Juice Liquid Bottling Line: The Complete Buying Guide In 2025

Mostly, people like to have juice instead of eating fruits and vegetables. The reasons vary from busy routine to doctor recommendation and personal like. Juicing is also beneficial for digestive health, thus, you will hardly find a person with no crave for it. Similarly, global beverage industry has witnessed a surge in juice production as well as its preservation which is perfectly done in bottles. That's why, to meet such large production needs, a Juice Liquid Bottling Line is designed.

This production line is a complete solution to process your bottles through unscrambling till juice filling, capping and labeling. Not only that, but it has simple operational procedure with easy maintenance routine. It also gives you high production efficiency along with precision and product safety. So, no matter what kind of juice or liquids you have in hand, a Juice Liquid Bottling Line will process it with proficiency. So, let's begin this journey of exploration!

1.What Is Juice Liquid Bottling Line?

Liquid juice bottling line- Picture Courtesy: accutekpackaging.com

Juice liquid bottling line is a collection of interconnected machines which make a production line to undergo the bottles through aligning, filling, capping, printing and labeling process. It consists of a bottle unscrambler, liquid juice filling machine, capping machine, inkjet printer and labeling machine.

This line is fully automatic with different units being linked together. Similarly, once the setting is done, it starts processing bottles through a series of steps in a consistent manner just with a single click. It ensures bottling accuracy and efficiency throughout operation. Moreover, it also supports the integration of secondary packaging equipment for further enhancing the production growth. Hence, it can be used in every sector dealing with liquids.

2.How Can A Juice Liquid Bottling Line Benefit Your Business?

A juice liquid bottling line can benefit your business by bringing in use its vary features. Let's look towards the most prominent ones!

Consistency

Consistently finished juice bottles- Picture Courtesy: tetripack.com

The modular design along with intermittent sensors located at each unit enable the juice liquid bottling line to maintain accuracy and precision while measuring juice, filling it into bottles, and the right application of labels. Therefore, every juice finished bottle is uniformly finished without under and overfilling.

Time Saving

Time saving icon- Picture Courtesy: Adobe Stock

Juice liquid bottling line is highly automated where the process goes on smoothly once operator set the machine. It carries out all the functions independently without any need for labours. Hence, the delays caused by manual intervention are reduced and the time is saved with efficient performance of the production line.

Robust Construction

Robust construction- Picture Courtesy: sraml.com

The solution is creation of highly durable and robust construction material with stainless steel as core element for contact parts and number of fill heads followed by anodized aluminum for the rest of body. Together they protect the juice liquid bottling line for longer working life.

Adaptability

Different size juice bottles- Picture Courtesy: Adobe Stock

It supports quick parts changeover to deal with the bottles of various sizes and shapes. Along with that, the juice liquid bottling line has wide range of programmability options which can save multiple settings for its convenient execution.

User-friendly

Easy to use icon- Picture Courtesy: fekrait.com

Each section of the production line possess a control unit where the parameters regarding concerned machine are fixed. Similarly, the PLC control panel allow user to interact with machine effortlessly.

3.Enlist The Bottles & Containers Supported By A Juice Liquid Bottling Line?

As far as the bottles and containers, which are supported by a juice liquid bottling line, are concerned, so, they are numerous in numbers. Depending upon the specifications of different units, you can use wide range of containers for liquid filling. These are enumerated below for your understanding:

Plastic Bottles

Juice plastic bottles- Picture Courtesy: Freepik

Plastic bottles are the most commonly used containers for juice packing. The reason is its high flexibility and cheap price which reduce the overall packaging cost and resist pressure.

Glass Bottles

Juice glass bottles- Picture Courtesy: Freepik

Glass bottles are also popularly used for delivering liquid juice, therefore, a juice liquid bottling line can better deal with glass bottles. They are highly hygienic and free from presence of bacteria as well as harmful chemicals that may emit when exposed to heat.

Jerrycans

Juice jerrycan- Picture Courtesy: yellowimages.com

Jerrycans are also processed by a juice liquid bottling line. They are useful for storing up to 5 liter of liquid juice. Hence, the production line can be adjusted in accordance with the size and shape of plastic made jerrycans.

Round Bottles

Various round juice bottles- Picture Courtesy: GreenPeople

A juice liquid bottling line can easily handle the processing of round shaped bottles. These bottles are often used for delivering all kinds of liquid beverages such as juice, soft drinks, milk shakes, and mineral water.

Square Bottles

Square juice bottles

Square shaped bottles are also popularly used especially for spirits and sausages etc. Hence, a juice liquid bottling line is best suitable to process square shape bottles easily.

Irregular Shape Bottles

Irregular shape juice bottles- Picture Courtesy: Webstaurantstore.com

By irregular shape means all the bottles with no specific shape and they may be in shape of any fruit, vegetable, or special shape. Therefore, you can process all these bottles by a juice liquid bottling line.

4.What Type Of Liquids Can Be Processed By A Juice Liquid Bottling Line?

This bottling line is useful for weighing and filling of extensive range of liquids along with liquid juice such as spirits, soft drinks, sauces, and milk etc. Let's know these all in below paragraphs:

Juices & Spirits

Watermelon juice- Picture Courtesy: frommybowl.com

This juice liquid bottling line is mainly used to pack all kinds of liquid juices, smoothie, cocktail, and juice with chunks. In addition to juices, spirits, wine, and other alcoholic drinks are often delivered in bottles for which this bottling line is suitable.

Soft Drinks

Multiple soft drinks bottles- Picture Courtesy: conveniencestore.co.uk

Soft drinks are water-based flavored drinks with added sugar such as coca cola, fanta, sting, and dew etc. As they require enclosed body for processing especially during packaging, a juice liquid bottling line is perfectly applicable to process them.

Mineral Water

Mineral water bottles- Picture Courtesy: pngitem.com

Mineral water is a growing necessity of all the travelers, restaurants, hotels, and airports etc., as it is clean and healthy. Therefore, its production line is almost everywhere a giant one. That's why, a juice liquid bottling line is capable of processing mineral water.

Sauces

Peri Peri sauce- Picture Courtesy: whiskaffair.com

Well, sauces also come under the category of liquids which we use in ou day to day cooking. These include ketchup, mayonnaise, soy sauce, chilli sauce, and vinegar etc. Similarly, juice liquid bottling line may also be used for sauces packing.

Syrups

Date syrup- Picture Courtesy: clearspring.co.uk

Medical syrups, herbal syrups, fruit syrups and other fluids are also suitable to be processed and packed by this bottling line.

Edible Oil

Sunflower oil- Picture Courtesy: stylecraze.com

Edible oil is unsaturated fat derived from plants and animals sources. It is used in industrial food manufacturing and home cooking. The common examples include sunflower oil, avocado oil, soybean oil, canola oil, and olive oil. So, a juice liquid bottling line is eligible for edible oil packing.

5.Explain The Working Principles Of A Juice Liquid Bottling Line?

To operate your juice liquid bottling line, you need to understand its working principles. In this way, below provided details will be helpful:

Setting

Setting parameters- Picture Courtesy: sraml.com

First of all, it is necessary to check each section of your juice liquid bottling line for good working condition. Along with that, you need to set the parameters of production line by using touch screen interface and control board connected with each section. For instance, fixing the volume of juice to be filled in each bottle, adjustment of data for printing, and the speed of conveyor etc.

Loading

In the second step, loading of different things into juice liquid bottling line will be taken place. For example, the feeding of bulk empty bottles into bottle unscrambler, large volume of juice into tank, stock of bottle caps into hopper, and the labeling roll into labeling machine.

Bottle Unscrambling

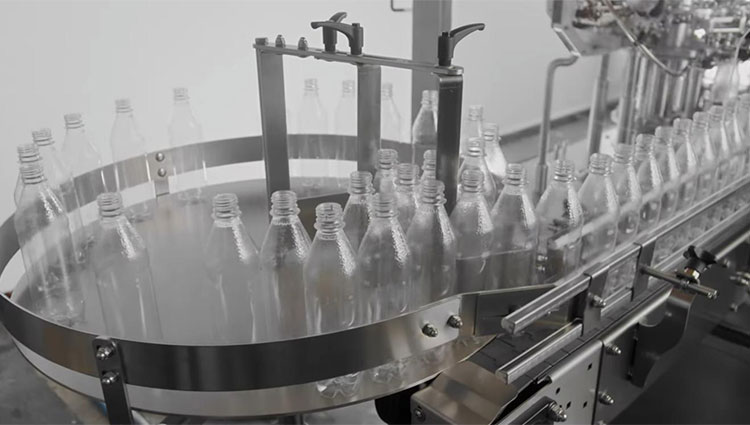

Bottles unscrambling- Picture Courtesy: sraml.com

Now, when the setting of bottling line along with material loading have been taken place the next step is to power it on. Similarly, the line will initiate bottle unscrambling with its first unit. During this process, randomly positioned bottles are serialized and provided to the rinsing unit through conveyor. After unscrambling, bottles are rinse with clean water and moved for juice filling.

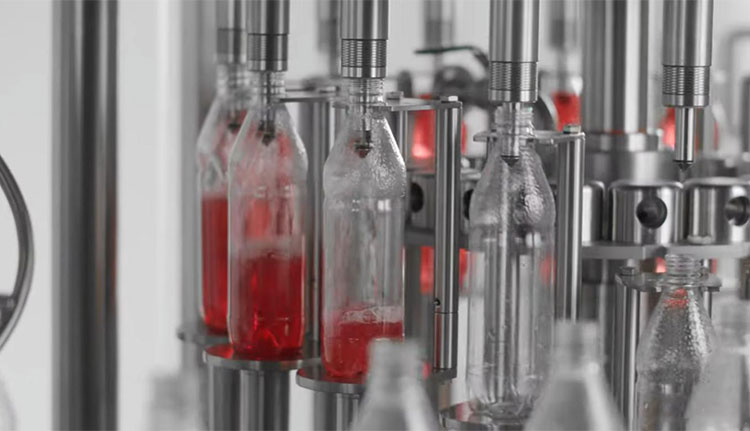

Juice Filling

Juice filling- Picture Courtesy: sraml.com

Proceeding further, the aligned bottles are moved ahead for filling under the nozzles. At the same time, juice filling machine start measuring the exact volume of juice and dispense it into the awaiting bottles. During filling, with the help of sensors and other controlling tools, overfilling and under-filling is restricted to reduce material waste and ensure sanity.

Bottles Capping

Bottles capping- Picture Courtesy: sraml.com

Upon juice filling, the bottles are mobilized for capping into a capping machine. Here, these bottles are supplied with caps one by one as they pass under the chute. Similarly, depending upon the type of capping technique being used, the caps are either screwed or crimped around the bottles' neck. Hence, airproof and leak proof sealing is created to avoid material escaping from bottle and the environmental elements getting inside.

Inkjet Printing

Inkjet printing- Picture Courtesy: DSI Printer

In this step, tightly capped bottles are moved ahead where they pass through the inkjet printing phase. It is mainly used for glass bottles, however, plastic bottles are also processed through this unit. It simply includes the printing of numerical data on the bottles such as manufacturing date, expiration date, price, and batch no etc.

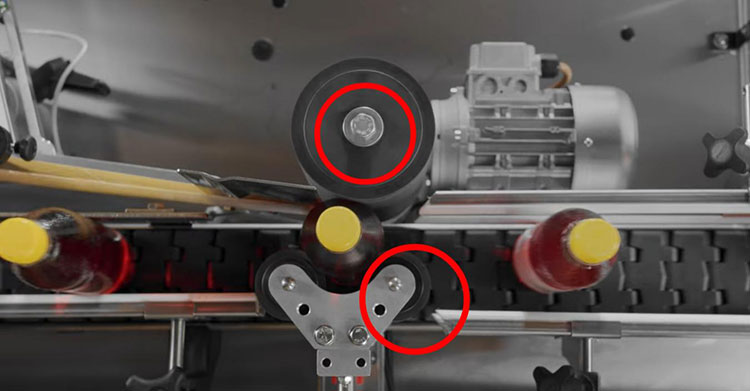

Bottles Labeling

Bottles labeling- Picture Courtesy: sraml.com

In the last step, bottles are labeled with labels. Depending upon the machine being used, it can be sticker labeling or shrink sleeve labeling. The former follows simple way where sticker labels are applied around the passing bottles. While as, in the latter, plastic label sleeves are dropped over the bottles after which bottles are passed by the heat to get the label shrink around them.

Bottles Discharging

Bottles discharging- Picture Courtesy: sraml.com

Finally, all the finished bottles are ready for outlet. So, they are sequentially discharged from the juice liquid bottling line for further packaging and shipping.

6.Name The Different Types of Machines Which Make Up The Structure Of A Juice Liquid Bottling Line?

In order to know the structure of a juice liquid bottling line, it is crucial to understand each unit which is part of the bottling line. For this, we have described different types of machines which make up the body of a juice liquid bottling line. These include:

| No | Machine | Description | Structure | Operation |

| 1 | Bottle Unscrambler

Allpack APC-A100 Automatic bottle unscrambler |

Bottle unscrambler is an automatic machine made for the serialization of scrambled bottles and their supply to juice liquid bottling line. | Its structure is made up of stainless-steel body, stable four feet, control unit, rotary channel, and a hopper for bottles loading. | It works by taking the randomly positioned bottles from barrel and processing them through rotary disc. Similarly, the bottles are rightly positioned and moved further for filling. |

| 2 | Bottle Filling Machine

FL-101 Automatic Filling Machine- Picture Courtesy: packleader.com |

Bottle filling machine is the core part of juice liquid bottling line integrated for the purpose of precisely weighing juice and filling it into bottles. | It is an assembly of a tank, weighing system, filling heads, conveyor, main frame, control system, electric cabinet, and bottle sensor etc. | The operation of bottle filling machine is simple enough which starts from juice weighing to bottle detection, juice filling, and bottle conveying. |

| 3 | Bottle Capping Machine

Allpack APC-D903 High Speed Capping machine |

Bottle capping machine is an excellent machine incorporated to the juice liquid bottling line for tight sealing of bottles opening. | The structure of machine consists of chucks, inserters, clutches, moto, gear boxes, gripper disc, sorters, supporting body, conveyor, shafts, sprockets and intuitive human machine interface. | It follows a sequential order to place caps over the bottles and then screwing them for tight sealing. |

| 4 | Inkjet Printer

Allpack- Small Character Inkjet Printer A300 |

Inkjet printer is yet another machine being part of the juice liquid bottling line for printing data on bottles. | It has small structure with few components including a control panel, main frame, bottle sensor, and printing head etc. | It works by storing data input given by operator. Afterwards, it spray the body of glass or plastic bottle and leave printed data behind. |

| 5 | Labeling Machine

Allpack APC-T1 Round Bottle Side Face Labeler |

Labeling machine is the last machine of juice liquid bottling line. Its function is to apply labels around the bottles. Depending upon your labeling machine, you may use a sticker labeling machine or shrink sleeve labeling machine. | The body of labeling machine is made up of a label film roll, label cutter, electric eye, label drive mechanism, control system, and label applicator. | It functions by first pulling the label film from roll and then applying these labels around the bottles. During operation, the blade keep splitting labels after detection and the sponge wheel press the label to get it stick to the bottle. |

7.Highlight The Various Applications Of A Juice Liquid Bottling Line?

Juice liquid bottling line is widely applicable to many industries in both food and non-food sector. In below paragraphs, we have enlisted the top areas where the use of a juice liquid bottling line can be found:

Beverage Industry

Various juice bottles- Picture Courtesy: Behance

Beverage industry is such a comprehensive sector where heavy duty machinery is needed to handle the production and packaging of different liquids It is used in beverage industry for the packing of juices, coffee, soft drinks, milkshake, spirits, and mineral water etc.

Food Industry

Bottles of different sauces- Picture Courtesy: nandosperiperi.com

The use of a juice liquid bottling line is also popular in food industry for bottling of different materials including sauces, edible oil, pastes, soups, liquid chocolate, and condensed milk etc.

Medical Industry

Cough syrup bottle- Picture Courtesy: kufma.com

Medical industry is one of the beneficiaries of a juice liquid bottling line in a way that it frequently packs syrups and other medicated liquids into bottles by using this line. Moreover, liquid medications used for animals and pets are also packed by it.

Chemical Industry

Dishwash liquid bottle- Picture Courtesy: regin.com

Chemical industry is involved in the manufacturing and processing of liquids in one way or another. Similarly, it also require a full fledged packing line to safely pack these liquids into bottles for which a juice liquid bottling line is ideally suitable. The common chemicals processed by it include liquid detergent, pesticides, dish washing gel, and bathroom cleaner etc.

Cosmetic Industry

Honey shampoo bottles

Another notable application of a juice liquid bottling line is cosmetic industry where liquids like shampoo, shower gel, hand washing gel, lotion, and hair dyes are popularly delivered in bottles.

8.What Quality Standards Should A Juice Liquid Bottling Line Meet With?

A juice liquid bottling line is meant for the packing of food products, therefore, it must adhere to certain national and international quality standards in order to be known for its safety. Some of the most popular and important quality standards are as follows:

ISO quality standard icon- Picture Courtesy: eciprocity.com

International Organization for Standardization (ISO)

ISO is an independent international organization established for ensuring the quality and services of products and machines by determining quality standards. Therefore, s juice liquid bottling line should meet with the principles developed by ISO.

Food and Drug Administration (FDA)

FDA is another USA based organization with primary focus on public health and safety in a way that all the goods and equipment which are associated with food and drugs directly and indirectly must comply FDA's regulations.

Good Manufacturing Practices (GMP)

GMP aims at promoting the production and manufacturing of quality products. For example, in case of juice liquid bottling line, GMP recommend 304 and 316 quality stainless steel for the construction of body and contact parts respectively.

Conformate European (CE)

This quality standards is applicable to all the goods and equipment which are either produced or sold inside European Union countries. Similar case applies for juice liquid bottling line to be certified by CE.

9.How To Ensure Leak Free Packing With A Juice Liquid Bottling Line?

Juice bottle with leaked cap- Picture Courtesy: testing-instrument.com

It is extremely annoying thing that your bottle is spilling liquid due to leakage. Now, the reasons are numerous which can be associated with bottles its or it may be due to poor sealing. Therefore, manufacturers used to practice certain leak tests for ensuring leak free juice packing into bottles. Among these, one such test is vacuum leak test.

In this test, the finished juice liquid bottle is placed inside the water filled chamber. The chamber is then closed and air is evacuated from the water filled container. Now, if the bottle has any leak, small air bubbles will be appeared and the juice will start dispersing into water. However, if it lacks leak then the state of bottle and water will remain stagnant.

In case of leak, you need to check if it is in the cap or body. The leak in cap or bottle neck shows the fault in capping, while as, the leak in body is the leaked bottle itself.

10.What Are The Cleaning And Maintenance Requirements Of A Juice Liquid Bottling Line?

Responsible user always try to take best care of the products at hand to keep it under use for longer. Similar theory can be applied to the beneficiary of a juice liquid bottling line. Therefore, we have designed this question for our valuable customers to guide them on the line's cleaning and maintenance requirements. So, let's have a look towards it!

Operator setting machine- Picture Courtesy: upkeep.com

Sanitization:Pay attention to the regular cleaning of each section by first shutting down the power connection. Then disassemble the components which are on direct contact to material and bottles such as hopper, filling nozzles, pipes, valves, label cutter, and applicator etc. Wash these parts with clean water and recommended sanitizer. After cleaning, get them dry and locate them on relevant places.

Wear and tear:You need to be aware of the wear and tear of parts that take place during operation. For this, it is necessary to conduct visual inspection of belts, chains, gaskets, and seals etc., and replace them timely if damaged. Keep in your inventory the frequently used parts always ready.

Greasing:In juice liquid bottling line, there are many parts which require proper lubrication. Therefore, you should check these areas and add food grade grease oil to reduce friction and premature parts wearing.

Calibration:Calibrate your juice liquid bottling line on daily basis especially when you are using the material with different properties such as high viscosity juice or bottles of different sizes.

Electrical Adjustment:It refers to the inspection of power connection, inspecting the sensors, and updating the software of juice liquid bottling line for smooth functioning.

11.Explain The Troubleshooting Of A Juice Liquid Bottling Line?

In case of sudden error or breakdown of machine you need to find the root cause and take relevant step to counter the issue. In this way, we have explained the troubleshooting of a juice liquid bottling line in below paragraphs. These include:

Bottle Unscrambler

Bottle unscrambling- Picture Courtesy: podmores-systems.com

Jamming of rotary disc

It happens when the transmission gear and friction plate gets damaged.

For this, you need to replace the friction plate and adjust the parameters of transmission gear.

Bottles getting damaged

Bottles often get defected during unscrambling when the sensor is unable to detect the presence of unscrambled bottle. Resultantly, the bottles fall over one another and cause damage.

It can be adjusted by setting the sensor and installing new one if damaged.

Bottle Filling Machine

Bottle filling process- Picture Courtesy: sraml.com

Nozzle blockage

It happens as a result of foreign object inclusion and the accumulation of juice inside nozzles.

Solve it by keeping the material tank closed with lid and cleaning its nozzles for free flowing of material.

Filling inconsistencies

Sometimes, the uneven placement of bottle filling machine results in inconsistent filling of liquids. Apart from this, the blocked nozzles is major cause of inconsistent filling.

It can be solved by placing the machine on straight smooth surface and keep the nozzles clean from lumps.

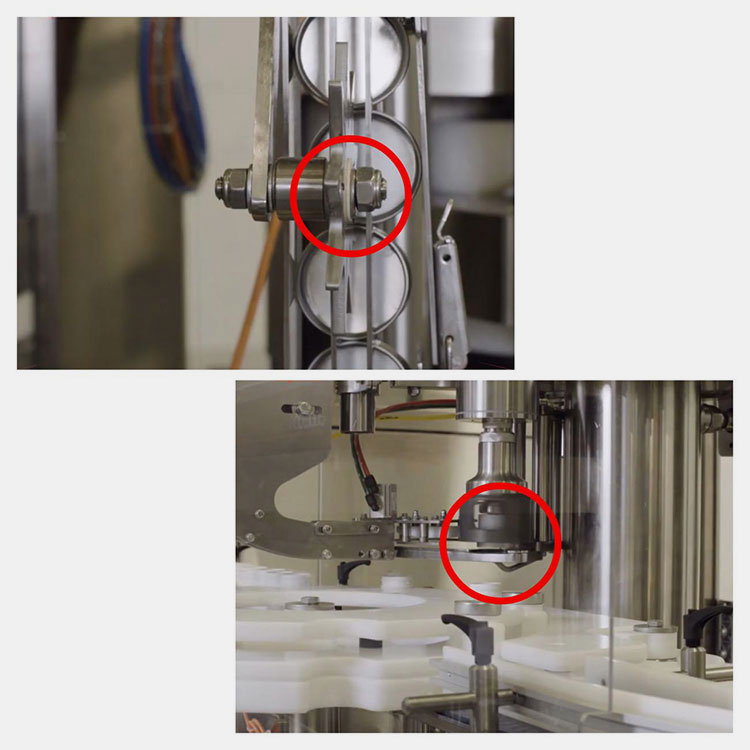

Capping Machine

Indicating capping errors- Picture Courtesy: altrimex.nl

Missing Cap

It is caused by the absence of caps in spindle, therefore, when bottles are passed through the chuck, they are not supplied with caps.

It can be adjusted by supplying the bottle capping machine with adequate caps and examining whether its parts are in good working condition to perform capping task.

Cap Breakage

The cap being applied over bottle's neck is having incompatible size which cause its breakage when applied. Another reason can be the excessive pressure on part of applicator.

Use the caps of similar size and reduce the cap application pressure through control panel.

Inkjet Printer

Inkjet printer fault- Picture Courtesy: Linx Printing Technologies

Printer not working properly

It happens either when the printer has poor connection with electricity or its parts are damaged.

So, you need to check the power connection and parts like sensor and printing head etc., for damage. In case they are out of order then replace them timely

Labeling Machine

Labeling machine faults- Picture Courtesy: sraml.com

Label feeding issue

12.Factors Essential For Selecting The Best Juice Liquid Bottling Line?

There are multiple factors responsible for choosing the best juice liquid bottling line. Each of them has its own worth and significance. Let's, explore these factors and include them in your list of considerations!

Production Speed

High production speed of juice liquid bottling line

Your prime consideration should be to look for the production speed of the juice liquid bottling line you want to purchase as it is the only reason that compel you to opt for it. Similarly, it can be found by checking the number of bottles the line is capable to finish per minute or per hour.

Packaging Preference

Another factor is associated with your choice which simply means reviewing the type of bottles, filling material, caps, and labels and opting for relevant machines. For example, you may ask your vendor to get a customized juice liquid bottling line that may include a shrink sleeve labeling machine instead of sticker labeling machine and gravity filling machine instead of piston filling machine etc.

Cost

Estimating cost- Picture Courtesy: freshbooks.com

The cost of juice liquid bottling line also matters a lot. Therefore, you need to estimate the overall expenditure combining the original price of line along with maintenance and operation cost. Similarly, if you want to purchase a high speed line in low price then second hand juice liquid bottling line will be reliable.

Vendor Policy

Company policy icon- Picture Courtesy: airmason.com

Keep in mind that your vendor is the manufacturer of juice liquid bottling line which you are about to buy. He is well aware of its functioning and quality but not you. So, in order to make vigilant purchase.consider the warranty policy, vendor experience, and customer service.

13.Why Choose Allpack As Your Vendor For Buying A Juice Liquid Bottling Line?

Allpack logo

Allpack provide you wide range of solutions related to juice liquid bottling line. You can also have other benefits which are enumerated below:

Experience

Allpack has over 11 years of long experience in the field of process and packaging. It produces machines and production lines related to medicine, food, and chemicals

High Quality

All its equipment are made up of quality material which can be proved by their certification of ISO, GMP, FDA, and CE. Not only that, but the company also provide you one year of warranty.

Customization

With Allpack, you can design your own bottling line of juice liquid as the company has one of the largest inventory of machines. Hence, you are free from the tension of choosing a juice liquid bottling line from selected numbers.

Customer Support

You can also get the professional support as a customer service for your purchased juice liquid bottling line.

Conclusion

To wrap up this buying guide about a Juice Liquid Bottling Line, we are hopeful to have conveyed the information of your necessity. This line can transform your existing production efficiency and so your labor returns. By following the above mentioned guidelines and explanation of the juice liquid bottling line's structure, working, and maintenance you can have the potential to reach your business to the highest. Even though, you got the relevant information, there might be any question that needs to be addressed. For that, you can contact us through through our website.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours