Back Sealing Granule Packing Machine: The Complete Buying Guide in 2025

Do you produce, manufacture, or process granular goods like grains, or seeds? If so, have you faced difficulties in packaging these items effectively and quickly while preserving the integrity of the product and reducing waste? Are you looking for a packaging solution that can improve your production efficiency and optimize your workflow while maintaining the freshness and quality of your products?

Finding the best packaging solutions is crucial in the fast-paced world of production and processing where accuracy and efficiency are key components. Introducing the back sealing granule packing machine, a vital component of contemporary production lines transforming the global packaging and delivery of granular products to customers.

However, what precisely makes these devices so essential? Let's explore the complex network of factors, difficulties, and advancements that influence granule packaging.

This article will delve into the comprehensive understanding of the back sealing granule packing machine.

1.What do you mean by back sealing granule packing machine?

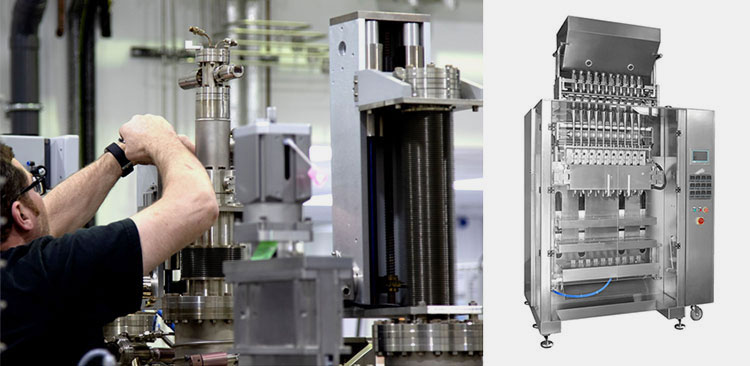

Back Sealing Granule Packing Machine

The back sealing granule packing machine is a specialized industrial equipment designed to package granular products efficiently, such as seeds, grains, or pellets. “Back sealing” refers to the method of sealing the packages. In this type of machine, the packaging material is transformed into a pouch, and the ultimate sealing is done along the back of the sachet, forming a secure seal.

2.Which industries can utilize the back sealing granule packing machine?

Various industries have adopted the back sealing granule packing machine for the secure packaging of multiple granular materials. Some common industries include:

Food Industry

Applications of the Back Sealing Granule Packing Machine in the Food Industry

The food industry is on top in utilizing the back sealing granule packing machine. Most of the food grains are popularly enclosed in a variety of packages by this device. Moreover, there is an increase in the demand for one-time servings of different granular products, which can be packaged into one-time-use packs.

The back sealing granule packing machine can handle and process several granular food articles, the most common items include tea, coffee, salt, sugar, grains, seeds, nuts, and spices like pepper.

Healthcare Industry

Applications of the Back Sealing Granule Packing Machine in the Healthcare Industry

Various granular drugs are effectively packaged into different sachet packs using back sealing granule packing machine. This device guarantees accurate packaging of individual drug doses into sachets or pouches, sustaining consistency in dosage and ensuring patient compliance and convenience.

Chemicals and Agricultural Industry

Applications of the Back Sealing Granule Packing Machine in the Chemicals & Agricultural Industry

The chemical industry is another sector that can utilize the back sealing granule packing machine for precise and hygienic packaging of various granular chemicals, such as pesticides, fertilizers, detergents, pigments, and agrochemicals.

Additionally, in the agricultural sector, the device can be used to enclose different seeds into packs, including flower seeds, vegetable seeds, etc. The device ensures effective packaging of products, preventing them from moisture and contaminants.

Cosmetics Industry

Applications of the Back Sealing Granule Packing Machine in the Cosmetics Industry

Another popular sector that can make use of the back sealing granule packing machine is the cosmetics industry. Various granular cosmetic items can be packaged accurately by this device. Cosmetic products such as bath salts, bath bombs, face masks, and scrubs often contain granular ingredients.

The back sealing granule packing machine packages these products into individual pouches, ensuring easy and hygienic applications for customers.

Veterinary Industry

Applications of the Back Sealing Granule Packing Machine in the Veterinary Industry

In the veterinary sector, granular animal feed materials are effectively packaged into secure packages using a back sealing granule packing machine, maintaining the freshness and quality of items. These materials include pellets, grains, and feeds for livestock, poultry, and pets.

3.Why should you get a back sealing granule packing machine?

If you have this question in your mind “Why should I get a back sealing granule packing machine for my industry” then you must be unaware of its incredible benefits and the value it offers. Investing in a back sealing granule packing machine can yield tremendous benefits for your business, from increased productivity and cost benefits to the consistent quality of your products.

In this section, you will find some of the vital benefits a back sealing granule packing machine can provide.

Efficient and Increased Production

Efficient and Increased Production

The back sealing granule packing machine automates the entire packaging process, resulting in increased efficiency of the process and ultimately elevating the production. It facilitates the large manufacturers to meet the market needs effectively.

Consistency in Quality

Quality Consistency

By eliminating human intervention to a larger extent, the back sealing granule packing machine not only increases production but also operates in a strict hygienic environment, resulting in the quality consistency of the materials.

Brand Value

Brand Building

You must know the fact that brands build on their quality and that’s what a back sealing granule packing machine offers. With effective and quality packaging of products, the device aids in building your brand and competes in the market.

Increased Shelf-Life of the Product

Improved Shelf-Life

Packaging of the product in a strict hygienic environment maintains its freshness and quality for a longer period and ultimately increases its shelf-life.

Easy Operation

Operational Ease

The back sealing granule packing machine is a user-friendly device and can be operated with ease, without requiring any specialized training.

Flexibility

Flexibility in Handling Products

One of the most incredible benefits a back sealing granule packing machine offers is its flexibility and versatility. It can handle granular products of various sizes and packages them effectively in multiple design packs.

Cost Benefits

More Benefits with Less Costs

The back sealing granule packing machine is a single-time big investment and it cuts down various auxiliary costs of the packaging process, including labor expenses, filling inconsistency, and resource spills/waste.

4.Back sealing granule packing machine: Describe its components and their function.

Components of the Back Sealing Granule Packing Machine

| Parts | Functions |

| Hopper | It is the topmost part of the device which temporarily stores the material to be packaged. Its size and shape vary with the models. It may have a vibratory mechanism installed to feed the product effectively to the device. |

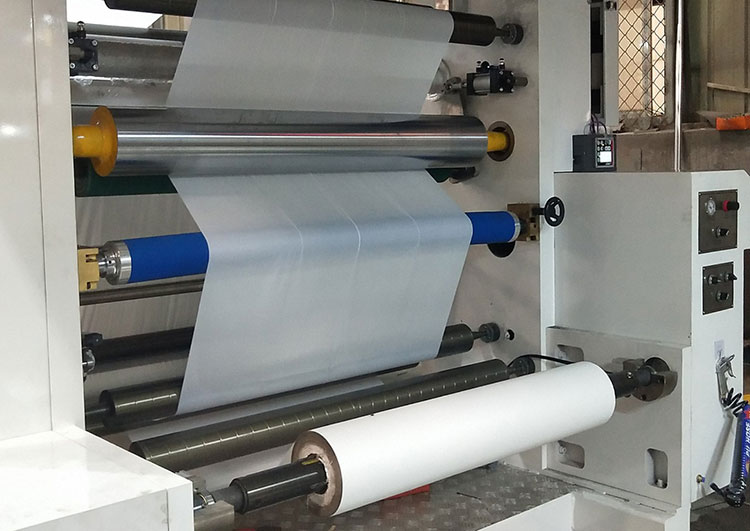

| Film | A large film roll of the suitable and recommended packaging material is placed which will be utilized for sachet formation. |

| Control Panels | There are multiple control panels installed on the device. One is the parameters adjustment control panel, used to regulate the process. The other one is the switch control panel that connects the device to the power supply required to operate the machine. |

| Clutch | It is the part that is responsible for the precise and timely cutting of the filled sachets from the continuous film. |

| Seal Modules | It consists of sealing bars or sealing clamps to effectively seal the package during the formation of packs and after filling. |

| Pouch Baffle | It is the outlet opening through which the finished packs get an exit from the device for further processing or delivery. |

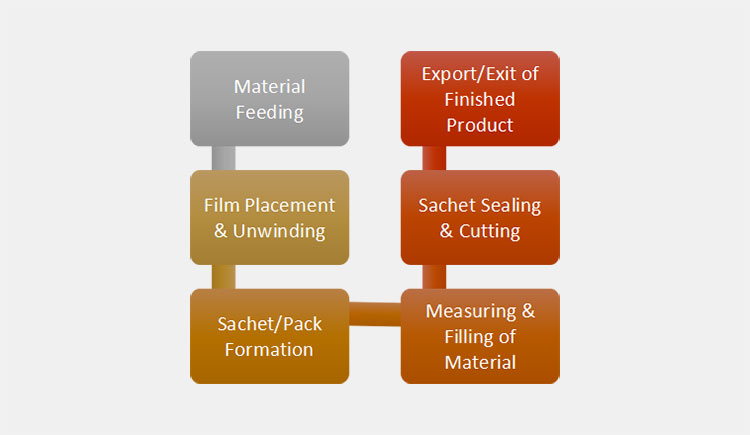

5.How does a back sealing granule packing machine work?

Working of the Back Sealing Granule Packing Machine

The working procedure of a back sealing granule packing machine is extremely convenient and user-friendly and does not require any specialized training. It has a simple operating mode and the worker only needs to adjust the process parameters.

So, let’s unleash the basic steps involved in the operation.

Operational Steps of the Back Sealing Granule Packing Machine

Material Feeding

It is the first step of the process which is either performed manually or using an automated mechanism, in this step a significant amount of the material is fed into the hopper for processing.

Film Placement and Unwinding

The next step in the operation is placing a large film roll onto the film frame appropriately. The device is started and the machine unwinds the film for sachet formation.

Sachet/Pack Formation

The film gets unwound and transformed into the desired form of packs by the shaping tubes. The film is folded and one rear edge is sealed to form a pouch.

Measuring and Filling of Material

The machine has automatic measuring and filling mechanisms. The precise amount of material is poured into each sachet.

Sachet Sealing and Cutting

After the filling, the open rear edge of the sachet is sealed, and a center back seal is also formed to ensure content security and opening ease.

Export/Exit of Finished Product

The finished sachets are expelled out of the device through the outlet portion.

6.What varieties of packs a back sealing granule packing machine can process?

The back sealing granule packing machine is a versatile device capable of handling and forming several packs and sealing them efficiently. Some common varieties of packs include:

Flat Pouches/Sachets

Back Sealed Flat Pouch

These are flat structured packs made from flexible materials and can be used to package a variety of granular products. It is usually formed in the pharmaceutical sector to package the drugs.

Stick Packs

Back Sealed Stick Packs

These are elongated sachets typically produced for packaging materials in unit doses. It is used to package various products, including certain drugs and food products.

7.Classify the back sealing granule packing machine.

The back sealing granule packing machine can be classified based on several aspects. Each one of them possesses distinctive features. So, let’s explore the different back sealing granule packing machine models.

Classification Based on Configuration

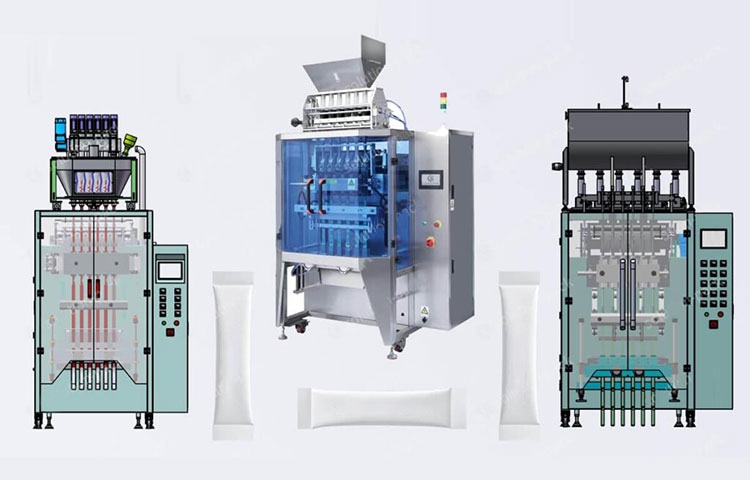

Vertical Form Fill Seal (VFFS) Back Sealing Granule Packing Machine

Vertical Form Fill Seal (VFFS) Back Sealing Granule Packing Machine

This is a specialized device that performs the packaging process automatically in a vertical direction. The device forms the package, accurately fills it, and then seals it effectively. The whole process is done from top to bottom direction.

This is the most widely employed model of the back sealing granule packing machine due to its efficiency and less occupying space.

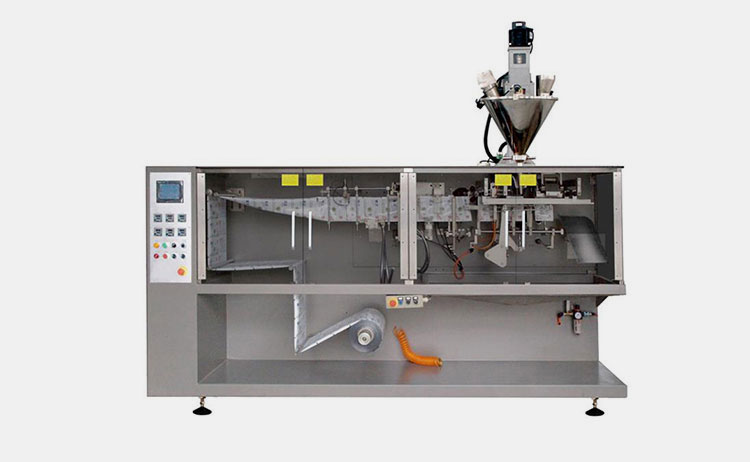

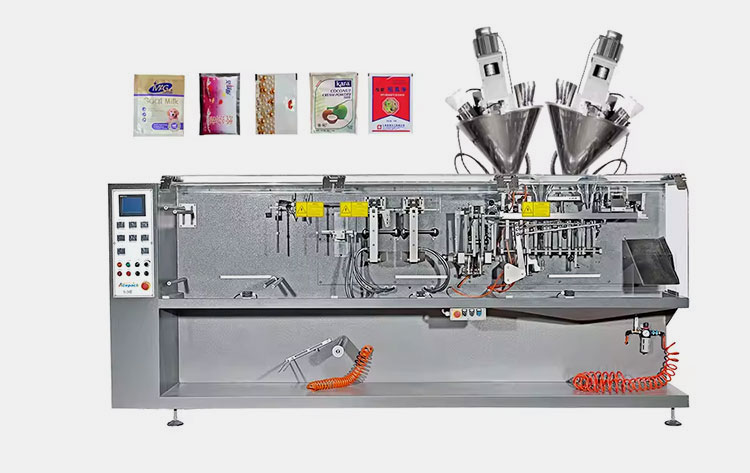

Horizontal Form Fill Seal (HFFS) Back Sealing Granule Packing Machine

AIPAK Horizontal Form Fill Seal (HFFS) Back Sealing Granule Packing Machine

This type of device is designed for large manufacturers having greater factory area as it occupies more space. It is efficient equipment processing the materials, from bag formation to filling and sealing, in the lateral direction. It allows for monitoring each processing step individually.

Classification Based on Automation

Semi-Automatic Back Sealing Granule Packing Machine

Semi-Automatic Back Sealing Granule Packing Machine

As the name suggests, it is a device that requires manual labor along with automatic processing. Some of the operational steps require a worker, such as material feeding and discharging of finished products. Other working steps are done by the machine automatically.

Automatic Back Sealing Granule Packing Machine

Automatic Back Sealing Granule Packing Machine

In this type of device, there is minimal to no need for manual labor. It only requires the operator to input the working parameters and the device then works automatically throughout the process. It is equipped with the latest technology that enhances the machine's efficiency and production capacity.

Classification Based on the Number of Lanes

Single Lane Back Sealing Granule Packing Machine

Single Lane Back Sealing Granule Packing Machine

The single-lane back sealing granule packing machine is designed to facilitate small to medium-scale enterprises that do not have extensive production requirements. This device has a single processing lane means that it produces a single pack at one time.

It is a recommended device for small operational settings but not suitable for large enterprises as it has a limited production capacity.

Multi-Lane Back Sealing Granule Packing Machine

Multi-Lane Back Sealing Granule Packing Machine

This is the advanced form of equipment that comes in multiple lanes and can process several packs at one time, enhancing the production capacity. It is a suitable device for large industries. The number of sachets produced at a time depends on the number of lanes (typically ranging from 2 to 20 or more).

Classification Based on Packaging Type

Stick Pack Back Sealing Granule Packing Machine

Stick Pack Back Sealing Granule Packing Machine

This device specifically produces back-sealed stick packs of various sizes. It can be utilized particularly in the food sector that deals with stick packs.

Pillow Bag/Flat/Sachet Back Sealing Granule Packing Machine

Pillow Bag Back Sealing Granule Packing Machine

This is the popular variant of the back sealing granule packing machine that produces granular pillow bags with effective back seals. It is particularly designed for pillow bags and is a suitable device for those who cannot afford the advanced and versatile models.

Classification Based on Filler Type

Auger Filler Back Sealing Granule Packing Machine

Auger Filler Back Sealing Granule Packing Machine

The auger filler back sealing granule packing machine has the auger filling mechanism installed. The term “auger” refers to the screw-like mechanism utilized to guide the product to the sachets. It is a popular device used in several industries due to its precise operation.

Volumetric Cup Filler Back Sealing Granule Packing Machine

Volumetric Cup Filler Back Sealing Granule Packing Machine

This type of back sealing granule packing machine utilizes a volumetric cup for measuring the ingredients and accurately filling them into the sachets. This device utilizes volumetric measurement principles to ensure uniform filling of products based on predetermined volume settings.

8.What are the Differences between a single-lane and a multi-lane back sealing granule packing machine?

A single-lane and a multi-lane back sealing granule packing machine are the two different variants available. Both of them have unique characteristics and advantages. You should know about the differences between the two and their respective features and then select the right equipment as per your needs.

Below are some of the key differences between these two variants.

| Features | Single Lane Back Sealing Granule Packing Machine | Multi-Lane Back Sealing Granule Packing Machine |

| Image |  |

|

| Number of Lanes | It contains only a single lane for processing materials. | It contains more than one lane to process materials (typically 2 to 20 or more) |

| Capacity | It operates on a single lane and thus has a limited production capacity. | It can handle a higher volume of materials and has a greater production capacity, as it operates on multiple lanes simultaneously. |

| Size | Single-lane devices are generally smaller in size and occupy less space. | Multi-lane devices occupy a significant area and have a larger and more complex structure. |

| Versatility | They offer simplicity and operational ease but may lack the versatility to handle multiple product variations. | These devices offer greater flexibility and can handle large production volumes and multiple product variations. |

| Cost | Single-lane devices tend to be more affordable and need a lower investment. | Multi-lane devices are more expensive due to their complex design and production capacity. |

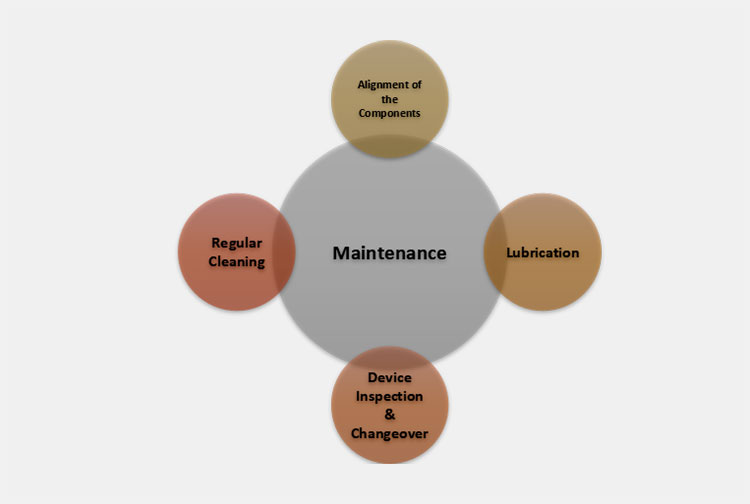

9.What are the general maintenance protocols for a back sealing granule packing machine?

Back Sealing Granule Packing Machine Maintenance

Regular maintenance and cleaning are key for keeping on top of the back sealing granule packing machine to satisfy your industry's regulatory and hygiene practices. It will also extend the lifetime and performance of the device.

Follow the following cleaning and device maintenance tips to keep it running smoothly and efficiently!

Alignment of the Components

Check all the nuts, bolts, and other components before starting the operation. Align all the components and tighten the screws so that the operation runs smoothly and efficiently.

Regular Cleaning

The managers should conduct a scheduled cleaning of the device to ensure the hygienic and efficient device functioning. Deep cleaning of the device should also be done periodically to clear the accumulated residues in any part of the device.

Lubrication

Continuous operation reduces the movement of the dynamic parts. The friction results in the delay and damage of the parts. Therefore, it is advised to lubricate the moving parts of the device regularly to avoid damage and a decline in the machine’s efficiency

Device Inspection and Changeover

Thoroughly inspect the device components for any damage or tear. Repair or replace, if necessary, the damaged components to prevent the breakdown during the working. Remember to repair or replace the parts by trained personnel.

10.How would you troubleshoot a back sealing granule packing machine?

Like every other industrial equipment, the back sealing granule packing machine can also encounter certain problems, which need to be rectified on time to avoid permanent damage, loss of resources, and breakdown. Troubleshooting is a term often used for the rectification of the issues of a device.

Here we will disclose some usually encountered problems, their potential causes, and possible solutions.

Film Wrinkling

Wrinkled Film

The film wrinkling can cause numerous problems, including improper sachet formation and machine obstruction.

Causes

Improper film placement.

Faulty dancing rollers or film frames.

Obstruction in the film path.

Solutions

Place the film in the center.

Replace the rollers or frame.

Clear the obstruction in the device.

Filling Inconsistency

Inconsistent Filling

The inconsistent filling results in the loss of resources as well as the lack of quality and uniformity.

Causes

Incompatible filling mechanism with the product being processed.

The filling nozzles or funnels may be damaged or worn.

The nozzles are obstructed.

The filling parameters are not adjusted properly.

Solutions

Ensure the right filling system for your product.

Repair, replace, or clean (as the case may be) the filling nozzles or funnels.

Adjust the filling parameters properly and cross-check them to validate.

Faulty Sealing

Defective Seal

The faulty sealing results in the product spilling during outer packing or transportation and results in the loss of resources.

Causes

Incorrect temperature or pressure adjustments.

Impaired sealing bars/clamps.

The sealing surface or film surface is dirty.

Solutions

Adjust the temperature and pressure settings accordingly.

Replace the sealing clamps.

Regularly clean the sealing surface to prevent dirt accumulation.

Inconsistency in Sizes of the Sachets/Packs

Packaging Sizes Variance

The variations in the dimensions of the packs can ultimately result in inconsistency in filling or degradation of the product’s quality.

Causes

Defective shaping tubes.

Film feeding is not smooth.

Cutting blades are dull or damaged.

Solutions

Replace the shaping tubes or cutting blades.

Ensure the proper film feeding.

11.What parameters should be considered before selecting a back sealing granule packing machine?

The packaging industry needs the top devices for product optimization. If you want to make your products more popular, one of the primary things you should consider is their packaging. So, it is evident that you need to contemplate some parameters before buying a back sealing granule packing machine.

Your Product Type

Product Type

What type of products are you packaging? Seeds, nuts, pellets, granules? Considering the shape, particle size, and state of the product will stamp out most of the options of the device.

Device Cost and Your Budget

Budget Assessment

It is usually the biggest factor involved in purchasing a device. Calculate your budget and look for the device that poises with your needs. The device cost not only consists of the investment cost but also includes the operational, maintenance, and spare parts costs.

Device Flexibility

Adaptability & Versatility

Your needs will change over time. It is therefore advised to select the flexible device, in terms of both the product and the packaging design. Anticipate the plans that must be adapted with the device, current as well as future objectives.

Technical Services

Technical Support & Spare Parts

Even the best of the devices break down. Impairment is inevitable, particularly in large manufacturing units. So, make sure an easily available spare parts supply to keep the process running smoothly.

Conclusion

It is evident that packaging is essential and plays a crucial role in various businesses by helping them deliver their goods to consumers. Quality packaging can help you build your brand through satisfied customers, in addition to accurate and rapid production. Over time, the packaging industry has expanded, and new technologies that increase its efficiency are being developed. If you are a manufacturer dealing with granular products and looking for a quality packaging device, then Allpack got you. Feel free to contact the Allpack, a reputable manufacturer of industrial equipment, for further assistance.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide