Picture Courtesy: Akley Machine

You have seen many sugar-coated tablets with printed information, either a name, logo, or strength. Sometimes, printing is done before polishing to strong adherence of ink over the coating layer. However, it can be dull after the polishing process due to the action of various solvents.

Similarly, common practice is to print after the polishing process to have clear effects. However, the effects of wax do not help you with strong adhesion. Therefore, modified shellac is used as a pre-print-based solution to have strong printing effects.

4.What materials are used for sugar coating in pharma?

A sugar coating solution is composed of various elements with their proper ratio. We have enlisted them just right below:

Sugar

Sugars- Picture Courtesy: Epicurious

This is the primary significant step used for sugar coating. The sugar application has various benefits such as, first of all, it gives you a sweet taste. The second reason is that it gives a smooth and shiny appearance to the tablets. Thirdly, it would be very surprising to know that sugar acts as a binding agent for the coating layers. The commonly used sugar in the process is the sucrose.

Corn Syrup

Corn syrup- Picture Courtesy: Fine Dinning Lover

This is known as a liquid sugar that gives a smooth texture and excellent appearance to the tablets. Apart from its sweet taste, it provides flexibility in the coating process and facilitates an even application of coating material without having risk for crystallization.

Colorants

Colorants

Colorants are included in the sugar coating to boost the visual appeal of the tablets. These provide a wide range of colors to distinguish the tablets. With different colors, patients, and caregivers recognize tablets immediately and precisely.

These coloring agents are both natural and artificial dyes. Moreover, color coding of tablets boosts patient compliance, as different colors attract children and elderly patients alike. Coloring agents also aid in improving the stability of the tablets.

Colorants may consist of water-insoluble pigments and water-soluble dyes, for instance, iron oxide pigment, aluminum lakes, etc.

Flavoring Agents

Favoring Agent- Picture Courtesy: Algonquin College

The flavoring agent is the essential component of the sugar-coating formulation. It is necessary for enhancing the taste and palatability of the tablet. The flavoring agent makes it easier for patients- especially those with sensitive taste buds- to swallow the medication. They impart the desired aftertaste and odor to tablets.

In certain cases, it may shift or mask the bitter taste of pills, making tablets pleasant to ingest. Flavoring agents may be naturally extracted from the plant, animal, or microbial source or may be synthetically formulated. Common examples of flavoring agents are mint, villain, or fruity extract.

Binders

Binder

Binders are adhesive, with the literal purpose of binding sugar-coating agents to the surface of the tablets. They are integral in creating consistent and even layers on the exterior of tablets. Moreover, they increase the stickiness and strength of the coating materials, making them long-lasting and preventing their peeling off or crumbling with time.

This helps in retaining the structural integrity of the tablets.

Binders may include gelatin, acacia, and cellulose derivatives to improve the durability and stability of coating, ensuring the integrity of tablets during the handling and storage stages.

Plasticizers

Plasticizer- Picture Courtesy: Aussie Candle Supply

Plasticizers are the agents, added in the sugar coating preparation to boost the flexibility, stretching, and elasticity of the film layer. With the addition of plasticizer, the coating film becomes soft, tough, and flexible, which aids in averting its cracking and brittleness. Due to pliability, the sugar-coating film can tolerate mechanical strain during the packaging, production, and, swallowing stages.

Some examples of plasticizers are glycerin and sorbitol, these materials enhance coating texture and handling features, consequently leading to improved efficacy and longevity.

Waxes

Waxes

Waxes are the polishing agents incorporated in the sugar coating formulation to improve the visual appearance of the tablets. Uncoated tablets are dull and lacking luster, so waxes are typically added to the sugar-coating film to impart a characteristic shiny and bright look to tablets. This increases the elegance of the tablets. Waxes also seal minute irregularities in the exterior of pills.

Furthermore, they improve the moisture and abrasion resistance of tablets by acting as a protective layer. Besides this, it also increases the mobility of tablets during the packaging stages by reducing their stickiness.

Important waxes in the sugar coating include beeswax and carnauba wax, which are incorporated about 80-95% w/w and 5-15% w/w, respectively.

Powders

Powders

Powders are a vital part of the tablet sugar-coating process, including the subcoating step. First and foremost, it helps in the absorption of surplus moisture content from syrups, thus averting the risk of tablet stickiness.

Furthermore, the powders boost the evaporation of moisture during the drying step by enhancing the surface area for evaporation. It also adds bulk and opacity to the sugar-coating formulation. Powders are constituted as a base for depositing sugar syrup and coloring agent layers.

Moreover, it provides smoothness and lubrication to tablets. Some powders like talc and calcium carbonate, facilitate the bonding of sugar layers and increase the longevity of the coating.

Conclusion

In summary, we hope the article on ‘Sugar Coating In Pharma: How To Make Your Tablets Better’ would be worth reading for you. Nevertheless, a sugar coating in pharma has been used for decades and still demonstrates high demand for it. The aforementioned details of sugar coating help in the making of better tablets. This is not only a simple method but allows you to enjoy high-quality solid dosage forms economically. If you are planning to implement sugar coating for your tablet then we suggest you contact our experts. Why us? Allpack is a trustworthy industry to offers solutions associated with sugar coating. Not only this, but you can facilitate with expert guidance related to the sugar coating process as well as equipment. For more information; contact us now.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours