Ice Lolly 4 Side Sealing Machine:The Complete Buying Guide In 2025

Ice lolly is a fun treat to enjoy in summertime! I think I ought to bring some information about how intact and perfect ice lolly reaches you. Nevertheless, it has a huge series of processing which transformed flavored liquid into summer treat. Yes, you love to taste them to cool down your throat.

Once you start making their business, you can’t stop till it is final packing. An ice lolly 4 side sealing machine is what you must opt for to pack them. What kind of machine is this? How it works? Why it is essential? This is the right place where you can explore the answers to all essential queries in your mind. Let’s read and enjoy the blog!

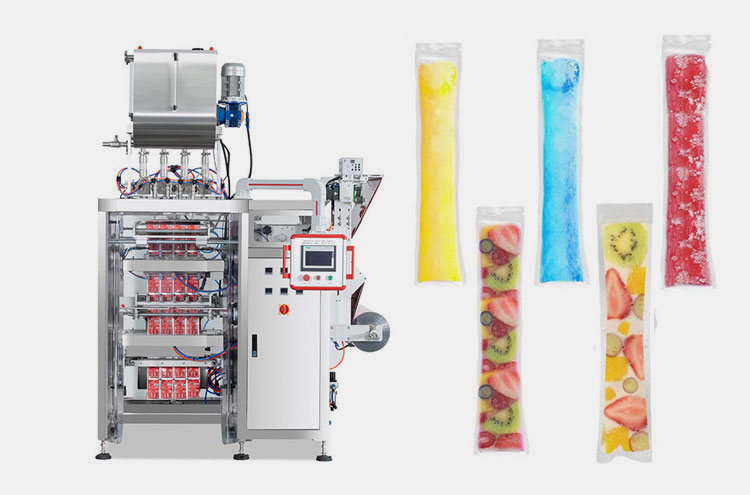

1.What is an ice lolly 4 side sealing machine?

If you want to know more about ice lolly 4 side sealing machine, then you need to dive into its details to fully understand it. It is described as a machine that uses high precision methods to seal various ice lolly into multiple packaging material which you can choose according to what you like.

By setting the sealing temperature to an optimum level, the machine seals these delicious ice lollies on all 4 sides, providing uniform covering and ensuring safe and secure packaging so that these mouth watering ice lollies can reach your doors with their original taste and flavour.

2.How is ice lolly 4 side sealing machine significant?

You might be thinking why you should invest in an equipment which would cost me money and whether it is worth investing in such. Well look no further! Because you’re about to read the huge benefits you will reap from buying this machine.

Versatile Packaging

Versatile packaging

These vibrant ice lollies can be sealed and packaged into multiple different packets of various design and colors. This will make your product more attractive and the your customers would not be able to stop themselves from buying it.

Digital Temperature Control

Digital temperature control

The machine is provided with a digital thermostatic temperature control which will seal the ice lollies on all 4 sides equally every single time. This ensures that your product will be free of any defects.

Maximum Protection

Maximum protection

One of the most important benefit you will get if you install this machine in your factory is that it will offer your ice lollies with optimum protection due to its excellent quality heat sealing rollers which will prevent any breakage of the packet.

Efficient Performance

Efficient performance

The advanced system integrated into ice lolly 4 side sealing machine allows for the automatic and precise sealing of these popsicles, allowing you to obtain thousands of sealed ice lolly packets in a single day, thus reaping huge profit margin for you.

3.Ice lolly 4 side sealing machine -Where it is applicable?

One of the best features you will find about ice lolly 4 side sealing machine is that you can use it in several industries for different products. So even if you are into more than one industry, you can install it because it will serve the same purpose. Let us discuss some of these industries below.

Pharmaceutical Industry

Medicines

If you are an industrial pharmacist, then this machine is the right one for you. It has the ability to seal various medicines and drugs in stick packs, blister packs, syringe and sachets. In this way your medicines will be perfectly sealed and protected from any harm and will reach the customer in its original form.

Food Industry

Various coffee powders

Food industry deals with multiple food items which need to be freshly packed, sealed and transported to the customer as quickly as possible. Ice lolly 4 side sealing machine can seal your fruits, vegetables, spices, meat and chicken items perfectly, so you don’t have to worry about your products getting spoiled!

Nutraceutical Industry

Vitamin supplements

Many items such as vitamins, food supplements are created in this industry and need secure packaging for their transport. So, if you install ice lolly 4 side sealing machine in your nutraceutical factory, then it will serve this purpose efficiently.

Chemical Industry

Chemical industry

If you deal with fertilizers, or substances like camphor, then you can install this equipment in your factory to seal them into various packaging, thereby protecting them from chemical degradation.

Cosmetic Industry

Cosmetic industry

Various beauty products like shampoos, creams, lotions, sunscreen and serums are packed in sachets, stick packs and pouches. Their ends can be easily sealed by ice lolly 4 side sealing machine. So, make sure you install it in you factory so that the customers can beautify themselves and become pretty!

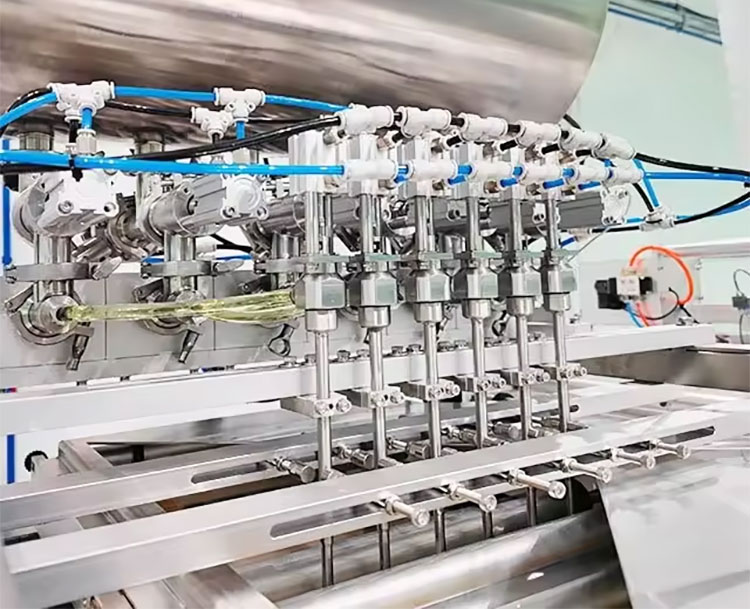

4.What is the structure of ice lolly 4 side sealing machine?

The ice lolly 4 side sealing machine is demonstrated with simple to complex structural designs required for the packing of ice lollies in the food industry. This is very essential to know about its major parts of the machine for easy operation and troubleshooting purposes. Please have a look on below picture and find important explanation about each component.

Parts of ice lolly 4 side sealing machine

Liquid Pump

To ensure a consistent flow of ice lolly formulation, a liquid pump is used. It is equipped at the topmost position of the machine which is responsible of picking mixture from the holding tank and transfer them towards lower parts of the machine for the filling purpose. A liquid pump is a promising unit that ensures you flow of the mixture is interruption-free during the processing.

HMI Screen with Rotary Swing Arm

You can put the required data and process parameters directly into the machine via HMI screen which allows you to facilitate easy and well-controlled access. This unit is also helpful in managing problems, maintenance, and process protocols.

Now you can move the HMI screen in various directions by using a rotary swing arm. This part of the machine enables you to access the screen in every direction.

Unwinding Film Guide Tension Structure

The unwinding film guide is responsible for opening the film around the film feeder ensuring that film operates via consistent supply and preventing the packing process from wrinkling or jamming.

Pulling Roller

The film roll is stretched with the help of a pulling roller via regulated ways. It is helpful in the sustaining of the alignment as well as film tension during the packing process.

Vertical Sealer

Your ice lolly packing is first joined around the edges by using a vertical sealer. The heat-sealing bars are responsible for controlled sealing to prevent unwanted leakage.

Horizontal Sealer

The horizontal sealer is responsible for the sealing of the 4 side seal pack from the horizontal side. Now your packing is 3 side seal but once it is filled with ice lollies mixture, Again a horizontal sealer creates a sealing to complete the packing around the 4 sides.

Cutter Assembly

Once the ice lolly 4 side sealing has been done, a cutter assembly role starts. It is responsible for the separation of each ice lolly pack by punching a sharp stamp cutter which evenly removes it from the chain of the ice lolly packing.

Finished Conveyor

The number of packing products leaves the ice lolly 4 side sealing machine by the help of finished conveyor that directly saves labor and time.

Foot Cups

It is useful in supporting the whole structure of the ice lolly 4 side sealing machine by offering a firm positioning of the machine that facilitates smooth working without creating vibration during the process.

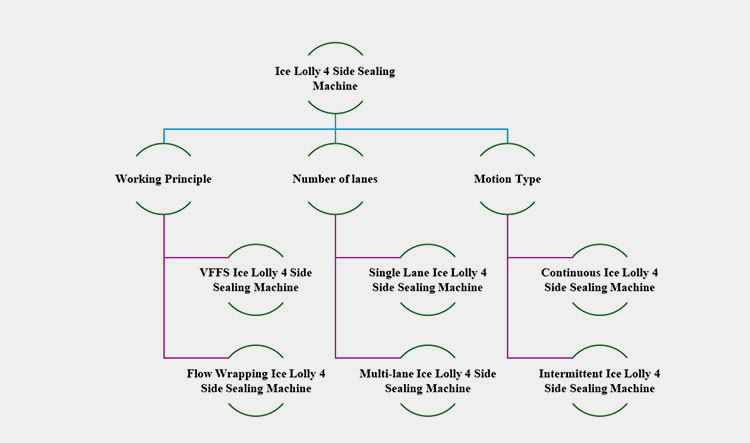

5.What is the classification of ice lolly 4 side sealing machine?

Ice lolly 4 side sealing machine is an advanced type of machine with many makes and models. This machine is divided into many types according to working principle, number of lanes, and motion type. Here we are detailing the classification of the ice lolly 4 side sealing machine for your ease:

According to the Working Principle

VFFS Ice Lolly 4 Side Sealing Machine

VFFS Ice Lolly 4 Side Sealing Machine

It is a specialized type of ice lolly 4 side sealing machine and is characterised by its vertical configuration. It packs an ice lolly in an upside-down orientation. It has forming tubes, sealers (vertical and horizontal), and cutters for forming, filling, and sealing.

Working Principle

It has an efficient mode of operation that occurs by film unwinding and transforming it into an ice lolly pouch via forming tubes. Then the filling nozzle loads the ice lolly into the said pouch from the top and finally horizontal sealer closes the top edges by heat.

Flow Wrapping Ice Lolly 4 Side Sealing Machine

Flow Wrapping Ice Lolly 4 Side Sealing Machine

It is a popular machine that gained traction over the recent years. It differs from the VFFS ice lolly 4 side sealing machine by its design and working principle. It has a horizontal mode of operation.

Working Principle

Ice lollies are loaded in the hopper by the operator or automatically. While the film load is affixed to the film holder. This film is unwound and travels to the machine. The conveyor is helpful in entrance of ice lollies into the machine for packing. The machine creates pack for positioning of the ice-lollies. Finally, sealing occurs to seal the packing forming a 4 side sealing pack. Afterwards, the finished ice lolly packaging is discharged from the machine.

According to the Number of lanes

Single Lane Ice Lolly 4 Side Sealing Machine

Single Lane Ice Lolly 4 Side Sealing Machine

It is defined by its single unit for forming, filling, and sealing the ice lolly packaging. This single lane ice lolly 4 side sealing machine has a single lane but comes in both automatic and semi-automatic modes. Its production efficiency is less due to the presence of only one lane. However, it also has its set of advantages like it usually occupies a small space and is mobile, thus it is easily moved around.

Working Principle

It wraps film materials around its bag former and forms ice lolly packaging, feeds ice lolly into the package, seals it at the top then cuts the ice lolly package from the rest of the film.

Multi-lane Ice Lolly 4 Side Sealing Machine

It has a complex body and heavy-duty build, thus it is not easily transferred from one place to another. However, it is a handy machine because of its higher output rate. This amazing machine has multiple lanes in the range of about 4-12. It is flexible, outputting different types of packaging styles with small variations.

Working Principle

It forms numerous stick packs in one cycle, fills them with ice lolly, and then seals, cuts, and discharges them concurrently.

According to Motion Type

Continuous Ice Lolly 4 Side Sealing Machine

Continuous Ice Lolly 4 Side Sealing Machine

It has state-of-the-art technology with which it forms, fills, and seals ice lolly packaging without taking any breaks. Therefore, it can produce a higher number of packaging than a simple intermittent ice lolly 4 side sealing machine.

Working Principle

Every step occurs simultaneously in the continuous ice lolly 4 side sealing machine. First, the film unwinds, travels to the bag former, folded and transformed into tubular packaging. Then it is filled with the required volume of ice lolly and the top edges are fused by heated sealer.

Intermittent Ice Lolly 4 Side Sealing Machine

Intermittent Ice Lolly 4 Side Sealing Machine

It is the latest advancement in the field of ice lolly 4 side sealing packaging. As the name indicates, it is an intermittent type of machine that takes a break after every forming, filling, and, sealing step. This useful machine has lower speed but has high accuracy.

Working Principle

It transforms a single film into numerous packs by cutting the packaging film, loading the ice lolly with multiple weighing heads, sealing the packaging at the top and then discharging filled ice lolly packs.

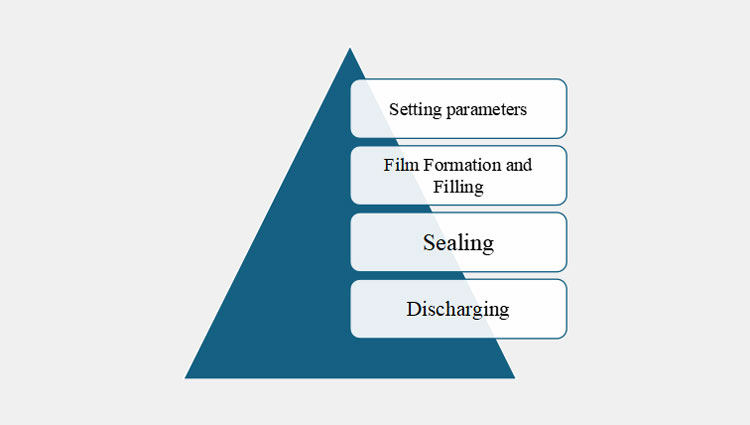

6.How does ice lolly 4 side sealing machine process?

Setting parameters

Setting parameters

Before starting the process, the machine is set to specific parameters like the sealing temperature, the size, and length of the sealing packs, the printing of the sticker, etc. After this, the machine is ready to initiate the process. The ice lollies solution is introduced to the machine where they will be filled and sealed.

Film Formation & Filling

The film roll gets open simply by circular movement of the rollstock screw which allows the movement of the film towards tube former which creates the lolly pack and fills the ice lolly solution inside.

Sealing

Sealing

The ice lollies are packaged inside the desired packets. Once filled, the heat sealing rollers seal the ice lollies by the concept of electromagnetic induction on all 4 sides of the packet by using a specific temperature.

Discharging

Discharging

Once sealed, the ice lollies are discharged from the machine where they are taken to the other side of the production line for final packaging and shipping to the supermarkets.

7.Is sealing temperature important for the ice lolly 4 side sealing machine?

Ice lolly 4 side sealing machine

Are you wondering whether sealing temperature is important enough and would you be able to ignore it if the temperature fluctuates? Well, the answer to that question is no. Sealing ice lollies at a specific temperature is extremely important with minimal temperature fluctuations. This is because if the value sways away from the desired range, your package can get broken, and your ice lollies will get damaged.

Ice lolly 4 side sealing machine only allows an error range of +- 1 C. This will ensure that your ice lolly packets are efficiently sealed and protected from any harm.

8.Does viscosity matter when using an ice lolly 4 side sealing machine?

Before installing an ice lolly 4 side sealing machine in your factory, you must know whether viscosity plays a role when packaging your ice lollies. Yes viscosity is extremely important and you need to keep it in check so that the product you are filling and packaging does not differ with every batch.

You can do this with the help of sensors given in this machine which will instruct the piston fillers to fill the ice lollies in the exact same amount and the heat sealing rollers to seal the package on all 4 sides with the exact temperature.

If in case your ice lolly recipe changes or you want to sell a different type whose viscosity is different, then you do not have to worry since the ice lolly 4 side sealing machine is equipped with real-time monitoring sensors that can easily adapt to different viscosities, providing you with cool, mouth-watering ice lollies enclosed in vibrant packaging.

9.How to maintain the ice lolly 4 side sealing machine for effective output?

Ice lolly 4 side sealing machine

There are various important suggestions that will help you in maintaining the ice lolly 4 side sealing machine in prime condition and you can be safe from unexpected downtime and avail the greater sanitation during the packing of the ice lolly.

Regular Cleaning of Your Machine

For longevity and a high-quality packing process, it is needed to standardize the hygiene of the equipment by following regular and standard cleaning of the machine.

Check the Seals and Pneumatic Components

To ensure perfect operability of the ice lolly 4 side sealing machine do regular checks of seals and pneumatic parts of the equipment.

Lubricate the Parts

Using optimal lubrication around the moving components of the ice lolly 4 side sealing machine would reduce the chances of vibration, and noise and extend the life of the machine.

Examine The Electrical Joining & Sealing Bars

Assessment of the electrical connection is essential for the optimal working of the machine preventing mishaps related to loose or worn-out connections, and inspecting the heating bars' heat regulation for suitable output.

Check The Film Roll

This is essential to check the loading of the film roll is correct and free from errors or compromised quality.

Conduct Regular Calibration

Regular Calibration is always helpful in attaining an accurate and consistent packing throughput. Therefore, you should always and regularly conduct the machine’s calibration to prevent unexpected downtime.

10.How do you manage basic problems with the ice lolly 4 side sealing machine?

Troubleshooting, preventative maintenance, and effective problem-solving tricks are needed to manage the ice lolly 4-side sealing machine against long-term problems. Methods for solving common issues are discussed below:

| Problems | Ways to manage it |

| Uneven Sealing

|

You can clean and preserve sealing parts. Repair worn or broken sealing parts.

Try to regulate the temperatures to propagate the heat evenly throughout the sealing temperature to improve material bonding. Ensure an adequate sealing pressure. Check that the pressure is enough to seal. Make sure the packaging material is damage-free and compatible with the sealing machine. |

| Machine obstructions | Turn off and unplug the device that is necessary to avoid accidents.

Remove trash or debris attached to seals and conveyor belts. Replace worn or damaged parts that may be obstructing. Sufficient concentration of lubricant is needed for efficiency and resistance reduction. |

| Erratic production | To seal evenly, monitor and adjust temperature, pressure, and speed.

Maintenance checks can find and fix performance issues. Maintain a supply of alternative parts to fix production issues immediately. |

11.What should you know when buying an ice lolly 4 side sealing machine?

When you are considering buying an ice lolly 4 side sealing machine, you must keep in mind some factors that will help you buy the best type. It should check all the boxes and help you in running your business with maximum benefits. Some of these factors are discussed below.

Production capacity

When you go to a company to buy this machine, you will see that there are multiple types ranging from automatic, and semi-automatic, single lane to multi-lane ice lolly 4 side sealing machine. Depending on the scale of your business, you should buy the type that would cater to your production capacity requirements.

Temperature control

Ice lolly 4 side sealing machine

This factor is extremely important, and you should never compromise on temperature control. You should only buy machine which can seal till a temperature of 300 C and only allows error range of +- 1 C. This will ensure that each of your sealed ice lollies is accurately packaged without any defect.

Different flavor options

Ice lolly 4 side sealing machine

Ice lollies come in various different flavors. They can be made from apples, strawberries, mango, bananas, berries etc. Due to this, your ice lollies can slightly differ in texture and viscosity. So, you should choose a machine which can easily adapt to these different requirements with ease.

Low maintenance cost

If you want to save your money, then buy only those ice lolly 4 side sealing machine that are low in maintenance. This way you can use your money by investing in a different section of your production line.

Conclusion

After reading the post, you will be pretty sure that your time and money really matters! An ice lolly 4 side sealing machine is promising equipment that is capable of saving your time and money by providing improved quality packing without requiring extra effort and investment. If you want to purchase the machine, we would like to welcome you to contact our team to avail a complete guidance related to equipment and delivery of the product at your doorstep. Our customer guidance team is here to help you 24/7. Let’s try our services now. Happy shopping.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide