3 Side Sealing Cartoning Production Line: The Complete Buying Guide In 2025

Isn’t products in 3 side sealed carton look aesthetically pleasing and attractive?

Customers are captivated towards stylish carton box packaging. There are different cartoning machines in the market but the 3 side sealing cartoning production line is frequently seen in industries.

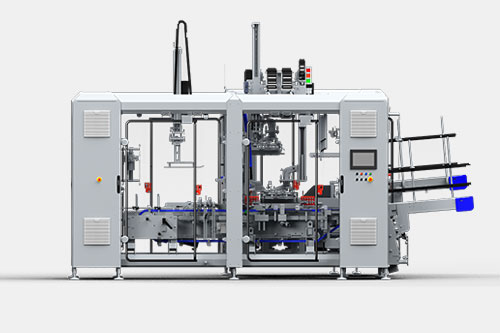

A 3 side sealing cartoning production line is an interconnected series of machines that take empty cartons, erect them, fill them with products, and then side-seal them. It is an efficient production line that fulfils its role from start to end without needing human intervention.

If you are interested in seeking knowledge about the 3 side sealing cartoning production line and want to understand various aspects of the cartoning process. Then without delay, start reading this informative buying guide.

1.How To Define 3 side sealing Cartoning Production Line?

3 side sealing cartoning production line

A 3 side sealing cartoning production line is a specialized packaging technology that is designed to create and seal the sachet or stick pack and secured by the cartons at all four sides to create a secure sealing carton that protects the inner products from meddling and also maintains merchandise integrity.

It has different machines that consist of different components like carton feeder, carton erecter, product loader, and carton sealing that feed the blank cartons, erect them, place the product inside the carton box, and seal them, respectively. It is an automated and efficient production line that minimizes the need for human labor.

2.Enlist the benefits of 3 side sealing cartoning production line.

Customers are spellbound by the unique and different packaging.

Therefore, a 3 side sealing cartoning production line is employed by the brand owner to expand their packaging horizons.

It frees you from manual handling, and it gives cost-effective results. Some of the useful benefits of 3 side sealing cartoning production line are explored below:

Cost-effective Solution

Cost-Effective

Buying a 3 side sealing cartoning production line requires huge capital but in the longer run it is a worthy investment. It decreases human supervision in turn saving labor wages. Furthermore, it also lowers human error and packaging waste, in turn saving the need to buy more blank cartons.

Extended Shelf life

Extended Shelf life

By packaging products in a carton, the 3 side sealing cartoning production line extends the shelf-life of the products by protecting them from mechanical damage and rough handling. It keeps the products safe during tough shipment and transportation. Moreover, it maintains the product integrity by protecting it from tampering.

Multi-Tasking

Multi-Tasking

The production efficiency of the 3 side sealing cartoning production line stems from its multi-tasking characteristics. It allows you to box numerous products in a limited time by carrying out different jobs like film formation, filling, then, carton erecting, carton folding, carton filling, and carton gluing with its advanced technologies.

High Brand Value

High Brand Value

Product display presentation is a failsafe way to attract and draw the possible customers. With cartoning products, the 3 side sealing cartoning production line increases the brand's worth. Beautiful chic boxes increase product aesthetics and boost brand image in the eyes of the customers.

Versatility and Flexibility

Versatility and Flexibility

One of the important advantages of a 3 side sealing cartoning production line is its flexibility. It can create versatile style boxes with minimal effort. Moreover, it can pack a broad range of products with minimal part change. This advantage is useful for businesses processing and distributing a wide range of products.

Efficient Performance

Efficient Performance

The advanced and sophisticated technology integrated into the 3 side sealing cartoning production line allows for accomplishing fast, automatic, and accurate sealing of the cartons. This swift performance allows you to box thousands of products in a single minute. This increased rate of cartoning translates into a huge profit margin for brands.

3.Figure out industrial uses of 3 side sealing cartoning production line.

One of the ideal characteristics of a 3 side sealing cartoning production line is that it is found in numerous industries. Due to the high demand for boxed products, nowadays, this production line is seen in all industries across the globe. Let’s talk about some of the important industries below:

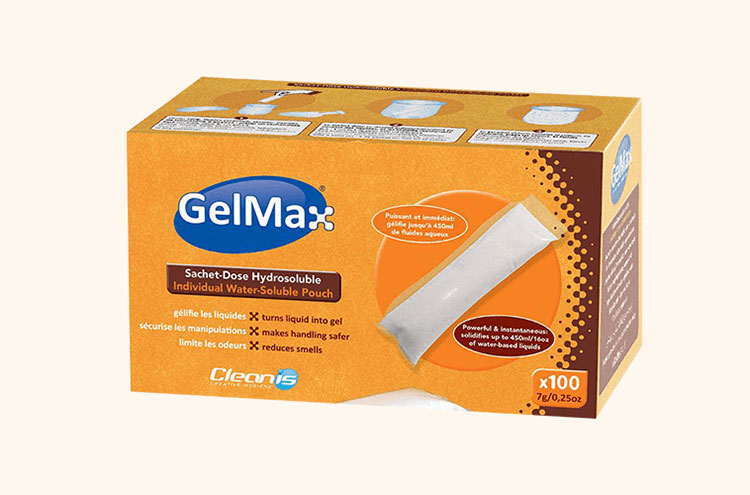

Pharmaceutical Industry

Use of 3 side sealing Cartoning Production Line in the Pharmaceutical Industry

In the pharmaceutical industry, a 3 side sealing cartoning production line is configured to process and pack different types of blister in 3 side sealing cartons. Also, different types of powders, bandages, syrup, ointment tubes, and other medical instrumentations are packed in tamper-proof cartons for increased product and better product display.

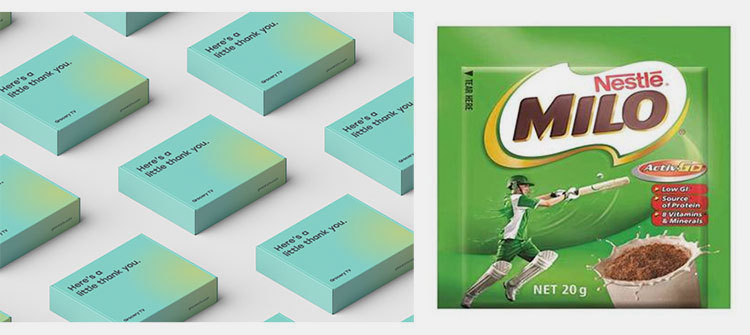

Food Industry

Use of 3 side sealing Cartoning Production Line in the Food Industry

One of the biggest utilizers of the 3 side sealing cartoning production line is the food industry. All the food items whether packaged in 3 side seal sachet, or pouches are further boxed into secure side-sealing cartons to increase the shelf-life of food items.

Confectionery and Snack Industry

Use of 3 side sealing Cartoning Production Line in the Confectionery Industry

Different types of confectioneries items like chocolates, candies, biscuits, sweet treats, and snacks like chips, popcorn, etc. are secured in the carton boxes by the 3 side sealing cartoning production line. The secured containment in the boxes protects the confectionery and snack items from contamination, oxygen, and moisture.

Beverage Industry

Use of 3 side sealing Cartoning Production Line in the Beverage Industry

A 3 side sealing cartoning production line is also found in the beverage industry, as different juice boxes and milk cartons are efficiently packaged by this production line. Filling machines can be integrated into this production line to attain accuracy and precision in the filling.

Cosmetic Industry

Use of 3 side sealing Cartoning Production Line in the Cosmetic Industry

Different cosmetic items like lotions, creams, foundations, blushes, and lipsticks are packed in sachets, pouches, or stick packs and boxed by the 3 side sealing cartoning production line. It increases product aesthetics which is beneficial for cosmetic brands. This production line caters to diverse production requirements through its adaptability and high functionality.

Electronic Industry

Use of 3 side sealing Cartoning Production Line in the Electronic Industry

Yes, this production line is installed in the electronic industry as well. It often packs earphones, batteries, bulbs, phone accessories, LED lights, etc. in 3 side sealing cartons. These cartons bestow high protection on the electronic by keeping them safe from scratches and dust.

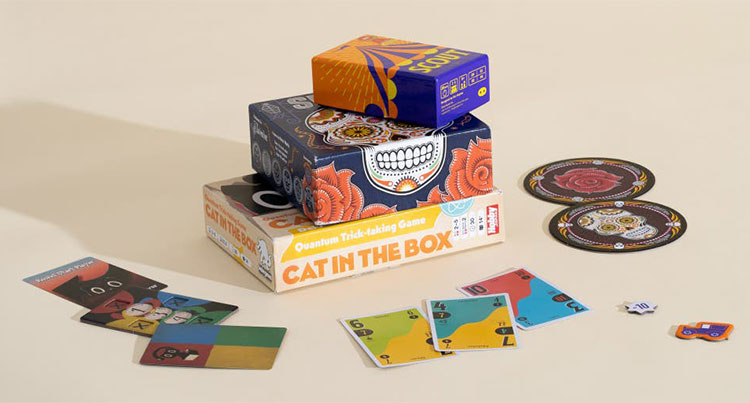

Recreational Industry

Use of 3 side sealing Cartoning Production Line in Recreational Industry

A broad range of recreational items like board games, puzzles, and small toys is effectively in the boxes by the 3 side sealing cartoning production line. These boxes make an attractive display for the grocery shelves.

Stationery industry

Stationery Industry

Diverse types of pens, pencils, crayons, diaries, journals, rulers, staplers and many more are boxed in the side-sealed carton by the 3 side sealing cartoning production line. This production line keeps the stationery items safe from mechanical damage.

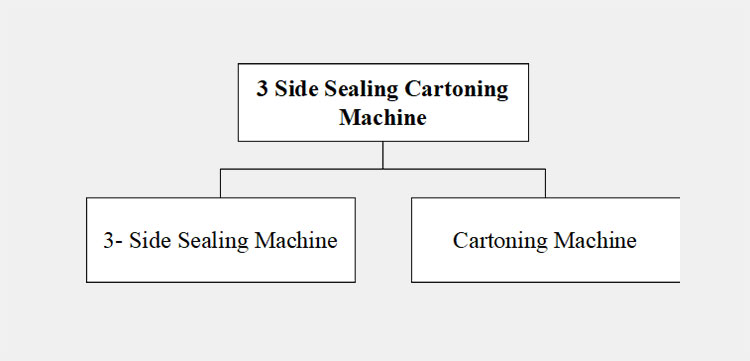

4.What are Types of Machines involved in 3 side sealing cartoning production line?

There are the two main types of machines involved in the 3 side sealing cartoning production line; the following types are described below:

3 Side Sealing Machine

A 3 side sealing are of various types:

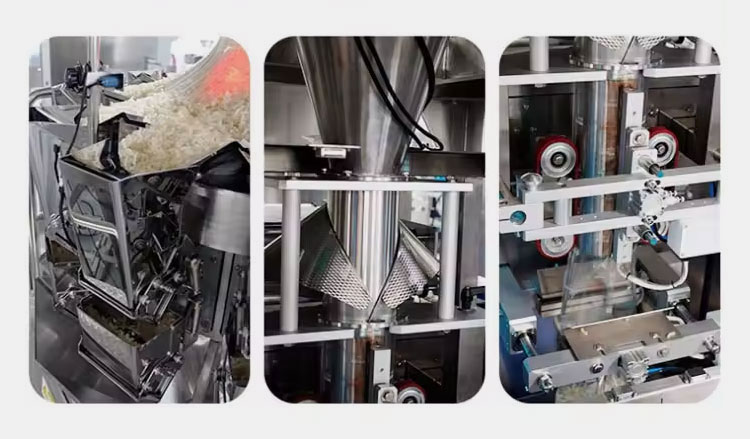

| Vertical Film Forming Sealing Machine

Picture Courtesy: Pyramid |

This is a compact machine which is capable of creating 3 side seal packing in a manner where products loading, film formation, sealing following by cutting and discharging take place in vertical direction. The machine can work and produce bag following working principle involving parts from top to bottom. |

| Horizontal Film Forming Sealing Machine

Picture Courtesy: Silicon Centre |

This is a large 3 side sealing production set up which is used in the large industries due to its high speed and more productivity. The machine is capable of forming 3 side sealing bags by following horizontal working steps such as film formation, filling, sealing, cutting. |

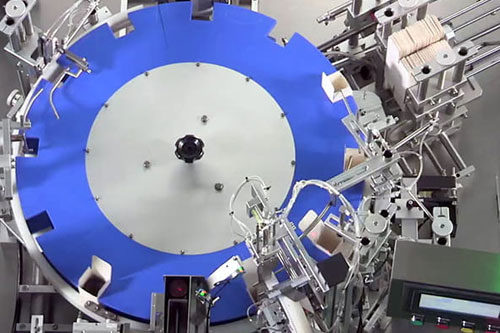

| Stick Packing Machine

Picture Courtesy: Lenis Packing |

This is an excellent machine that gives you sufficient amount of narrow stick packing with 3 side sealing which is mostly used for single serving products. Same as above, the working steps are involved with forming, sealing, cutting, discharging using either single or multi-lanes of the machine. |

Cartoning Machine

A cartoning machine are classified into the following:

| Vertical Cartoning Machine

Picture Courtesy: Sirosilo |

A type of cartoning machine where products are fed into the machine using a vertical fashion. The dropping of the carton is following top way where product is loaded and goes for folding and sealing. |

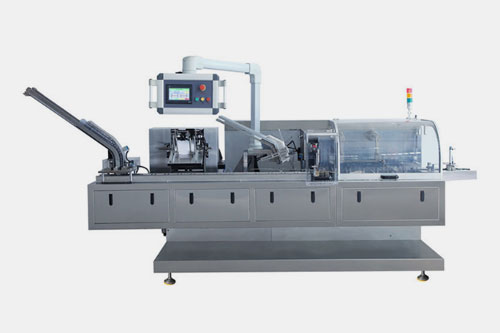

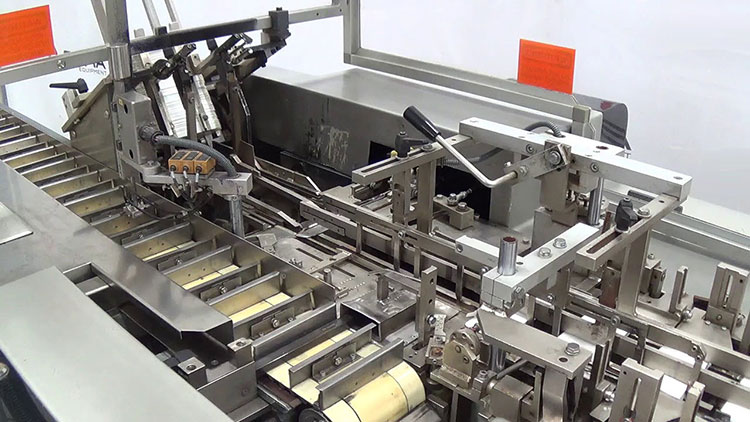

| Horizontal Cartoning Machine

|

These machines handle products that are inserted horizontally into the carton. The process typically involves picking of flat carton, feeding of product following horizontal pattern and glue or ultra-sonic tuck in flap sealing. |

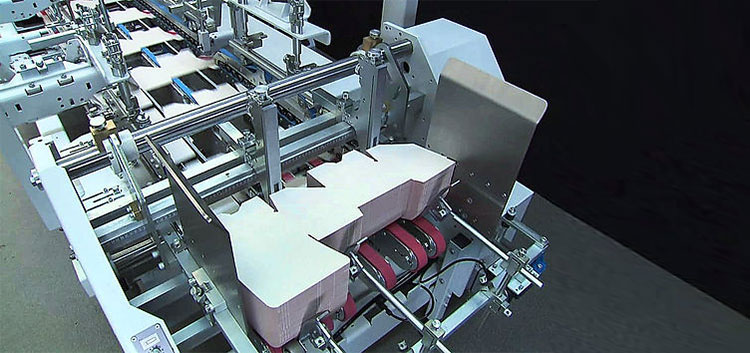

| Wrap Around Cartoning Machine

Picture Courtesy: Camagroup |

A flat sheet is used by wrap around cartoning machine that can pack the entire 3 side sealing pack by packing all around. The product stays in the middle with the help of robotic arms they keep it inside. This is compact and a flexible equipment which hygienically follows the working in a short time frame. |

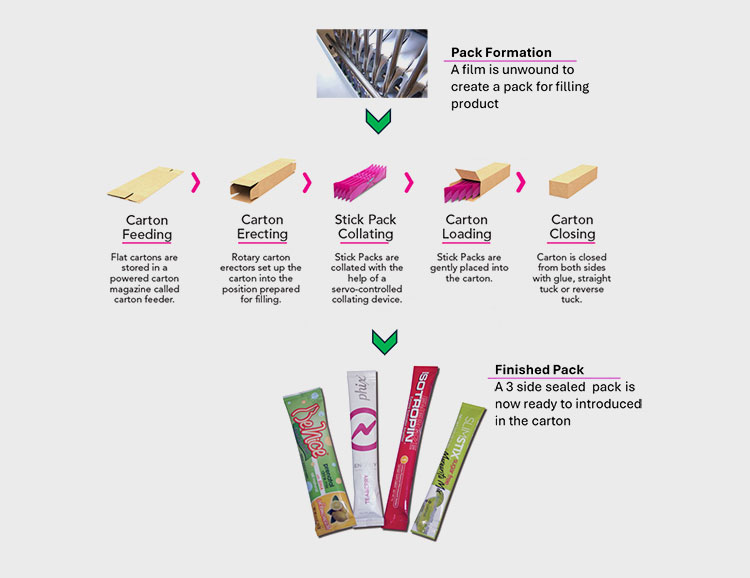

5.What are the working steps of 3 side sealing cartoning production line?

The working principle of a 3 side sealing cartoning production line is synchronized and coordinated, where each step is carried out efficiently to pack different goods into cartons. Let’s explore the working principle of the 3 side sealing cartoning production line explained in 2 diverse phases.

The working principle of 3 side sealing cartoning production line

Phase I- Primary Packing

To create 3 side sealing pouch, sachet, stick packing, you will need to load the products in the filling and sealing machine. The working of the machine is described below:

Film Formation

Film Formation

The film roll is adjusted in the screw roll of the machine and its linkers to make firm and intact network. A film is opened during work and rolled around the former to make a shape of the sachet or stick pack.

It is sealed on the left edge of the pack and bottom of the pack.

Products Filling

A 3 side filling and sealing machine

The product to be filled is simultaneously loaded inside the pack once the sealing done. Upon acquiring the correct amount of the product inside the final top seal is applied to close the pack and secure the product inside.

Pack Discharging

3 side seal pack

The prepared pack is separated from the chain of packs by the help of facilitated cutters or knives in the machine and discharge via ‘Exit’ or the outlet.

Connection

With the help of conveyor the prepared sachet, stick packs are transferred from filling and sealing machine to the cartoning line.

Phase II

This is the final phase where packed products are subjected the secondary packing. A cartoning machine is responsible for this process. The working step of this phase is mentioned below:

Product Loading

Product Loading

At first, the products are automatically loaded onto the conveyors using a robotic arm and feeder. The products are placed one by one on the conveyor.

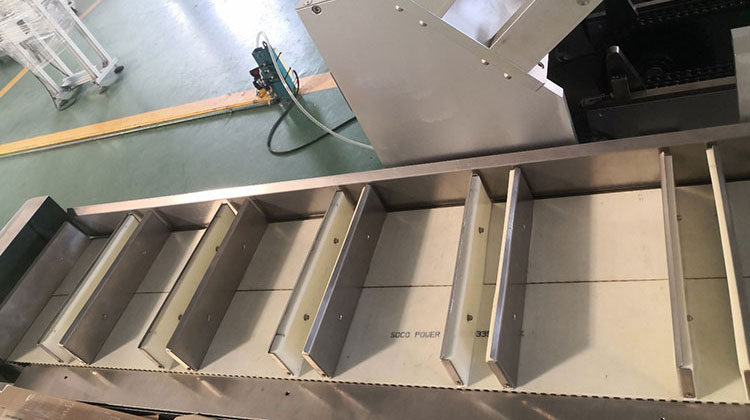

Blank Carton Loading

Blank Carton Loading

The large stack of blank cartons is loaded on the blank magazine from where they are picked up by the grippers and taken to the carton erector section.

Carton Erecting

Carton Erecting

At the carton erectors, the sides of the blank carton are folded, and an open carton box is created. This step is carried out by mechanical arms or the suction devices that are effective in folding the blank cartons.

Product Feeding in Carton

Product feed

After carton erecting, the products from the conveyors are placed onto the erected carton. The product feeding mechanism differs based on the products. Gravity-based systems and pushers are used for placing the solid items in the carton while the accumulation systems precisely load the smaller items in the carton.

3 Side Sealing

3 side sealing

Upon product filling, the flaps of the carton are folded and sealed using hot melt glue or cold glue. For proper bonding of the sides, pressure is applied to effectively seal all the 3 sides. The upper or lower flaps are also closed and folded.

Carton Discharge

Carton Discharge

Finished cartons are then moved to the next step of the production line where labeling of cartons or preparation for shipment occurs by palletizing.

6.What are the types of cartons does 3 side sealing cartoning production line handle?

Cartons come in all sizes and forms. So, 3 side sealing cartoning production line can handle diverse carton types. Some of these carton types are:

| Tuck-End Carton

Tuck-End Carton It is a type of carton with two sides (front and back) and two openings. These openings have flaps on the top and lower end of the box. These flaps are folded inward and secured during the product boxing process. It is used for packaging cosmetics and electronics that need secure closure. |

Reverse Tuck Cartons

Reverse Tuck Cartons It also has upper and bottom flaps; however, they are folded inward and tucked at the opposite ends of the carton sides to form a more protective closure. This allows easy access to the inner contents and these boxes are routinely found in the cosmetic and food industry. |

| Display Cartons

Display Cartons- Picture Courtesy: Emanc Packing These cartons have transparent windows and a clear panel to display the inner product. Users easily see the condition of the product through this clear window and this carton makes an attractive retail display. |

Hanging Tab Carton

Hanging Tab Carton- Picture Courtesy: Halcon Packaging A small die-cut tab is present at the top of cartons. These die cuts allow users to hang the carton on the hooks in homes and display shelves. |

7.What are the sealing types in the 3 side sealing cartoning production line?

There are two main sealing types in 3 side sealing cartoning production line which are:

Hot Melt Glue Sealing

Hot Melt Glue Sealing

In this method, hot melt glue is applied for sealing. It is a thermoplastic adhesive and melts on heating while solidifies on cooling. A dedicated adhesive spraying nozzle loads a precise quantity of glue on the sides of carton flaps and when carton flaps are joined together, a strong bond is created between them. It is a cost-effective and versatile method.

Ultrasonic Welding

Ultrasonic Welding

It is the latest technology in which high-frequency sound waves are utilized for creating friction that melts designated sites on the carton flaps. This creates a strong bond between the flaps. It is utilized for forming tamper-evident seals and is appropriate for heat-sensitive carton materials as it does not require a heat source.

8.How to clean and maintain the 3 side sealing cartoning production line?

Cleaning and maintaining the 3 side sealing cartoning production line increases the longevity and ascertains the smooth packaging operation. Some of the cleaning and maintenance steps are penned below:

Maintenance of the 3 side sealing Cartoning Production Line

| Cleaning | First shut down the equipment and use brushes to remove loose debris and glue buildup from the production line.

Remove the product residues from the surface of the production line. Use a wet cloth and mild cleaning agent to clean the conveyors, guides, and external components of the production line. Pay special attention to sealing components, glue nozzles, and other components that carry out the sealing process. This step gets rid of product buildup. |

| Lubrication | Oil and grease every mobile joint of the production line for smooth working performance. The lubrication processes must be carried out as per the instruction of the manufacturer. |

| Calibration | Calibrate and align different parts like guides, sensors, and sealing mechanisms for precise operation. |

| Replacement of Defective Parts | Perform monthly or quarterly assessments of defective parts like belts, rollers, guides, sensors, and seals and replace them if required. This assessment identifies the problem early and decreases the frequency of breakdowns. |

| Software Updates | To take advantage of recent features and security measures, it is best to keep software up to date. |

9.What is the quality control measures in the 3 side sealing cartoning production line?

Quality control measures in 3 side sealing cartoning production line

Quality control measures are implemented in the 3 side sealing cartoning line to ascertain the uniformity, safety, and integrity of packed goods. Here is a list of quality control measures present in the 3 side sealing cartoning line:

| Visual Inspection | Different visual inspection systems like camera or vision systems are integrated with the 3 side sealing cartoning production line to check different visual defects in the cartons, for example, weak sealing, incorrect folding, and missing flap |

| Weight Checking | For checking missing or extra items in the cartons, weight-checking tests are included in the 3 side sealing cartoning production line. This ensures the correct weight of the product in the carton. The cartons are rejected if they do not have a specified weight. |

| Seal Integrity | Different seal integrity tests are implemented to check the proper seal of the cartons. Mechanical tests and sensors ensure that adhesives are applied correctly as well as cartons are fully secured. |

| Barcode Checking | Different barcodes and labels of the cartons are checked by the scanner to ensure these labels are correctly placed and are legible. For tracking and tracing the cartons through the supply chain, this quality control measure is essential. |

| Content Checking | The inner content and their arrangement are checked through X-rays or camera vision systems. These integrated devices can identify the presence of foreign objects, missing products, and incorrect placement of the product. |

10.What are the Common Problems and Their Fixes in 3 side sealing Cartoning Production Line?

The 3 side sealing cartoning production line is a remarkable production line performing various tasks speedily, however; some frequent problems arise in the 3 side sealing cartoning production line that impacts its speed and efficiency. These common problems, their causes, and fixes are discussed below:

Misalignment of the Film & Carton

Misalignment – Picture Courtesy: Packaging experts

Blank film and cartons are not aligned properly causing product damage.

| Cause | Fix |

| Wrong installation and leveling of 3 side sealing cartoning production line .

Defective or worn-out guides, belts, and gear. Debris, dust, or obstruction. Defective sensors and motors can also interrupt the alignment step. |

Properly install, set, and calibrate the machine.

Repair or replace old or damaged guides, belts, and gear. Always use cartons of uniform shapes and sizes. And film from good sources and machine compatible material. Clear the dust, debris, or other obstructions in the path of the blank cartons. Repair defective sensors and motors. |

Non-Uniform Glue Application

Non-Uniform Glue Application

Sometimes, the application of adhesive is inconsistent, causing poor, weak, or excessive sealing.

| Cause | Fix |

| Poor cleaning and maintenance of the glue spraying nozzles.

Improper alignment of glue applicators. Variation in glue viscosity. Poor quality of adhesive material. |

Routinely clean and maintain glue spraying nozzle.

Adjust the alignment of the glue application. Adjust the settings to accommodate variations in the glue viscosity. Use high-quality adhesives as per the recommendation of the manufacturer. |

Inaccurate Weight

Inaccurate Weight

The cartons have the incorrect weight of the products, which leads to user dissatisfaction.

| Cause | Fix |

| Poor calibration and maintenance of the weight-checking systems.

Defective or damaged weighing systems. |

Calibration and maintenance of weight-checking systems should be performed at regular intervals.

Repair or replace damaged weighing systems. |

Weak Sealing

Weak Sealing of Carton- Picture Courtesy: Tau Energy

The 3 side sealing carton is uneven or incomplete, which can affect the integrity of the packed product.

| Cause | Fix |

| Decreased sealing pressure and temperature while sealing.

A dirty sealing mechanism disrupts the sealing process |

Check and repair the faulty adhesive applicator.

Fix the settings of sealing pressure and temperature to ascertain proper sealing. Clean the dirty sealing pressure to ensure debris or glue buildup does not interfere with the sealing process. |

Improper Folding of Cartons

The carton folding is inconsistent, leading to poorly formed cartons.

Improper Folding of Cartons

| Cause | Fix |

| Improper setting of carton folding mechanism.

Failure to adhere to proper maintenance schedule. Adjustable guides for carton positioning are not used. Moving parts of the folding mechanism are not lubricated. |

Adjust the settings of the carton folding mechanism.

Routinely maintain and clean the 3 side sealing cartoning production line. Use adjustable guides for the proper positioning of cartons. Lubricate the moving parts of the folding system, |

11.How to buy the best 3 side sealing cartoning production line?

When you are planning to buy the 3 side sealing cartoning production line, you should consider some important factors that will surely aid you in making the right selection. You should tick mark all the boxes which will help you in running a smooth business. These buying factors are detailed below for your ease of understanding:

Production Capacity

Production Capacity

It is a foremost important factor when buying 3 side sealing cartoning production lines. Every variant of this production line has a different production capacity. So, first consider the size of your production then you should buy the kind of production line that would cater to your production goals.

Carton Type

Carton Type

The 3 side sealing production line is an adaptable unit processing different types of cartons. So, determine which type of carton will you produce and package. Then select the production line that can easily adapt to your required carton type.

Product Type

Product Type

Different products have different shapes and sizes which require different types of feeding mechanisms. So, it is important to select your product type, so that you can easily choose a feeding mechanism integrated into the 3 side sealing cartoning production line.

Cost

Costs

Every manufacturer wants to earn big profits. For earning profit buy the 3 side sealing cartoning production line that is in your budget range. Because overspending will result in decreased profit margins. So, calculate your budget and capital required to buy the production line and then choose the right type of 3 side sealing cartoning production line that fulfills your required production demands.

Reputable Manufacturer

Reputable Manufacturer

Always search and write down the names of reputable manufacturers in the field. Reputable manufacturers have experience in designing 3 side sealing cartoning production lines and will offer the best quality production line with a long running life.

Conclusion

Now, you have reached the end of this detailed blog about the 3 side sealing cartoning production line and hopefully, you should have more knowledge about this production line. In summary, the 3 side sealing cartoning production line is sophisticated and state-of-the-art equipment, ensuring secure and successful packaging of cartons and boxes. Various pharmaceutical, food, and beverage industries adopt this superb production line for fast, versatile, and reliable packaging. If you are keen on adding a 3 side sealing cartoning production line or want an answer to your queries then without further ado contact Allpack, the best assistance you will ever have.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide