Liquid Milk 4 Side Sealing Machine: The Complete Buying Guide In 2025

Packaging liquid milk can be challenging in many aspects including taste, optimum shelf life, and efficacy.

Are you facing the challenges that are halting your business growth?

Introducing innovative technology in the world of packaging solutions: the liquid milk 4 side sealing machine. This machine stands out as a game changer for various businesses across industries. Now, you need not worry about the traditional options for packaging that are inefficient, time-consuming, and prone to errors.

The liquid milk 4 side sealing machine can streamline your liquid product packaging operations, enhance productivity, and satisfy market demands.

Looking for a detailed guide to the liquid milk 4 side sealing solution? You are at the right place!

This article will explore the features, working, and benefits for your business. Join us as we unleash the basics of this ultimate solution.

1.What is a liquid milk 4 side sealing machine?

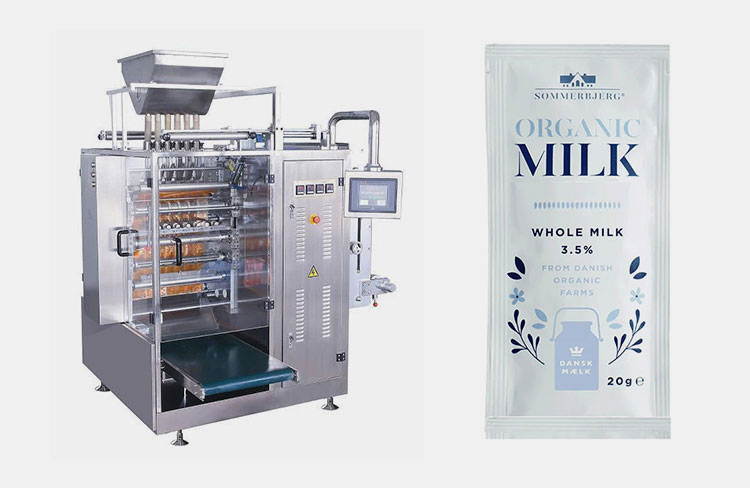

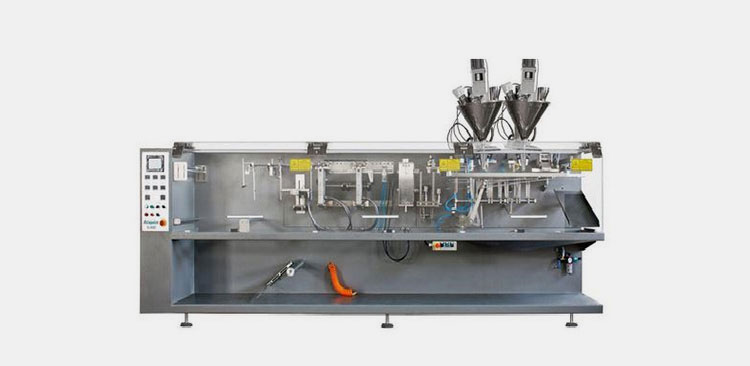

Liquid Milk 4 Side Sealing Machine

The liquid milk 4 side sealing machine is a specialized device that can produce sachet or stick pack filled with liquid products at a rapid rate with precise filling and efficient operation. The device is designed to have multiple lanes (ranging from 1 to 12 or more) that can determine its productivity.

The single lane device comes in a separate design while the multi lane advanced equipment contains more than one lane to enhance productivity.

The model with more lanes will have greater productivity and the capability to produce more sachets or stick packs at a time. Due to its efficient, accurate, and robust production, the device is popular across various industries dealing in liquid products, whether food, beverages, chemicals, cosmetics, or pharmaceuticals.

2.Why should you invest in a liquid milk 4 side sealing machine for your business?

Installing a liquid milk 4 side sealing machine in your industry has several benefits for your business, particularly if you are in the dairy or beverage industry. Here we are enlisting some compelling benefits this device can provide.

Efficiency

Efficient Processing

Every manufacturer desires efficient production and that’s what a liquid milk 4 side sealing machine offers. The device automates the packaging operation, which significantly speeds up production. This feature allows you to satisfy production demands without relying on manual labor.

User-Friendly

User-Friendly Interface

The liquid milk 4 side sealing machine has a user-friendly interface and can be operated easily without extensive training. The device uses advanced technology with digital features through which the entire process can be monitored and regulated easily.

Cost-effective

Cost-effectiveness

This device lowers your overall operational costs. Although initially, the device requires a substantial investment, it can be cost-effective in the cumulative expenses in the long run. You will not need to keep extra workers and pay them. Additionally, automated processing reduces the chance of errors and material waste.

Accuracy

Accuracy in the Size and Filling of Stick packs

The accuracy in the product filling is crucial in terms of profit but is more essential in the healthcare sector where a specified dose of the product is filled in individual sachet and stick packs.

Increased Productivity

Increased Productivity

Different variants of the liquid milk 4 side sealing machine have varied operating speeds, allowing you to regulate the production speed as required. Overall, the device increases productivity in comparison to the traditional packaging.

Improved Packaging Quality

Improved Packaging Quality and Brand Image

The liquid milk 4 side sealing machine ensures uniform and effective seals on all four sides of the sachet and stick pack. This enhances the aesthetic look of the product and improves the sealing integrity, reducing the chances of leaks and contamination. Quality packaging is crucial in keeping the product fresh and increasing its shelf-life.

3.What industries can utilize a liquid milk 4 side sealing machine?

The liquid milk 4 side sealing machine is popular across various industries. Multiple sectors have included it in their production lines. Some common sectors are;

Dairy Industry

Applications in the Dairy Industry

The primary industry for a liquid milk 4 side sealing machine is the dairy industry. The device is utilized for packaging liquid milk, flavored milk, creams, and other dairy products in different sachets and stick packs. Effective, hygienic, and secure operation aids in preserving the product's freshness for a long time.

Food and Beverage Industry

Applications in the Food & Beverage Industry

The liquid milk 4 side sealing machine is also popular in the food and beverage sector due to its ability to produce appealing products at a rapid rate. Examples include juices, coffee, vinegar, energy drinks, and sauces.

Healthcare Industry

Applications in the Pharmaceutical Industry

In the healthcare industry, the device is utilized for packaging unit-dose liquid syrups and health supplements in sachets and stick packs. Precision and hygiene are vital in the health sector and this device packs precise volume efficiently and is easy to use by the patients.

Chemical Industry

Applications in the Chemical Industry

In the chemical industry, the liquid milk 4 side sealing machine is used for packaging certain chemicals, such as acids, liquid compounds, test products, laboratory reagents, and cleaning solutions. Proper and effective sealing guarantees that the hazardous chemicals are safely contained.

Cosmetics and Personal Care Industry

Applications in the Cosmetics Industry

Many liquid beauty products are packaged using the liquid milk 4 side sealing machine. These include lotions, body oils, creams, shampoos, and conditioners. The device aids in producing single-use sachets and stick packs which are popular among the customers.

4.What are the basic components of a liquid milk 4 side sealing machine?

There are several components in a liquid milk 4 side sealing machine. These components work together to form quality sachets and stick packs. Some models may have additional components but the major parts are the same in all models.

The basic components you will find in a liquid milk 4 side sealing machine are listed below.

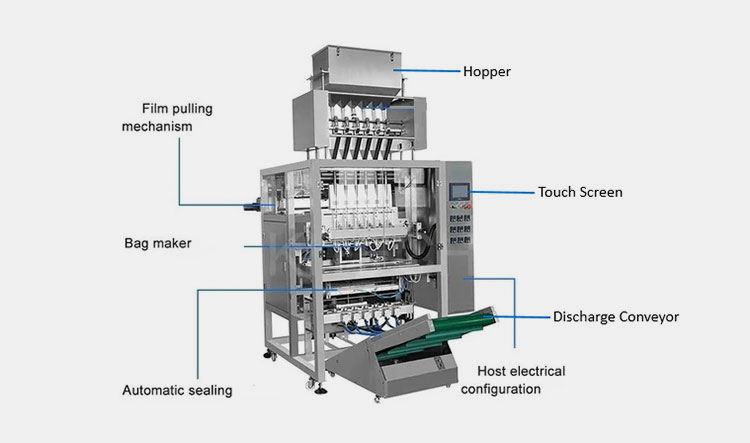

Components of Multi lane Liquid Milk 4 Side Sealing Machine

Hopper

A hopper is an inverted container that holds the bulk material (a significant amount) before directing it to process. It can be of various shapes, such as rectangular, pyramidal, or conical. The quantity of material it can hold depends on its capacity, which can be varied with different models. The rate of material supply can be regulated in certain models.

Film Pulling Mechanism

The film-pulling mechanism involves:

The film frame – that holds the large film roll such that it can unwind smoothly.

The dancing rollers – these are responsible for unwinding the film roll, and facilitating its feed to the machine.

Bag Maker

A bag maker section contains a forming/shaping tube responsible for the fabrication of sachets and stick packs of the desired dimensions from the supplied film. The film material get folded around the forming tube and sealed to form a packet.

Automatic Sealing

The sealing station comprises vertical sealing bars and horizontal sealing clamps. They are responsible for the effective heat-sealing of the sachets (forming stage and after filling) and stick packs.

Touch Screen

The screen panel aids in the spot-on monitoring and regulation of the process parameters. The device is instructed for the process through the touch screen.

Discharge Conveyor

The discharge chute/conveyor facilitates the exit of the finished packets from the machine.

Host Electrical Configuration

It consists of the touch screen and the “power switch” that connects the device to the power supply needed to run the machine. It can also contain the “emergency stop button”, which causes immediate cessation of the process in case of an incident.

5.How does a liquid milk 4 side sealing machine work?

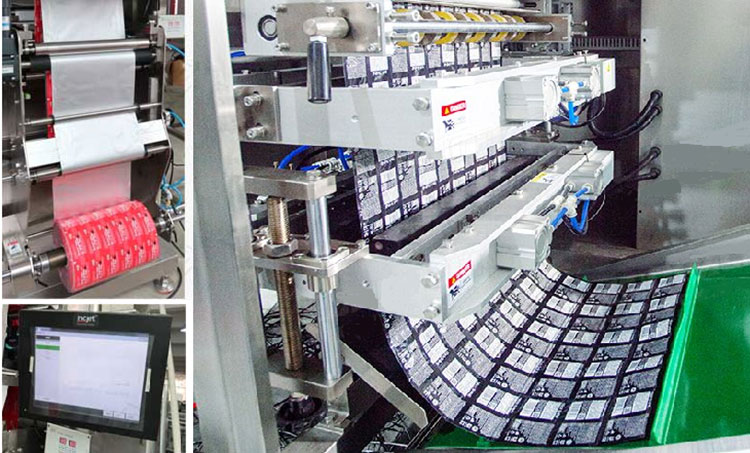

Working on a Liquid Milk 4 Side Sealing Machine

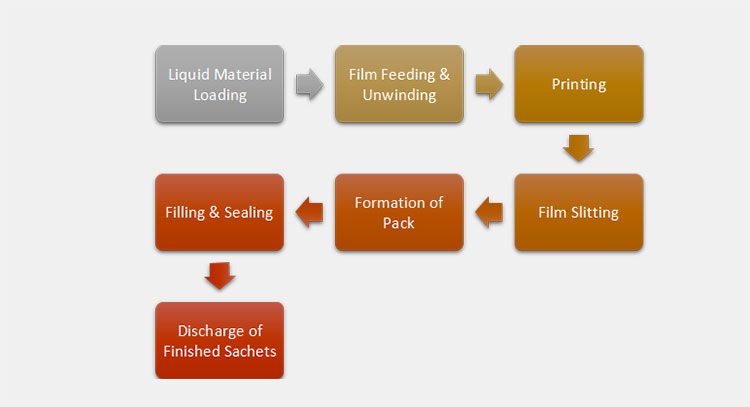

The liquid milk 4 side sealing machine can have several lanes (1-12) that work in the same fashion. The working of this device includes a few basic steps:

Steps of the Working Process

Liquid Material Loading

The process starts by loading a significant amount of product into the hopper. The dimensions of the hopper will determine the volume to be loaded. The loading is done manually or using an automatic mechanism.

Film Feeding and Unwinding

Another beginning step is placing the film roll on the film frame and unwinding it, which will carry the product. A reel will grip the film material as it unfolds utilizing a cross-seal clamp, keeping it moving.

Printing

It is an optional step and can be done by certain variants. The device with a date imprinting system will position the date imprint on the packages via a registration roller.

Film Slitting

The film is headed towards the slitting section. In this step, the film is cut down into strips. The number of strips produced relies on the number of lanes in the device. The film is cut down via cutting blades while still in tension.

Formation of Packs

After slitting, the strips will be directed to the shaping tubes. Only a single strip can pass a lane. The strips form a pouch by such folding that the edges join each other. The tubes can be adjusted to produce specific edge seals (lap/fin).

Filling and Sealing

In this step, various heated seal bars guide toward the tube, creating a vertical seal. After this, lateral sealing clamps will form a top-edge seal on one pack and a bottom-edge seal on another pack.

After that, the liquid material will enter the pouch. For accurate filling, multiple filling techniques are utilized, such as piston fillers or volumetric fillers.

Discharge of Finished Products

After filling, blades cut down the pack which are directed towards the outlet and get discharged.

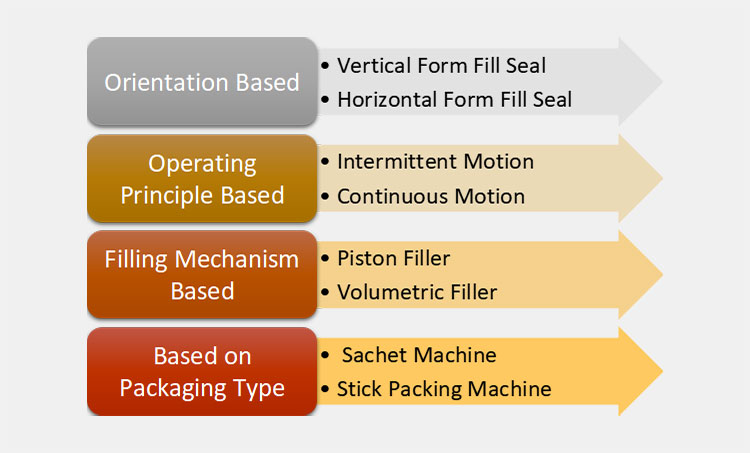

6.How do you classify a liquid milk 4 side sealing machine?

There are various models of the liquid milk 4 side sealing machine available designed based on different requirements. Each of them has unique characteristics and features. It can be classified based on orientation, operating principles, and filling mechanisms installed.

Classification of Liquid Milk 4 side sealing Machine

Classification Based on Orientation

Vertical Form Fill Seal (VFFS) Liquid Milk 4 Side Sealing Machine

Vertical Form Fill Seal (VFFS) Liquid Milk 4 Side Sealing Machine

In the vertical form fill seal (VFFS) liquid milk 4 side sealing machine the materials are processed downwards and the finished products are expelled from the bottom. The device forms, fills and seals the packages in the vertical configuration.

Horizontal Form Fill Seal (HFFS) Liquid Milk 4 Side Sealing Machine

Horizontal Form Fill Seal (HFFS) Liquid Milk 4 Side Sealing Machine

In contrast to the VFFS device, the horizontal form fill seal (HFFS) liquid milk 4 side sealing machine processes the materials side wise. The material is fed into one side of the device and the finished products are expelled from the other end. The device forms fills, and seals the packages in the lateral configuration.

Classification Based on Operating Principle

Intermittent Motion Liquid Milk 4 Side Sealing Machine

Intermittent Motion Liquid Milk 4 Side Sealing Machine

In this type of machine, the packaging process occurs in a start-pause fashion. After producing one pack through each lane, the device pauses before processing another pack.

Such devices are suitable for small production sectors or products requiring precise filling.

Continuous Motion Liquid Milk 4 Side Sealing Machine

Continuous Motion Liquid Milk 4 side sealing Machine

In a continuous-motion liquid milk 4 side sealing machine, the process occurs continuously without stopping until the feed is available (product and film). These variants are ideal for high-speed operations where efficiency is a primary priority.

Classification Based on Filling Mechanism

Piston Filler Liquid Milk 4 Side Sealing Machine

Piston Filler Liquid Milk 4 side sealing Machine

This type of machine has a piston installed as a filling mechanism, facilitating the filling process. The piston pushes the liquid from the feeding cup into the sachets or stick packs. The piston moves back and forth to create a vacuum for a specific liquid volume and then draws it into individual packs.

Such fillers offer precise control over filling volume. They are typically used for viscous liquids that require a push, such as sauces, syrups, etc.

Volumetric Filler Liquid Milk 4 Side Sealing Machine

Volumetric Filler Liquid Milk 4 side sealing Machine

The volumetric fillers use a calibrated cylinder, measuring a predetermined volume of liquid, and then fill the sachets and stick packs. They are typically used for thinner liquids such as milk, juices, water, etc.

Classification Based on Filling Mechanism

Sachet Liquid Milk 4 Side Sealing Machine

Sachet Liquid Milk 4 Side Sealing Machine

A commonly used single serving milk packaging which is helpful in the acquiring 4 side sealing sachets presenting a leak proof protection. It is typically designed with piston filler if required for liquid packing and ranges from a few hundred milliliters promising very accurate outcomes.

Stick Packing Liquid Milk 4 Side Sealing Machine

Stick Packing Liquid Milk 4 Side Sealing Machine

Compact and high production equipment offering formation of a narrow and cylindrical shape packing with maximum efficiency. The machine is present with multi lanes which make so many stick packs at one time with accurate portion of milk into it with an airtight sealing.

7.How is a liquid milk multi lane 4 side sealing machine different from a single lane equipment?

| Features | Liquid Milk Single Lane 4 Side Sealing Machine | Liquid Milk Multi Lane 4 Side Sealing Machine |

| Image |  |

|

| Production Capacity | This device has a single processing lane means that it can produce a single pack in one cycle. | This device has multiple processing lanes means that it can produce more packs in one cycle (depending on the number of lanes). |

| Structure and Size | It has a simple structure with a small footprint, occupying less space. | It has a more complex structure and larger footprint, requiring a large space to install. |

| Cost | It is often more affordable and less expensive comparatively. | It requires greater investment and is expensive due to its high speed, efficiency, and complexity. |

| Flexibility | The single-lane variant is less flexible comparatively and requires frequent changeovers for diverse purposes. | The multi-lane equipment offers greater flexibility and requires slight adjustments for varying needs. |

| Applications | It is suitable for small to medium enterprises that have limited production needs. | It is the best solution for high-production industries. |

8.How to improve the efficiency of a liquid milk 4 side sealing machine?

Maintaining a liquid milk 4 side sealing machine ensures proper and smooth functioning. Conducting regular maintenance programs guarantees the longevity and top performance of your device.

Here are some basic maintenance tips that can be followed to get the best out of your device.

Routine Cleaning

Routine Cleaning

Manual cleaning is done following SOPs, which emphasize hygienic practices and regular maintenance inspections carried out by qualified personnel. Regular cleaning must be done to prevent the accumulation of liquid material or dust and bacterial contamination. Thoroughly clean the entire device using a soft cloth along with water or other suitable agent, keeping the device in top condition.

Regular Inspection

Inspection of the Device for Damage/Wear

Conduct regular examinations of all components to check for any damage or wear. In case of faulty components that need repair or replacement, follow it on the spot to avoid permanent damage.

9.What problems can be faced while using a liquid milk 4 side sealing machine and what are their solutions?

A liquid milk 4 side sealing machine like all other industrial equipment can encounter some technical problems, resulting in reduced productivity and efficiency of the device. Timely identification followed by rectification of these problems is crucial to avoid any major loss or incident.

Some typically encountered problems include:

Film Creasing

Film Creasing

The potential reasons for film creasing can be:

- Faulty rollers or film frame

- Misalignment of film roll

- Obstructed shaping tube or other component

Solution: replace the faulty component (roller or frame). Adjust the film roll to the center. Clean out the obstructed path.

Machine Jamming

Device Breakdown/Jamming

The device jamming can be due to:

- Friction in the moving parts

- Dirty components

- Improper adjustments of parameters

Solution: lubricate the moving parts. Clean the device regularly. Properly adjust the process parameters as per the product and film material.

Poor Sealing

Poor/Defective Sealing

The reasons for faulty sealing can be:

- Worn or damaged sealing bars/clamps

- Too high or low temperature of the sealing section

- Inadequate pressure or sealing time

Solution: replace the damaged sealing bars/clamps. Adjust the sealing temperature, pressure, and time as required.

Inconsistent Filling

Filling Inconsistency

The non-uniformity in the filling process can be due to:

- Clogged filling nozzle

- Defective piston or improper calibration of volumetric cylinder

- Disordered conveyor

Solution: replace the filling component. Repair the piston and validate its functioning. Calibrate and verify the cylinder. Adjust the conveyor speed.

10.What quality standards should a liquid milk 4 side sealing machine conform to?

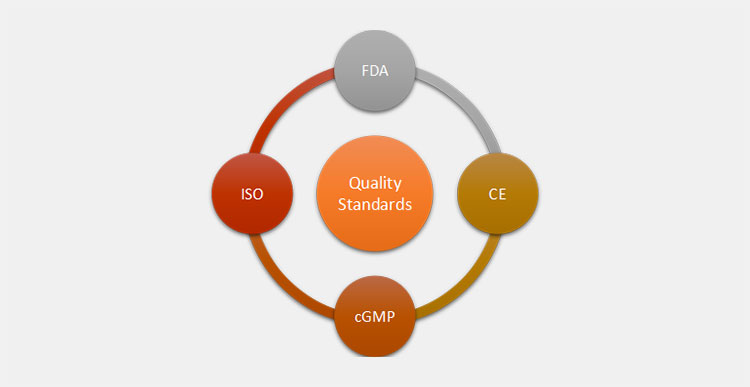

Quality Standards Certifications

The liquid milk 4 side sealing machine must comply with international quality standards to ensure product safety, efficiency, and regulatory compliance.

These quality standards and certifications include:

Food and Drug Administration [FDA]

FDA guidelines ensure the protection of public health through safe, effective, and secure products/materials. It guarantees that the machine materials are safe for food or drug contact.

European Commission [CE]

Although this mark is required for goods sold in the European Economic Area (EEA), it is accepted throughout the world. It implies that the sold product has been examined to satisfy safety, health, and environmental security needs.

Current Good Manufacturing Practices [cGMP]

The cGMP specs ensure that the device satisfies the minimal requirements for the processes and facilities used in the products’ manufacturing, processing, and packaging.

International Organization for Standardization [ISO]

The ISO certification enhances the credibility of a product/device by signifying that the device satisfies all the needs and requirements for the customer’s safety and health.

11.What factors will determine the price of a liquid milk 4 side sealing machine?

The price of different variants of the liquid milk 4 side sealing machine can vary based on several factors and characteristics of the model, such as:

Automation level

Manufacturing speed

Production capacity

Construction material

Machine design

Quality standards compliance

Model and properties

Warranty and technical services

12.How to pick the right liquid milk 4 side sealing machine for your business?

Choosing a liquid milk 4 side sealing machine can be tough because of the variability in specs requirements of different manufacturers for their products.

Before buying a liquid beverage multi-lane stick packing machine it is important to ensure that the device meets your specific business needs. Here are some key factors to consider.

Production Rate

Rate of Production

The manufacturers should know the number of packs they need to produce per minute/hour. Different models have different production rates based on the number of lanes. Knowing the required production rate and opting for the device that can satisfy your needs is important.

Seal Type

Type of Seal (Lap vs Fin)

The liquid milk 4 side sealing machine can form either a lap seal or a fin seal. Choose the device with your desired features of sealing type. Some of the variants have adjustment options.

Cost

Costs & Budget

It is an important factor that should be considered before shopping. Assess your budget and the entire cost of the device, including purchasing, operation, and maintenance expenses. Evaluate the predicted return on investment (ROI). Select an option that can satisfy your needs efficiently.

Technical Support

Technical Services by Manufacturers

It is important to ensure the technical services from the supplier to avoid difficulty in the device maintenance and spare parts. Buy the device from a reputable manufacturer, offering warranty, training, and after-sale services.

Quality Standards Compliance

Quality Standards Compliance

The certifications of the quality industrial standards are crucial for safe and efficient processing. Therefore, it must be verified that the device is quality-certified to ensure safe operation.

Conclusion

Let’s wrap things up! The liquid milk 4 side sealing machine is an incredible and efficient equipment, popular across various industries. If you have not adopted this innovation, you might fall short in the market competition. You must plan to invest in this device and boost your business growth. So, if you want to buy this device, contact a reputable manufacturer that can guide you better and Allpack is undoubtedly one of them. Feel free to contact us and get your desired equipment.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours