Fresh Food Counting Machine: The Complete Buying Guide In 2025

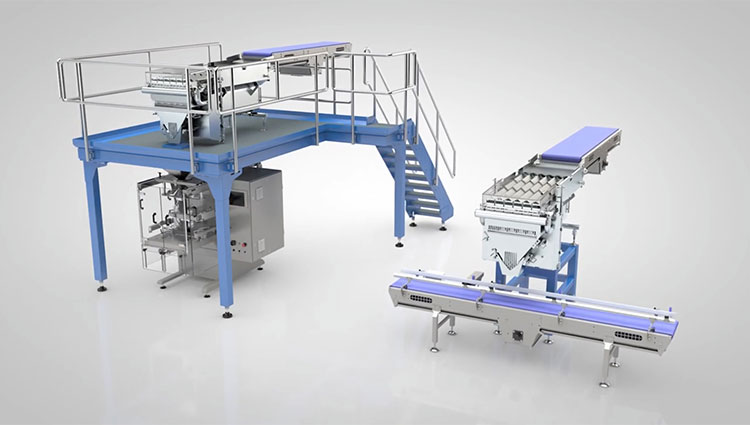

It was the practice of past when people used to eat the food of their own gardens or local area. But the growing population and advancements in technology has resulted in the safe mobilization of fresh food all around the world. Now, a person sitting in USA can enjoy the native food of China. Wondering How? Of course due to quality packaging! However, packing staple fresh food is a time taking process which has been made easy with a Fresh Food Counting Machine.

This machine is highly spectacular with innovative features that enable it to perfectly count variety of fresh food. It has a simplified structure made up of quality material which is convenient to operate. Moreover, it offers user-friendly operation procedure, maintenance requirements, and can be easily troubleshooted. Apart from this, you will know many other aspects of a Fresh Food Counting Machine in this guide. So, let's begin exploring these all!

1.What Is A Fresh Food Counting Machine?

Fresh food counting machine- Picture Courtesy: cremer.com

Fresh foods are the goods which we use in our daily life consumption such as fruits, vegetables, herbs, meat and poultry etc. As they are inevitable for our survival, their production and processing is also very important. However, most of these fresh foods are perishable due to which they require safe and hygienic machines especially for counting. One such machine is known as fresh food counting machine.

The machine is highly qualified to count these products with precision and efficiency. Its 304 stainless steel body is perfect to protect the food from getting spoil. Moreover, it is highly flexible and can be easily customized for counting different types of products in multiple industries.

2.How Do A Fresh Food Counting Machine Benefits You?

A fresh food counting machine can benefit you in many ways. Not only can you use it for your business growth, but it also ensures the quality of your packaging. So, let's shed light on some of the notable features and advantages of this machine:

Safety

Safe stainless steel body of fresh food counting machine- Picture Courtesy: cremer.com

The very first and most important aspect of a fresh food counting machine is its ultra safe body which is made up of a corrosion resistant and antibacterial stainless steel. It provides a safe environment for the processing of your sterile and soft fresh food. Moreover, the machine has a transparent window over working chamber which restrict the external elements such as dirt and pollution etc., from getting into the machine.

Customization

Customization of a fresh food counting machine- Picture Courtesy: cremer.com

Another advantage of the machine is its capability to adjust with different types of packaging machines. For instance, you can use this machine for packing the fresh food into pillow pouches, clamshells, and boxes etc., by integrating it to the relevant machinery.

High Automation

High level automation- Picture Courtesy: getextendly.com

Fresh food counting machine is designed with automatic technology for each step. Taking from the vibratory trays through counting sensor and to the container detector, it administers the operation automatically ultimately leads to efficient performance.

Advanced Control System

The machine has innovative control system with user-friendly interface which provides multiple options to be used for its execution. Moreover, it supports different languages and has the capacity to store number of settings.

Counting Accuracy

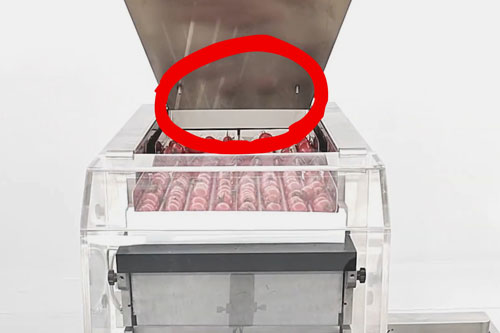

Accurate counting of cherries

By taking help from its advanced detection system, fresh food counting machine intelligently count the food products by eliminating errors and rejecting damaged and alien goods. In this way, counting accuracy is achieved in each cycle.

3.What Food Products Can Be Counted By A Fresh Food Counting Machine?

Enumerating the food products which can be counted by a fresh food counting machine, you will be amazed that how extensive range of goods the equipment can process. Hence, we have explained these food products under the following headings. These include:

Fruits

Various fruits in basket- Picture Courtesy: fruitsmith.com

Fruits including apples, lemons, oranges, guava, plums, dragon fruit, peaches, and apricots are the popular ones which require counting and packing in boxes and bags etc. Therefore, a fresh food counting machine can be used to count these fruits.

Vegetables

Vegetables- Picture Courtesy: theculinarypro.com

Vegetables are displayed on the shores of market shelves and they are often prepacked in packages for customer as well as seller convenience. Therefore, tomatoes, onions, garlic, radish, and potato etc., can be easily counted by this machine.

Herbs & Spices

Herbs & spices- Picture Courtesy: freshndelicious.com

Various types of herbs and spices are also properly processed through counting and packing phase. Therefore, you can take the help of a fresh food counting machine to count ginger, turmeric, flowers, and chillies etc.

Berries

Various types of berries- Picture Courtesy: purewow.com

Different types of fresh berries including blue berries, black berries, cran berries, and cherry etc., are small and difficult to count manually. They are also very sensitive, thus, to carry out their counting and packaging a fresh food counting machine is always suitable.

Meat & Poultry

Meat & poultry- Picture Courtesy: vikingvillagefoods.com

Meat and poultry products such as eggs, beef sticks, and chicken pieces also need counting and thorough processing during packaging. Hence, this machine is applicable to carry out the function of counting.

Sea Food

Various fresh seafood- Picture Courtesy: csfhungary.hu

Fish, shrimps, prawns, and other sea food are often freezed and then packed in multiple packages for safety. However, before their packaging, they are counted for which a fresh food counting machine can be used.

4.Explain The Working Process Of A Fresh Food Counting Machine?

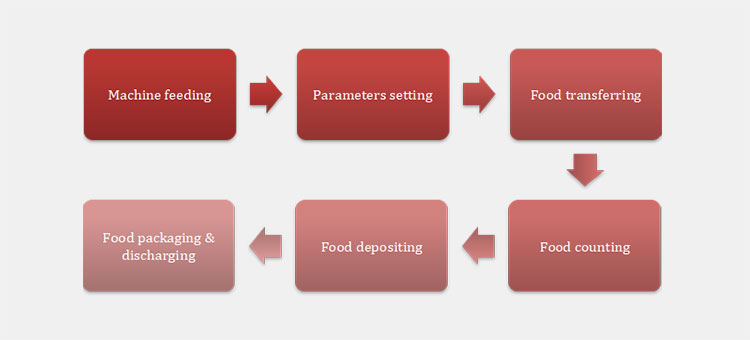

Bringing in use the fresh food counting machine require you to know the working process of the machine. This working process is based on simple predetermined principles. So, let's know each step in detail and become proficient in operating a fresh food counting machine!

Machine Feeding

The first working principle simply include the feeding of machine with fresh food for counting and packages for the counted food packaging. For this, the machine has a large hopper which can be loaded with fresh food either manually or a feeding system can be integrated for non-stop functioning. Similarly, depending upon the packages type, they are also loaded in machine.

Parameters Setting

Parameters setting- Picture Courtesy: cremer.com

The second stage involves setting machine properly. Here, the operator is required to fix the amount of fresh food to be counted for each cycle. Similarly, the speed of vibration and other adjustments are carried out.

Food Transferring

Upon machine starting, the fresh food laid inside the hopper is transferred towards the stainless steel plate located under the hopper. This transferring of fresh food from hopper onto plate helps in the gradual and safe supply of food to the machine.

Food Counting

Tomatoes counting- Picture Courtesy: Allpack

Moving forward, the fresh food move towards the vibratory channels where the constant vibration of these plates results in the segregation and alignment of food. Similarly, the counting step become easy and one by one food is counted by the sensors.

Food Depositing

As the counting process goes on, counted fresh food is collected into the separation flaps and then deposited from these individual flaps into the single collection unit.

Food Packaging

Food packaging- Picture Courtesy: Allpack

Once counted food is deposited into collection unit, the packaging step is meant to be started. Similarly, the food is discharged into the package.

Package Discharging

Package discharging- Picture Courtesy: Allpack

Finally, the finished food package is discharged by the machine and the food is ready to be placed on market shelves.

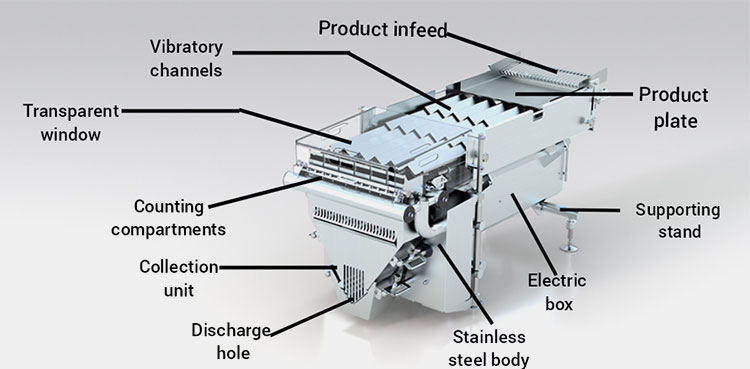

5.What Components Make Up The Structure Of A Fresh Food Counting Machine?

Fresh food counting machine is made up of several components each performing its particular task. These comments are described below:

Components of fresh food counting machine- Picture Courtesy: cremer.com

Product Infeed

Product infeed is a part of the machine where fresh food for counting is supplied to the machine. This supply can be done by placing a hopper which can be manually loaded with fresh food, or an automatic feeding system can be integrated with machine to provide food continuously.

Product Plate

Product plate is located right under the product infeed unit. When fresh food is supplied to the hopper or infeed unit, then these food products are gradually transferred to the product plate for homogeneous processing.

Vibratory Channels

Vibratory channels are multi-lane corrugated trays which are placed in a synchronized manner over one another in such a way that the start of each tray is placed right below the edge of upper tray. These vibratory channels are connected with a motor and play significant role in counting fresh food by dispersing and aligning them through vibration.

Supporting Stand

Fresh food counting machine has a supporting stand which helps in the stable placement of the machine over any surface or other machines like form, fill, and seal machine etc.

Electric Box

The machine has a proper electric and control system. The connection of these electrical components is secured in a single place for safety and easy administration and that place is called electric box or electric cabinet.

Transparent Window

Transparent window is yet another important component of a fresh food counting machine which is placed over the multi channel working area. This part ensures the protection of fresh food against environmental elements and aid operator in clear observation of the operation.

Counting Compartments

There are multiple counting compartments located in machine. Its number depends upon the number of rows in each vibratory channel. During counting process, counting compartments perform the task of counting food and collecting these food units into individual flaps.

Collection Unit

Collection unit is situated right below the counting compartments. When fresh food counting is done for each cycle, the counted products are collected in this unit for final discharge.

Stainless Steel Body

The machine is made up of durable and quality stainless steel material which highly resist bacteria, corrosion, and other chemical reactions.

Discharge Hole

It is the discharge funnel of machine which is used to discharge the counted fresh food from machine into the passing containers and packages.

6.Are There Any Types Of A Fresh Food Counting Machine?

There are many types of a fresh food counting machine available in market. Each machine has its own specifications and features which perfectly enable them to perform their assigned tasks. In below paragraphs, you we will be showing some of the popular types. So, just start reading these all!

Multi Channel Fresh Food Counting Machine

Allpack- ALPK High Speed Fully Automatic Seed Counting Machine

This multi channel fresh food counting machine by Allpack is a wonderful machine which is capable of processing different types of fresh food. It can be connected with other machines to make your specific packaging needs such as form fill seal packaging machine, premade pouch packaging machine, and a conveying system for container filling. This machine uses vibratory multi channel system for the counting of fresh food like lemons, olives, berries, and cabbage pieces etc.

Structure

The structure of machine is a bit complex with multiple vibratory channels which are placed over one another to carry out counting. Apart from it, the machine has a control system, detection system, separating flaps, collection unit, and a hopper.

Working Process

Its working begins with fresh food transportation from hopper onto the vibratory channels. These channels then segregate the food products and align them in rows. Similarly, they are counted one by one and collected in a compartment from where they are discharged into relevant packages and containers.

Industrial Vision Fresh Food Counting Machine

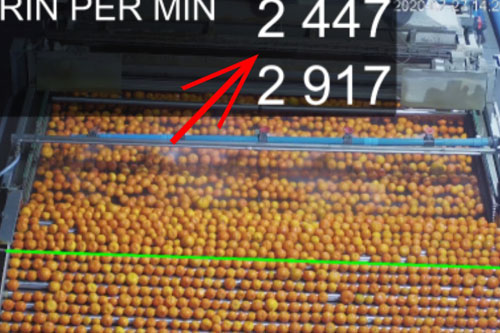

KCS-C Conveyor Counting System- Picture Courtesy: robrosystems.com

Industrial vision fresh food counting machine is the most prestigious and advanced machine being made for the purpose of counting the fresh food of different sizes and shapes. It uses AI engine quickly learn to count okay parts and reject the deformed ones. It supports the integration of other machines to automate the packaging process.

Structure

The structure of machine is concise and consists of few notable parts including a hopper, electric enclosure, AI visual inspection engine, control board, conveyor belt, and a conveyor.

Working Process

The machine works by taking fresh food from hopper onto the plate. From here they are mobilized towards conveyor belt where visual inspection system takes note of the passing food units. These counted fresh food keep discharging into the collection container until the single batch counting is completed and machine get stopped and wait for another container.

Fresh Fruit Food Counting Machine

F16-TC FRUIT COUNTER- Picture Courtesy: revsrl.com

This type of fresh food counting machine is designed with automatic technology and multiple rubber rollers to count the number of fresh foods including fruits and vegetables especially of spheroidal shape such as garlic, tomatoes, avocado, pears, and peaches etc. It has a supplementary device for supervising counting.

Structure

The machine has a simple structure displaying a slide conveyor belt which consists of multiple rubber rollers on both sides of a passage. Moreover, it has a control system, main frame, discharge chute, a product infeed unit.

Working Process

It has simple working principles where fruits and vegetables are transported through specifically moulded soft rubber. Similarly, the advancement of fresh food causes the rubber rollers to rotate on themselves and resulting in the rotation of fresh food they are holding. Hence, the counting process takes place and the counted fresh food get discharged into package.

7.What Type Of Packages Are Supported By A Fresh Food Counting Machine?

Depending upon the type of fresh food counting machine being used, multiple packages and containers are supported by the machine. Some of the popular ones are as follows:

Pouches

Green beans pillow bag- Picture Courtesy: taylorfarms.com

Pouches are flexible packages made up of plastic, aluminum, laminated paper, or mixture of these materials. They are extremely light weighted and cheap in price. Therefore, most of the fresh food manufacturers prefer using pillow pouches, gusseted pouches, or doypack pouches for packing fresh food like tomatoes, cheese sticks, lemons, and fruits etc.

Trays

Fresh meat & chicken tray packaging- Picture Courtesy: anlpackaging.com

Trays are also very popular for delivering fresh food like chicken, meat, sea food, and vegetables etc. That's why, you can easily process trays by a fresh food counting machine for depositing counted food.

Clamshell Packages

Strawberry packed in clamshells packages- Picture Courtesy: victorypackaging.com

Clamshell packages refer to the plastic based thermo formed containers which are light weighted and give extra strength to food against moisture, air, and pollution. They are of different shapes, sizes, and types and all these clamshell packages are supported by a fresh food counting machine to deliver food products.

Cardboard Boxes

Orange filled cardboard box- Picture Courtesy: theproduceguyz.com

Cardboard boxes are corrugated cartons which are made from paper fiber and wood pulp. It is extremely light weighted and environmentally friendly. Due to corrugated layers inside the cartonn, they are providing additional safety for fresh food throughout their shipping and transportation. So, a fresh food counting machine is ideally suitable for accommodating these containers.

8.Enlist The Uses Of A Fresh Food Counting Machine?

The modern-day production and processing of fresh food is becoming highly dependent upon machines. Now, the manual work is fading away and the place of labours has taken by the machines. Similarly, counting is very important step especially when it comes to fresh food counting. Thus, the applications of a fresh food counting machine are numerous including:

Food Industry

Fresh food market shelves

Fresh food counting machine is widely applicable in multiple food industries dealing with food products such as vegetables, fruits, sea food, meat and poultry products etc. This machine helps in their safe and efficient counting.

Prefabricated Food Industry

Prefabricated food products

Prefabricated food industry is another broad application of a fresh food counting machine. Here, wide variety of food products such as baked goods, snacks, fried food, and confectioneries etc., are made which require proper counting. Hence, this machine is employed for accomplishing this task responsibly.

Household Industry

Laundry pods- Picture Courtesy: dxlauto.se

Daily use objects and essentials are commonly used items which are prepared in large industries. During their packaging, one of the most challenging tasks is to find the best way for their accurate which is indeed possible with the fresh food counting machine.

Medical Industry

Medical devices- Picture Courtesy: iStock

Medical industry is also an aspirant to avail the services of this machine. In this way, most of the healthcare sectors have high demand for fresh food counting machine to count their abundant drugs, syringes, surgical instruments, and other objects.

Stationary Industry

Multiple stationary items- Picture Courtesy: stationers.pk

Stationary industry is among other applications of the fresh food counting machine where essentials like erasers, sharpeners, and paper clippers are frequently counted and packed in different packages.

9.How To Check The Quality Of A Fresh Food Counting Machine?

Checking the quality of a fresh food counting machine is one of the crucial aspects to confirm the equipment compatibility for your products. After all your fresh food require extra hygiene and safety during operation. That's why, to help you in this way, certain quality standards are established internationally whose compliance mark the quality of the machine. These are as follows:

Quality certification icon- Picture Courtesy: pngimg.com

GMP

Good Manufacturing Practices is a quality standard which is concerned with the construction material of a fresh food counting machine. It establishes 304, 316, and other safe stainless steel material for machine to ensure its safety against corrosion and bacteria.

ISO

International Organization for Standardization is another most important quality standard that works on national level in almost every state. The fresh food counting machine you want to purchase should adhere to its policies and must be certified by it.

UL

UL is the abbreviation for Underwriters Laboratories which is an important certification for the electrical system of a fresh food counting machine to ensure its safety against shocks and accidents.

CE

Another prominent quality standard is CE which is used for all the machines which are either produced in European Union countries or meant for selling. So, if you are a resident of European Union countries, then make sure to purchase a fresh food counting machine which comply to the rules and regulations set up by CE.

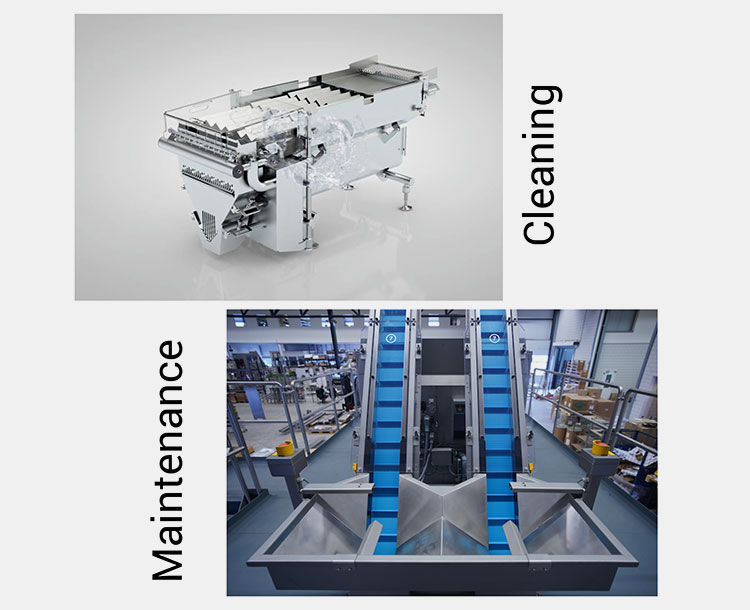

10.What Are The Maintenance Requirements Of A Fresh Food Counting Machine?

Food manufacturers use a fresh food counting machine millions of times each year which can definitely alter the working efficiency of machine. However, there is a way to reduce downtime and frequent wear and tear which ultimately leads to its longer working life and that is through maintenance. Proper and regular maintenance is a necessity. Therefore, we have suggested some ways to follow in this respect:

Cleaning & maintenance of fresh food counting machine- Picture Courtesy: cremer.com

Cleaning:Cleaning is inevitable for maintaining a fresh food counting machine. Hence, you need to clean your machine thoroughly with non acidic water. During cleaning, it is important to remove out all the dirt, debris, and leftovers of food. Once washed, use a dry neat cloth to wipe the wet surfaces.

Lubrication:As a fresh food counting machine has motor, conveyors, and other movable parts, it becomes necessary to keep these parts lubricated. So, add recommended grease to these parts and avoid possible friction and parts resistance.

Parts Changeover:While using the machine, any part of it may get defected or out of order. In such case, showing irresponsibility may cause other parts damage. Hence, it is pertinent to take note of such parts and change them timely.

Software Updates & Setting:Fresh food counting machine runs through automatic technology which is backed by advanced controlling tools and softwares. Therefore, with time it is essential to update the machine softwares and setting to meet the new demands and counting targets.

11.Troubleshoot The Common Pitfalls Of A Fresh Food Counting Machine?

If you keep your fresh food counting machine under good working condition by following proper cleaning and maintenance steps, there is less chance that it will get affected by pitfalls. However, spontaneous problems may occur due to some technical fault. So, you just need to find the issue, assess its causes, and take the required steps. For this, consider the information below:

| i. Feeding error | ||

Food feeding error- Picture Courtesy: REV Packaging Solutions |

Cause:

Overloaded hopper causes poor flow of product. The outlet of hopper may be too narrow to product transferring to plate |

Solution:

Reduce the volume of food products loaded in hopper to 2/3 of its size. Adjust the hopper a bit upward to allow smooth flow of products. |

| ii. Product transmission fault | ||

Product transmission fault- Allpack |

Cause:

The channels are loose. Speed of vibratory motor is inaccurate. |

Solution:

Tight the multi channels screws. Adjust the speed of vibratory motor. |

| iii. Counting fault | ||

Highlighting food counting fault- Picture Courtesy: capterra.com |

Cause:

The counting sensors may be dirty or blur. Counting number is not fixed in the machine. The sensors may be damaged. |

Solution:

Clean the sensors with tidy cloth. Make sure to set the counting numbers before starting operation. Replace the defective sensors. |

| iv. Jamming of vibratory channels | ||

Displaying jamming of vibratory channels- Allpack |

Cause:

Channels are placed inaccurately. Channels are blocked due to product sticking in them. |

Solution:

Remove the channels and relocate properly. Make sure the vibratory trays are tight and have slide synchronization to avoid jamming. |

| v. Control system issues | ||

Control system fault- Picture Courtesy: cremer.com |

Cause:

There might be software problem. |

Solution:

Update your machine to the latest software. |

12.Tips For Choosing The Best Fresh Food Counting Machine?

Most of the businessmen find it tricky to choose the best fresh food counting machine. And they have multiple questions regarding machine due to which they get confused. To help you out, we have talked about similar concerns and addressed most of the relevant questions in the incoming paragraphs. Make sure to take help from these tips:

Production Volume

Production volume of fresh food industry- Picture Courtesy: LinkedIn

Firstly, being a businessperson, it is your prime responsibility to observe the production volume you are currently working on. After doing this, you will be able to determine the level of your business, for example, whether it is medium size or large scale. Then, you will easily choose between the machines available in market.

Type of Packaging

Different types of fresh food packaging

As the task of a fresh food counting machine is mere counting, it is always in need of other machines which become its integral part. However, for this you are required to tell your vendor the type of packaging you want for your fresh food. For example, it can be flexible packaging or rigid packaging. Similarly, the adjoined machine will be affected by your choice of packaging.

Cost

Knowing about the cost of fresh food counting machine which you want to purchase is necessary. It will include all the expenses including original price, operational and installation charges. So, calculat the cost and then select the most compatible reliable machine.

Warranty Policy

Warranty policy- Picture Courtesy: chrysler-factory-warranty.com

Quality assurance of the machine is very important which, among many other things, can be examine by the presence of its warranty. Hence, the machine must have at least one year of warranty.

13.What's New For You With Allpack's Fresh Food Counting Machine?

Allpack is a reputable supplier of industrial packaging solutions for over 13 years which shows its long-standing expertise in the field. The company offers wide range of applications for pharmaceutical, food, hardware, and chemical processing. When it comes to highlight our fresh food counting machines, then you will be amazed. So, let's discuss what's new for you with Allpack's fresh food counting machine!

Allpack company logo

Wide Variety

Allpack has wide variety of fresh food counting machines. Depending upon your production level and budget you can opt for single head, double head, or multi head vibratory channel fresh food counting machine.

Customization

Another most significant fact about Allpack is that we are always ready to provide associated machines for fresh food counting machine as per your demands. You will be given the opportunity to design your own machine by keeping in view the packaging requirements.

Quality Assurance

Allpack offers you a one year of complete warranty which is enough for ensuring the safety of your fresh food counting machine. In addition to it, all our machines are certified by GMP, ISO, and CE.

Conclusion

Let's wrap up this comprehensive review on the Fresh Food Counting Machine with a reminder that the importance of this machine is growing everyday and everywhere. Not only is it applicable to fresh foods but its use goes beyond food and cover under its umbrella the household, hardware, and stationary items. Moreover, it is extremely reliable due to convenient operation, compact structure, and numerous features. With simple maintenance routine, you can take benefit it for decades. So, make sure to choose the machine wisely. In this way, if you need any assistance just contact us through our website!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide