Industrial Pin Counting Machine: The Complete Buying Guide in 2025

Are you looking for a perfect powerhouse which can count your products accurately into different packages with ease? Can the machine be used in different sectors or it is restricted to only one field? Does its benefits outweigh its disadvantages? Is it going to be worth investing in such equipment? Will it benefit you in the long run? And if so, can it easily maximize profits so that you can that capital to invest in your business and expand it?

Well, these mind boggling yet practical questions can make anyone go crazy! But you don’t have to worry. Because we have got all the answers to your questions! Let me present to you industrial pin counting machine. One of the most sought after equipment for counting any product into bags, pouches and bottles. To tell you more about this wonderful piece of art, we have to go into detail about this machine. So hold tight! And lets dive into the details of this blog!

1.What is an industrial pin counting machine?

Allpack Industrial pin counting machine

Industrial pin counting machine is an effective equipment which can be used to count pins, buttons, needles, pills, chocolate balls and much more accurately into bags and pouches. This multi-featured machine has many characteristic unique features to offer you. Thus it can give you maximum benefits and provide you with product which will be accurately filled inside the packaging material in every batch.

The latest technology facilitates the industrial pin counting machine in yielding profitable output and will give you best results with minimum wastage. So this is one of the best machines out there for the counting process and many industries have opted for it to carry out this task.

2.What are the benefits of industrial pin counting machine?

Are you wondering if you choose to invest in this equipment, would it be able to reap benefits for you or not. And does its advantages outweigh its disadvantages? Here we have answers to your questions because this beautiful piece of art has many pros which we will talk about below!

High production capacity

Industrial Pins- Picture Courtesy: Nancy Notion

One of the best advantages you will notice about this machine is that it has the ability to count hundreds of products, whether you deal with buttons, pins, pills or jellies in just a few minutes. So it will give you thousands of products filled and packaged every day. So you can earn huge profits and invest the extra income back into your business for its expansion.

Accurate counting

Its most attractive feature which will make sure you install this machine in your factory is the fact that it counts your products like pins, safety pins, pills, candies with accuracy and dispenses them into bags, pouches and bottles. So you won’t have to worry about unequal number of product in your package since it will fill the exact same number every single time.

Versatility

Are you involved in more than one sector? Do you have businesses in multiple fields that need a counting machine? Then industrial pin counting machine is the best choice for you. You can use it to count virtually anything. From pins, buttons, candies, capsules, moth balls, it will accurately count them and fill them into your desired packaging material.

Compact design

Various styles of industrial pins

If you have a small workspace and you are worried whether you would be able to fit in a counting machine for your product then an industrial pin counting machine will be worth the investment. Its small, compact design can easily integrate in your production line without taking too much space.

Long-term use

Pin Sachet/Pouch

If you plan on expanding your business and transforming it into a reputable and large scale multinational corporation, then using industrial pin counting machine will be beneficial for you because it can be used for long period of time. It can easily be integrated with other machine and requires very simple maintenance. So it can serve you for a very long period of time.

3.What are the applications of industrial pin counting machine?

You must be thinking by now whether industrial pin counting machine can be used in multiple sectors like the food, pharmaceutical or chemical industry. Because you might be involved in more than one field and you would be in need of a counting machine. Well, industrial pin counting machine can be used in many industries so let’s discuss them below.

Pharmaceutical industry

Vitamin supplements

If you are an industrial pharmacist, then you have come across the right blog. If you use industrial pin counting machine then it will accurately count your pills, capsules, and tablets which can then be packaged into bottles and pouches. So the customers will get the desired number of pills to consume, ensuring safe and effective medication.

Chemical industry

Mothballs

If you deal with products like camphor balls, baking soda, color powders and much more, then using industrial pin counting machine will be very cost-effective since it will accurately count these products and package them safely into bags. So you will get perfectly counted products which are volatile and vulnerable to dust and air secure in their bags.

Food industry

Gummy bears

Thinking of food can make anyone’s mouth water! If you belong to the food industry then choosing industrial pin counting machine can be beneficial for you. It can count candies, gummy bears, chocolates, toffees and many more food items with high precision and dispense them into pouches and bottles. So do consider this equipment for your factory.

Cosmetic industry

Hair Pins- Picture Courtesy: 7th travel

Cosmetic industry manufactures many beauty products which are used by millions across the globe. So if you are from this sector, using industrial pin counting machine for your business will help you in counting items like hair products, wax beads, foundation powder, serum capsules accurately into bottles.

Hardware industry

Various screws in a box

Attention to all tech-savvy people out there! If you have items like circuits, metal wires, nuts, bolts, handles etc. You can use industrial pin counting machine to count them with high precision which can then be packaged in bags and containers. So make sure you check this machine when you go to the market.

Veterinary industry

Animal medicine

Just like there are medicines and drugs for human beings, there are medicinal drugs for animals as well. So if you are involved in this sector, installing industrial pin counting machine to count animals’ pills, capsules and tablets will be a safe and cost-effective method to ensure that good quality products will reach at the customer’s door.

4.What is the working principle of an industrial pin counting machine?

The way this equipment is quite simple and you wouldn’t have trouble understanding its mechanism. So let us see its working principle below.

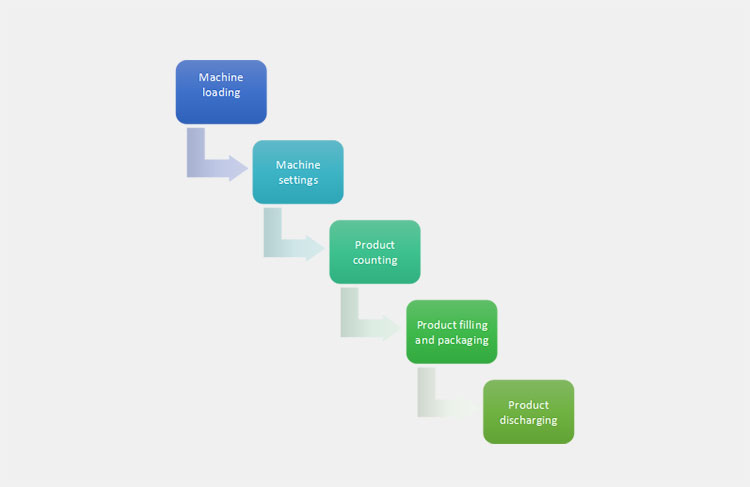

Machine loading

This is the first step of the working where you have to load the machine with your desired product. This product can be pins, capsules, jellies, detergent pods etc. The hopper is now filled with the product ready to go through the next step.

Machine settings

Before the counting step begins, you should set the parameters of the machine according to your requirements. These include the exact number of product which need to be counted and filled, the sealing temperature, the discharging of the final product etc.

Product counting

Now, the industrial pin counting machine will count the exact the number of product which need to be filled inside the package with high precision. The counted product is now ready to be filled inside your desired packaging material.

Product filling and packaging

After the product has been counted, the machine will fill and package inside a pouch, bag or bottle. This is done with the help of piston fillers and horizontal and vertical heat sealers.

Product discharging

Finally, the packaged product is now ready to be discharged from the machine. After this, you can send it to the other part of the production line where it will be shipped to its final destination.

5.Describe the structure of an industrial pin counting machine.

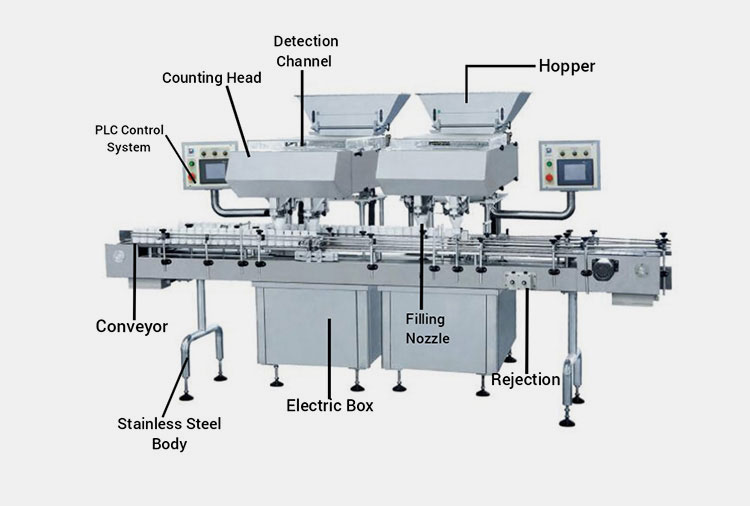

Industrial pin counting machine

| No | Parts | Functions |

| 1) | Hopper | This is the storage area of the machine where your desired product is loaded and is kept for some time after which it is sent to the next part. |

| 2) | Detection channel | This part is provided with the vibratory trays which consist of the product. It continuously vibrates so that the product is counted with accuracy and then is ready to be filled inside the packaging material. |

| 3) | Counting head | This is the main part where the counting of the product takes place and only exact number of these products are packaged. |

| 4) | PLC control system | This part is equipped with advanced software system and is used to control the parameters of the machine and to initiate or terminate the process. |

| 5) | Conveyor | This parts acts like a transporter where it moves the bottles or containers from one place to another for the filling process. |

| 6) | Stainless steel body | The body of the machine is made from this stainless steel material which makes it strong, durable and anti-corrosive. |

| 7) | Electric box | This the heart of the machine which consists of all the wires and electrical components through which the machine works and operates. |

| 8) | Rejection | As the name suggests, this part is responsible for filtering out the defected products. It rejects the defected products and only allows the normal ones to be filled. |

| 9) | Filling nozzles | This part, as the name implies fills the counted products inside the bottles or containers with the help of gravity or high pressure. |

6.Name the packages and containers the industrial pin counting machine can support.

One of the finest features you will notice about industrial pin counting machine is the fact that it has the ability to count and fill your product in virtually any packaging material you like. Let’s see what kind of these packages are.

Bottles

Various pins in bottles

Bottles are one of the most popular packaging material out there due to its cheap price and long lasting quality. It is made of plastic or glass and is provided with a lid at its top for covering. You can easily use them to fill your product.

Pouches

Pins Pouches

These easy to use, cheap and durable pouches come in variety of version like standup pouches, zipper pouches, spouted pouches etc. They are light-weight and perfect for packaging.

Jars

Colorful pins in a jar- Picture Courtesy: Make and take

Jars are wide shaped containers which are made of strong durable material like glass. They have a wide lid at the top for an airtight covering. They are ideal for packaging nuts, candies, pulses, grains etc.

Boxes

Pins Box

Industrial pin counting machine can easily package products inside boxes which are made of lightweight cardboard material. They are easy to handle and can be transported with ease.

7.Explain the types of industrial pin counting machine.

If you go to the market, you will see that industrial pin counting machine comes in various versions. However, these types differ in their characteristics. So what makes them different from each other? Let us see them below.

Automatic industrial pin counting machine

Automatic industrial pin counting machine- picture courtesy: kenweigh.com

One of the best types of industrial pin counting machine you will find in the market is the automatic industrial pin counting machine. This type is equipped with latest technology and has an outstanding high production capacity.

It can count hundreds of pins in a minute. So it can help you in counting and packaging thousands of products in a single day if you have a large scale business. Moreover, you wouldn’t need a worker to carry out the process since it does the whole process on its own and you would only have to monitor it through the control panel.

The loaded hopper then automatically moves the product to the vibratory trays where they will count exact number of your product and send the counted product to the filling nozzles. These will then fill them in bottles and jars with the help of high pressure. Finally the bottles or the jars are sealed and discharged from the machine.

Semi-automatic industrial pin counting machine

Semi-automatic industrial pin counting machine- picture courtesy: madeinchina.com

This kind has a smaller and more compact design than the automatic industrial pin counting machine. It is ideal for you if you have a medium sized business and you require a moderate production capacity. Moreover, if you have financial restrictions, then you can opt for this type since it is cheaper than the automatic industrial pin counting machine. It also requires a worker to load the hopper with the product and discharge it from the machine.

8.Is there any production line for industrial pin counting machine?

AIPAK industrial pin counting line

Are you thinking whether you would be able to integrate industrial pin counting machine with your production line? Is it compatible with the rest of the machines? Well we have good news for you. Because the answer is yes! You can use it with other machines to carry out an integrated process. So let’s see what these machines are.

| Unscrambler

|

This is the first machine in the production line which you will set up. It is equipment that you can use to align the random bottles in one direction. The perfectly arranged bottles now move in one line through the conveyor belt where they are sent to the filling station. You can now add the product of your choice inside these bottles. Its parts include hopper, taper plate, turntable, mold, aligner, PLC control etc which help carry out the bottle orienting process. |

| Industrial pin-counting machine

|

The next machine you will set up is the industrial pin counting machine itself. After the bottles have been arranged in an orderly fashion, your desired products like industrial pins, capsules, chocolate balls are now moved from the hopper to the vibratory trays where exact number of them will be counted. These counted products are now ready to be filled inside the arranged bottles or packaging materials such as pouches, jars. |

| Bottle capping machine

|

Finally, you will add bottle capping machine in the last part of your production line. After your bottles or pouches have been filled with your counted products and the desiccator, it is now ready to be closed with an air-tight lid. The machine takes the cap or a lid, aligns it with the bottle and by using pressure, it closes the opening of the bottle with the cap, giving an air-tight closure to prevent it from any spillage or contamination with dust. |

| Induction Sealing Machine | In the case of bottles or jars, to protect industrial pins against oxidation or rusting, an induction sealing machine is used to bind a layer of barrier film and form a strong seal by using electromagnetic radiation. This is also known as an ideal machine to produce tamper-evident packing. |

| Labeling Machine | To boost your product with the company’s name, quantity of pins, packaging date, and related information is applied by using a labeling machine that applies labels over the surface of the container. |

9.How to maintain an industrial pin counting machine?

Operator working on a machine

You must be aware of the fact that no matter what kind of machine you buy, whether it is expensive or cheap, it requires certain maintenance so that it can work at its optimum level. But you don’t have to worry about maintaining industrial pin counting machine because it is just like every other machine out there and requires basic cleaning and checkup. So if you follow the points, you will have no problem in dealing with this machine.

Cleaning: you must have observed that after operating this machine for a while, you can see dust particles on parts. So to remove them, take a fabric cloth and clean them especially the parts like hopper, vibratory trays, conveyor belts, stainless steel body etc.

Lubrication: it is inevitable that after some time, the movable parts of the machine and the conveyor belt will operate at a lower efficiency. This is because due to friction, they don’t run as smoothly as they did before. So it is important for you to lubricate these parts with oil so that they can start running at their optimum level again.

Inspection: Often, people think that if they don’t see any prominent or visible problem with the machine, it is running perfectly and there is no problem with it. However, this is not always the case. So you need to inspect the machine and its parts thoroughly to make sure that there are no damaged parts or any misalignment inside the machine that will render it inoperable eventually.

Adjustment: before you start the machine’s process, it is critical to set the parameters according to your desired requirements. So make sure that you adjust them using the control panel. You would also have to make sure that all the parts are in their designated place to ensure proper functioning of the machine.

10.What are the problems and solutions of industrial pin counting machine?

Perhaps, one day, you will come across some problems when you have been using industrial pin counting machine for some time. But these problems are almost similar to other machines and have easy to solutions to tackle them. So you don’t have to worry whether you would be able to use it again because the machine will become operable once you solve them.

Incorrect counting

Incorrect counting

Causes

This is a very common problem you can face, that is, the sensors will not count the products correctly. This is due to the accumulation of dust on the sensors.

It can also be due to the problem with the sensitivity of the sensors.

Solution

Take a fabric cloth and clean the sensors to remove the dust particles on them.

To correct the sensitivity of the sensors, you would need to use the adjustment knob to bring the sensitivity level back to normal.

Product jamming

Pins jamming – Picture Courtesy: Loackmaster

Causes:

Sometimes, due to high speed, your products can get stuck inside and they are unable to move to the next component.

The vibratory trays are not in line with each other due to which they do not count the products efficiently and they get jammed together.

If you overfill the hopper with the products, then the hopper will be unable to move it to the counting compartment completely, causing them to get stuck.

Solutions:

Lower the speed so that your products can easily flow inside the machine.

Align the vibratory trays according to the instructions given in the manual and tighten its screws so they don’t move from their place during the counting process.

Do not overfill the hopper with lots of products. Instead, load it with certain number of the products to ensure smooth running of the process.

Sudden alarm noise

Sudden alarm- Picture courtesy: C.E KING

Causes:

The sudden alarm noise indicates that there is dust buildup on the machine.

The machine may not have enough number of bottles or containers to fill the product. Hence it is triggering the alarm.

Loose vibratory trays can also trigger the alarm.

Solutions:

Clean the machine regularly to avoid dust buildup especially on the sensors.

Make sure that the machine has an adequate number of bottles to fill your products.

Tighten the screws of vibratory trays so that they remain in their place.

Product spilling during discharging

Product dripping

Causes:

This can happen when the distance between the filling nozzles and the bottles is too wide and the nozzles then miss the target of filling your products inside the bottles.

The speed of the conveyor belt is incorrect.

Solutions:

Decrease the gap between the filling nozzles and the bottles so that the products land perfectly inside it.

Adjust the speed of conveyor belt accordingly to ensure that it is transporting your products smoothly.

11.What are the factors for choosing the best industrial pin counting machine?

We know how hard it is to buy machines for your business which are quite expensive and you wonder whether the decision you are making is worth it or not. Whether it will prove beneficial for you or not. And whether the type of equipment I am buying will be compatible with my production line or not. But don’t worry. Because we’ve got you covered. We will give you some information on how to choose the best industrial pin counting machine. So let’s take a look below.

Production capacity

production capacity

Before you reach the conclusion of which type of industrial pin counting machine you are buying, it is important for you to know your factory’s production capacity and whether the type of industrial pin counting machine you are buying will be able to cater to that demand. If you have a high production capacity, then go for automatic industrial pin counting machine. However, if you have medium or low-sized production capacity, then it would be better for you to invest in a semi-automatic industrial pin counting machine and manual industrial pin counting machine.

Financial capital

Industrial pins

It is natural for a person to see how much financial capital they have to invest in a certain equipment. If you have ample capital to invest in, then there will be no problem for you buy an automatic industrial pin counting machine. However, if you have financial restrictions and need the capital to invest in other sectors, then you should go for semi-automatic industrial pin counting machine.

Types of packaging material

Various assorted pins

Every product needs a certain kind of packaging material. These can be bottles, containers, jars, and much more. But it is quite important for you to know that not every machine is compatible with every packaging material out there. So make sure that before you buy industrial pin counting machine, it is compatible with the packaging material you wish to use.

Working space

Pins of various styles

Another important factor which you would have to consider is how much working space is available in your factory. If you have ample space, then investing in an automatic industrial pin counting machine will be ideal for you. However, if you do not have enough space, then consider semi-automatic industrial pin counting machine for your factory.

Conclusion

Well, we hope that by now you will be well aware of industrial pin counting machine. What kind of benefits it can provide you, its specifications and features and the problems and solutions of it. In short, industrial pin counting machine is one of the best machines out there to count your products. If you invest in this equipment, it will surely reap huge benefits for your business and you would be satisfied with its quality and its performance. If you have any questions regarding industrial pin counting machine, feel free to contact us anytime! For more information and details, visit our website allpackchina.com

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide