V Blender: The Complete Buying Guide In 2025

Do you know what happens if compounds in formulations are not blended properly?

In the manufacturing industries, blending of powders is considered an integral element behind the success of any product. What makes it possible?

Picture Courtesy: Body+ Soul

There are various types of blenders designed and available in the market that have been best known for dealing with challenging tasks of blending and making consistent and uniform particle distribution throughout the mixing bed. Among them, the V blender is the most popular machine as it is simple and performs tremendous processes without needing your expertise or technical knowledge.

In this article, you’re going to explore V blender and how it interplays a challenging task consistently. Don’t go anywhere if you’re planning to purchase this machine; I know you will find this page very informative! Let’s start with our post.

1.What is a V blender?

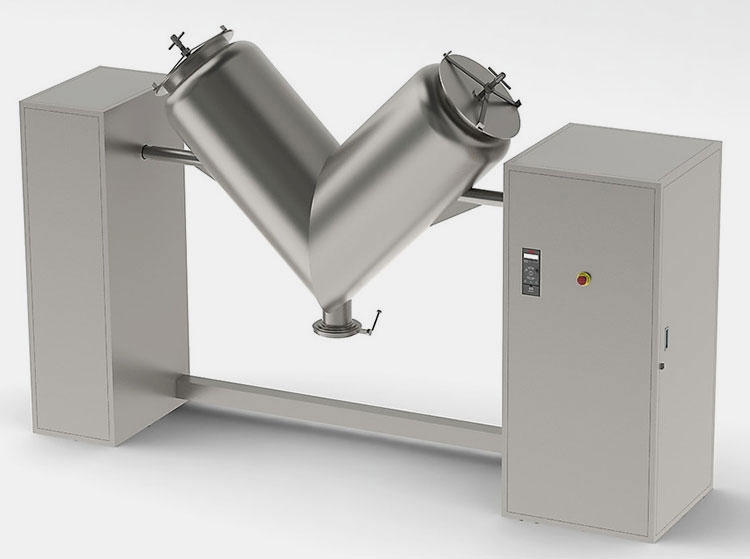

V Blender- Picture Courtesy: GrabCAD

It is one of the most frequently utilized blenders, belonging to the family of tumbling blenders. It is also called a twin-shell blender, due to its two hollow cylindrical. It has a distinctive V shape, thus the name V blender. The two angled cylinders are fused to create a V shape that has a unique role in diffusive blending.

It smoothly mixes solid-solid particles in any ratio. Moreover, it also blends solid-liquid ingredients precisely. V blender provides uniform blends of granulated, ground, and powdery materials.

2.Why V blender is so significant?

V blender is a great industrial equipment that processes up to 10 different ingredients in one cycle. It has a pivotal role in the manufacturing industry because of its unlimited benefits. This type of blender generates substantial profit margins for the industries.

Here are some common pros of V blender that boost its significance in different industries.

Homogenous Mixing

Homogenous Mixing

V blender has a characteristic V shape that makes mixing and blending easier. Its designs ensure homogenous and complete mixing. Its mixing action boosts the flowability of different particles, thereby, promoting diffusive amalgamation. This blender consistently leads to the division and combination of powdered mixture.

Gentle Handling

Gentle Handling- Picture Courtesy: Apel Laser

One of the major concerns in industries is the mixing of fragile substances. Therefore, a V blender is typically involved in the gentle handling and mixing of fragile materials because of the absence of a shaft or rotor. This results in low impact mixing force, causing minimal size reduction of particles.

Unlike other traditional blenders, the V blender ensures low-shear mixing. Hence, there is no loss of structural integrity with the V blender.

Accurate Blending

Accurate Blending-Picture Courtesy: Lifeboost Coffee

V blender is known for its accurate blending. There is less than 2% blending nonuniformity with this blending machine. Moreover, the use of a V blender results in less amount of trace compounds. Precise and fast mixing in a small blending cycle is one of the significant advantages of the V blender.

Versatility

Versatility- Picture Courtesy: Body+Soul

This blending equipment is highly recommended for dry mixing of various free-flowing materials. These substances have diverse bulk densities and weights. Furthermore, it is capable of processing feeds of a miscellaneous nature like granules, powders, liquids, or solids.

Cleanability

Cleanability- Picture Courtesy: Eminence Organic Skin Care

Thanks to its unique V-shaped structure, it is convenient to clean and maintain. Moreover, with few moving parts, operators have an easier time cleaning different areas of the V blender. Cleaning of this machine is also aided by the fact that it has two separate vents for loading and discharging.

It is produced using stainless steel that is hygienic and has cleaning flexibility.

Safety

Safety-Picture Courtesy: The Unwinder

Its enclosed design plays a pivotal role in preventing contamination of blends. Also, it creates a dust-free environment, enhancing the operator's safety. It is fitted with safety rails and guards that minimize direct contact to the machine, while it is running.

It also includes a locking door to avoid over-agitation of materials.

3.What is the role of V blender in various manufacturing sectors?

V blender is a trusted machine in all industrial sectors due to its uniform and state-of-the-art mixing performance. Pre-mixing of raw feed is extensively accomplished due to V blenders. Let’s discuss the role of V blender in different manufacturing sectors.

Pharmaceutical Industry

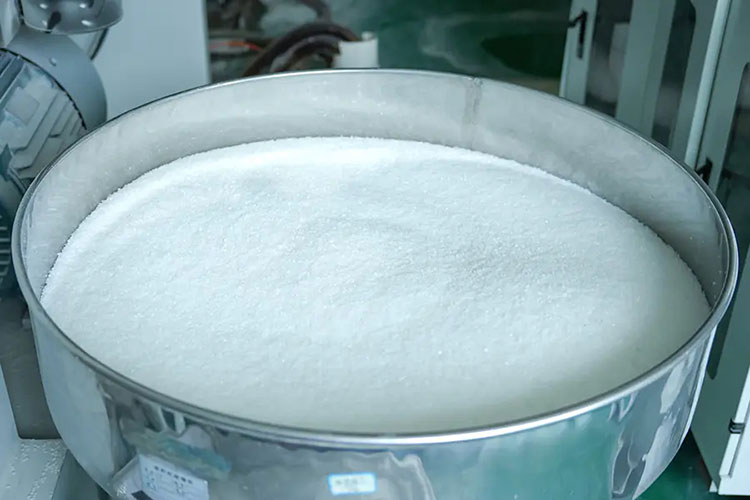

Pharmaceutical Powder

V blender is frequently found in the pharmaceutical industries because of its ideal mixing efficiency. Its accuracy makes it valuable in the pharmaceutical industry, as minute errors in formulation can ruin the potency of medication. Pharmaceutical manufacturers prefer the V blender due to its simple and gentle blending action. It handles active ingredients with great care.

Nutraceutical Industry

Nutraceutical Powders

Due to the numerous health-related benefits of nutraceutical supplements, their use is increasing day by day. So, to achieve homogeneity of the blend, the V blender is mostly utilized in the nutraceutical sector. Herbal formulations, energy bars, and vitamin and mineral blends are some of the products fabricated using V blender in the nutraceutical industry.

Food Industry

Food Powder

Mixing and blending are two vital processes in the food industry. As a result, V blender is an indispensable part of the food industry. It has a noteworthy role in creating ideal blends of spices and herbal mixes. V blender is highly demanded in the food sector because it enhances the culinary experience by forming homogenous mixtures.

Chemical Industry

Chemical Powders

V blender is usually utilized in the chemical industry before end manufacturing. It has a significant part in the blending of various kinds of chemical powders like pigments, paints, additives, coatings, detergents, and cleaners. This equipment formulates a uniform distribution of chemical components.

Agriculture Industry

Agriculture Powders

Seamless blending of different agriculture constituents leads to the production of animal feed, granular fertilizer, pesticide materials, and other farming chemicals. For this purpose, V blender is increasingly utilized in the agriculture field. It yields precise and uniform mixing outcomes.

Cosmetic Industry

Picture Courtesy: Treehugger

Delicate blending of fragile cosmetic powder is a typical use of V blender in the cosmetic industry. This industry relies on the V blender to form an ideal cosmetic combination, as it does not comprise the properties of powders. It is commonly used in the manufacturing of talcum powders, cosmetic pigments, blushes, eye shadows, and many more.

4.What is the working of the V blender?

V blender relies on gravitational force to blend the materials. The working principle behind this machine is diffusive mixing. To operate the V blender at its maximum blending efficiency, it is vital to learn about its working. Thus, we are detailing the working of the V blender for your learning.

Feeding

Feeding- Picture Courtesy: Jerónimo Martins

The raw feed is usually loaded in the V blender at the start of the operation. It is done through feed ports, located at the top of the machine. It is advised to fill the V blender with about 50-60% of its total volume. Increasing this range results in a doubling of mixing time if uniform mixing is required.

Blending

Picture Courtesy: Denver Business Journal

As soon as the feed materials are loaded up to the desired volume, the mixing action of the V blender begins. The entire mixing shell rotates to achieve diffusive mixing. Due to the 360° rotation of the V blender, an avalanche of materials is created. In this falling of materials, the particles are split and fused, resulting in an even blend.

The mixing is attained by random falling of materials. The ingredients constantly fall towards and away from the central point with the movement of the vessel. This random movement with frictional force between the feed and walls of the V blender results in a consistent but delicate mixture.

Discharging

Discharging of V Blender- Picture Courtesy: Stil Pekarna

Finally, the blended mixture is discharged from the vent fitted with a butterfly valve. This port is found at the bottom of fused shells. The opening of the butterfly valve is either controlled manually using a hand lever or automatically using pneumatic controls.

5.What is the structure of a V blender?

This machine is composed of twin mixing vessels or barrels that are connected mutually at the angle of 70-90° to create a V shape. There is a huge assortment of parts in the V blender. These components act together to ensure that every blending batch has precision and consistency.

Some fundamental parts that have an essential role in blending are penned below:

Parts of V Blender

| Inspection Port | This vent along with the feed port is enclosed by cover to maintain the blend integrity. There are different types of inlet covers such as the ones that are secured by the safety pin and those that are locked by the clamp rings. This port aids in cleaning, checking, and maintaining the machine. |

| Intensifying Bar | It is the optional component present in some versions of V blender. It is fixed on the rotational axis of the equipment and functions as a lump breaker. The intensifying bar also plays a part in breaking large agglomerates. It offers adequate shear for reducing chunks. |

| Feed Port | This is the feeding inlet from which raw feed is poured into the machine. It is located at the top of the V shell. The inlets are hermetically sealed to maintain a dust-free environment. |

| Trunnion | It is a cylindrical structure that provides stability and support to the mixing vessel. It bears the whole weight of the equipment and allows the vessel to rotate. |

| Mixing Vessel | It is a V-shaped vessel and is one of the most critical components of the machine. The actual blending process happens in the mixing vessel. The rotation of the mixing vessel is essential in the cascading of materials that in turn causes the mixing of feed.

This part is fitted with intensifying bars, spray nozzles, jackets, and vacuum systems for increased mixing efficiency. |

| Safety Guard | It is a cage-like structure and is a fundamental safety feature. Its function is to safeguard operators from dangers during the machine's working. Some dangers include rotating parts and sparks. |

| Discharge Port | It is the vent from where blended materials are removed from the V blender. It is situated at the bottom part of the equipment, where two shells are joined. For optimal efficiency, the discharge ports are equipped with a butterfly valve that prevents material wastage. |

| Alarm Light | It is a detector that functions as a visual indicator by blinking light to notify the operators of abnormalities in the working of the V blender. It is an important tool from a safety perspective, as it helps decrease the risk of accidents. |

| Control Panel | It typically provides a platform for starting and stopping the machine. It is the main programming component of the machine that regulates the functionalities of the V blender. It is customized with different buttons and sensors to optimize the programming performance. |

| Gear Box and Motor | This blending machine is moved by the explosion-proof motor that is coupled with the gearbox. This assembly is responsible for maintaining the speed of the device. |

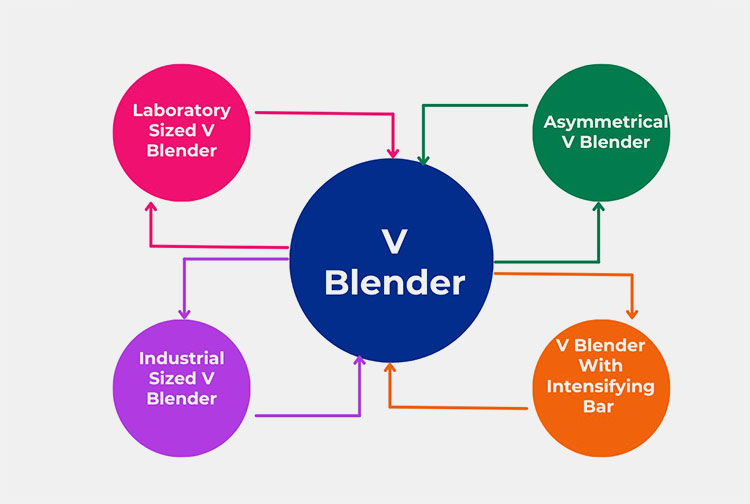

6.What are the types of V blenders?

There are diverse types of V blenders, depending upon their size and types. We are discussing each category one by one.

Types of V Blender

According to Size

There are two major kinds of V blenders based on size such as:

Laboratory Sized V Blender

Allpack Laboratory Sized V Blender

It is a small-sized portable V blender, highly recommended for small industrial research and developmental settings. It is mainly employed to attain rapid blending outcomes. This machine has a compact size and occupies less space on the bench tops.

It comes in laboratory sizes with a working volume of 5 liters to 1 cubic foot. Laboratory-sized V blender has a tilting design, aiding in quick discharge and cleaning. Moreover, it has a quick mixing time.

Industrial-Sized V Blender

Allpack Industrial-Sized V Blender

This machine is an innovative and preferred blending machine in mass-scale manufacturing. It is frequently seen in the production sector because of its high working capacity. It is best for processing bulk-density materials, ranging from 50 lbs/cu.ft to 900 lbs/cu.ft.

The design construction of this device is similar to that of its smaller V blender counterpart; however, it has a higher production rate. It is constructed in such a way that it can tolerate heavy loads and continuous blending cycles. This equipment can be furnished with automatic loading systems that offer swift material feed.

This machine has heavy-duty motors, essential in rotating demanding mixing vessels.

According to Design

In the market, two main types of V blenders are present based on their design.

Asymmetrical V Blender

Allpack Asymmetrical V Blender

It is a new variant of the conventional V blender. It has varying-length cylinders that form V shape mixing vessel. This asymmetrical design increases the flowability of powders, minimizes the chances of powder segregation, and lowers the blending time.

Moreover, this design allows more complex tumbling action and improves the mixing pattern of the powders and granules. It also decreases dead zones and improves interaction between particles in case of solid-liquid mixing. However, it is difficult to access and maintain an asymmetrical V blender.

V Blender with Intensifying Bar

V Blender with Intensifying Bar- Picture Courtesy: Munson Machinery

V blender often comes with intensifying bars or agitators. This intensifying arm or baffle is located inside the V blender. It is involved in high-shear mixing because it generates turbulence or high-shear force with the rotation of the mixing vessel.

A v blender with an intensifying bar is employed for blending cohesive and lumpy powders. It is best for both dry and wet mixing. It disperses the powder agglomerates to achieve better-blending consistency.

7.What materials can be blended in a V blender?

V blender is an all-inclusive machine, capable of processing a diverse range of materials. Some of these products commercially blended by this machine are stated below:

Mineral Powders

Mineral Powders- Picture Courtesy: ALTANA AG

Different types of minerals like metals and ceramics are daily processed in the chemical and construction industry. V blender is the characteristic machine to obtain the best blends of minerals. It is suitable blending equipment for brittle and abrasive powders.

Spices and Herbs

Spices and Herbs

V blender is a top-notch machine for mixing dried spices and herbs. This blended mixture of herbs and spices is often used in different cuisines to bring out mouthwatering flavors. It is also incorporated in supplements and skin care formulations.

Baby Food

Baby Food

Various kinds of baby formulas are blended by this device because of its sanitary design and clean construction. It is produced using stainless steel material that is food grade and it safely processes baby powders, averting the entry of foreign objects and contaminants.

Cosmetics

Cosmetics

Colorful and vibrant pigments create different types of shades and blushes. For producing such a mixture of cosmetic powders like mica and talc, V blender is increasingly used in the industries. It smoothly and softly blends different aesthetic additives due to the absence of moving blades.

Plastics

Plastic Resins- Picture Courtesy: Plastivision

Yes, plastic materials like resins and fillers are also processed in a V blender. This blender normally handles plastics in powdered and granular form. Moreover, the V blender is customized with cooling options to blend heat-sensitive plastics.

Flour

Flour

It is perfect for dry mixing of flour products. It gently rotates to evenly distribute flour particles without degrading them. It can process whole, refined, white, and brown flour for use in different bakeries.

8.What are cleaning and maintenance tips for a V blender?

When you regularly use a V blender, you see different types of residues like dust, product build-up, and other debris both on the exterior and interior of the machine. This could majorly deteriorate the performance level and operational expectancy of the machine. So, to avoid these issues, it is imperative to examine, clean, and maintain the V blender routinely.

Here are some cleaning and maintenance tips for you:

Cleaning

Cleaning of V Blender- Picture Courtesy: High-tech Conversions

| Disassembly | For absolute cleaning, it is a must to dismantle the removable parts like the butterfly valve and intensifying bar. Remove the covers. |

| Regular Cleaning | Clean the exterior surfaces of the V blender after every use to prevent the stickiness of products. It also saves the subsequent batches from cross-contamination. |

| Cleaning Agents | It is best to use food-grade cleaners to wash the machine. Also, warm water and mild detergent always do the best cleaning job. Moreover, for resistant residues, it is recommended to use compressed air and low-pressure water spray. |

| Drying | Before reassembling, ensure the parts and surfaces of the V blender are fully dried to avoid rusting and contamination. |

Maintenance

Maintenance of V Blender- Picture Courtesy: GEA

| Inspection | Routine inspection is a key step in preventive maintenance. Checking abnormalities in machine operation like degraded seals, cracks, noise, etc leads to effective machine operation. |

| Lubrication | The frictional buildup is a part of the normal working of a machine and causes damage to different mobile components. So, lubricate mobile parts for smooth mixing. |

| Calibration | Ensure calibration of the V blender is per the required range. |

| Part Replacement | In case of wear and tear of the parts, immediately repair or replace them to prevent further impairment. |

| Structural Alignment | Different structure components must be adjusted accordingly for a longer running life. For example, nuts and screws must be tightened, mixing vessels must be aligned, and intensifying bars must be positioned properly. |

9.What are the technical faults with possible solutions for the V blender?

Different minor technical errors will arise in the machine if it is working. These faults are cause of major headache for the manufacturers because they decrease profit margins. Nevertheless, these problems are easily tackled by taking suitable measures.

Here is the list of common technical faults in the V blender along with the possible solutions.

Longer Powder Mixing Time

Longer Powder Mixing Time

Cause

This is caused by several reasons:

- High level of powder in the machine.

- Powders are improperly loaded in the equipment.

- Powder particles have varying sizes.

Solution

It is recommended to:

- Fill the V mixing vessel about two-thirds.

- Load the V-tank in the horizontally as opposed to vertically.

- Use sieves to ensure uniform size of powder particles.

Material Damage

Material Damage- Picture Courtesy: Mercury Scientific Inc

Cause

It is caused by the setting of wrong mixing parameters.

Increased mixing speed is also the reason for material damage.

V-tank construction and characteristics of feed are incompatible.

This issue is also due to the use of intensifying bar at extreme mixing velocity.

Solution

It is best to:

Reset the mixing process parameters.

Lower the mixing speed.

Readjust the design of the equipment as per the properties of the starting material.

Decrease the mixing speed or forgo the use of an intensifying bar if not required.

Nonuniform Mixture

Nonuniform Mixture- Picture Courtesy: BulkInside

Cause

Overloading of the mixing vessel is one of the causes of non-uniform mixtures.

Insufficient mixing time could lead to this problem.

The incorrect design of the intensifying bar is also the reason for the nonuniform mixture.

Solution

The appropriate suggestions for this issue are:

Fill the V mixing vessel by 2/3 and leave 1/3 empty for consistent mixing.

Give adequate time for mixing.

Use appropriate design intensifying bar.

Abnormal Noise

Abnormal Noise in Machine- Picture Courtesy: iPharmachine

Cause

The major reasons for abnormal noise in the V blender are:

Inadequate alignment of components.

Damaged bearing.

Overloading of mixing vessel.

Worn-out drive belts and motor

Solution

It is advised that:

Realigned the skewed parts.

Replace the worn-out bearing.

Lower the level of materials in the mixing tank.

Attend to the mechanical issues in the drive mechanism and motor.

Powder Separation During Mixing

Powder Separation During Mixing- Picture Courtesy: Nihao Water

Cause

The main reasons for powder separation are:

Differences in the sizes of feed particles and their bulk densities.

Poor feeding sequence.

Inadequate blending timings.

Solution

The possible solutions to this problem are:

Ensure consistency in sizes and densities of feed.

Load the mixing vessel in the correct sequence.

Alter the blending duration.

10.What are the important factors you should determine before selecting the V blender?

Careful planning is a failsafe way to guarantee a successful outcome and this assiduous consideration is especially useful when selecting the V blender. Manufacturing units rely on the ideal machine to achieve higher profit returns. So, we are writing some prime factors that should be pondered before choosing the equipment.

Ponder on Desired Output

Desired Output- Picture Courtesy: ILC Dover

It is the pivotal factor that should be given due importance when purchasing a V blender. Determining the number of batches per shift and the working volume of each batch will give you inkling regarding the size of the mixing vessel, length of the blending cycle, and rotational speed of the prospective V blender.

Powder Specifications

Powder Specifications- Picture Courtesy: Brainy Gains

Powders are available in all kinds of forms, like moisture-sensitive, brittle, fragile, and thermos-sensitive. Knowing the nature of materials aids you in opting for a V blender that will have spray nozzles or an intensifying bar.

Determine Mixing Densities of Starting Feed

Mixing Densities of Powder- Picture Courtesy: Barry Callebaut

Different models of V blenders have diverse working capacities for different mixing densities of the product. Some machines will process higher mixing densities, while other models are more suited to mixing densities of products that are at the lower end of the spectrum.

Asking about bulk density will help you in opting for a well-matched V blender.

Measure Floor Space

Measure Floor Space- Picture Courtesy: Euipnet

V blender has a larger footprint, so it requires more room for its operation. When planning to buy a new machine, first, measure your floor space and the area where you will set up your V blender. This will help in selecting the right-sized equipment.

Conclusion

Let’s conclude this buying guide about V blender by highlighting important points related to this machine. For instance, the V blender is an autonomous unit, capable of meeting strenuous demands of heavy-duty productions. Its simplicity, reliability, consistency, and, flexibility have expanded its horizons far beyond the food and pharmaceutical industries. So, are you interested in having a customized solution for your blending needs? Then click on the given Allpack link to become our valuable customer.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide