Chicken Sauce Bottling Line: The Complete Buying Guide In 2025

The chicken sauce brings flavor to different cuisines and is the perfect addition to dining tables. This yummiest sauce usually comes in bottle packaging. But do you know which bottling line is involved in the packaging of chicken sauce bottles? The answer is very simple.

A remarkable and efficient bottling line is known as the chicken sauce bottling line. The high demand for chicken sauce bottle packaging has compelled manufacturers to look for an alternative to manual packaging and that is where the chicken sauce bottling line is evolved. It is increasingly integrated into the packaging line because it effectively carries out the bottling process.

Do you want to know more about the chicken sauce bottling line before adding this production line to your business? Then you are at the right place. Buckle up for an informative journey because we are detailing everything that there is to learn about the chicken sauce bottling line.

1.What is a chicken sauce bottling line?

Chicken Sauce Bottling Line- Picture Courtesy: Picture Courtesy: vkpak

The chicken sauce bottling line is a production line for packaging chicken sauce into bottles on a larger scale. This bottling line has an interconnected series of machines that efficiently perform different jobs of filling, capping, and labeling. Its main purpose is the automation of the packaging process.

Chicken sauce bottling line is the requirement of every biggest manufacturing firm as it effectively processes and fills chicken sauce in bottles without the risk of contamination. Its hygienic packaging is approved by quality control authorities.

2.How is the chicken sauce bottling line advantageous to production?

A chicken sauce bottling line is highly advantageous to production because of its high performance and ability to deliver extraordinary results in significantly less time. It is a necessity of rapidly evolving businesses as it upholds packaging quality. Some of the exceptional advantages of the chicken sauce bottling line are given below:

Versatile Adaptability

Versatility- Picture Courtesy: Reddit

There is no fixed standard in production when it comes to the shapes and sizes of chicken sauce bottles, consequently chicken sauce bottling line processes all kinds of designs of bottles. This production line has evolved to package a broad range of bottles with simple adjustments in parts. It is a handy bottling line that saves manufacturers from the difficult task of purchasing different equipment for different contour bottles.

Error Free Packaging

Error-Free Packaging- Picture Courtesy: tashvock

Manual processing and packaging the chicken sauce bottles is bound to have some packaging errors like incomplete cleaning, underfilling, crooked caps, and mislabeling. This reduces the product quality and results in a higher loss of revenue. But with the chicken sauce bottling line, you get error-free processing and the best product quality.

Time-Saving

Time-Saving- Picture Courtesy: Picture Courtesy: Adoboloco®

Filling, capping, and labeling chicken sauce bottles can be tough and tiresome jobs, needing a huge time and effort, often resulting in work strain for the operator. However, because of the chicken sauce bottling line, the packaging task is completed in less time. This production line allows manufacturers to package large numbers of bottles in a short duration.

Packaging Without Breaks

Packaging Without Breaks- Picture Courtesy: Behance

Packaging chicken sauce bottles by hand is filled with breaks and monotony, often resulting in increased downtimes. But the chicken sauce bottling line easily operates for longer periods without needing any breaks. This characteristic of the chicken sauce bottling line maximizes uptime and reduces idle time.

Consistent Performance

Consistent Performance- Picture Courtesy: World Brand Design Society

In every step from risning bottles to labeling them, the chicken sauce bottling line maintains consistency. It involves different machines that accurately and precisely package chicken sauce bottles every time. Therefore, this bottling line is needed in large-sized industries due to its consistent performance and no packaging variation.

Enhanced Hygiene

Enhanced Hygiene- Picture Courtesy: we and the color

Due to its automation, there is little to no contact between the operator and machinery. This reduces the contamination risk. Furthermore, there are high-efficiency sanitation machines employed in the chicken sauce bottling line that lead to enhanced hygiene in the production.

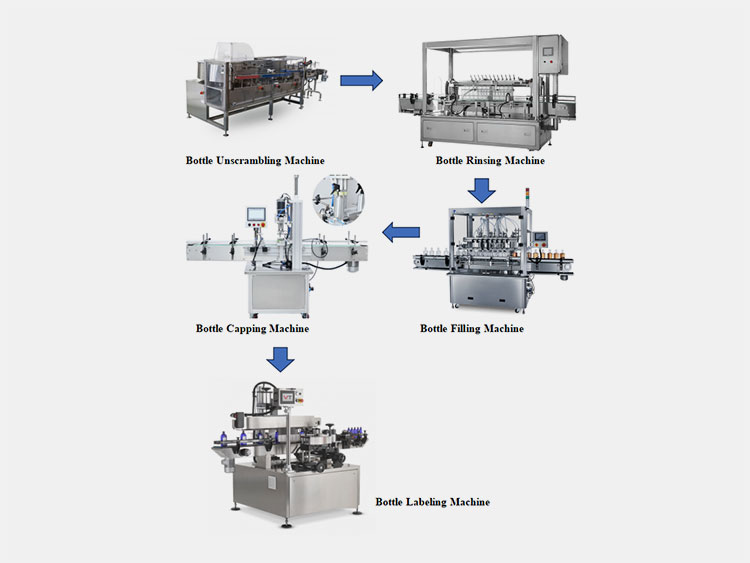

3.What machines make the chicken sauce bottling line?

There are various machines included in the chicken sauce bottling line. These machines are discussed one by one below:

Bottle Unscrambling Machine

It is the first in line machine in the chicken sauce bottling line. It correctly feeds the bottles at fixed gaps on the conveyor. It correctly positions the bottle in an upside-down manner for subsequent filling, capping, and labeling steps. It automatically detects the positioning of bottles and correctly places them. It removes the need for human operators.

Bottle Rinsing Machine

This equipment thoroughly rinses and cleans the chicken sauce bottles to avoid any cross-contamination. The bottle rinsing machine cleans both the exterior as well as the interior surfaces of the chicken sauce bottles. Its purpose is to wash out any undesired debris, dust, and microorganisms by using air blower and water washing systems.

Bottle Filling Machine

The bottle filling machine is the critical machine in the chicken sauce bottling line that precisely loads chicken sauce into the bottles. Different types of fillers are used in this machine for gradually dispensing the right quantity of sauces.

Bottle Capping Machine

For tightly sealing the chicken sauce bottles, a bottle capping machine is employed in the industries. It affixes different kinds of caps on the bottlers to avert the chances of leakage and spillage. This machine is also integral in upholding chicken sauce freshness and product integrity.

Bottle Labeling Machine

As the name indicates, this machine dispenses and fixes labels onto the exterior side of chicken sauce bottles. This machine labels essential pieces of information like the ingredient list, nutritional value, and expiry date on the chicken sauce bottles.

4.How does the chicken sauce bottling line work?

The chicken sauce bottling line is an integrated set of machines, where each machine plays its role perfectly in packaging chicken sauce bottles. Here is a list of working steps in the chicken sauce bottling line.

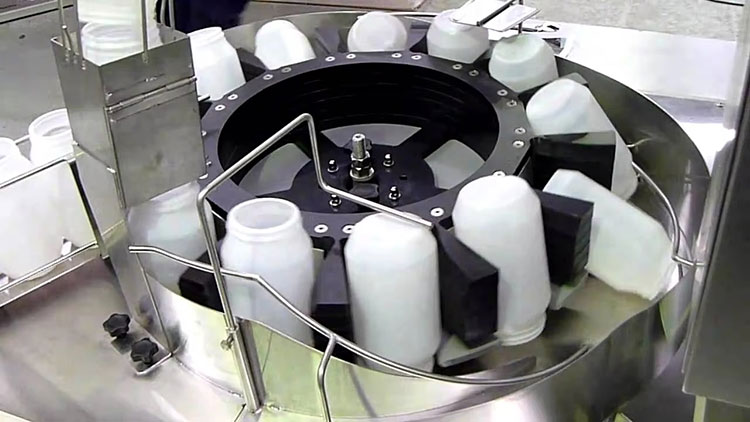

Bottle Unscrambling

Bottle Unscrambling

This step aligns the bottles at fixed intervals, one after the other on the conveyor. Bottles from large hoppers are put on the conveyors with their necks in an upside-down position. First bottles lie down their middle and hooks place them in a standing manner.

Bottle Rinsing

Bottle Rinsing- Picture Courtesy: Traktech

Different approaches like vacuum, air, water, and ultrasonic waves are used for rinsing the bottles. Bottles moving towards rinsing nozzles are counted. The bottles are tilted, so, water gushes into the bottle to remove any dust or debris. The loose debris is sucked by the vacuum. Afterwards, chicken sauce bottles are erected and warm air is passed inside the bottles to dry excess water.

Bottle Filling

Bottle Filling- Picture Courtesy: Serac

The bottles after drying, are passed to the filling unit, where filling heads first speedily load the chicken sauce into the bottle. Before reaching the preset volume of the chicken sauce, the filling slows down, and then bottles are gradually filled to attain the required volume. This is done to avoid overfilling.

Bottle Capping

Bottle Capping- Picture Courtesy: Closure Systems International

In this step, the first caps are filled in the hopper. The filled chicken sauce bottles are conveyed to the capping machine, where torque is applied by the spinning disks to tightly set the caps on the bottles. In other types of capping machines, chuck holds the cap and rotates it onto the bottles to tightly close the opening of the bottles.

Bottle Labeling

Bottle Labeling- Picture Courtesy: HERMA

First, the labeling film is unwound and labeling heads press the labels onto the chicken sauce bottles. This labeling head is in complete synchronization with the speed of bottles. The labeling head pauses when labels are fixed on the bottles. By identifying the registration mark, the label head controls the placement of labels. After labeling, the labeled chicken sauce bottles are conveyed to the next packaging stages.

5.Enumerate the industrial applications of the chicken sauce bottling line.

Besides pouches, bottles are utilized in almost every industry. Therefore, the chicken sauce bottling line is integrated into every major industry of the world. Let’s explore some important industrial applications of the chicken sauce bottling line.

Food Industry

Use of Chicken Sauce Bottling Line in Food Industry- Picture Courtesy: Honda

Hygiene is an important aspect of the food industry, therefore, for contamination-free processing of food bottles, the chicken sauce bottling line is employed in the food production line. First and foremost, this bottling line packages chicken sauce in plastic and glass bottles. It also processes other sauces like hot sauce, condiments, dressings, syrups, vinegar, and oils, to name a few.

Beverage Industry

Use of Chicken Sauce Bottling Line in the Beverage Industry- Picture Courtesy: Behance

This industry is one of the main industries that process enormous quantities of bottles. Different types of bottles are increasingly utilized for packaging different kinds of carbonated drinks, juices, liquid tea, milk, and liquid coffee. So, the chicken sauce bottling line is a major part of the beverage industry that efficiently fills, caps, and labels beverage bottles.

Pharmaceutical Industry

Use of Chicken Sauce Bottling Line in the Pharmaceutical Industry- Picture Courtesy: designerpeople

It is very important to accurately fill and label the pharmaceutical bottles to avoid dose inaccuracies and medication misuse. Thus, the chicken sauce bottling line is increasingly seen in the pharmaceutical industry to consistently packaging different types of medication syrups and emulsion bottles.

Cosmetic Industry

Use of Chicken Sauce Bottling Line in the Cosmetic Industry- Picture Courtesy: Oui Charcuterie

Aesthetics is an important aspect of the cosmetic industry. Beautifully packaged products go far beyond to attract and engage customers. Therefore, the chicken sauce bottling line has found its use in the cosmetic industry as well. It processes different bottle types of cosmetic oils, serums, dyes, lotions, and creams.

Chemical Industry

Use of Chicken Sauce Bottling Line in the Chemical Industry

Although it seems peculiar, the chicken sauce bottling line is also utilized in the chemical industry for the filling and subsequent packaging of both laboratory and household chemicals such as paints, grease, engine oils, and many more.

Personal Care and Household Industry

Use of Chicken Sauce Bottling Line in Personal Care Industry- Picture Courtesy: Dieline

Huge quantities of shampoos, liquid soaps, body washes, sanitizers, detergents, dishwashers, bleaches, and cleaning agents are filled in stylish and conspicuous bottles. These bottles are automatically and rapidly processed by the chicken sauce bottling line.

6.What fillers are present in the chicken sauce bottling line?

Fillers in Chicken Sauce Bottling Line- Picture Courtesy: Serac

In the chicken sauce bottling line, fillers are an important component that correctly dispenses chicken sauce into the bottles. Three main types of fillers are present in the chicken sauce bottling line. These are:

| Piston Filler | This is the type of volumetric filler that uses a piston device for filling. It creates a stroke movement which is responsible for loading the chicken sauce. During the forward movement of the piston in the cylinder, the chicken sauce from the hopper is pushed into the cylinder and during its backward movement, the chicken sauce is forced into the filling nozzle. |

| Pump Filler | This is an efficient type of filler that loads both thinner and thicker consistency chicken sauce. It uses a rotating pump for fluidizing the chicken sauce from the hopper. The hose pipes deliver exact quantities of chicken sauce to the filling nozzles. |

| Gravity Filler | It is only utilized for filling thinner viscosity chicken sauce. Gravity filler has a simple design and, in this filler, natural gravitational force pulls the chicken sauce from the hopper into the filling nozzles and finally into the bottles. There is no special equipment for dispensing low-viscosity sauce in this filler. |

7.What bottles are processed by the chicken sauce bottling line?

A versatile design bottle tempts customers to buy chicken sauce. Hence, there are a variety of bottles processed by the chicken sauce bottling line such as:

Types of Bottles According to Material

| Plastic Bottles

These are typically used for packaging chicken sauce. Plastic is a readily available material and is inexpensive. It is chemical and weather-resistant. Plastic bottles are light in weight and are sturdy. |

Picture Courtesy: designerpeople |

| Glass Bottles

Typically glass bottles are used by luxurious brands for filling chicken sauce. They are of premium quality and generally expensive. Glass is an inert material and provides remarkable protection against environmental conditions like heat, air, and moisture. |

Picture Courtesy: Mother Earth News |

Types of Bottles According to Shape

| Round Bottle

It is the standard shape of the bottle and has a cylindrical design. It is easy to label and process standard-shaped bottles. It resonates with customers through its orthodox look and feel. |

Picture Courtesy: Behance |

| Rectangular Bottle

It has four sides with a small neck. It is easily stackable and stored. It has a unique shape that boosts brand image. |

Picture Courtesy: Lazaris |

| Triangular Bottle

It features three different corners and is used for expensive high-end chicken sauces. |

Triangular Bottle- Picture Courtesy: AHEAD |

| Boston Round Bottle

This type of chicken sauce bottle has round shoulders, and a small neck in addition to its cylindrical shape. It has a conventional look. |

Picture Courtesy: IT Sauce |

| Specialty Bottle

These are unique-shaped bottles employed by high-end brands to captivate and magnetize customers, increasing their chances of sales. These specialty shapes include tear-drop designs, convoluted design bottles, and hourglass designs. |

Picture Courtesy: Packaging of the World |

8.What types of labels are handled in the chicken sauce bottling line?

Labels display information about chicken sauce. Thus, different types of labels are used in the chicken sauce bottling line to communicate information. These labels are:

Heat Shrink Labels

Heat-Shrink Labels- Picture Courtesy: Shopee Philippines

Although they are not used frequently, heat-shrink labels can create a bold presentation due to their full-body graphics. They are made of heat-shrinkable films that mold to the contours of bottles. Heat-shrink labels offer a three-dimensional branding and huge marketability space. These are tamper-evident.

Pressure Sensitive Labels

Pressure Sensitive Labels

It is a widely used label type with chicken sauce bottles. Pressure-sensitive labels are typically made with plastic or paper and have adhesive applied to their back end. These have high printing quality and are employed for their detailed graphics. They are easily applied and require little to no maintenance.

Wrap Around Labels

Wrap Around Labels

These labels are wrapped around the full circumference of the chicken sauce bottles. These are commonly used for round-shaped bottles. They are economical when produced in high amounts. They provide a large area for showcasing information.

Double Side Label

Double Side Labels

These are labeled on the front and back panels of the rectangular chicken sauce bottles. They offer a clean and organized look with no cluttering, so they are useful in boosting product shelf appeal.

9.What caps are processed in the chicken sauce bottling line?

Caps and leakage prevention go hand in hand. Brands employ different kinds of caps to not only seal the chicken sauce bottles but also to attract customers. Striking caps also promote brand image. Therefore, we are detailing different types of caps processed by the chicken sauce bottling line.

Cork Caps

Cork Caps- Picture Courtesy: designerpeople

These caps are created from natural and synthetic materials like tree bark. They are cylindrical and are tightly fit in the mouth of the bottle. An airtight seal is offered by them. They are used with gourmet and gift items where product look is essential.

Nozzle Caps

Nozzle Caps- Picture Courtesy: World Brand Design Society

They are pointed in shape with a small nozzle for easily pouring out the chicken sauce. Nozzle caps are often used with plastic and squeezable bottles. They offer convenience to users in usage and reclosing the bottle.

Screw Caps

Screw Caps- Picture Courtesy: Packaging of the World

It is the most frequently utilized cap type for chicken sauce. There are many types of screw caps but the most abundant one is standard screw caps. They support continuous threads along its circumference that are fixed onto the neck of bottles.

Flip top Caps

Flip top Caps- Picture Courtesy: Dieline

They are also called dispensing or hinged caps and have a flip top for ease in reclosing the bottles. Chicken sauce is easily dispensed by these caps, which is expedient for the customers. They are designed for portion control that decreases mess and wastage of chicken sauce.

10.What are the challenges and solutions of the chicken sauce bottling line?

The chicken sauce bottling line, like other machines, may face serious challenges that could disrupt the normal flow of operations and significantly reduce the uptime of production. Below mentioned are the common challenges in the chicken sauce bottling line and their solutions.

| Cause | Solution | Image |

| Inaccurate Fill Levels | ||

| Poor calibration of fill devices.

Differences in the chicken sauce viscosity. Pressure in the filling devices is not accurate. |

Recalibrate the filling device.

Use an advanced type of filler to handle variability in viscosities. Ensure the filling pressure is consistent. |

Inaccurate Fill Level- Picture Courtesy: Heatonist |

| Contamination of Chicken Sauce | ||

| Presence of contamination during the filling process.

Inadequate rinsing and cleaning. |

Properly sterilize the filling environment before batch processing.

Use clean-in-place equipment for proper washing and cleaning. |

Contamination of Chicken Sauce- Picture Courtesy: Behance |

| Missing Labels | ||

| Inconsistency in sensitivity of labeling sensor.

Labeling head does not have high speed. The conveyor speed is too high. |

Fix the sensitivity of the labeling sensor.

Ensure the labeling head is adequate to solve the problems of missing labels. Reduce the conveyor speed. |

Missing label- Picture Courtesy: Lazada Philippines |

| Inadequate Bottle Rinsing | ||

| Clogged rinsing nozzles.

The pressure of the water spray is not accurate. |

Properly clean the rinsing nozzle.

Ensure there is sufficient pressure on the water spray. |

Inadequate Bottle Rinsing- Picture Courtesy: DirectIndustry |

| Improper Sealing of Caps | ||

| Inadequate pressure during the capping process.

Sealing liners are of poor quality. Variability in bottleneck design |

Fix the pressure to ensure proper sealing.

Use best-quality sealing liners. Ascertain there is consistency in bottleneck designs. |

Improper Sealing of Caps- Picture Courtesy: The New York Times |

11.What are the consideration points for procuring an ideal chicken sauce bottling line?

Typically, the chicken sauce bottling line has advanced and sophisticated machines that have high-tech specifications, consequently resulting in high purchase costs. Hence, it is of paramount importance to consider the following point when investing in a chicken sauce bottling line for a particular application.

Calculate Return on Investment

Calculate Return on Investment- Picture Courtesy: QAD

First, set aside your possible budget for procuring a chicken sauce bottling line and calculate the potential return on investment. It is important to consider the purchase cost of the chicken sauce bottling line, but it should not come at the expense of product quality and bottling line efficiency. Always, take into account your long-term advantages and how they will affect the growth of your business besides considering purchase cost.

Determine Production Volume

Production Volume- Picture Courtesy: Asia Pacific Food Industry

Production volume is what matters most to the manufacturer. So, it is crucial to determine your current production capacity. This is because there are different types of chicken sauce bottling lines present in the market. These bottling lines have their precalculated production capacity.

You can only purchase a well-matched chicken sauce bottling line if you have data regarding your production volume.

Access Versatility

Access Versatility- Picture Courtesy: Dieline

You should check whether the chicken sauce bottling line has the versatility to accommodate different types of bottles. This will help you to fulfill evolving bottle requirements. With a quick change of filling nozzles and conveyor height, the bottling line can be easily customized to acclimate different shapes and sizes of chicken sauce bottles.

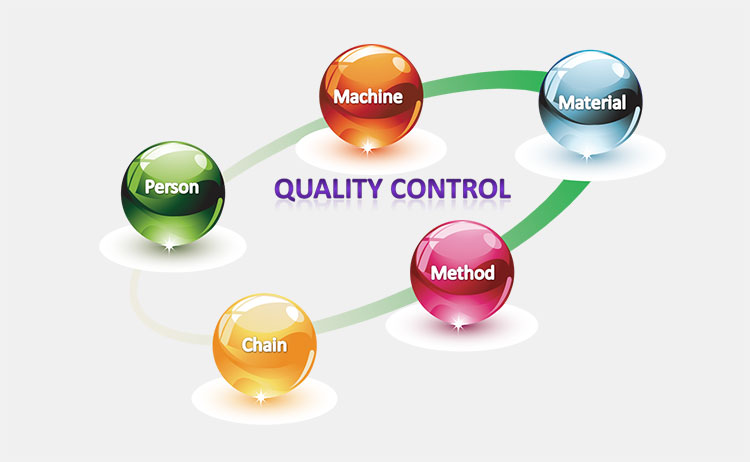

Quality Check

Quality Check- Picture Courtesy: WinterSun

Quality is an important aspect and it should be never compromised. There are different quality standards like ISO, GMP, and CE that you can use as a measure to inspect the quality and hygiene of the chicken sauce bottling line.

Conclusion

In short, the chicken sauce bottling line is a highly adaptable unit that meets your varying production requirements through its efficiency and enhanced capability. It positively impacts the expansion of your business via its high-tech technology and customizable features. Integration of the chicken sauce bottling line will result in huge income. So, if you are keen on investment then without further ado contact a renowned manufacturer Allpack. We have an extensive catalog of machines and bottling lines related to chicken sauce.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide