Multi Lane Stick Packing Machine: The Complete Buying Guide in 2025

As you can see, stick packing is commonly used in food, cosmetics, and agriculture. Have you wondered what kind of machine is used to make this seemingly ordinary stick packaging? To be honest, the multi lane stick packing machine has been applied in various industries.

If you are looking for information about the multi lane stick packing machine? You will find it right here. This complete buying guide will help you understand relevant information about the machine, including the definition, application industries, working principle, etc.

Follow my footsteps, and I will take you through the multi lane stick packing machine.

1.What Is the Multi Lane Stick Packing Machine?

Multi Lane Stick Packaging Machine

The multi lane stick packing machine, as the name implies, has several lanes, which refers to a machine that performs the task of packing some products in stick packing. This machine has been applied in many industries.

Don’t you believe it? So let’s move on to the section with this information.

2.Which Industries Use Multi Lane Stick Packing Machines?

At present, stick packing has been applied to every aspect of our lives. You must be stunned by the wide use of multi lane stick packing machines in the industries, including food, chemistry, and pharmaceuticals.

Food industry

Food Stick Packing - Sourced: globalsources

The food industry is the most widely used field of multi lane stick packing machines. You must have seen the products below.

- coffee

- milk powder

- seasoning powder

- sugar

- honey

- jerry

- chocolate powder

- oatmeal

Chemical industry

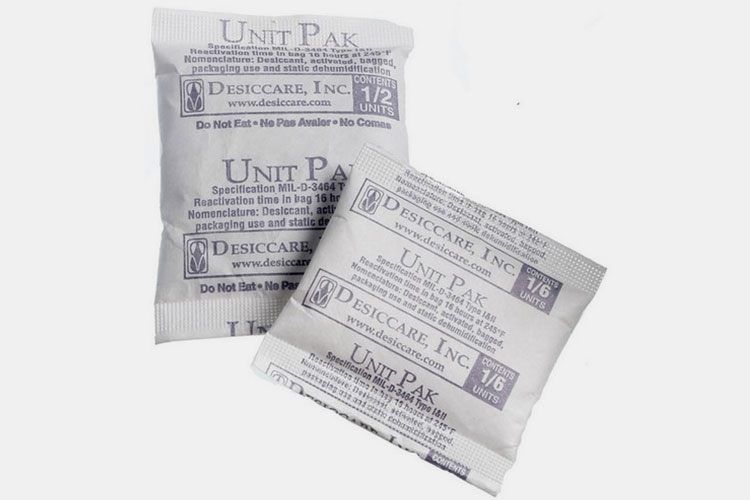

Desiccant - Sourced: berlinpackaging

Chemical materials usually need to be well sealed to prevent leakage or pollution. The multi lane stick packing machine can provide tight packaging, ensuring that products are not affected by external environment during storage and transportation. The specific products are shown below.

- desiccant

- oxygen absorber

Cosmetics and personal care products

Cosmetics - Sourced: makeup

For the convenience of customer travel or to provide trial use, many companies currently use multi lane stick packing machines. The specific products are as follows.

- lotion

- face moisture

- exposed skin care

- liquid foundation

Pharmaceutical industry

Heartburn & Indigestion Relief Double Action - Sourced: beecost

Pharmaceuticals are prone to moisture and spoilage in the market environment, which affects their efficacy. The material of the medicinal stick packaging can completely block the entry of moisture and oxygen, ensuring the effectiveness of the pharmaceuticals.

3.What Materials Are Commonly Used in Multi Lane Stick Packing Machine?

The multi lane stick packing machine can package a variety of materials, including powder, liquid, and granule in various forms.

Powder

The multi lane stick packing machine is suitable for packaging fine powdered substances such as coffee powder, milk powder, seasoning powder, and pharmaceutical powder.

Through precise measurement systems and efficient packaging processes, it can ensure that the quantity and quality of each powder pack meet the predetermined standards, providing consumers with safe, hygienic, and convenient packaging products.

Liquid

Liquid - Sourced: sciencephotogallery

Have you ever tried a small bag of coffee liquid? Do you think that is very comfortable? Actually, the multi lane stick packing machine is suitable for many liquid products, such as beverages, condiments, and cosmetics.

Through a specialized liquid filling system and sealing technology, the multi lane stick packing machine ensures that liquid materials will not leak or be polluted during the packaging process, while maintaining their original quality and taste.

Granule

Granule - Sourced: istockphoto

For granular materials such as candies, seeds, and nuts, the multi lane stick packing machine can provide fast and accurate measurement and packaging services.

Through precise control and flexible adjustment, it can adapt to granular materials of different sizes and shapes, achieving efficient and stable packaging effects.

4.Why Can You Invest in a Multi Lane Stick Packing Machine?

“What can I gain from investing in a multi lane stick packing machine?” You must ask this question. Here are some benefits of multi lane stick packing machine for you.

(1)Improving production efficiency

Improving Production Efficiency - Sourced: llumin

The multi lane stick packing machine adopts advanced automation technology, which can achieve fast and accurate packaging operations, greatly shorten time, reduce the cost of manual packaging, and thus improve production efficiency and output.

(2)Enhancing the accuracy

The multi lane stick packing machine uses high-precision measuring devices, such as motor driven screws, and electronic weighing systems to achieve precise measurement and dispensing of materials.

(3)Meeting customers’ personalized needs

Stick Packing for Liquid

With the continuous changes in the consumer market, consumers’ demand for personalized products is also getting higher and higher. The multi lane stick packing machine can be customized according to the needs of enterprises, making the packaging of products more in line with the personalized needs of consumers.

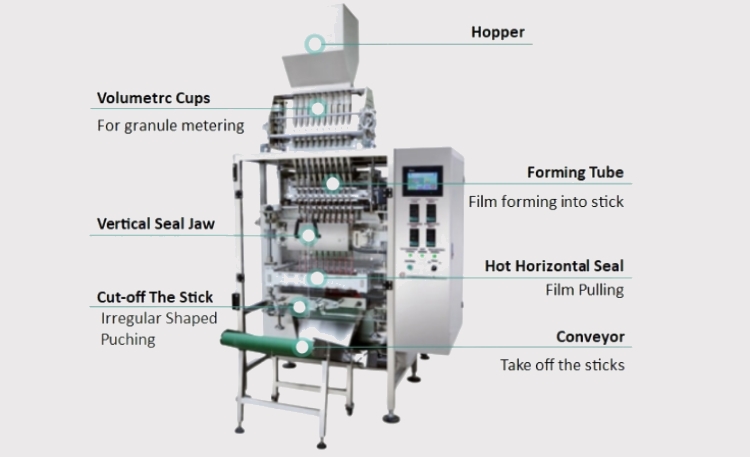

5.What Are the Main Components of a Multi Lane Stick Packing Machine?

So, what constitutes a multi lane stick packing machine? I will give you a retailed introduction of the main components of the machine.

The Main Components of a Multi Lane Stick Packing Machine

Hopper

Its design is usually based on the physical characteristics of the material to ensure that the material can flow smoothly into the forming tube. The shape and size of the hopper may vary depending on the type of material and packaging requirements.

Forming Tube

Forming Tube

The forming tube is located after the hopper, and its main function is to guide and shape the materials in the hopper into the predetermined packaging shape. The internal design of the formed tube can be adjusted as required to accommodate materials of different shapes and sizes.

Vertical seal jaw

After the material is formed into a predetermined shape through the forming tube, the vertical seal port will heat or cold seal the top of the packaging material to ensure the top of the packaging is closed. This step is crucial for preventing material leakage and maintaining packaging integrity.

Hot Horizontal seal

Hot horizontal seal is another crucial step in the multi lane stick packing machine, which seals the bottom or side of the packaging material. This step ensures that the bottom or side of the packaging is completely closed, further preventing material leakage.

Conveyor

The conveyor is another important component of the multi lane stick packing machine, which is responsible for removing packaged products from the machine and transporting them to the next stage or collection point. The design of the conveyor can be customized according to the needs of the production line, including parameters such as speed, direction and length.

Cutting Device

Cutting Device - Sourced:vikingmasek

It is responsible for accurately cutting materials during the packaging process to form a predetermined length of stick packaging.

6.How Does a Multi Lane Stick Packing Machine Work?

The working principle of a multi lane stick packing machine mainly involves the steps of continuous conveying, positioning, cutting, and forming steps of packaging materials. The following is a detailed explanation:

The Working Principle of the Multi Lane Stick Packing Machine

| Material conveying

|

The multi lane stick packing machine is equipped with a conveying system, which conveys continuous packaging materials from trays to the packaging area through conveyor belts or other conveying mechanisms. |

| Material positioning

|

When the material is transported to the predetermined position, the machine will accurately detect the edge or predetermined position of the material through positioning systems (such as photoelectric sensors and mechanical positioning pins), ensuring that subsequent cutting and forming operations can be carried out accurately. |

| Material cutting

|

When the material reaches the cutting position, the cutting device (such as a rotating blade and thermal cutting knife) will cut the material according to the preset specifications and length, forming a certain length of stick packaging material. |

| Product molding

|

If the packaging machine also includes molding function, after cutting, the machine will fold, seal or perform other forms of molding treatment on the stick material to form the final packaging product. |

| Product output

|

The formed packaged products will be transported to the output area, waiting for subsequent collection, packaging, or boxing operations. |

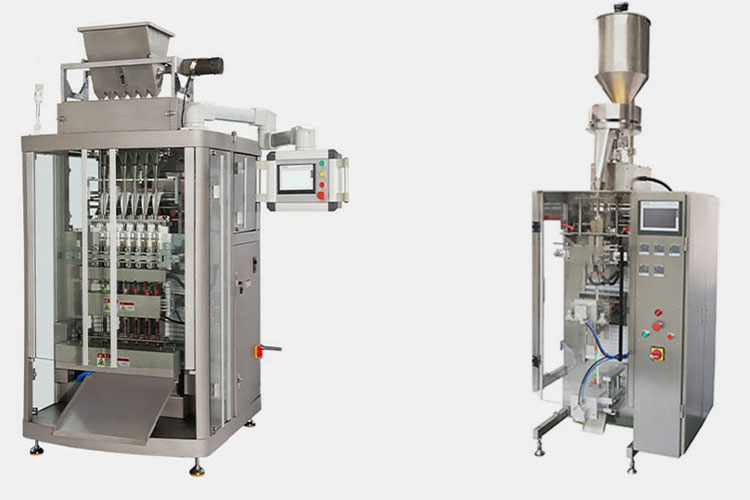

7.What Is the Difference Between the Multi Lane Stick Packing Machine and the Single Lane Stick Packing Machine?

Multi Lane Stick Packing Machine (Left) & Single Lane Stick Packing Machine (Right)

The difference between the multi lane stick packing machine and the single lane stick packing machine was reflected in several aspects, including appearance, cost and production capacity.

Appearance

From the image above, you can visually see the differences between them in appearance. The number of lanes in a multi lane stick packing machine is more than that in a single one.

Cost

Cost - Sourced: teamly

Generally, a multi lane stick packing machine costs more than a single one, due to the former has more complex processes.

Production Capacity

The common multi lane stick packing machine can produce 2-12 lanes, with a packaging speed of 25-45 packages per minute per lane.

A multi lane stick packing machine can complete the production volume of several single lane stick packing machines, thereby saving equipment space. This is a significant advantage for factories that require large-scale production and limited space.

8.What Customization Options Are Available for Multi Lane Stick Packing Machines?

Absolutely, you can customize the multi lane stick packing machine, such as the type of fillers and sealing types.

The Type of fillers

Based on different materials and products, the multi lane stick packing machines can use several fillers.

The Type of Fillers

| The type of fillers | Products |

| Liquid Fillers | liquid and paste type products |

| Auger Fillers | spices, flour, coffee, pharmaceutical powders, and powdered chemicals |

| Volumetric Fillers | non-dusty powders like sugar and salt |

Sealing Type

In addition, you can choose different sealing type, such as 3 side sealing and 4 side sealing.

3 side sealing

3 Side Sealing

3 side sealing refers to the packaging form in which the three edges of a package are sealed together. The advantage of 3 side sealing is compact packaging, material saving, and easy opening and re-sealing.

4 side sealing

4 Side Sealing - Sourced: peakmilk

4 side sealing refers to a packaging form in which all four edges of a package are sealed together. This packaging form is usually used for products that require complete sealing, such as powdered or granular food, pharmaceuticals, etc.

The advantage of the 4 side sealing is its good sealing performance, which can effectively prevent the product from being damp, oxidized, or contaminated, while also protecting the shape and quality of the product.

9.How to Choose a Reliable Manufacturer of Multi Lane Stick Packing Machines?

Trust me, in order to choose a reliable manufacturer of multi lane stick packing machine, you must go through four steps.

Reliable Manufacturer - Sourced: thenonstopgroup

Step 1: Clarify your requirements

You should clearly define the specifications, quality standards, quantities, and delivery deadlines of the multi lane stick packing machine.

Step 2: Market research

Market Research - Sourced: henkinschultz

You should conduct market research to understand the manufacturer of multi lane stick packing machines in the industry and their market positions. And then, you can visit the official website of the manufacturer to learn about their history, business scope, and production capacity.

Step 3: Comparing prices and factors of products

Comparing Prices and Factors of Products - Sourced: icon-icons

Although price is one of the factors to consider when choosing a manufacturer of multi lane stick packing machines, it should not be the only criterion. You should consider factors such as product quality, performance, service, and price comprehensively, and choose the manufacturer with the highest cost-effectiveness.

Step 4: On-site inspections

You can arrange on-site inspections of manufactures to observe the production sites, equipment conditions of multi lane stick packing machines.

And you can communicate with the management and technical personnel of manufacturers to understand their technical level, and service capabilities.

10.How Do You Increase the Lifespan of a Multi Lane Stick Packing Machine?

To be honest, the lifespan of the multi lane stick packing machines need your maintenance. Unreasonable operations will inevitably bring some problems.

Maintenance - Sourced: southernfield

If you want to increase the lifespan of the multi lane stick packing machine, you should at least do the following.

(1) Regular inspections

- You can regularly check the sensitivity of the sensor.

- You can check the electrical control circuit and the connections of each sensor and tighten them.

- All lubricated parts should be filled with sufficient lubricant to prevent parts wear.

(2) Fault handing

For common faults such as uneven or loose sealing, specific steps need to be followed for inspection and handling.

- You can check the temperature setting, it may be necessary to gradually heat up to achieve the desired sealing effect.

- You can check if the heating plate is intact, and replace it promptly if there is any damage.

- You can check if the position of the front and rear knife holders is appropriate, and clean any foreign objects in the knife holders.

For fault of the machine unable to start, specific steps need to be followed:

- You can check for foreign objects or impurities inside the machine, clean and restart.

- You can check if the electrical system is functioning properly, such as power supply, switches, and wiring.

(3) Regular cleaning

Regular Cleaning - Sourced: sunriseindustrial

The multi lane stick packing machine is a high-speed operating equipment, and long-term operation can cause dust, oil stains, and other pollutants. Regular cleaning can extend the lifespan of equipment.

12.What Is the Future of Multi Lane Stick Packing Machines?

Stick Packaging

The industry of multi lane stick packing machines is constantly pursuing efficiency, environmental protection, and intelligence, as well as responding quickly to market changes. With the continuous progress of technology and changes in market demand, the future of multi lane stick packing machines will become more diverse and innovative.

Technological development trends

The technological progress of multi lane stick packing machines will be an important development direction. With the development of automation and intelligent technology, the multi lane stick packing machines in the future may become more efficient, flexible, and able to adapt to more packaging needs.

Industry applications

Food Stick Packaging

Multi lane stick packing machines are widely used in various industries such as food and beverages, personal care products, pharmaceuticals, home care, and health products. With the continuous development of these industries, the demand for multi lane stick packing machines will also further increase.

Conclusion

Finally, we have come to the end of our guide today. I believe that you have acquired relevant information about the multi lane stick packing machines. If you have anything misunderstandings, you can consult Allpak, we will be glad to help you.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide