Combination Weighing And Packaging Line: The Complete Buying Guide In 2025

Are you looking for an amazing multi-functional machine which has the ability to weigh and package your product simultaneously in one go? Do you want an equipment which can do multiple functions so that you don’t have to invest and buy more than one machine? If you do find such type, is it going to benefit you in the long run? And is it going to yield results exactly the way you want? Can you use it in more than one sector if your business stretches across more than one industry?

If you have all these questions coming across your mind then you have stumbled upon the right blog! Because we are about to tell you about a magnificent machine known as combination weighing and packaging line. We will discuss about it in detail so buckle up! Because we are going to take you on a journey of getting to know about combination weighing and packaging line.

1.What is combination weighing and packaging line?

Combination weighing and packaging line

Combination weighing and packaging line is an equipment which weighs your product and packages them simultaneously. This amazing ability of combined weighing and packaging together streamlines your whole process, giving you maximum benefit in a short period of time. The packaged product can then be sent to final packaging where it sent to the warehouse for shipment to its destination.

The machine is equipped with latest technology and will offer you advanced features with minimal wastage. Thus, giving you maximum benefits and saving you from heavy losses.

2.What are the benefits of combination weighing and packaging line?

Are you wondering whether combination weighing and packaging line would be worth investing and installing it in your factory? Will it benefit you in the long run and keep on doing so without incurring heavy losses for you? Well we have got answers to your questions so let’s read about this work of art can benefit you in number of ways!

Continuous operation

Food supplements powder

One of the most attractive feature you will find about this machine is the fact that it weighs and packages two products simultaneously. If one product is being packaged after weighing then the other product has been already introduced into the machine and its weighing process has already begun. This will give you more products in less time and save your money.

Integration

Meal replacements powders -Picture Courtesy: costpricesupplements

One of the biggest benefit you will get from buying this machine is that it can do combine weighing and packaging for your product. So you won’t need a separate equipment for weighing and packaging. The machine can do both the processes for you. This will save you a lot of money which you can use it in your business for other important purposes.

Accurate dispensing

Electrolyte powders in sachets

Do other machines in your factory package inaccurate products so you don’t get uniform packaged goods in every batch? Well not this one. Combination weighing and packaging line has an amazing ability to accurately weigh your product and package them with high precision every single time. So you will get twin products which look and weigh exactly the same.

Versatility

Medicinal powder

Are you involved in more than one industry where you need an equipment which can perform combined weighing and packaging? We’ve got you covered! Because this machine can be used almost in every industry. From weighing and packaging snacks to chemicals. This equipment can do it all!

High production capacity

Dairy whitener powder

Do you need a machine which can package thousands of your product in a single day? Well we have good news for you! Because combination weighing and packaging line can weigh and package as many as 50 bags/min. So it can cater to your high production demand with ease, making it an equipment worth investing.

Minimal wastage

Washing powder

Combination weighing and packaging line is designed in a way that it will weigh and package maximum products with minimal wastage. So your products won’t get spoiled and you won’t have to throw them away.

3.What are the applications of combination weighing and packaging line?

You might be wondering whether you can use combination weighing and packaging line in more than one industry you might be dealing in more than one sector. Well we have wonderful news for you! From snacks, candies to pet food, beauty products and chemicals, this equipment can weigh and package them all. Let us discuss each of the industry in which you can use it.

Pharmaceutical industry

Electrolyte replenishing packets

Are you a pharmacist or someone from a pharmaceutical company who’s looking for an efficient machine to weigh and package your medicines simultaneously? We introduce you to combination weighing and packaging line. This equipment can weigh and package your medicines, capsules, tablets and pills accurately. So the customers can get accurate dosage of medicine every time.

Food industry

Instant coffee powder

Combination weighing and packaging line would be great for you if you deal in food industry. It can efficiently weigh and package snacks, sweets, chocolates, dry fruits and much more into standup pouches, zipper pouches or bags. So you can ship them perfectly sealed in an airtight packaging which won’t get spoiled.

Nutraceutical industry

Vitamin supplement powder

Nutraceutical industry manufactures products like vitamin supplements, meal supplements and energy boosters. All of these can be packaged by combination weighing and packaging line safely into your desired packaging material.

Chemical industry

Color pigments powder

If you deal with chemicals, then weighing and packaging them into bags would be your top most priority. Thus, combination weighing and packaging line can weigh and package silica, camphor, color pigments and much more simultaneously into bags, containers and pouches. So investing in this equipment would be worth it for you.

Household product industry

Washing powder

Many household items like detergent powders, cleaners, dishwasher soap and rat killer tablets can be weighed and packaged by combination weighing and packaging line as smoothly as possible. So if you deal with these items, then do consider installing this equipment in your factory.

Cosmetic industry

Face powder -Picture Courtesy: purple.com

Everyone nowadays wants a beautiful and radiant skin and want to look like a biggest celebrity of their country! But in order to fulfill their wish they need reliable beauty products which give them same results all the time. Combination weighing and packaging line can make their dreams come true by weighing and packaging items like wax beads, beauty soaps, foundation powder into jars and containers. So grab this equipment and put it in your factory to make this world full of beautiful looking people!

Insecticide industry

Insecticide powder

Insecticide and pesticides are insect killers which harm the crops and farmlands. So to maintain their efficacy combination weighing and packaging line can weigh and package them efficiently so that farmers can use them to protect their crops.

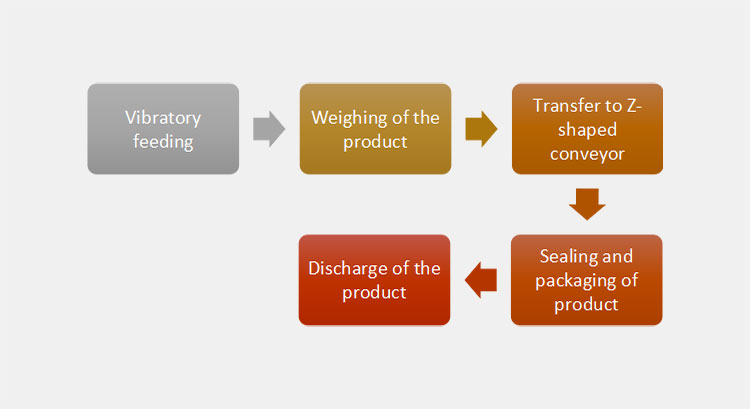

4.What is the working principle of combination weighing and packaging line?

The working mechanism of this equipment is quite easy to understand so we will tell you in order how it works so you won’t get confused when you are trying to initiate the process.

Vibratory feeding

First of all, the product you choose is introduced into the vibratory feeder. This feeder is used as a storage space where all the product is brought into it so that it can then be sent to weighing.

Weighing of the product

The product is then weighed with the help of load cells. This step is essential since it ensures that only the exact amount of product reaches the packaging section so that you get equal and accurate products every single time.

Transfer to Z-shaped conveyor

After your product has been weighed, it is then transferred to Z conveyor. This conveyor is made of multiple sections of different angles that enables the product to be moved vertically and horizontally. The product then reaches the packaging section.

Sealing and packaging of the product

The product now reaches the sealing section where the packaging materials like bags or pouches are introduced and the product is poured inside them. The filled bags or pouches are sealed using vertical and horizontal sealers.

Discharge of the product

The perfectly sealed product is then discharged from the machine where it is sent to a different part of the production line for final packaging and shipment to its final destination.

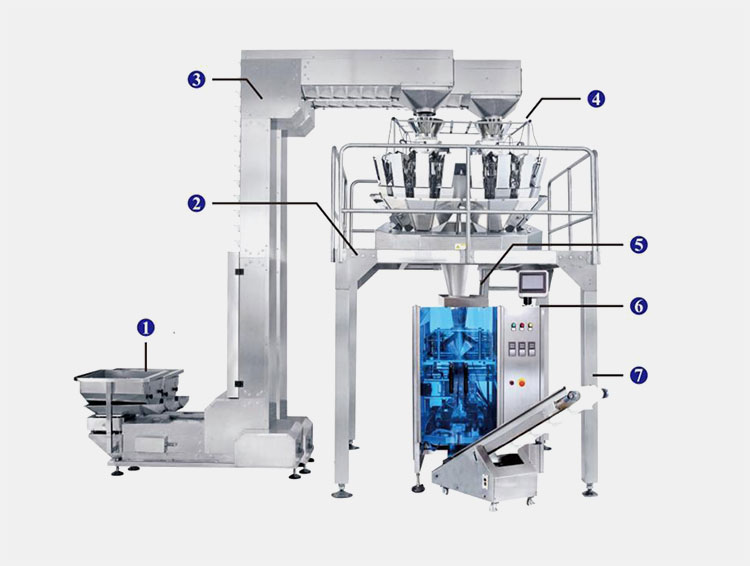

5.Describe the structure of combination weighing and packaging line.

Combination weighing and packaging line has many distinctive parts. Each have their own unique function and characteristic which enable them to work so efficiently. Let us discuss each of them below.

| No | Components | Functions |

| 1) | Vibratory feeder | This is the first part of the machine in which the desired product is introduced. The product is stored here and then sent to the next part for further processing. |

| 2) | Working platform | This part is used to overlook and monitor the whole process. The worker can use to check whether the machine is properly doing its job and adjust the parameters accordingly. |

| 3) | Z-shaped elevating conveyor | This special type of conveyor has two horizontal ends and one sloping end whose angles are above 30° and below 90°. They are responsible for carrying the product from the feeding end to the packaging end. |

| 4) | 10 heads weigher | This part is where your product will be weighed at the exact amount you desire to give you exact product. |

| 5) | Freefall metal detector | This component is where your weighed product will fall freely and go into the sealing part. It is also responsible for detecting any damaged or contaminated product and discard it if necessary. |

| 6) | VFFS | These are the sealers where the weighed product is sealed by vertical sealers in bags or pouches. |

| 7) | Finished product conveyor | After the product has been packaged, it is then discharged from the machine through finished product conveyor. |

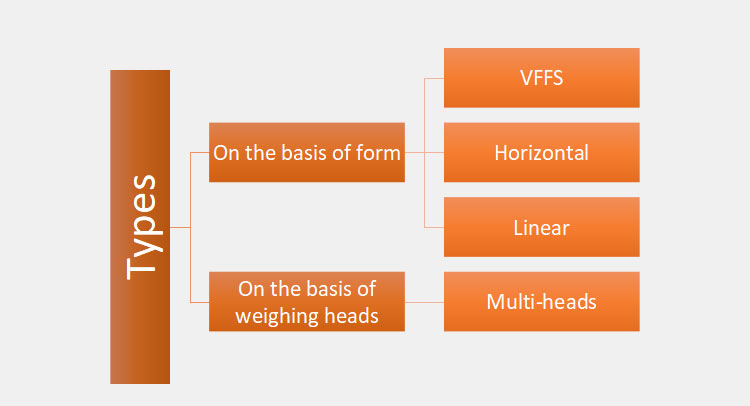

6.Explain the types of combination weighing and packaging line.

Combination weighing and packaging line has few types. Each have their own specifications and features which can then be used in different sectors for different purposes. So let’s discuss these below.

We can classify combination weighing and packaging line:

On the basis of form

VFFS combination weighing and packaging line

VFFS combination weighing and packaging line

This is known as vertical form and fill seal combination weighing and packaging line. As the name suggests, it has vertical sealers as its distinctive feature. It is quite easy to use and has PLC control and advanced features which will yield perfectly sealed products for you.

Working principle

The machine working principle is quite simple. Firstly the required product is fed into the vibratory feeder. Secondly, it is moved to the weighing section where it is weighed with high precision. Thirdly, it is transported to the vertical sealers by the conveyor belt. The vertical sealers then use high pressure and temperature to package your product into pouches or bags. The sealed bags are then discharged and dispatched for final shipment.

Horizontal combination weighing and packaging line

Horizontal combination weighing and packaging line-Picture Courtesy: jwweigher.com

Another category which exists is known as horizontal combination weighing and packaging line. This type is composed of horizontal sealers and has latest human interface features to smoothly operate the weighing and packaging process simultaneously.

Working principle

The mechanism of this is similar to VFFS combination weighing and packaging line. The product is introduced into the vibratory feeder which then sends it to the weighing area where it is weighed. The weighed product is sent to the horizontal sealers to package your product into bags and pouches. The air-tight package is then moved to the other side of production line where it is wrapped for shipment to the consumer end.

Linear combination weighing and packaging line

Linear combination weighing and packaging line -Picture Courtesy: packkingconveyor.com

The shape of this machine is aligned in a straight form and the whole process of weighing and packaging takes place in an align way. It is ideal for packaging items like medicinal powders, spices and herbs.

Working principle

The solid product like medicinal powders are fed into the hopper. The powder is weighed accurately by the weighing section so that equal amount is filled into the packet. The package like sachets, pouches and bags are sealed using sealers and is then discharged from the machine for further processing.

On the basis of weighing heads

Multi-heads combination weighing and packaging line

Multi-heads combination weighing and packaging line -Picture Courtesy: weighpack.com

Under this category comes multi-heads combination weighing and packaging line. There can be many heads including 10, 20 and 32. The greater the number of multi-heads, the more products you would be able to weigh at the same time so you can benefit from it if your factory demands high production capacity.

Working principle

The product which are in solid or granular form are introduced into the feeder. The stored product is then transferred to the multi-heads weigher where it is weighed accurately. The weighed product is moved to the vertical sealers by the help of conveyor belt where it is sealed, packed and discharged through the conveying outlet.

7.How to maintain combination weighing and packaging line?

Worker maintaining machine

You must have noticed that all the machines, no matter what function they perform, whether they are cheap or expensive, all require maintenance at some point. So does combination weighing and packaging line. It is very important to maintain it as best as you can so that it gives you optimum results and function for many years to come. Don’t worry because we are going to teach you how.

Cleaning: you must have noticed that after using this machine for some time, there would be presence of dust on it. So to get rid of this, use a piece of fabric cloth to clean all the parts like hopper, vibratory feeder, working platform etc.

Lubrication: this is an essential step as it is very important for you to oil the moving parts of your machine since it would’ve developed friction over time and the efficiency would’ve been greatly reduced. So use a lubricant oil or grease to ensure optimum working so that you get the desired results.

Inspection: this crucial step is a must since you would need to check at least on a weekly basis whether all the parts are perfectly doing their job. If not, then fix them or replace them with a new one so that you can continue with the process.

Adjustment: before you start the process, you need to make sure that all the parameters have been adjusted accordingly and if not, then set them to their required values. You would also have to see that all the parts have been perfectly adjusted to the machine after they have been cleaned thoroughly.

8.What are the factors for choosing the best combination weighing and packaging line?

It is quite cumbersome to ultimately decide which kind of machine would prove to be best for your company. And you can be quite concerned whether the machine you are buying would be worth the heavy investment and whether and it will benefit you in the best way possible or not. But don’t worry! We have answers to your fears! We are going to tell you how you can buy the best possible combination weighing and packaging line for your company so that it will reap you benefits for years to come!

Financial capital

This is the first factor that must come to your mind when you would be buying combination weighing and packaging line. If you have the means of buying a new one, then go for it because it will be worth it. However, if you cannot afford to buy the new one, then you can simply go for the second-hand one which will be cheaper but offer you the same features.

Production capacity

Various spice powders

This factor would be quite important for your factory. Before buying, you have to check whether the combination weighing and packaging line you are intending to buy can cater to the production demand of your factory. If it cannot, then it would be futile to buy it.

Working space

Vitamin K2 supplement powder

Everyone’s working space is different since the availability of the area depends on the space and the number of machines situated in the production line. So before buying, it is important to see whether combination weighing and packaging line would be able to fit in your factory or not.

Type of packaging material

Various food flavors in stand-up pouches

Do you deal with packaging materials like jars, containers or other kind like stand-up pouches, zipper pouches, flat pouches or special shapes bags? If you use these kind of packaging materials for your product then it is critical for you to see whether combination weighing and packaging line you are opting to buy has the ability to package your products into these packaging materials.

Conclusion

So we have thoroughly discussed about combination weighing and packaging line and we hope that you would learned about it in detail and gained some knowledge about its features, benefits, specifications and its types. What kind of combination weighing and packaging line you would require for your factory depends on your unique demands. So it is important for you to see that your demands and the type you are buying is in line. And if you are wondering and still doubting whether you should invest in combination weighing and packaging line, then you should go for it because it will be worth your investment.

For more information and details, please visit our website allpackchina.com

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours