8 Most Important Parts of Liquid Filling Machine You Must Know

Ever pondered how liquid filling machines operate with such accuracy and efficiency? Every day, hundreds of bottles, jars, or other containers need to be filled precisely with liquid. How do they accomplish it? What makes them so popular to be integrated into various packaging lines across industries?

Liquid filling machines are available in a range of different designs. They are constantly evolving as the need for automation and accuracy increases. Therefore, automatic variants have largely replaced the traditional and less accurate versions.

Whether you own a food and beverage, pharmaceutical, cosmetic, or chemical business, gaining insights into the intricate functioning parts of this device may have a greater influence on your operations.

In this blog post, we will explore the eight most important parts of a liquid filling machine that you must know. Find out how each part is essential to the filling operation and how understanding this could assist you in maximizing effectiveness and guaranteeing the highest possible quality in your manufacturing facility.

1.Liquid Filling Machine

Liquid Filling Machine

A liquid filling machine is specialized machine structured to fill various forms of liquids in multiple containers. It offers numerous incredible benefits, including rapid production, efficient processing, accuracy, and preserving the product’s quality.

Due to its incredible versatility, it is widely employed across industries for several purposes.

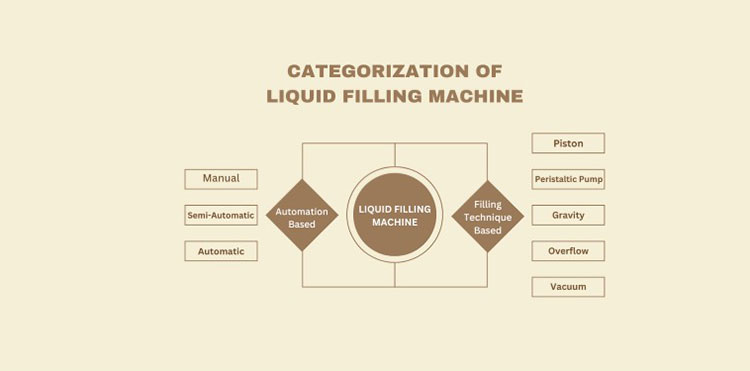

2.Different Types of Liquid Filling Machines

You possibly have gone through various types of liquid filling machine. With distinct benefits, these models are made for a range of items. Such as:

Categorization Based on the Level of Automation

Manual or Handheld Liquid Filling Machine

Manual or Handheld Liquid Filling Machine

It is engineered to be use manually or processed by hand. The operator must perform the whole procedure. This gadget is the ideal choice for newly established or small operational businesses.

It has a low production capacity and the processing competency and precision depend on the worker’s skillfulness.

Semi-Automatic Liquid Filling Machine

Semi-Automatic Liquid Filling Machine

This is combination of automation with some options of manually operated machine. However, you must position receptacles beneath filling spouts, oversee the entire procedure, and turn switches to commence and terminate filling.

The most commonly used models of the semi-automatic device are of the workbench type. This device can process all kinds of liquids. It can be tailored with a piston or pump-based filling mechanism. It is an ideal machinery for average-sized manufacturing operations.

Automatic Liquid Filling Machine

Automatic Liquid Filling Machine

A greated technology particularly developed for large manufacturing batches. You can manage working with lesser involvment and obtain results with improved perfection,. It offers you various working prinicples. For example, gravity, overflow, and vacuum filling techniques.

Categorization Based on the Filling Technique

Automatic liquid filling machines have similar fundamental parts with a distinctive filling mechanism installed. The basic classification related to filling techniques are discussed below:

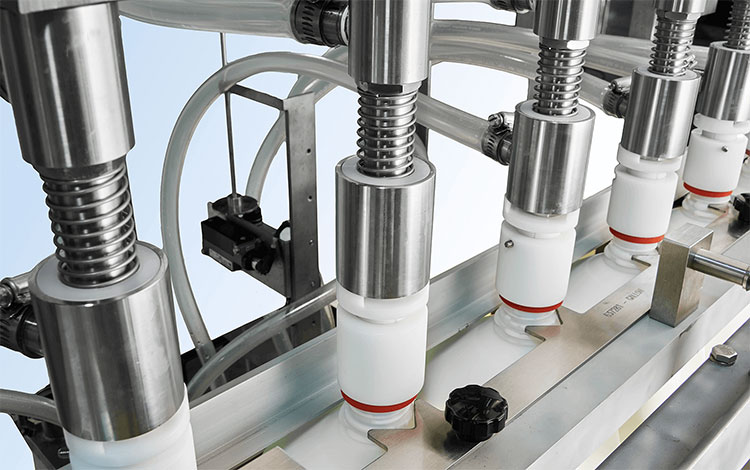

Piston Liquid Filling Machine

Piston Liquid Filling Technique

Although free-flowing liquids can also be processed with piston filler, it is typically employed for viscous materials. Viscous liquids need a little prodding when filling since they do not flow readily. Liquids are injected into a calibrated chamber and then forced through the spout into the receptacles using a piston.

Peristaltic Pump Liquid Filling Machine

Peristaltic Pump Liquid Filling Technique

This kind of liquid filling machine employs a peristaltic pump to load the predetermined liquid content into each vessel. The rest of the structural elements are the same as the piston device.

Gravity Liquid Filling Machine

Gravity Liquid Filling Technique – Picture Courtesy: Neumann Packaging

The gravity liquid filling machine exploits gravity to move liquids from the storage pool into the receptacles. This gadget is subject to a time-varying regulation. It allows the same liquid quantity to be poured into each receptacle.

Overflow Liquid Filling Machine

Overflow Liquid Filling Technique

This device is developed to fill receptacles with liquid via plunging spouts. The spouts dive into the vessels to form a protective barrier, averting the spillage. The surplus fluids are poured back into the storage tank when the spouts are pulled once it reaches a specific amount.

Vacuum Liquid Filling Machine

Vacuum Liquid Filling Technique

The vacuum filling machine is generally employed to pour viscous liquids into the receptacles as it prevents the material from degradation. The device uses a sucking action to draw liquids into vessels. Once a predetermined content of liquid is poured, the sucking action is released and the receptacles are guided to another packaging section.

3.8 Most Important Parts of Liquid Filling Machine You Must Know

An automatic liquid filling machine comprises several individual parts, working in collaboration to maintain a smooth operation. Each part provides unique services to complete the task efficiently. Here you will explore the 8 most important liquid filling machine parts and their function in the filling procedure:

Container Feeding System

Container Feeding System

It is the initial part of the liquid filling machine. This system is responsible for feeding empty receptacles to the device. The receptacles are manually placed into the system.

Then the bottle unscrambler gyrates, allowing the receptacles to orient and progress towards the conveyor that guides them to the filling section. It guarantees a steady flow of containers and guards against manufacturing line clogs and disruptions. It can be categorized based on the number of filling heads.

Conveyor Belt/Platform

Conveyor Belt/Platform

You may never know about the importance of the conveyor belt in the liquid filling machine. So, here we are, describing how important part it is! The conveyor platform/belt carries the containers throughout the device during the filling operation.

It can be tailored with sensors and other accessory parts to ensure containers move in an orderly manner. Moreover, it can also be personalized according to the container sizes plus its speed is regulated per the production requirements.

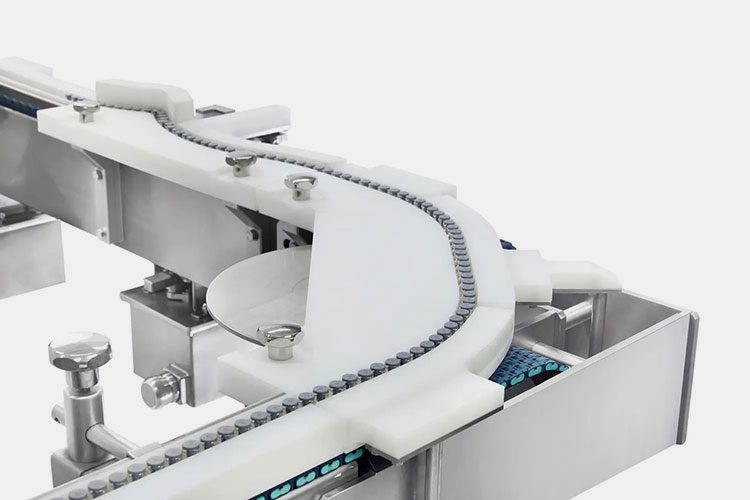

Rotation Table

Rotation Table- Picture Courtesy: Ipharmachine

The receptacles are rotated to each filling station by the main rotation table. Thus, it is unquestionably a necessary element of any liquid filling machine. It enables the synchronization of many filling stages. Another vessel is likely being closed as the first is being filled.

Additionally, the rotation table provides a sturdy foundation for the filling spouts ensuring accurate filling of every canister. The sensor atop the platter will sense the absence of receptacles beneath the filling spout and cut off the pneumatic pump.

Capping Section

Capping Section

The capping section is typically employed at the terminal position of the device. After filling bottles, they are directed toward the capping segment by the conveyor belt. It is a crucial tool of a liquid filling machine, guaranteeing proper closing of receptacles to prevent spills and leaks.

HMI Control Panel

HMI Control Panel

The HMI control panel is an advanced technological tool. It is a crucial part of the device. It is a user-friendly touch interface, which allows you to regulate and monitor all the process parameters.

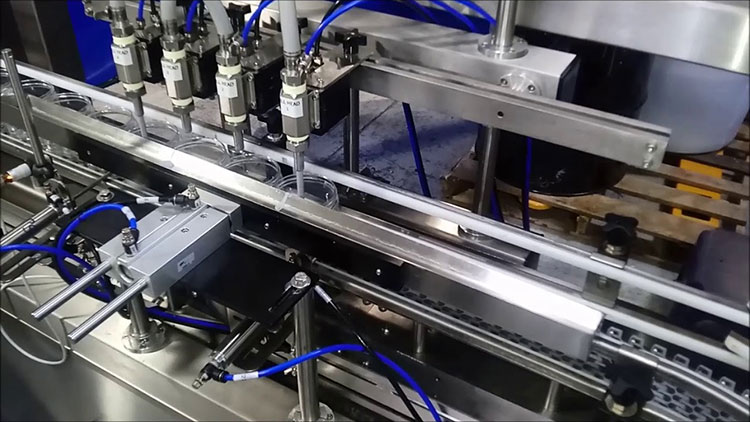

Filling Spouts/ Filling Heads

Filling Spouts

It is one of the most important parts of the liquid filling machine. It is the practical part involved in liquid dispensing. It is more than simply a part, though. It regulates both the liquid filling precision and the flow path.

Based on the liquid’s viscosity, there are various filling spouts available. Mostly employed ones are linear spouts, extruding spouts, and overflow spouts.

Linear spouts are largely employed and adaptable spouts. It has a simple structure that allows for a large number of liquids to pass through easily.

Extruding spouts are specifically employed for purging air from receptacles before and after filling to avoid product deterioration and adulteration.

Overflow spouts fill the receptacles to the brim consistently. When the liquid attains a specific level within the vessel, excess liquid will flow back to the reservoir.

Hopper

Hopper

This is a bulk tank where you can load liquid solution in the bulk concentration and can infeed protocol into the HMI control panel so it will allow the guided volume of liquid when process is started.

Discharge Hopper

Discharge Hopper- Picture Courtesy: Cozzoli

This is a narrow tube that helps you in the feeding of liquid solution during the preparation or dose making. Also, it ensuring the customer extra cleaning by easy to clean options.

Conclusion

Several sectors are dealing with the packaging of liquid products. Therefore, it is an indispensable component of various production lines across industries. Now, that you’ve read the blog ‘8 most important parts of liquid filling machines you must know’, you would probably know the importance of these elements in the device and their role in optimum performance. Getting the best suitable parts for your machinery is crucial to enhance production efficiency and accuracy. If you need further knowledge about these parts or assistance in getting the ideal ones for your business, please contact Allpack, a leading industrial equipment manufacturer.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide