Laundry Beads Counting Machine: The Complete Buying Guide In 2025

Are you a manufacturer wishing to enhance your laundry beads manufacturing line's efficiency, speed, and accuracy? Do you believe manual counting techniques need too much time and are susceptible to mistakes? Are you finding it challenging to maintain the consistency of beads in each package? If so, the laundry beads counting machine might be the solution you need.

Laundry beads, also called scent boosters, have grown in popularity as an addition to laundry routines. These tiny, aromatic beads are added to the laundering cycle to improve the aroma of freshly cleaned garments. With the rising demand for these goods, producers are constantly looking for more effective ways of producing and packaging them.

In this buying guide, you will discover how this innovative technology can transform your business. Say goodbye to manual counting and hello to a more efficient and cost-effective means of conducting business.

1.What is the laundry beads counting machine?

Laundry Beads Counting Machine

The laundry beads counting machine is a specialized device developed to count and dispense the laundry beads into each container efficiently and precisely. It is an indispensable device to ensure productivity, uniformity, and quality consistency.

The device is tailored with advanced sensors and technology for processing and handling various items in multiple industries. It aids in rapid and precise dispensing of items and eliminates human involvement and mistakes.

Note that, apart from the chemical industry, this device is also applicable in the pharmaceutical, food, and agriculture industries.

2.How does the laundry beads counting machine enhance the overall user experience?

The laundry beads counting machine is becoming popular across various industries due to the tremendous advantages offered by this device. The device enhances the overall user experience in several ways. Here we will discuss the major benefits of the laundry beads counting machine:

| Precise Counting

The laundry beads counting machine uses automated detecting mechanisms, leading to accurate counting results in each container or package. |

|

| Operational Efficiency and Productivity

The laundry beads counting machine offers robust production with efficient results, ultimately maximizing production output and business growth. |

|

| Time and Labor Savings (Cost-effectiveness)

Automation in the production line using the laundry beads counting machine results in rapid manufacturing and consumes less time to produce a greater number of packages. Furthermore, it minimizes human intervention during the processing, leading to the ultimate cost savings. |

|

| Product Uniformity

The laundry beads counting machine has advanced counting sensors, resulting in accurate counting and uniform product packaging. |

|

| Quality Control

Minimizing human involvement during the process prevents contamination and maintains a clean environment and quality consistency. Producing consistently quality products also aid in building consumer satisfaction with the brand and company. |

|

| Customization with Advanced Features

The laundry beads counting machine allows for easy changeovers and customization to handle various shapes and sizes of beads or pills and packaging containers. |

|

3.How can a laundry beads counting machine be utilized in multiple industrial production lines?

The automatic laundry beads counting machine is renowned for its efficient, accurate, and robust packaging of multiple granular products. Therefore, several industries have adopted and integrated this innovative device into their production lines.

Some of the common industries where a laundry beads counting machine can be utilized are:

Chemical Industry

Use of the Laundry Beads Counting Machine in the Chemical Industry – Picture Courtesy: The Spruce

It is the primary industry for the laundry beads counting machine which is utilized to package several granular chemicals, such as laundry beads, naphthalene balls, pool chemicals, etc.

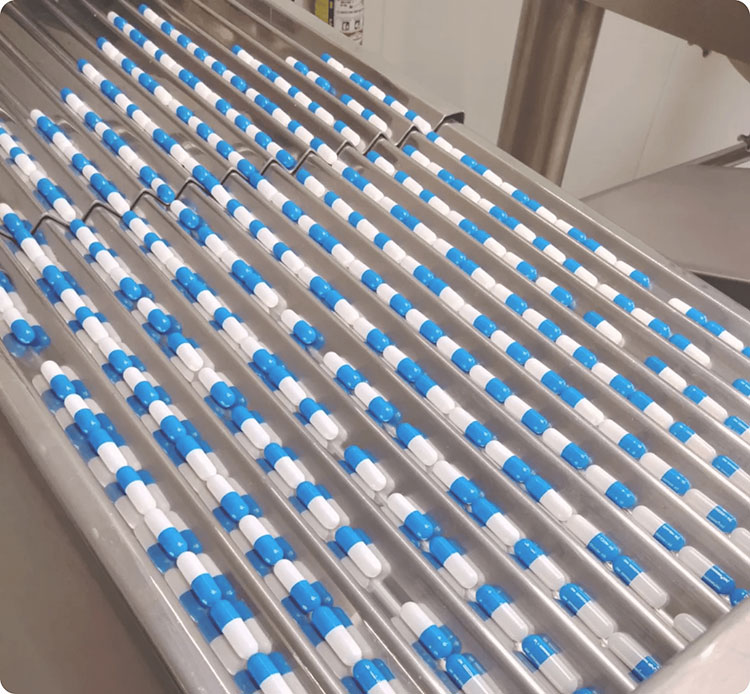

Pharmaceutical Industry

Use of the Laundry Beads Counting Machine in the Pharmaceutical Industry

Yes, you read that right. The laundry beads counting machine is also used in the pharmaceutical industry where precise counting and packaging are crucial for dispensing accurate dosing of medications. The device is used to count and package several tablets and capsules.

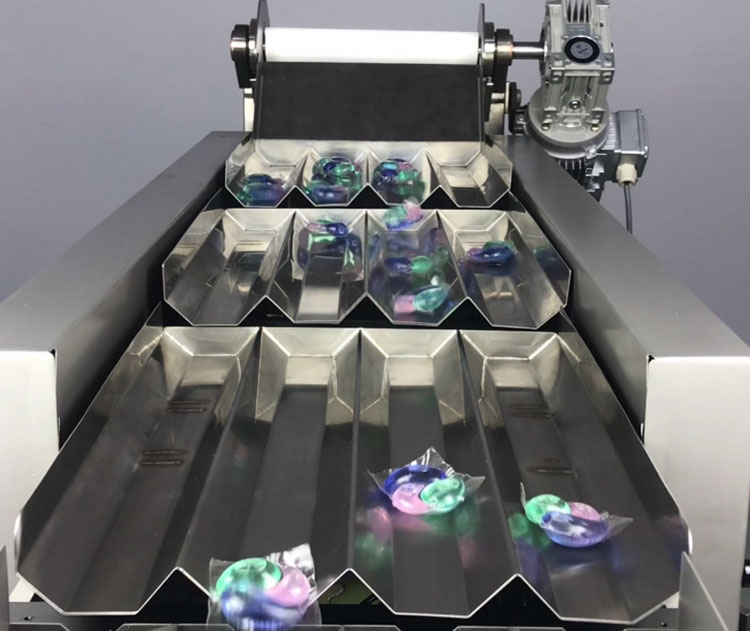

Food Industry

Use of the Laundry Beads Counting Machine in the Food Industry

It is another popular sector where the laundry beads counting machine is utilized for efficient packaging of various food items, such as candies, gums, and beans.

Nutraceutical Industry

Use of the Laundry Beads Counting Machine in the Nutraceutical Industry

Similar to the pharmaceutical industry, the laundry beads counting machine is used to package several nutraceutical supplements.

Cosmetics Industry

Use of the Laundry Beads Counting Machine in the Cosmetics Industry

The laundry beads counting machine counts and packages various cosmetic items like beauty and hair growth pills in the cosmetics industry.

Agricultural Industry

Use of the Laundry Beads Counting Machine in the Agricultural Industry

In the agricultural industry, the laundry beads counting machine counts and packages several seeds, fertilizers, pesticides, and grains.

Hardware Industry

Use of the Laundry Beads Counting Machine in the Hardware Industry

The laundry beads counting machine can also be utilized for counting various hardware tools, including screws, nuts, and bolts.

Veterinary Industry

Use of the Laundry Beads Counting Machine in the Veterinary Industry

In the veterinary industry, the laundry beads counting machine is used to package pet foods and medications.

4.Describe the fundamental components of a laundry beads counting machine.

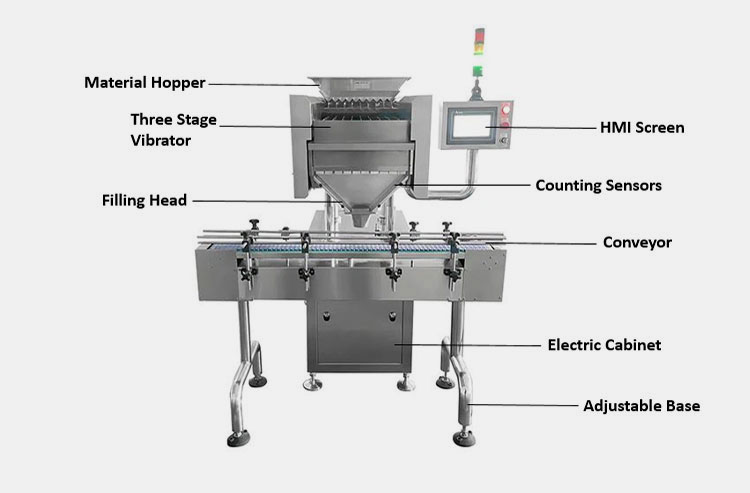

The laundry beads counting machine has several key components, facilitating its efficient operation. These components are described below:

Components of the Laundry Beads Counting Machine

Material Hopper

The material hopper in the laundry beads counting machine temporarily stores and distributes the beads for counting into the device. It is located at the top of the device. The majority of the device variants have one hopper while some advanced forms have more than one to enhance productivity. The beads or other materials can be loaded into the hopper manually or via an automated tool.

Three Stage Vibrator

This section contains various vibratory plates and is one of the most crucial sections of the device. It is located beneath the hopper. The plates contain several vibratory channels to carry, organize, and segregate the beads, facilitating the counting process.

Counting Sensors

The photoelectric sensors are another critical component of the device and lie at the heart of the device. They are positioned beneath the vibratory channels and receive the beads for counting. The beads are detected when passed through the sensors that disrupt the light beam. It guarantees precise counting.

Filling Head

The filling heads contain nozzles that direct the counted beads to the containers. The funnel dispenses the beads while aligning with the bottleneck. The funnel’s mouth can be customized based on the container.

Conveyor

The conveyor transits containers to be filled with beads. It synchronizes with the counting mechanism to ensure the accurate dispensing of beads into the correct container at the right time.

HMI Screen

An HMI touchscreen is a crucial part of the device with a user-friendly interface, allowing the workers to monitor and manage the counting and filling operations.

Electric Cabinet

The electric cabinet houses the entire electrical components of the laundry beads counting machine. It plays a crucial role in keeping the components from the external environment and maintaining the safety of workers from potential hazards.

Adjustable Base

The base is responsible for the firm positioning of the device.

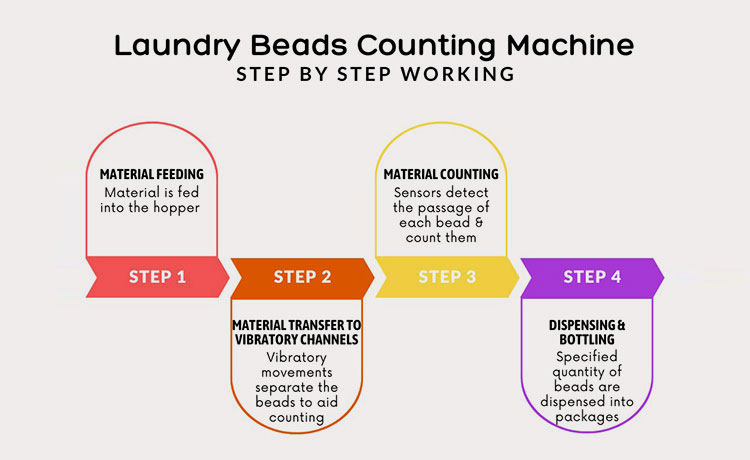

5.What is the working procedure of the laundry beads counting machine?

Laundry bead packaging efficiency and precision have reached a new height with the automatic laundry beads counting machine. The device can process huge production volumes quickly and with minimal human involvement.

The device is made up of vibrating plates and several sensors. Every element and component guarantees an accurate and efficient counting procedure. Here is a detailed investigation of the workings of the laundry beads counting machine:

Step 1: Feeding Beads into the Hopper

The process begins by feeding the material into the hopper. It can be done manually or using a mechanized equipment. The hopper is facilitated with a vibrating mechanism to maintain the orderly flow of materials to the device.

Step 2: Beads Transfer to the Vibratory Channels

The hopper aids in the regulated transfer of beads toward the vibratory channels. The vibratory plates employ vibrations that perform a dual function: segregating the beads to avoid sticking and positioning them for accurate counting. The vibratory movements guide the beads toward the discharging head and detecting sensors.

Step 3: Beads Counting

There is placed a sensor head on top of each filling funnel. They play a crucial role in counting. As the beads discharge from the funnel, the sensor detects their passing and makes them count. The advanced sensor technology ensures accurate counting and the dispensing of the intended amount of tablets.

Step 4: Beads Dispensing and Bottling

The desired quantity of beads is dispensed after precise counting into the packaging containers placed under the funnel on the conveyor rail. After getting filled, the containers are guided for further processing.

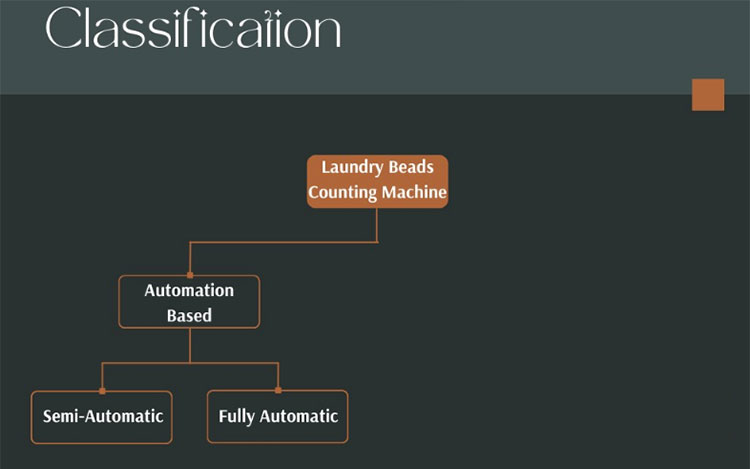

6.Classify the laundry beads counting machine.

There are multiple varieties of laundry bead counting machines on the market. They are distinct in a few ways. These gadgets can be divided into several categories. Let’s explore these different models of the laundry beads counting machine.

Automation Based Categorization

Semi-Automatic Laundry Beads Counting Machine

Semi-Automatic Laundry Beads Counting Machine – Picture Courtesy: SED Pharma

The semi-automatic laundry beads counting machine is automated to a certain degree but still needs human intervention. These gadgets are commonly used in tabletop form.

The manual steps are material loading, container placement, and discharging of filled containers. Automatic processing steps done by the device include aligning, counting, and dispensing a desired quantity of beads into each container. When it comes to productivity, these technologies outperform manual ones.

This device can handle various shapes and sizes of products and is suitable equipment for small and medium-level production sectors.

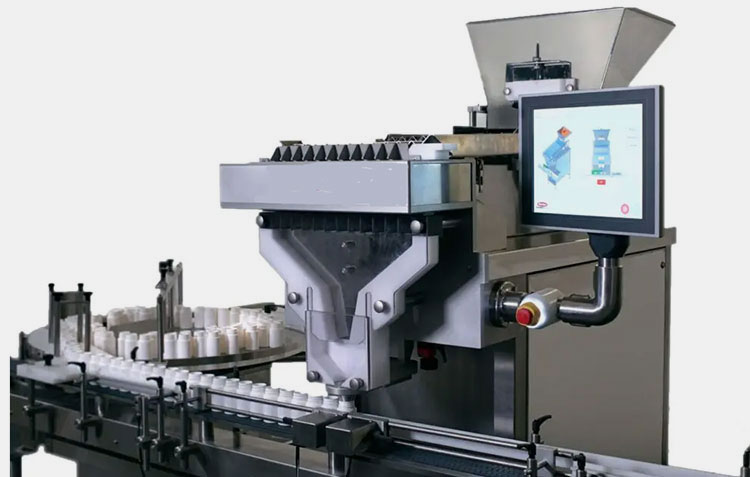

Fully Automatic Laundry Beads Counting Machine

Fully Automatic Laundry Beads Counting Machine

It is an advanced form of laundry beads counting machine designed specifically for the precise handling of large production volumes. The device comprises digital and sophisticated components, resulting in top-level device performance.

These components minimize human-prone errors and ensure accurate material counting. These devices are designed with an intuitive touch interface that lets users monitor and control the process parameters.

7.What items can be counted using a laundry beads counting machine?

The laundry beads counting machine can be adapted to count various items effectively apart from the laundry beads. Some common products that are counted using a laundry beads counting machine are:

| Laundry Beads

The device is specifically engineered for its main function, precisely calculating and distributing laundry beads for rinsing clothes. |

|

| Tablets and Capsules

The device is used in the pharmaceutical sector for accurate counting of several forms of tablets and capsules. |

|

| Seeds and Grains

The device can also count various seeds and grains for agricultural and gardening purposes. |

|

| Candies

Small candies and other confectioneries are counted using this device. |

|

| Nuts and Screws

The device is also used for counting small hardware tools, such as nuts, screws, bolts, etc. |

|

| Buttons

The device is employed in the textile sector for counting buttons for garments. |

|

| Dried Fruits

The device can also be used to count and package various mixed nuts. |

|

8.What measures have to be taken to ensure the longevity of the laundry beads counting machine?

Cleaning & Maintenance of the Laundry Beads Counting Machine

The laundry beads counting machine requires a substantial investment. You will need to conduct regular maintenance programs to optimize its functioning and ensure its longevity. Effective maintenance is crucial to get the most out of this device. Following are some of the tips you should comply with to prevent the machine breakdown:

Before using the device, make sure

- There should not be any dirt on the hopper and vibratory section.

- All the nuts and bolts should be fastened.

- The button on the screen panel must be in the initial position.

- The power supply should be uninterrupted.

- The device should be firmly in place.

After each counting batch or scheduled period, disinfect the contact parts, such as the hopper, vibratory channels, and filling funnels, and then dry them with a gentle fabric.

Cleaning

- Regularly remove the dust from the device.

- Clean the key components with ethanol or other recommended cleansing agent.

- Wipe out the sensors with a soft fabric.

- Disassemble the device for deep cleaning.

Maintenance

- Regularly inspect for damaged or torn components and consider immediate repair or replacement.

- Lubricate the moving parts regularly, such as conveyor belts, for efficient operation.

- Check the sensors for optimized functioning.

9.What challenges are faced while using the laundry beads counting machine and how to rectify them?

The laundry beads counting machine is sophisticated equipment, but even the most advanced and expensive devices encounter certain problems owing to their continuous operation. Timely rectification of these issues is crucial to avoid major incidents and material loss.

Here we will discuss some common challenges that one may face while using the laundry beads counting machine and how to rectify them:

Materials Become Lodged

Material Lodgment

| Causes

Device over-speeding The components are not synchronized. |

Solution

Adjust the device speed as per the product characteristics. Ensure the synchronicity of the device components. |

Non-Uniform Counting

Non-Uniformity in Counting – Picture Courtesy: Altrimex

| Causes

Sensors are dirty or damaged. The beads are clogged due to malfunctioning of vibratory channels. The parameters are not set properly. |

Solution

Clean the sensors with a soft cloth. Check the sensors for damage and consider immediate replacement. Repair the vibratory trays. Validate the process parameters. |

Misaligned Packaging Containers

Misaligned Packaging Containers

| Causes

The conveyor is moving at a high speed. The conveyor belt is torn. |

Solution

Regulate the conveyor speed. Replace the conveyor belt. |

Conveyor Jamming

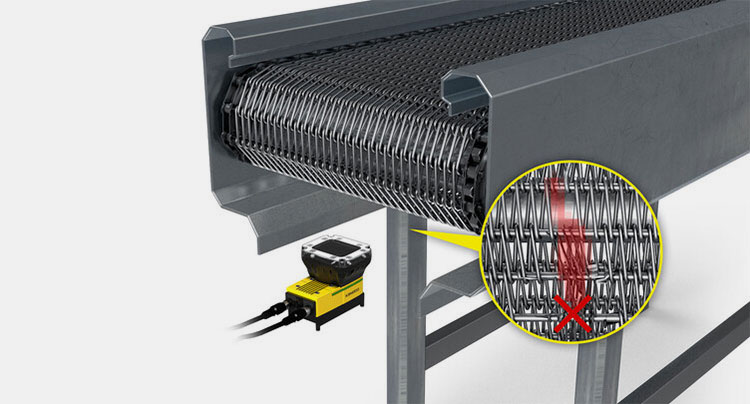

Conveyor Jamming – Picture Courtesy: Cognex

| Causes

Lack of lubrication in the conveyor system. The conveyor belt is loose or damaged. Obstruction in the conveyor path. |

Solution

Regularly lubricate the conveyor system for optimum performance. Adjust the conveyor belt or replace the damaged one. Clear the obstruction in the conveyor path (if any). |

10.Describe the essential factors to consider before buying the laundry beads counting machine.

Choosing the best laundry beads counting machine for your business might be challenging given the wide variety of devices available. In this section, we will go over some important considerations when purchasing a laundry beads counting machine.

You can choose the most precise and effective device for your requirements by paying attention to these pointers.

Consider Your Needs

Consider Your Requirements

It is an important parameter to consider while investing in the laundry beads counting machine. Evaluate your requirements and choose the device that could satisfy your demands effectively. For example, if precision is your top priority, you must consider a device with advanced sensors and optics.

Production Capacity of the Device

Production Capacity of the Device

Different models have varied features in terms of production speed and counting accuracy.

Based on your demands, select a device with the relative production capacity.

Take Into Account the Device Cost and Your Budget

Budget Evaluation

It is one of the most crucial factors involved in purchasing the laundry beads counting machine. Estimate your finances and consider the entire expenses related to the device, including initial investments, maintenance, and operational costs.

Product Characteristics

Product Characteristics

Different materials have different properties. Evaluate your products to be processed and their respective characteristics. Select an ideal device for your products for optimum performance.

Device Personalization

Device Personalization & Versatility

The variants with customization features are ideal ones. It is advised to choose a model with customization properties and efficient results.

Quality Certifications

Quality Certifications – Picture Courtesy: Hartford Technologies

The laundry beads counting machine with quality certifications are recommended for better and more efficient results and the safety of products and workers.

The Bottom Line

An automatic laundry bead counting machine has been an indispensable device in the chemical industries and sectors dealing with granular products since it makes it easier for manufacturers to enhance efficient production and generate significant business growth and profits. That's why this device will be a smart investment for your business. Different variants offer several options for precise counting and effective production. Whether you own a small enterprise or a large manufacturing industry, there will be a model that suits your requirements. So, don’t miss out on this device's significance; without further delay, contact Allpack, choose the most suitable model for your company, and streamline your counting process!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours