Pesticide 4 Side Sealing Packing Machine: The Complete Buying Guide in 2025

Are you trying to find a trustworthy, effective technique to package your pesticides? Have you been trying to find a machine to help you produce goods more quickly and efficiently without sacrificing their integrity or safety? If so, you might be curious about the newest packaging technology innovation—the pesticide 4 side sealing packing machine.

In agricultural and pest management, pesticide packaging ensures efficacy, safety, and adherence to regulations. As the demand for efficient and dependable packaging solutions increases, the pesticide 4 side sealing packing machine is making waves in the market.

The pesticide 4 side sealing machine provides a novel solution to packaging using a tamper-proof and secure seal that is crucial when handling sensitive and possibly dangerous materials like pesticides. Knowing the features and advantages of the pesticide 4 side sealing packing machine is vital for businesses aiming to stay ahead of the market competitors.

In this comprehensive buying guide, we will explore the details of this amazing technology. Join us on this journey!

1.What is a pesticide 4 side sealing packing machine?

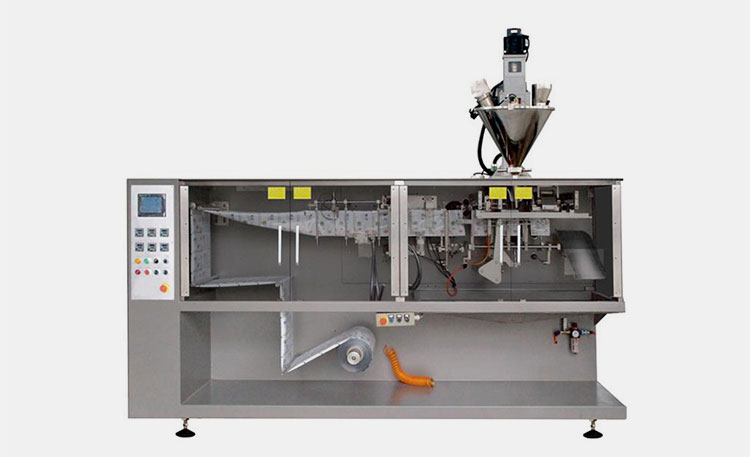

Pesticide 4 Side Sealing Packing Machine

The pesticide 4 side sealing packing machine is a remarkable piece of equipment used in the agricultural industries to package various pesticide chemicals efficiently. The entire packaging process of different products, including pesticide packing, is increasingly automated in today's industrial world.

Manufacturers can satisfy their current needs and remain competitive using automated pesticide 4 side sealing packing machines. The device helps businesses save time and money by streamlining the intricate production process and reducing operating expenses.

2.What are the benefits of using a pesticide 4 side sealing packaging machine?

Picture Courtesy: Forbes

Given the intense rivalry in the market today, manufacturers must figure out how to differentiate their brands on the shelves from those of their rivals. Additionally, buyers tend to favor a product with an eye-catching and innovative packaging design. The pesticide 4 side sealing packing machine is beneficial in this regard.

In addition to sparing you from the tiresome manual packaging, the automated processing of the device will benefit you in the following ways:

Cost-effective

Cost-effective Equipment

A pesticide 4 side sealing packing machine may be expensive initially, but the cost savings are substantial in the long run. The efficiency and caliber of output contribute to the company’s growth and improve return on investment.

Furthermore, the automation of the process reduces labor costs, time consumption, and human errors.

Efficient and Rapid Production

Efficient & Rapid Production – Picture Courtesy: Multi-Pack Solutions

A manufacturer with high production demand always seeks speed while maintaining efficiency. The pesticide 4 side sealing machine offers rapid production with efficient and accurate results, making it an ideal tool for various industries.

Precision

Precise Filling & Sachet Production – Picture Courtesy: Pestfix

Automatic weighing and metering mechanisms are installed in the pesticide 4 side sealing packing machine. Precise product loading in the sachets is made possible by these technologies. Furthermore, packaging is made reliably in terms of size and shape every time with an exact forming station. Thus, uniformity in each batch is ensured.

Flexibility

Flexibility & Versatility

Certain variations of the pesticide 4 side sealing packing machine are highly versatile and adaptable, making them an excellent industrial tool that helps manufacturers process several products.

Operational and Maintenance Ease

Operational & Maintenance Ease – Picture Courtesy: ECHO Machinery

Strong and sturdy stainless steel is used in the construction of the equipment. In addition to being corrosion resistant, this material is also easily cleaned. Because each part is simple to remove, cleaning and maintaining this machine is made easy.

Moreover, the device has a user-friendly panel system through which the entire process can be easily monitored and controlled without extensive operating training.

Brand Building

Brand Building

The automated features and reduced human intervention ensure uniform sachets production with consistent quality. This helps in the resource preservation and increased shelf life of the product, resulting in improved brand awareness of providing quality products.

3.What are the industrial applications of a pesticide 4 side sealing packing machine?

The pesticide 4 side sealing packing machine is a versatile and indispensable tool in various industrial applications. Its accuracy and effectiveness in precisely packaging pesticides and other chemicals make it useful in multiple industries. Here are a few important industrial uses:

Agricultural Industry

Use of Pesticide 4 Side Sealing Packing Machine in the Agricultural Industry

The pesticide 4 side sealing packing machine has extensive applications in the agricultural sector. It efficiently packages various products such as herbicides, fungicides, insecticides, and powdered and liquid fertilizers.

Chemicals Industry

Use of Pesticide 4 Side Sealing Packing Machine in the Chemicals Industry

In the chemical industry, the pesticide 4 side sealing packing machine packages industrial chemicals that require secure, effective, and tamper-proof storage. It ensures safety and compliance with strict industrial regulations.

Horticulture and Greenhouse Industry

Use of Pesticide 4 Side Sealing Packing Machine in the Horticulture & Greenhouse Industry – Picture Courtesy: UW Madison News

The pesticide 4 side sealing packing machine is also used in the horticulture and greenhouse industry to seal pesticides and growth regulatory chemicals for plants in secure packaging.

Pharmaceuticals Industry

Use of Pesticide 4 Side Sealing Packing Machine in the Pharmaceutical Industry

In the pharmaceutical industry, the pesticide 4 side sealing packing machine maintains the purity and efficacy of sensitive pharmaceutical compounds via safe and secure packaging. It packages single-dose medicines in individual sachets for convenient use.

Food and Beverage Industry

Use of Pesticide 4 Side Sealing Packing Machine in the Food & Beverage Industry

Yes, you read that right. The pesticide 4 side sealing packing machine is also utilized in the food and beverage facilities to package various powdered and liquid beverage items such as juices, food powders, coffee, tea, etc.

Veterinary Industry

Use of Pesticide 4 Side Sealing Packing Machine in the Veterinary Industry

The pesticide 4 side sealing packing machine can also be used to package various veterinary products in secure sachets, such as animal health products, feed, and medicines.

Cosmetics Industry

Use of Pesticide 4 Side Sealing Packing Machine in the Cosmetics Industry

In the cosmetics industry, the pesticide 4 side sealing packing machine is used for packaging various cosmetic and personal hygiene products in sachets, such as talcum powder, hair growth oils, shampoos, creams, and baby powders.

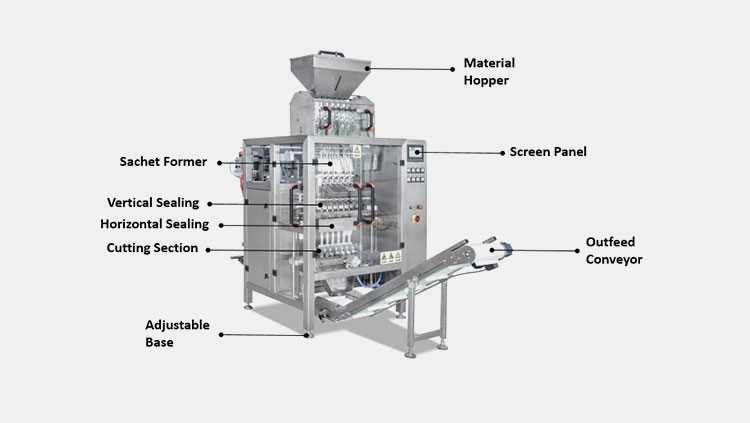

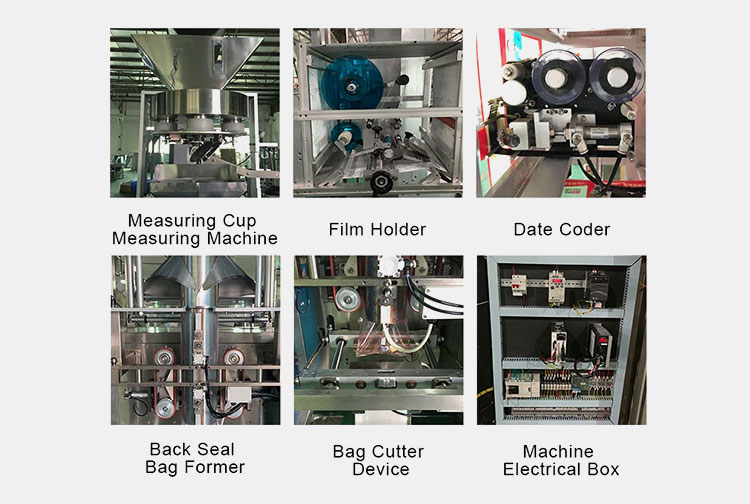

4.What are the fundamental components of a pesticide 4 side sealing packing machine?

The pesticide 4 side sealing packing machine consists of several basic components that work in perfect harmony to provide optimal functioning. Below, we'll go over each of these elements in more detail:

Components of the Pesticide 4 Side Sealing Packing Machine

| Components | Description |

| Material Hopper | It is a component that temporarily holds a significant amount of the material (depending on its size and capacity) and maintains its steady supply. |

| Sachet Former | It comprises shaping tubes responsible for producing sachet packs of desired dimensions from the supplied packaging film. |

| Vertical Sealing | The vertical sealing section consists of the heated sealing bars, forming the side edges of the sachets. |

| Horizontal Sealing | The horizontal sealing section consists of the sealing clamps, sealing the top and bottom edges via applied pressure. |

| Cutting Section | This section is responsible for cutting the formed sachets using the cutting knives. |

| Screen Panel | It is an important component through which the entire process is controlled. |

| Outfeed Conveyor | The component that provides an exit to the finished sachets from the machine. |

| Adjustable Base | The component that offers a firm base and desired adjustments to the device. |

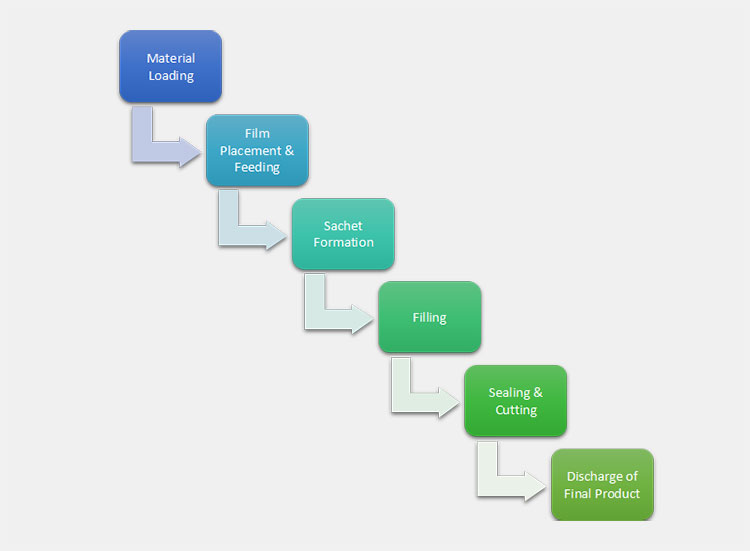

5.How does a pesticide 4 side sealing packing machine work?

Working of the Pesticide 4 Side Sealing Packing Machine

The pesticide 4 side sealing packing machine comprises several components that perform different functions. The components work in synchronicity for optimal and streamlined operation. Here are the basic functional steps described briefly:

Working Steps of the Pesticide 4 Side Sealing Packing Machine

| Material Loading

It is the primary step of the process in which the material gets loaded into the hopper to be supplied and processed. The material is either loaded manually or via an integrated automatic mechanism. |

| Film Placement and Feeding

A large packaging film reel is properly placed in the center of the film holder which is then unwound and fed to the machine for the sachet formation. |

| Sachet Formation

In this step, the shaping tubes fold the supplied packaging film and produce the sachets of the desired dimensions. |

| Filling

In this step, a significantly metered amount of the material gets filled into each sachet via filling nozzles. |

| Sealing and Cutting

The filled sachets are ultimately top-sealed to secure the material followed by the cutting of the sachets from the continuous film. |

| Discharge of Final Product

The finished sachets get expelled from the device via an outfeed conveyor. |

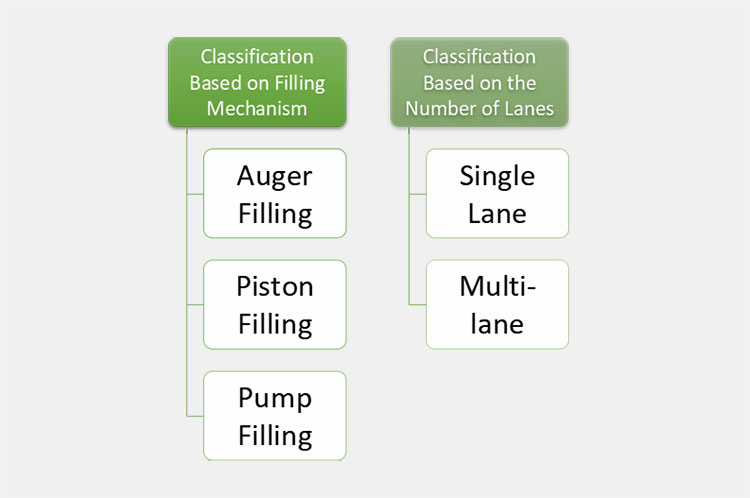

6.How do you classify a pesticide 4 side sealing packing machine?

The pesticide 4 side sealing packing machine has evolved over the years, including various architectures and functionalities to meet the specific requirements of its customers. The market offers a variety of models.

These models are categorized based on configuration, automation level, filling mechanism, and number of lanes. Here is a detailed overview of these categories:

Classification of the Pesticide 4 Side Sealing Packing Machine

Classification Based on Configuration

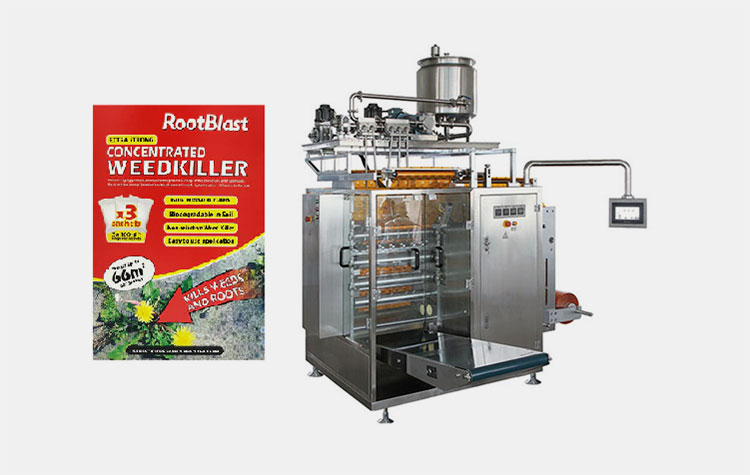

Vertical Form Fill Seal (VFFS) Pesticide 4 Side Sealing Packing Machine

Vertical Form Fill Seal (VFFS) Pesticide 4 Side Sealing Packing Machine

The pesticide 4 side sealing packing machine with vertical form, fill, and seal technology is a productive and rapid manufacturing equipment. It is the perfect piece of machinery for handling products that flow freely. The appliance is well-known for its quick operation.

With the help of sealing clamps and a shaping tube, packing films are formed into the wrapping bags. After that, the materials are added to the sachets and top-sealed using horizontal sealers.

Horizontal Form Fill Seal (HFFS) Pesticide 4 Side Sealing Packing Machine

Horizontal Form Fill Seal (HFFS) Pesticide 4 Side Sealing Packing Machine

The HFFS machine variant has several horizontally structured sections for making sachets, product filling, and sealing the sachets. It is a well-functioning automated instrument.

The film reels are unwound and guided towards the bag-producing region where the desired form of sachets is produced. The filled station receives the formed sachets after which the package is securely shut with sealing clamps.

Classification Based on Automation

Semi-Automatic Pesticide 4 Side Sealing Packing Machine

Semi-Automatic Pesticide 4 Side Sealing Packing Machine – Picture Courtesy: Fodapack

As the name indicates, the semi-automatic pesticide 4 side sealing packing machine has partial automation with human involvement for certain processing steps, including material input and removing filled sachets. However, the rest of the activity is completed by the machine automatically.

Automatic Pesticide 4 Side Sealing Packing Machine

Automatic Pesticide 4 Side Sealing Packing Machine

Full automation eliminates the need for constant human intervention in the packing process. All that is required of the worker is to set the working parameters; the gadget takes care of the rest.

These gadgets are made up of sensors that help to coordinate different parts of the process. For example, a filling sensor determines the estimated amount of product and signals the device to stop filling. The sensors guarantee functional precision and help to minimize human mistakes.

Classification Based on Filling Mechanism

Auger Filler Pesticide 4 Side Sealing Packing Machine

Auger Filler Pesticide 4 Side Sealing Packing Machine – Picture Courtesy: iPharmachine

Precise and consistent amounts of dry granules, powdered pesticides, or other materials are filled into sachets using this kind of pesticide 4 side sealing packing machine. The powder is driven to the auger plate using a rotating auger screw in this apparatus.

The powder is then transferred from the plates into the sachet. The auger blades also revolve in the opposite direction to avoid air entrapment.

Piston Filler Pesticide 4 Side Sealing Packing Machine

Piston Filler Pesticide 4 Side Sealing Packing Machine

The piston filler pesticide 4 side sealing machine packages the liquid pesticides and other liquid goods into the sachets. The device guarantees precise filling using a piston. The liquid product is drawn into the sachets from the hopper using a smoothly operating piston.

Pump Filler Pesticide 4 Side Sealing Packing Machine

Pump Filler Pesticide 4 Side Sealing Packing Machine

This equipment is used to precisely and reliably fill sachets with liquid products. It is the ideal device for the pharmaceutical sector. The liquid is directed from the hopper to the nozzle using revolving pumps. It is a flexible tool that works with both viscous and non-viscous liquid substances.

Classification Based on the Number of Lanes

Single Lane Pesticide 4 Side Sealing Packing Machine

Single Lane Pesticide 4 Side Sealing Packing Machine

This kind of equipment has a single lane for processing the material. Small businesses might benefit from it because of its affordable price and efficient performance.

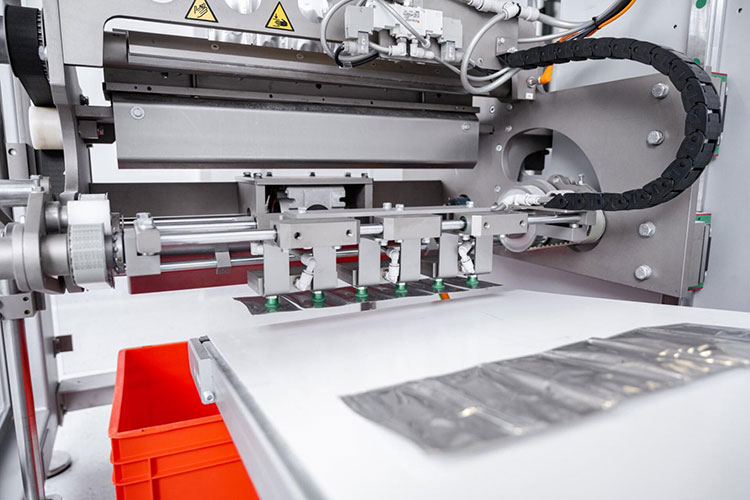

Multi-lane Pesticide 4 Side Sealing Packing Machine

Multi-lane Pesticide 4 Side Sealing Packing Machine

This device is an upgraded version with numerous lanes that operate concurrently to create multiple sachets at once. Its purpose is to increase the rate of production. It is mostly embraced by large manufacturing sectors. Its intricate design and effective operation make it a costly gadget.

7.What is the typical production speed of a pesticide 4 side sealing packing machine?

Picture Courtesy: pharmaalliance

Different pesticide 4 side sealing packing machine models have different production speeds. The number of sachets that each model can produce in a minute determines its rating. An automated pesticide 4 side sealing packing machine can usually form, fill, and seal 200–300 sachets in a minute.

However, the real pace of production depends on several variables, including the nature of the product, the size of the bags or sachets, the type of equipment, and the operator's abilities.

By running a test trial, one may estimate the machine's speed.

8.Can the pesticide 4 side sealing packing machine be customized for different packaging sizes and shapes?

Multiple Sized Sachets

"Yes, in most cases," is the brief answer. Changeover, the process of altering the equipment to accommodate different types of bags or sachets, may require minutes or hours, dependent upon several variables.

Not every time is a universal machine the ideal option. If your needs are more varied it is recommended to invest in a variety of technologies or to automate certain particular process stages.

The pesticide 4 side sealing packing machine is made to work best under certain conditions, which justifies this. Modifying the machine's settings to accommodate varying needs might be challenging, costly, and ineffective.

Sometimes it's better to have a device that excels at one job rather than one that accomplishes several tasks "just all right."

9.What types of pesticides can be packaged using a pesticide 4 side sealing packing machine?

A pesticide 4 side sealing packing machine is highly adaptable and can handle several pesticide types. The varieties of pesticides that may be packed using this equipment are discussed in depth below:

Liquid Pesticides

Liquid Pesticides

These are the widely used pesticides and can be packaged using piston and pump type pesticide 4 side sealing packing machine. These pesticides can be applied via aerosol sprays and fogging. Examples of these pesticides include;

- Insecticides:They are used to control or kill insects.

- Herbicides:These are used to control unwanted vegetation and weeds.

- Fungicides: They are formulated to eradicate or prevent plant fungal infections.

- Rodenticides:They are used to control rodent populations.

- Nematicides:They control and target nematodes affecting plant roots.

Powdered Pesticides

Powdered Pesticides

These are solid forms of pesticides. They are used for long-term pest control. Such pesticides can be packaged using the auger filling pesticide 4 side sealing packing machine. Examples of powdered pesticides are:

Dusts:These are finely crushed powders that can be directly applied to the surfaces of plants.

Wettable Powders:Powders that are reconstituted with water and applied as a spray.

Granules:They are coarser than dusts and are applied for soil treatment and long-lasting control.

10.What are the maintenance requirements for a pesticide 4 side sealing packing machine?

For optimal functioning and long life of the pesticide 4 side sealing packing machine, managers should pay special attention to the device’s regular cleaning and maintenance. Here are some protocols you can follow for the device’s maintenance.

Device Cleaning and Lubrication

Cleaning & Lubrication – Picture Courtesy: CBS News

Wipe the device exterior with a gentle cloth, water, or a suitable cleansing agent. Additionally, clean the device components such as the hopper, feeder, and filling nozzle to reduce the possibility of cross-contamination.

Do a thorough cleaning of the machine once a week. Take out every component and thoroughly wash it with a gentle cleaner that works well to eliminate the product residue. Use proper sanitizers for device sterilization.

Periodically lubricate all the dynamic parts of the machine to prevent friction and ensure smooth working.

Maintenance and Changeovers

Maintenance & Changeovers – Picture Courtesy: Parsable

Inspect all the components for any damage, leaks, or tears. Repair or replace the damaged components or indicate any sign of damage, immediately. Calibrate the filling and shaping systems after replacement and maintenance. Regularly update the device software.

11.What are the common challenges faced during the operation of a pesticide 4 side sealing packing machine, and how can they be overcome?

Some common problems may arise when running the pesticide 4 side sealing packing machine that could cause production delays and downtime. Nonetheless, if you know these unforeseen faults and their fixes in advance, troubleshooting them will be simple.

For your convenience, we will outline a few typical issues, their root causes, and solutions.

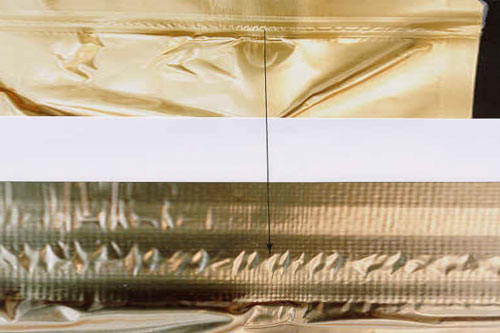

| Furrowing of the Packaging Film | ||

| Causes | Solution | Image |

| Obstructed path of the packaging film.

Insufficient film tension. The film was not positioned correctly on the holder/film frame. The dancing rollers are defective or loose. |

Clear the obstruction in the path of the film.

Check and validate the film tension to be maintained. Place the film roll appropriately in the center of the holder to ensure smooth function. Tighten the dancing rollers or replace the defective ones. |

Picture Courtesy: BowePack |

| Broken Seals | ||

| Causes | Solution | Image |

| Impaired sealing jaws.

The parameters such as sealing temperature, pressure, and time are not adjusted properly. The sealing section is dirty. |

Repair or replace the sealing clamps.

Monitor the process parameters (sealing pressure, temperature, time) and regulate them accordingly. Regularly clean the sealing station. |

|

| Variable Sachet Sizes | ||

| Causes | Solution | Image |

| Incorrect adjustment of the dimensions.

The software may be outdated or have an error. The film feed is not smooth. The cutting blades are dull or damaged. |

Properly adjust the desired dimensions and validate them.

Update the device software regularly. Ensure the smooth film feed. Inspect the cutting blades and replace them (if necessary). |

|

| Inconsistent Filling | ||

| Causes | Solution | Image |

| Improper settings of the fill parameters.

The product supply is not uniform. The filling nozzles are damaged or blocked. The filling components are not calibrated. |

Set the filling parameters and cross-check them.

Ensure the product feed is smooth and uniform. Clean the nozzles or replace them (if damaged). Calibrate the components regularly, particularly after changeovers. |

|

12.What should businesses consider when selecting a pesticide 4 side sealing packing machine?

A pesticide 4 side sealing packing machine requires a substantial financial outlay, therefore making the right decision is crucial to your business's long-term success.

When looking for a pesticide 4 side sealing packing machine, some crucial things to take into account are;

Budget Estimation

Budget Estimation – Picture Courtesy: The News International

Determine whether the purchase prices of several machine variants are within your budget by estimating and comparing them. When making a purchase, take into account the machine's utility consumption as well as the expenses of upkeep and repairs.

Product Type and Characteristics

Product Type & Characteristics

Different items have distinct features and characteristics. A device variant may handle one item efficiently and may not be able to process other types of items effectively. The items you handle and wish to package should be familiar to you. Think about the machine type that can handle your items with the best results.

Production Capacity and Needs

Production Capacity & Needs Evaluation

Evaluate your production demands and the capacity of the machine. If you own a large-scale industry with high-volume production needs, you must opt for the advanced and automatic form of the device to satisfy your needs. Small businesses should go for semi-automatic variants or variants with limited production capacity as they are economical and could meet their requirements.

Device Flexibility

Device Flexibility of Handling Several Products

It is crucial to choose a pesticide 4 side sealing packing machine that can handle a range of goods effectively and is adaptable. The best gadget to choose is one that can handle several items with easy changeovers and adjustments.

Regulatory Compliance

Regulatory Compliance – Picture Courtesy: Sensidyne

Any company's top focus should be the wellness of its customers. To guarantee the product’s security and effectiveness, a machine variant that complies with regulatory requirements should be chosen. Public trust in the business will also increase with sanitary goods and packaging.

Conclusion

The pesticide 4 side sealing packing machine is an essential tool that each manufacturer should own to increase the packed goods' effectiveness, dependability, and caliber. Knowing the essential features of a pesticide 4 side sealing packing machine will make it easier to choose one that will be ideal for your needs. Select the device that best suits your production needs. If you are seeking to get this amazing equipment or need any further guidance, contact Allpack, you will be guided in a better way. Please get in touch with us if you need the ideal packing solution!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide