Liquid Beverage Multi Lane Stick Packing Machine: The Complete Buying Guide In 2025

Can a one sip of a refreshing drink lift your spirits? But imagine if you could satisfy your thirst for that feeling of freshness whenever you wanted to. This desire has prompted packaging experts to focus on solutions that serve two purposes: convenience for consumers and affordability for the producers while at the same time taking care of the environment.

This is where the liquid beverage multi lane stick packaging machine will help. This advanced machine is manufactured for the sole purpose of preserving the true nature of different beverages. The machine is equipped with functions aimed at increasing performance, accuracy, and capacity thus serving as a real powerhouse. To take full advantage of its potential, it is vital to know its structure, functions, types, and the way it works. Furnished with this know how, you can explore the world of liquid beverage packaging and grasp its entire dynamics. So Let’s have a look and discuss about!

1.What Is A Liquid Beverage Multi Lane Stick Packing Machine?

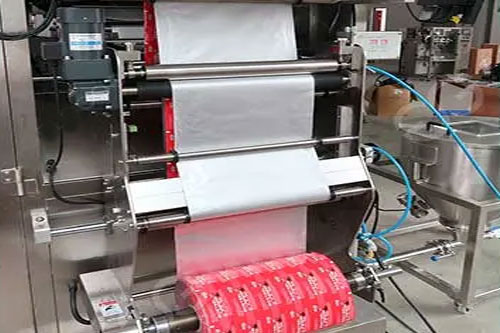

Liquid beverage multi lane stick packing machine architecture

To pack liquid beverages by the multi lane packing machine, you must be familiar with what actually is the liquid beverage multi lane stick packing machine. A liquid beverage multi lane stick packing machine is a machine that is designed to pack liquid beverages into stick packs efficiently and accurately. Interestingly, these machines differ from conventional packaging methods, including bottles or pouches, since they use multi lane systems to package multiple units simultaneously.

Basically, a liquid beverage multi lane stick packing machine provides the automation of packing, sealing, and cutting individual stick packs, thus improving productivity and efficiency. These machines are designed to meet the specific needs of liquid beverages, like viscosity and temperature sensitivity, which guarantee that the product's integrity and quality will be preserved throughout the packaging process.

2.Significance of A Liquid Beverage Multi Lane Stick Packing Machine: How Is It Important?

Uses of liquid beverage multi lane stick packing machine

If you want to pack liquid beverages in a bulk, the liquid beverage multi lane stick packing machine is the best choice. It has numerous significance such as;

Time saving

A liquid beverage multi lane stick packing machine can make several stick packs in a short time.

Ease of Use

The automatic versions of liquid beverage multi lane stick packing machines are simple to operate.

Thus, one can use the machine without much training.

Support Equipment

It is possible to use other support equipment with a stick packing machine.

Cost effective

This machine will enable you to fulfill your production requirements while at the same time reducing your operational costs.

Accuracy

A liquid beverage multi lane stick packing machine is very accurate, reliable, time saving, and can achieve high production capacities.

Production Capacity

Liquid beverage multi lane stick packing machines are available at different production speeds.

This enables you to modify your production rate according to your requirements.

Maintenance

It is quite easy to keep a liquid beverage multi lane stick packing machine in good condition.

Thus, the operator can repair and replace parts of the machine easily.

3.Why Do You Need A Liquid Beverage Multi Lane Stick Packing Machine?

This machine is necessary to pack liquid beverage

The multi lane stick packaging system is renowned for its multiple industrial advantages as it utilizes a single machine to manufacture stick packs while concurrently handling loading and unloading operations. Finally, this renders it a favorable choice for industrialists to incorporate into their production process.

The multi lane stick packing machine has versatile applications, as outlined below:

Flexible and Adjustable Stick Pack Production: This machine is highly suitable for packaging things in different states of matter. In addition, you can acquire a range of stick pack sizes and capacities at the fastest feasible speed. This machine is highly adaptable, simultaneously handling multiple products and enhancing producers' productivity.

Prevent Product Loss: With advancements in technology and enhanced specifications of multi lane stick packaging machines, you can ensure precise and accurate product quantities in every package. Using this machine significantly reduces the probability of product waste, resulting in high cost effectiveness.

High Safety and No Cross Pollution: The multi lane stick packaging machine reliably seals and protects your product from the outside world. Cross contamination, which promotes germs and shortens product shelf life, is not a concern. A multi lane stick packaging machine can help your firm flourish.

Space Reductions: A multi lane packaging machine saves time, money, and floor space by producing high productivity—this benefits enterprises with limited space or a crowded manufacturing layout. A multi lane stick packaging machine is now accessible for professionals to install and operate.

Greater Accessibility: This machine is customized to meet your needs. In every firm, you may need to move your machine. Multi lane stick packing machines are portable and hygienic. You can leave your machine outside, and it will still work.

Constant Stick Packs Output: A multi lane stick packaging machine can produce consistent and convenient output, ultimately packaging high quality goods that align with consumers' expectations.

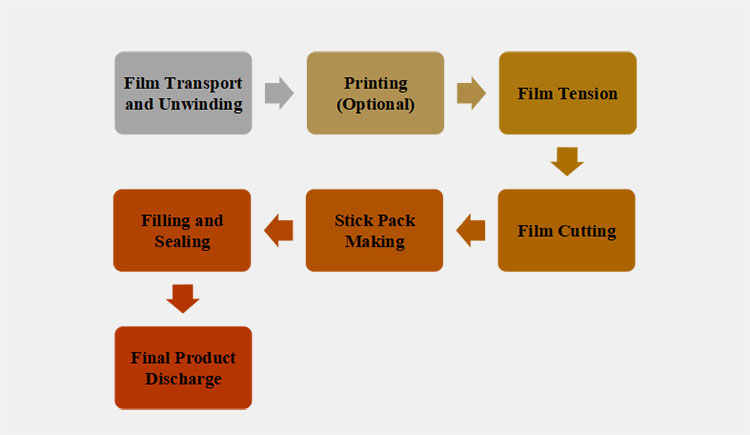

4.What Is The Operational Principle of A Liquid Beverage Multi Lane Stick Packing Machine?

Imagine this: you are aware of the little packets of liquid beverages, such as coffee or energy drinks, that are usually in the shape of single serving packs, right? Obviously, a multi lane stick packing machine is a wonderful machine that plays a vital role in making everything work smoothly. Its operational principle is based on the efficiency and the accuracy. The steps involved in operational principles are as follows;

| WORKING PRINCIPLE OF A LIQUID BEVERAGE MULTI LANE STICK PACKING MACHINE | |

|

STEP 1: FILM TRANSPORT AND UNWINDING |

|

|

Liquid beverage multi lane stick packing machines use a single sheet of film material rolled around a core, usually referred to as rollstock. The film is unwound from the film reel, positioned at the rear part of the machine. The film unwinding process is done by means of movement of the cross seal jaws, located at the front of the stick pack machine. |

| STEP 2: PRINTING (Optional) | |

|

This step is optional during machine performance. If the machine is equipped with a date stamping device, the film is fed around a registration roller and you know when the film was taken. This way, you can completely understand the position of the date stamp on the package in relation to the horizontal seal. The film is filmed through a sensor that reads eye marks and controls the position of the horizontal seal in relation to the printing on the film. |

| STEP 3: FILM TENSION | |

|

After, the film is rolled through a set of nip rollers. The nip rollers apply a uniform pressure on the film which is useful in maintaining the film at a constant tension and thus keeps the dancer arm in the proper position.

In the unwinding, the film is unwound from the roll and moved over a dancer arm, which is a weighted pivot arm at the rear of the machine. The arm has rollers which are rolled one after another. The film is being pulled from one side to another as the arm moves up and down to keep the film under tension, and an automatic film tracking sensor also makes sure the film will not wander from one side to another. |

| STEP 4: FILM CUTTING | |

|

Then the film moves towards the cutting chamber. During such processing, the large roll of the films is cut down into smaller due to the multiple lanes of the machine.

The cutting disk knives that perform this step are not motorized. The film, which is still under tension, is being cut by the knives that are in touch with the specially designed roller. The film is segmented into individual stick packs as it is threaded through this assembly. |

| STEP 5: STICK PACK MAKING | |

|

From the film cutting chamber, the cut film goes over several forming tubes one for each lane. As the cut film crests the shoulder (collar) on each forming tube, it is folded around the tube so that the end result is a 'stick pack' shape with the two outer edges of the film overlapping each other. |

| STEP 6: FILLING AND SEALING | |

|

After the films stop moving, the hot vertical sealer bars in each lane move forward to seal the film vertically. They press against the forming tube to put the seal. After that, a single horizontal sealing jaw seals the top of one stick pack and the bottom of the next. At the same time, the product is passed from the forming tubes to each bag, through a filling machine that guarantees the right amount and release of the product. |

| STEP 7: FINAL PRODUCT DISCHARGE | |

|

After the product has been released into each stick pack, the knife blade moves forward and cuts the bag or the horizontal seal is “notched” just under the horizontal seal jaw. |

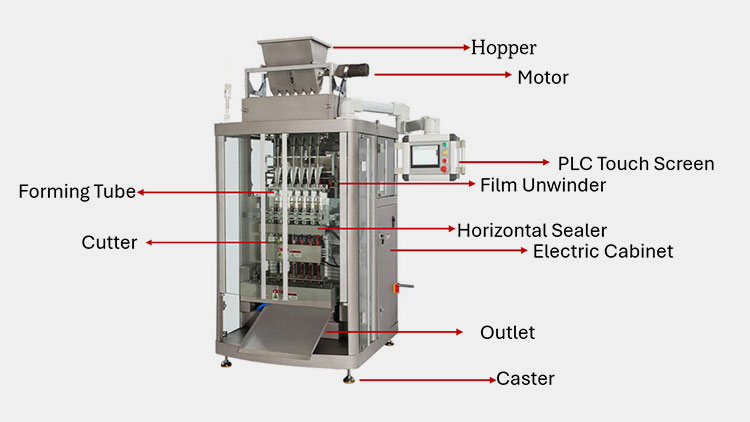

5.Describe The Components Of A Liquid Beverage Multi Lane Stick Packing Machine.

Main component of liquid beverage multi lane packing machine

The main components used to operate the liquid beverage multi lane stick packing machine include a Hopper, Motor, PLC Touch Screen, Forming Tube, Sealer, Electric Cabinet, Outlet, Roll stock, Sensor, Blade Cutter, Caster, and. Conveyor System. Let's see the function of each component.

Hopper: All the products that are to be packed inside the stick packs will first be in the hopper. It enables the stick packing process to take place non stop as long as there are products in the machine.

Motor: This part will turn the electrical energy into mechanical energy that will then work the parts of the machine.

PLC Touch Screen: This part of the machine is present in the control panel. It could be based on a touch screen or a human based interface. A control panel gives the operator the ability to set the stick packing parameters and to monitor the stick packing process.

Forming Tube: The sealing material is flat as it goes into the stick packing machine. The forming tube has the role of producing the cavity by rolling the film stock. It will be the place for the products before the sealing will occur.

Sealer: The sealer is an essential part that guarantees that each stick pack is tightly sealed, thus, it keeps the freshness and the quality of the liquid beverage inside.

Electric Cabinet: It has all the electrical units that will help in generating the power for the stick packing machine.

Outlet: It is part of the machine, from where the product is discharged to the packaging system.

Roll stock: It is a round sector of the stick packing machine that will receive the film that will make the packs.

Sensor: This component of the machine is used to reduce emergencies or accidents. The sensors will emit a noise alerting the operator of some problem the machine may have. In certain cases, the stick packing machine may be stopped by the emergency shut down system to avoid any hazards.

Blade Cutter: The created tube will form a long continuous tube that is hollow. The blade cutters are the ones who are responsible for slicing the tubes into strips.

Caster: The caster is the main part for mobility, the component that enables the machine to be easily moved and located in your production space.

Conveyor System: They assist in the movement of substances from one part of the machine to another.

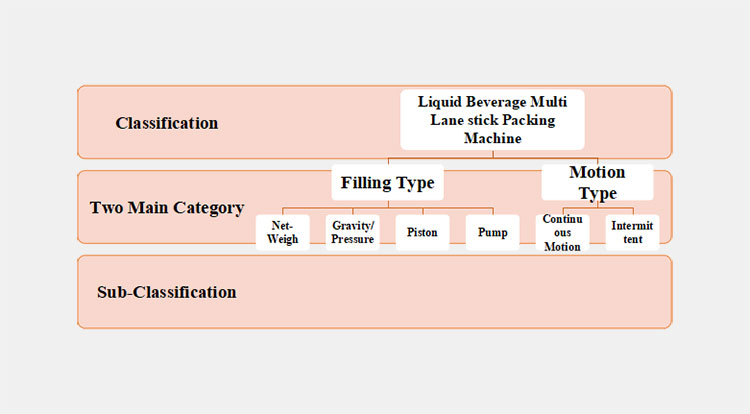

6.What Is The Classification Of A Liquid Beverage Multi Lane Stick Packing Machine?

Net weight liquid beverage multi lane stick packing machine

Gravity liquid beverage multi lane stick packing machine

Piston liquid beverage multi lane stick packing machine

Pump liquid beverage multi lane stick packing machine

Continuous motion liquid beverage multi lane stick packing machine

Intermittent motion liquid beverage multi lane stick packing machine

Based on filling and motion type, the liquid beverage multi lane packing machine comprises different parts, which include.

Classification Based on Filling Type

Net Weight Liquid Beverage Multi Lane Stick Packing Machine: This is the only machine that loads liquid beverages by weight. This machine is utilized for filling liquid beverages, in which the fill differences affect the product quality.

Gravity/ Pressure Liquid Beverage Multi Lane Stick Packing Machine: This machine has a simple structure and an easy design, that includes a hopper, filling hose, and fill pipes. It blends thinner viscosity liquid beverage as a result of the natural gravitational force and the pressure difference.

Piston Liquid Beverage Multi Lane Stick Packing Machine: The machine is mostly used for filling and packing of all kinds of liquids, such as you can fill liquids with the thinner as well as the thicker flow rate.

Pump Liquid Beverage Multi Lane Stick Packing Machine: This machine has a hopper, hose pipes, filling nozzles, and pumps. It is regarded as a safe machine for filling sterile liquid beverages since the liquids do not touch the filling devices. The rotation of pumps enables this machine to precisely dispense liquid beverages into the stick packs.

Classification Based on Motion Type

Continuous Motion Of Liquid Beverage Multi Lane Stick Packing Machine: This liquid beverage multi lane stick packing machine works non stop without a break between the cycles. It is more suitable for higher production settings as it produces liquid beverages at much higher rates. It cuts the downtime and is highly efficient. It is more difficult than the stick machine for the intermittent motion liquid beverage packing.

Intermittent Motion Of Liquid Beverage Multi Lane Stick Packing Machine: It packages with intervals. The forming process stops when the machine is filling the liquid beverage stick packs. It has less productivity and is used in small and medium scale productions. It can be used to fill a wide range of liquids because of its intermittent motion.

7.Is Liquid Beverage Multi Lane Stick Packing Machine Able to Handle Different Shapes and Cutting Types?

Different shapes of the stick pack

| Shape and Cutting Type Handle By Liquid Beverage Multi Lane Packing Machine

When we talk about different shapes and cutting style, the question comes in our mind is whether liquid beverage multi lane stick packing machine handle different shapes or not. Oh Yes this machine can handle these. Now let's discuss it in detail. |

||

| SHAPE

Different type of shape of the product obtained from the liquid beverage multi lane stick packing machine |

||

| Rectangle Shape

Widely used pack all over the world, having four sides and four corners. The parallel sides of the rectangular shaped stick packs are the same. |

Bottle Shape

Secondly, commonly used shapes of the stick pack produced by the liquid beverage stick packing machine. It has a broad base that narrows down to the top. It has a small top part in the shape of the bottle cap. |

|

| Round Corner Shape

Less common type of pack style having round edges. These stick packs are more handy and they lower the chances of cutting, which is a problem with the straight corner stick pack. |

||

| CUTTING STYLE | ||

| Flat Cut

This stick pack is usually with straight ends and is the most typical cut type of the stick pack. It is the result of regular cutting knives in the liquid beverage stick packing machine. |

Zigzag Cut

This type of cut, the left and right turns alternate, is the variation of the usual straight cuts. The liquid beverage stick packing machine uses a special type of cutting blade to form this pattern on the stick packs. |

|

| Round Cut

It is another kind of stick pack. This kind of cut gives you round cornered stick pack. |

Shape Cut

It is a special kind of stick cut that comes in a range of shapes that are different from normal zigzag and round cuts. |

|

8.What Are The Special Requirements Need For Handling A Liquid Beverage Multi Lane Stick Packing Machine?

Special requirement to handle liquid beverage multi lane packing machine

Operating a liquid beverage multi lane stick packing machine requires specific measures to ensure efficient performance and protect product integrity. Imagine this scenario: you have a series of elegant machines arranged in a row, prepared to produce flawlessly packaged beverages.

Here are the key points to remember:

Material Compatibility: At first and foremost, the compatibility of the materials is of primary importance. It is quite important to guarantee that the machine's parts, for example, the tubes and seals, are compatible with the particular liquid beverage that you are packaging. Different beverages have their own characteristics; therefore, it is important to choose the materials that can be used in their production without causing any problems.

Sanitation Requirement: Sanitation is an absolute requirement. These machines must possess high cleanliness and sanitization to comply with health and safety regulations. Consider the presence of sleek and polished surfaces and use stainless steel materials, which facilitate easy cleaning and reduce the likelihood of contamination.

Precise Administration: It is essential. You desire the machine to be capable of accurately dispensing the accurate quantity of liquid for every stick pack, guaranteeing uniformity and preventing any occurrences of excessive or insufficient filling. The focus here is on precision.

Sealing Process: Furthermore, it is vital to consider the process of sealing. Effective sealing is crucial for preventing leakage and maintaining liquids' freshness. No matter if the sealing is done by heat or ultrasonic sealing, it is required to have the systems that can make the firm and secure seals that can withstand the problems of transportation and handling.

Flexibility: The other crucial aspect to think about is the flexibility. You desire a machine that can easily adjust to different pack sizes, filling volumes, and packaging materials. The capacity to make immediate modifications guarantees the smooth functioning of your manufacturing process and empowers you to meet diverse consumer requirements.

Training: Training is crucial, without exception. To ensure optimal functionality, your operators must comprehensively understand the complexities of these devices, encompassing their operation, troubleshooting, and maintenance.

Therefore, those are the precise criteria for operating a liquid beverage multi lane stick packing machine. You can quickly manufacture accurately packaged beverages by acquiring the necessary equipment and expertise.

9.How Does Liquid Beverage Multi Lane Stick Packing Machine Different From The Liquid Beverage Single Lane Stick Packing Machine?

Liquid Beverage Multi Lane Stick Packing Machine |

Liquid Beverage Single Lane Stick Packing Machine |

Both types of machines, single lane or multiple lane liquid beverage stick packing machines, are used to pack liquid beverages. Although both have their own type of significance they are slightly different from each other as represented below.

| Liquid Beverage Multi Lane Stick Packing Machine | Liquid Beverage Single Lane Stick Packing Machine |

| COST | |

| This machine will charge you extra cost in contrast to single lane liquid beverage stick packing machine. | It is less expensive than the liquid beverage multi lane stick packing machine. |

| PACK FORMATION | |

| This machine with multiple vertical configurations use several lane stick packing machines when forming stick packs. | This machine will form stick packs in a single vertical configuration. |

| RATE OF PRODUCTION | |

| The production rate is much higher in liquid beverage multi lane stick packing machines. | This machine shows a lower production rate as compared to a multi lane packing machine. |

| SIZE OF THE COMPANY | |

| This machine requires a larger surface area, so it is suitable for industries with more surface than small industries. | This machine could be a better choice in the small to medium size industries. |

10.What Are The Technical Features Of A Liquid Beverage Multi Lane Stick Packing Machine?

Technical Specification of the liquid beverage multi lane packing machine

The liquid beverage multi lane stick packing machine is a powerhouse of precision and productivity, a symphony of innovation. Now, let's go into the technical features, where every detail is the reason for its attraction and efficiency.

| Technical Features | Specification |

| Machine Weight | Maximum 900 Kg. |

| Maximum Film Width | Maximum 520 mm. |

| Maximum Film Roll Diameter | Maximum 320 mm. |

| Power Supply | 220 V, and 50 Hz or 60 Hz. |

| Number of Lanes | 1 to 12 maximum |

11.How Do You Improve The Efficiency Of A Liquid Beverage Multi Lane Stick Packing Machine?

Machine use to pack liquid beverage

Increasing the effectiveness of a liquid beverage multi lane stick packaging machine necessitates modifying numerous aspects of its operation. Here are a few tactics for you to think about:

Control of Quality

Use strong quality control techniques to reduce manufacturing flaws and machine outages caused by faults or clogs. Verify that each element fulfill quality specifications.

Production Planning Optimization

Create effective production schedules to reduce downtime and increase throughput. Reduce delays by coordinating the delivery of packaging supplies and liquid ingredients.

Training of the Employees

Confirm that machine workers have received acceptable training so that they know how to handle the equipment, how to troubleshoot it, and what anticipatory actions to take. Expert operators can reduce downtime by rapidly detecting and fixing issues.

Robotic and Integration

To remove human error and streamline operations, look into automation options. Mechanizing material management, filling, sealing, and labeling procedures can result in important competence aids.

Data Gathering and Analysis

It will be aided by the use of sensors and monitoring systems to track key performance indicators (KPIs) such production rate, downtime, and error rates. Analyze the data to identify obstacles and regions that could use upgrading.

Improved Packaging Design

Work with packaging professionals to develop designs that maximize stick packing machine productivity. Consider factors such as operating convenience, sealing integrity, and material compatibility.

Constant Improvement

Encourage your organization to adopt a continuous improvement culture. Encourage employees to submit proposals for increasing productivity, and then put them into action based on feedback and analysis.

Conservation of Energy

To minimize heat loss, construct insulation and variable speed drives, as well as purchase energy efficient gear.

Manufacturer Interaction

Close collaboration with suppliers is required to ensure the timely delivery of consumables and spare parts. Building trust with suppliers might help to prevent downtime caused by component shortages.

12.How Do You Troubleshoot The Common Errors Of A Liquid Beverage Multi Lane Stick Packing Machine?

Handling of liquid beverage multi lane packing machine

Unexpected difficulties can delay production and cause problems later on. However, a methodical strategy is employed to detect and resolve such issues. The solution and troubleshooting for this machine are discussed below:

Problem and its solution

| Packaging Film Mis Feeding | |

| Problem | Solution |

| The packaging film is not tracking correctly to the forming, filling, or sealing components. It is caused by inappropriate film tension, obstruction, or jamming along the passage of packaging film. Improper alignment of guides and sensors contributes to this problem. | Assess the film tension to guarantee it is not excessively tight or loose. Clearing the barrier in the film path also resolves the issue. Align the sensors and guides properly based on the measurement of the film. |

| Ineffective Sealing | |

| Problem | Solution |

| The stick packs' sealing is inadequate because the two film layers are not well bonded. This issue is frequently caused by an inappropriate temperature and pressure. This poor sealing issue is also caused by dirty or worn out sealing parts. | This problem can be readily resolved by maintaining adequate temperature and pressure. The sealing temperature and pressure should not be excessively high or low. This issue can also be resolved by repairing old sealing bars and cleaning them well. |

| Unreliable Fill Quality Management | |

| Problem | Solution |

| There may be variations in filling volume or weight. This problem is caused by out of calibration filling systems; however, air leaks in the system may also create this issue. Inappropriate fill quality can also be caused by inappropriate pump device settings. | This difficulty is rectified by tuning the filling mechanisms, which then precisely distribute liquid beverage in stick packs. Checking for and repairing air leaks also solve this problem. This problem can be solved by resetting the machine's specifications. |

13.What Are The Main Tips For Selecting The Best Liquid Beverage Multi lane Stick Packing Machine?

Stick packed of liquid beverage

Selecting a liquid beverage multi lane stick packing machine might be challenging due to their wide variety. This is a result of the various manufacturers and the variations in characteristics among the devices. When buying a stick packaging machine, take into account the following factors:

| Rate of Packing | This is how many stick packs you plan to produce in a certain amount of time. Stick packing machines with multiple lanes yield a higher packing rate compared to those with only one lane. |

| Hopper Capacity | Verify that there is sufficient product in the hopper to prevent repeated refills. It will save time when packing if you do this. |

| Type of Seals | Either fin seals or lap seals can be produced using this machine. The two outside edges of a lap seal will overlap, creating a flat seal. Fin seals will create a seal that resembles a fin by joining the inner sections of the outer borders. Lap seals use less material and provide an attractive appearance. |

| Requirements for Quality | Stick packaging machines that satisfy global standards should always be used. This is to protect the products' and operators' safety. Additionally, it guarantees the marketability, efficacy, and dependability of the production process. |

| Body Material | Select durable stainless steel stick packing machines. This ensures that it works properly and endures a long time. |

| Filler’s Type | One can equip a stick packing machine with a liquid pump filler, volumetric filler, or auger. Select the one that best meets your needs for production. |

| Financial Resources | Your available funds will affect the kind of stick packing machine you can purchase. But always make sure the machine you select can meet your needs for manufacturing. In addition, inadequate financial means could lead to subpar packaging. Comparing the budget estimate with financial requirements and opinions is crucial. |

| Level of Technology | Advancements in technology are ongoing. The efficacy of a stick packing machine is dependent on the degree of technology employed. Technology also makes it possible to produce superior stick packaging. |

| Efficiency | Consistently choose a stick packing machine that produces excellent packaging outcomes. |

Conclusion

In conclusion, this full guide on the liquid beverage multi lane stick packing machine has been created to provide you with all the information on the features, advantages, and factors that will enable you to choose the best model in 2024. This up to date machine is a necessity for any packaging line, thus, the packaging process will be more efficient and accurate. Its ability to run several lanes at once will increase productivity and at the same time, it will keep the quality which will make it a cost effective investment for businesses looking to the operations acceleration. Should you be motivated to enhance your production levels, you can reach out to Allpack customer care for the most sophisticated solutions and the best professionals that will help you.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours