Gummy Candy Counting Machine: The Complete Buying Guide in 2025

Gummy candies are everyone’s favorite! Do you know why? This little fruit candy stores a wide range of flavors you love, with playful shapes and nostalgia in every bite ultimately captivating your taste buds. If you’re sad; just grab the bottle of gummy candy and pick one gummy candy, it will lift your mood I believe.

Today in the markets, you will find various brands with multiple packaging options for gummy candy, however, the packing process strictly follows the accuracy of gummy candy in each box. Is it done manually? No, a gummy candy counting machine is an absolute solution bringing this complex process in several minutes without any risky handling. So come on, read about gummy candy counting machine if you want to purchase them for your production line.

1.What is a gummy candy counting machine?

Gummy candy counting machine- Picture Courtesy: Pharma Packaging

This is specialized equipment meant for counting and packing gummy candy and other related items. Previously, counting gummy candy was a challenging task due to its sticky texture and maintaining safety.

A gummy candy counting machine is intended to save your time and allow a rapid counting task without spending much labor and constant concentration. It is now possible to attain seamless gummy packing in individual bottles or packing material with high hygiene and sanitation in manufacturing sectors.

Remember, gummies are long been known for their challenges due to their sticky nature, but this machine has brought an excellent solution carrying a dose accuracy and better counting due to its sleek construction and high automation.

2.Why a gummy candy counting machine is important?

We believe that gummy candy counting is a challenging task, and this goal is perfectly dealt with by a gummy candy counting machine. that’s why, it is considered an important tool for bringing a total solution for the gummy packing process. This machine is of high value and can run your company by offering the following beneficial properties below:

Fast & Advanced Technology

Advance machine- Picture Courtesy: NBC News

The equipment plays an important role in making customers happy by implementing advanced visualization technology for counting gummy candy. It is useful in catering to small, moderate, and even large gummy candy batches. The counting process takes place a short time making your packing process much easier and efficient for every individual packing gummy candy container.

Easy Operation, Compact Structure & Maintenance

Easy to use

Do you know that machines can be greatly fit in every production area due to their compact sizes? whether you have a small space, you can fix a benchtop machine, if you’re running greater production capacity, you can install a large setup. It is pretty easy to install, and easy to operate, you won't need training for its operation. Due to its simple design, it is pretty straightforward to clean and maintain to keep your cost reduced.

Easy Change-over

Flexible change over-Picture courtesy: Base Drop

You can switch the machine from various types of gummies to different other items quickly. Surprisingly, this time-consuming procedure is absolutely very simple. A gummy candy counting machine reduces your time waste and improves productivity as machine makeup and procedure are ideal when used in busy production setups.

Effective Integration with More Units

Easy to integrate with other machines- picture courtesy: WIRED

The machine can double its speed when allowed to integrate with other units of the production line to handle gummy candy counting. This package can significantly improve your higher output and you can meet your goals in a back-to-back manner.

No more Gummy Candy Blocking

Easy flow of materials

If you’re thinking about gummy candy blocking then using a gummy candy counting machine offers multiple vibrating channels that gently shake to move gummy candy continuously. There are almost no chances of blockage or getting them stuck hence a consistent flow of items takes place without interrupting your workflow.

Handles Sugar and Sanded Gummies, Oiled, Pectin, and Vitamin Gummies

Handle various products—picture courtesy: Food Manufacturing

Whatever the kind of gummy candy you’re producing in your manufacturing sector, this is an ideal solution once you’re subjecting them to count and pack without any problem.

3.Where a gummy candy counting machine is used in the market?

A gummy candy counting machine is getting everything perfect for you; that’s why it is hooked to a broad range of industrial applications.

Confectionery Industry

Confectionery Industry- Picture Courtesy: AAK

Investing in making and packing confectionery is not an easy thing. You will need to be assured that every step is best fit for running the business, a gummy candy counting machine has a worthwhile role in counting products like gummies, candies, jellies, beans, chocolates, and related items by quality standard processing and throughput.

Medicine Industry

Pharma industry

Creating medicines, and medicinal tools requires a harmonious combination of standard products and extra care for packing them till they reach the patients.

A gummy candy counting machine is made up food food-grade materials and ensures you count products like tablets, capsules, pills, granules, and medical supplies such as needles, lancets, pins, and assessment tools are packed rightly in every packing container correctly as mentioned in the label.

Herbal Industry

Herbal products

Who doesn’t love taking herbal supplements that are free of risks and side effects in an enticing formulation of gummy candy? The gummy candy counting machine is used in herbal industries for counting herbal supplements carefully and safely.

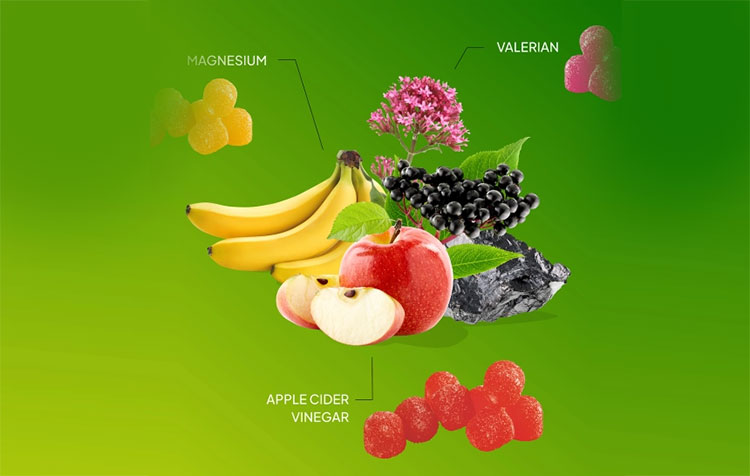

Nutraceutical Industry

Nutraceutical Industry- Picture Courtesy: Tanis

Over the past years, there has been a huge popularity in the making of sweet gummy candy nutraceuticals. The market has added significant value to the need for gummy candy counting machines for the daily packing of supplements and delivering them to meet the market demand in straightforward ways. This includes calcium supplements, multivitamins, hair, nails, skin supplements, probiotics, sleep-inducing and others.

Cannabis Industry

Cannabis Industry- Picture Courtesy: FIVE CBD

Due to growing awareness cannabis industry's high demand also has been hooked to gummy candy counting machines for its effective counting solution for production. This includes CBD gummy candy, THC gummy candy, and related combination supplements.

Cosmetic Industry

Cosmetic Industry

Did you know, that your makeup products are also available in gummy candy form to create fun-filled solutions when using them for birthday parties, weddings, or any planning? This includes lipsticks, lip balms, blush gel, etc. The gummy candy counting machine is useful in this way to count and pack rapidly in beautiful bags or bottles. Moreover, this machine is used for the packing of waxing beans, manicures, pedicures, and facial-related products in their bottles or containers.

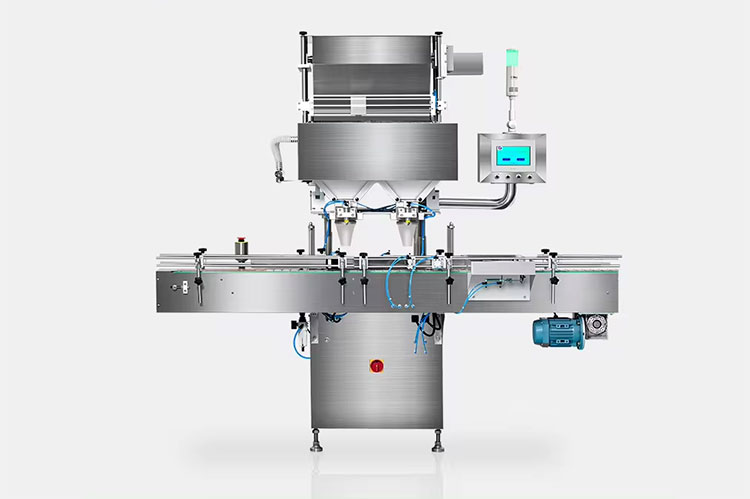

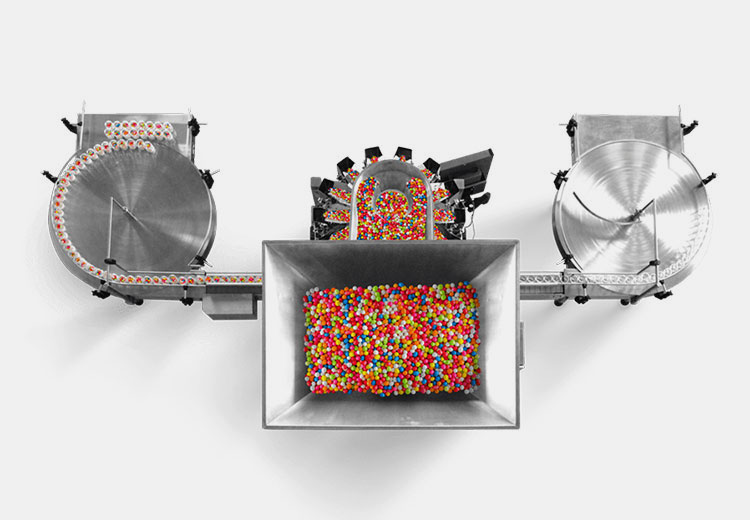

4.How does a gummy candy counting machine work?

Gummy candy counting machine

The working of the gummy candy counting machine is pretty simple and categorized into the following steps:

Steps of gummy counting machine working

STEP 1: Gummy Candy Loading

| The gummy candies are loaded into the bulk hopper using a floor elevator in many cases; which brings uniform quantities of gummy candies using vibratory plates which helps in separated and aligned gummy transportation. The hopper is mainly designed with string dispensers allowing easy flow of gummies without risk of sticking to one another. |  |

STEP 2: Vibratory Channel

| From the hopper, the gummy candy drops into the multiple vibratory lanes of the gummy candy counting machine that are meant to shake gently. The purpose of this section is to allow uniform movement of gummy candy from the hopper toward the counting section without interruption or stopping. |  |

STEP 3: Counting & Filling

| The gummy counting machine is equipped with a sensory optical system that scans each gummy before it is dispensed into a bottle or container. The machine counts the target number of gummy candies to be packed and drops them into the packing materials. Side by side, it can reject the batch in case of faulty gummy candy. Once they’re filled, the batch is sent to the next phase of the production line. |

|

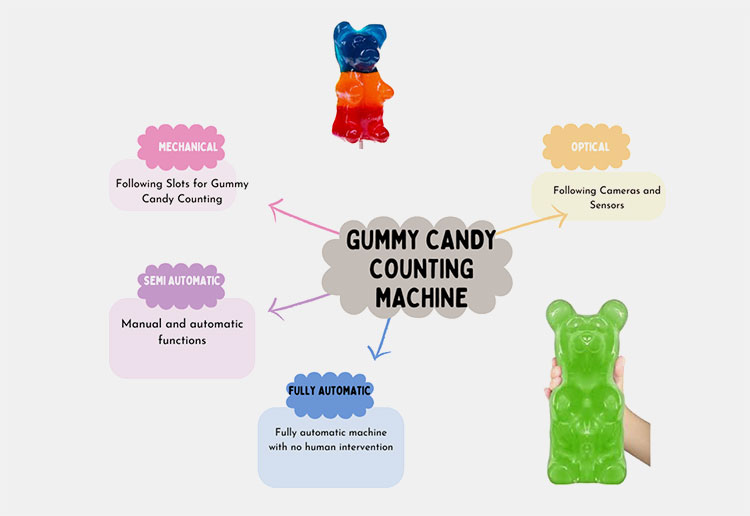

5.How to classify a gummy candy counting machine?

With time, there are various types of gummy candy counting machines are introduced into the market. Every new machine provides modern features and meets the recent demands of the manufacturer to make counting tasks much easier. We have categorized various types below:

Types of gummy candy counting machine

Mode of Operation

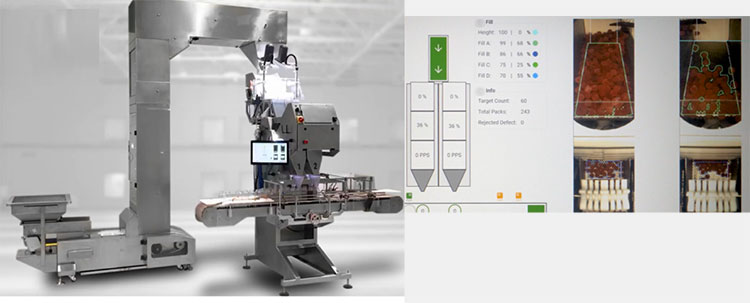

Optical Gummy Candy Counting Machine

Optical Gummy Candy Counting Machine- Picture Courtesy: BellatRex

Optical as its name suggests, provides gummy candy counting by capturing the view from high-tech sensors and equipped cameras inside the machine which displays an entire view of gummy candy when transported through different counting sections.

The high-tech sensors radiate lights that blink when gummy candy passes through and are recorded in the system; side by side, the machine provides images of every gummy candy. By gummy candy counting machine software interpretation, you can simply watch the results which ensures the process works well up to your requirements. Also, the machine is suitable for detecting and showing gummy candy of various shapes and sizes and notifying all major and minor details required for correct counting and assessment.

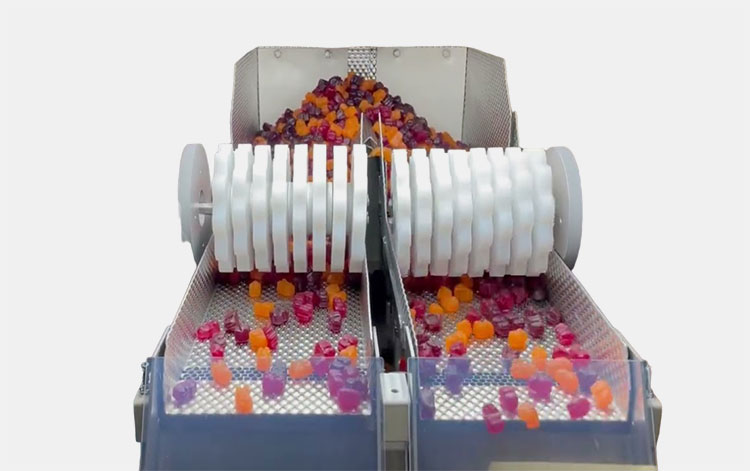

Mechanical Gummy Candy Counting Machine

Mechanical Gummy Candy Counting Machine

This machine working principle relies on physical operation which is also known as a slot counter. The machine design is composed of various slots. The rotary disc transports the number of gummies into each filling disc where every individual gummy fits into each slot and that is marked as one gummy candy in the machine’s system.

This machine is very accurate without carrying chances of error as a single slot is responsible for occupying a single gummy candy which is tallied as a counted. There’s one drawback at one time machine can count gummy candy in a single shape and size.

Mode of Automation

Semi-Automatic Gummy Candy Counting Machine

Semi-automatic gummy candy counting machine

The semi-automatic gummy candy counting machine is a combination of manual and automatic operation where need of operator is required throughout the procedure for placing and removal of bottles or any packaging material. However, the counting of gummy candy takes place automatically once you pour the pre-determined amount of gummy candies into the hopper of the machine.

Fully Automatic Gummy Candy Counting Machine

Allpack fully automatic gummy candy counting machine

This is an excellent solution for a large production batch because it can carry the entire procedure from gummy candy loading to the discharging of filled containers automatically.

Here, you do not need to have constant monitoring of any operator as the machine itself can record the data and ensure that every batch is precise and accurate.

If you’re not sure, then it gives you the option to recall past records and watch the data of the dispensed batch. The automatic machine is available in optical as well as mechanical gummy candy counting machine which is ideal for high production and high capacity with promising results.

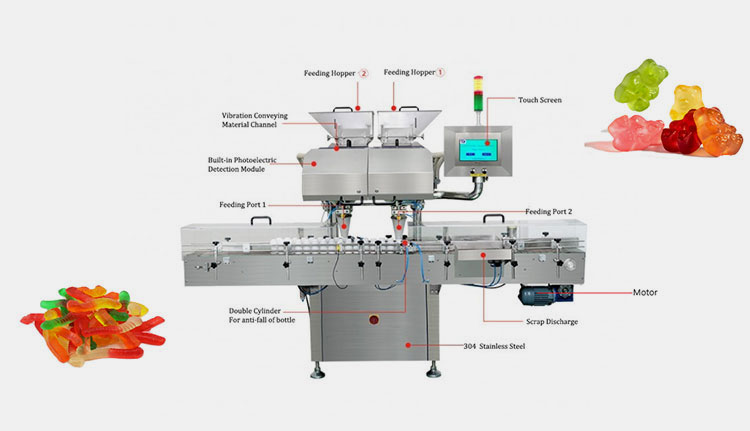

6.What are the parts of a gummy candy counting machine?

The gummy candy counting machine is composed of different types of motorized, electrical, and, computerized components. These parts perform different jobs to precisely count gummy candies. A few of these parts are listed below:

Parts of Gummy Candy Counting Machine

| Feeding Hopper | A large-capacity hopper is present on the upper side of the gummy candy counting machine. It assists in storing large volumes of gummy candies before the packaging operation. |

| Touch Screen | This touch screen has clearly labeled options for programming the gummy counting machine. It is an intuitive control panel with the help of which operators can supervise the machine and view the progress of the counting operation. |

| Vibratory Conveying Channel | As the name indicates, this part runs through its vibrations. It has cavities in which gummy candies are moved in a single file. Its vibration helps in the alignment of the gummy candies. This channel forms a pass way between the hopper and the photoelectric detection module. |

| Photoelectric Detection Module | It is the core part of the gummy candy counting machine. It uses a light source that illuminates the path of gummy candies and a sensor that detects the passing gummy candies by disruption in the light beam. |

| Feeding Port | It is the filling part of the gummy candy counting machine. From the photoelectric detection module, the gummy candies are moved to the feeding port, which is also called the filling nozzle. It is the main device that dispenses gummies into the packaging. |

| Double Cylinder | They are present at the conveyor of the gummy candy counting machine. Their function is to prevent the falling of bottles. |

| Stainless Steel Body | The body of the machine is designed with the stainless steel material. It is long long-lasting alloy because of its anti-corrosivity. Moreover, it is a hygienic substance due to its ease of cleaning. |

| Scrap Discharge | The defective gummies are collected in the scrap discharge collection unit. The broken or damaged gummies after detection are transferred into the collection bin and are rejected from the system. |

| Motor | Electric energy is transformed into mechanical energy by the motor. The latter is required for moving different parts of the machine. |

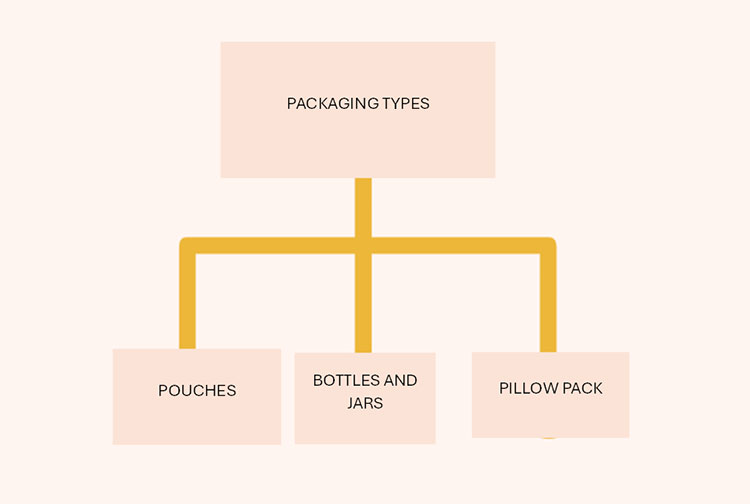

7.What packaging materials can be filled with gummy candy counting machine?

The gummy candy counting machine is suitable for filling the following packaging types:

| Pouches

The gummy candies are commonly stored in flexible pouches with the help of a gummy candy counting machine. whether standup pouches, or gusseted pouches, the machine is super awesome for counting, filling, and sealing them by using a pouch-filling system. |

|

| Bottles & Jars

Whether glass or plastic bottles and jars, it can be counted efficiently and filled by a gummy candy counting machine. this is the common packaging type that is mainly used for greater durability and safe transportation from one country to another ensuring the product is intact and protected. This is mainly required for packaging of medicine gummy candy and other related items such as herbal, nutraceuticals, etc., |

|

| Pillow Pack

The limited or small quantity of gummy candy is mainly dispensed in pillow packs that look like a ‘pillow shape sachet’. The machine used for this purpose has the ability to create pillow-shaped sachet and serve the gummy candy of required serving. |

|

8.Is it possible to integrate a gummy candy counting machine with other machines?

Picture Courtesy: Factory6

Yes, the gummy candy counting machine has capability to work along with another unit to make the packaging process efficient and fast. There are the following sets of machines mainly integrated into the gummy candy counting machine production line. For example:

Bottle Unscrambler Machine

| Picture | Description | Working principle |

|

To count and fill containers with gummy candy, it is necessary to subject them to a filling machine in an organized and upright manner. For that, a bottle unscrambler machine is mostly integrated with gummy candy counting machines. | A random amount of bottles or containers are loaded into the machine. The rotary discs and a high blower followed by vibration lead to correct the orientation of each bottle which fixes the position and conveyor carrying them into the next machine with proper alignment. The presence of a sensor ensures that each container has acquired the correct position while following a smooth streamline. |

Gummy Candy Capping Machine

| Picture | Description | Working Principle |

Picture courtesy: Icon Equipment |

The filled gummy candy bottles are required to be secure by positioning caps over them. A gummy candy capping machine is integrated just next to the counting machine to receive items once they’re catered with an accurate number of products. | The caps for bottles or containers are loaded into the hopper and received by the feeder. By application of torque, the gripper picks and secures caps over each bottle to close them tightly. |

The Gummy Candy Induction Sealing Machine

| Picture | Description | Working Principle |

|

Every manufacturer aims to provide tamper-evident products to you. For that, they use a gummy candy induction sealing machine which ensures that the dispensed product is accurate and authentic. | The number of capped products seamlessly passes through the zone of the gummy candy induction sealing machine where high electromagnetic radiation melts the caps layer of the bottle and forms a strong bond once it cools down and assures that sealing is unbreakable till the end-user. |

The Gummy Candy Labeling Machine

| Picture | Description | Working Principle |

|

The prime machine improves the branding of your company by applying labels over the packaging materials. It is included in the brand and information related to gummy candy such as expiry date, manufacturing date, ingredients, storage details, etc. | In most cases, the label roll unwinds and prints simultaneously and is applied on the pre-determined position of the packaging materials. This machine is capable of dealing with bottles, and containers of various shapes and sizes. |

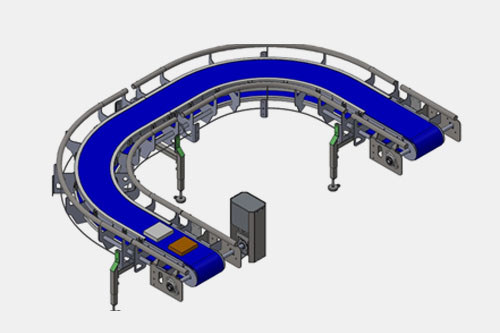

Conveyor System

| Picture | Description | Working Principle |

|

This is an assisting tool that ensures the smooth transportation of packing items from the start till the end of the production line. | The conveyor is driven by a belt of chains which follows a controlled speed driven from the machine’s system to carry an interrupted movement. |

9.What features allow gummy candy counting machine suitable for dietary products?

The gummy candy counting machine is suitable equipment for health-related and dietary supplements due to the following features.

International Standard Compliance

Quality standards- picture courtesy: merchesini

The gummy candy counting machine is certified with quality international standards which ensures that the machine complies with super hygiene and all essential certification ensures safety. For example, FDA, ISO, and cGMP.

Advanced Optical Sensors and Cameras

High sensory system

The machine is equipped with cameras and sensors which detect minor discrepancies. Thus, it is the safest feature that it offers to manufacturers so they can only distribute those batches that comply with precision.

Safe Construction & Super Clean

Super clean unit

The machine is made up of stainless steel and ensures a high level of cleanliness which is absolutely essential for dietary and food-related products.

10.What are the common mistakes and troubleshooting with a gummy candy counting machine?

Even though the gummy candy counting machine is a high-tech solution and works smoothly, still sometimes it faces unanticipated problems that decrease the counting and packaging efficiency. However, with a few tips, these problems can be troubleshooted easily.

Non-Uniform Product Flow

Non-Uniform Product Flow- Picture Courtesy: BellatRx Inc.

| Cause | Troubleshooting |

| Gummies have irregular shapes and shapes.

Hindrances in the feeding channels. Inadequate vibration intensity. |

Employ a pre-sorting strategy, so that correct shapes and sizes move along the vibratory channels.

Check and clean the feeding channels. Reset the settings of vibration to achieve uniformity in the product flow. |

Gummy Candy Damage

Gummy Candy Damage

| Cause | Troubleshooting |

| The surfaces of the vibratory channel and guides are rough.

High speed of conveyor. |

Check and ensure the channels and guides are smooth by cleaning and polishing them.

Lower the speed of the conveyor. |

Incorrect Counting

Incorrect Counting- Picture Courtesy: BellatRx Inc.

| Cause | Troubleshooting |

| Misalignment of photoelectric sensors.

Sensors are not cleaned. Inaccurate calibration of sensors. Poor gummy candy flow. |

Realign and level photoelectric sensors correctly.

Check and ensure sensors are appropriately cleaned. Perform adjustments to the calibration of sensors. Maintain steady product flow. |

Jamming of Feeders

Jamming of Feeder- Picture Courtesy: BellatRx Inc

| Cause | Troubleshooting |

| There is overloading in the feeders.

Poor settings of vibratory channels. Sticky or irregularly shaped gummies are present in the feeder. |

Ensure gummy candies are uniformly fed in the feeder with no overloading.

Adjust the settings of vibratory channels. Use anti-clumping devices to avoid sticking of gummies. |

Display Shows Irregular Counts

Display Shows Erroneous Counts- Picture Courtesy: PallayPack

| Cause | Troubleshooting |

| Inaccurate counting due to old software.

There are bugs in the software. Incompatibility between software and the system. |

Restart the machine to fix the software issues.

Check the error log file and identify bugs in the software. To fix the incompatibility issue, re-update the software. |

Gummies Stickiness

Gummies Stickiness- Picture Courtesy: PallayPack

| Cause | Troubleshooting |

| Gummies absorb moisture from the environment, making them sticky.

Poor gummy coating. Increased temperature causing stickiness. High quantity of sugar and other syrups in the gummy formulation. |

Decrease the humidity or use a de-humidifier.

Use sufficient amount of coating agents. Lower the temperature during gummy candy counting. Readjust the gummy formulation. |

11.What are Quick Tips for the Effective Operation of a gummy candy counting machine?

A gummy candy counting machine is an essential tool in the food and medical industry. Cleaning and properly maintained equipment can keep your production safe against malfunctioning. There are certain tips for cleaning and maintaining a gummy candy counting machine that is considered helpful in the extension of the machine’s life and performance.

Cleaning is Mandatory

Gummy candy counting machine

A cleaning of a gummy candy counting machine is essential for the best performance of the equipment. As you know the machine is subjected to products of various flavors, items, ingredients, etc. therefore, to avoid the remnant of previous substances or other products may contribute to unnecessary consequences.

You should clean the machine quickly after performing work and recommended to look before beginning the process. This should be done by inspection and cleaning using a dry cloth. In some cases, you can wipe off the sticky material by using IPA (isopropyl alcohol; a disinfectant) to reduce the chances of microbial growth.

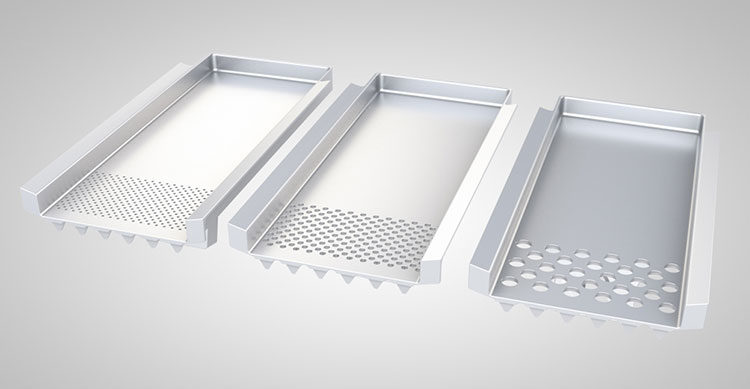

Easy to clean without tools

Parts removal- Picture Courtesy: Cremer

Today, the modern gummy candy counting machine series provides easy removal of contact parts such as vibratory plates so you can clean them easily and oil the vibratory parts for smooth functionality. In this way, you can enjoy safe and convenient processing for longer periods of time.

Calibrate programming

Calibrate programming- Picture Courtesy: Merchesini

It is convenient to calibrate the programming, delete unwanted data, and re-adjust the settings for rapid and fast control of the machine that will save your time and minimize the risk of human error.

Product dust extraction

Dust Suction- Picture Courtesy: Medicalexpo

This is pretty normal that machines can cater to various products such as tablets, pills, capsules, gummies, beans, seeds, etc., and producing dust is very normal. Today, a gummy candy counting machine features a vacuum dust extraction unit that helps in the sucking of dust and makes the system preventive against debris compilation on various important parts such as sensors, and cameras.

Conclusion

With a gummy candy counting machine, it is easier to manage gummy candy packing correctly and accurately. With Allpack company, we are always here to bring advanced innovations to boost the gummy candy counting portfolio. As a result, you can get excellent equipment series with new developments and recognized systems with non-stop operability. Interested in knowing our one-stop solution for gummy candy counting machines? Get in touch with Allpack experts now!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide