Protein Powder Stick Packing Machine: The Complete Buying Guide In 2025

Protein powder is popular among masses especially those with low level of protein growth or who want to increase their regular protein intake such as older people, kids, and athletes. In this way, range of products are being used for making protein powder in order to provide the consumers with their choice of protein powder. In similar fashion, there is a rise in demand for handy protein powder packs like single serving stick packs.

Therefore, the packaging industry is working on fulfilling this dream and has introduced the cutting-edge Protein Powder Stick Packing Machine which has gained excellence in packaging. The machine is highly versatile, adaptable, and efficient in its performance. You can employ it for meeting daily needs of protein powder stick packing. So, don't hold up and be ready to uncover the magics of a Protein Powder Stick Packing Machine in this informative review!

1.What Is Protein Powder Stick Packing Machine?

Allpack- APK Multilane stick packing machine for powder

Protein powder stick packing machine is a form, fill, and seal packaging machine specifically designed to pack protein powder into stick packs. The machine uses single layer of film, process it around a bag former and turn it into beautiful stick packs.

This machine is the creation of modern and sophisticated technology where all of its parts are controlled automatically through sensors and control system. It offers extremely convenient way for operation by displaying necessary information about the machine over control panel. Moreover, it accommodates variety in producing different packaging formats.

2.Write Down The Benefits Of A Protein Powder Stick Packing Machine?

Protein powder stick packing machine comes with substantial advantages and is very beneficial for making your business more lucrative. Underlying explained benefits are some of the prominent ones:

Robust Construction

Robust construction of single lane powder stick packing machine- Allpack

Protein powder stick packing machine is made up of high quality durable stainless steel, compact machinery and is having a concise footprint which makes it easy to mobilize. In addition to it, the transparent window of machine ensures good visibility of the product flow as well as entire packaging process without any interruption.

User-friendly

Operator using touch screen control panel- Picture Courtesy: Universal Pack

The most eminent quality of a protein powder stick packing machine is its advanced technology represented by the intuitive control system and flexible design of the machine which support easy handling. Moreover, the automatic system for cleaning with no need for parts disassembling indicates optimal accessibility of machine.

Adaptability

Various types of protein powders- Picture Courtesy: nomeatathlete.com

Adaptability and resilience are the other advantages of this machine which can be better described by its ability to support fast, easy, and automatic parts changeover. Along with this, a protein powder stick packing machine can be calibrated with different filling systems to suit eclectic needs depending upon powder properties such as auger filler, basculating filler, and volumetric filler etc.

Efficiency & Accuracy

Various collagen powder stick packs

By undertaking multiple tasks in a single run, protein powder stick packing machine can give you optimal production output while at the same time maintaining packaging accuracy and consistency.

3.Name The Types Of Packaging Material Used By A Protein Powder Stick Packing Machine?

A protein powder stick packing machine is capable of processing wide range of packaging material for forming stick packs. These are described below:

Plastic Film

Multiple smoothie powder in plastic stick packs- Picture Courtesy: kencko.com

Plastic films are the most common type of packaging materials processed by a protein powder stick packing machine. They are extremely light weighted, moisture resistant, and easily get sealed through heat. The popular plastic films being used by this machine include Polyethylene (PE), Polypropylene (PP), Polyvinyl chloride (PVC), and Polyethylene terephthalate (PET) etc.

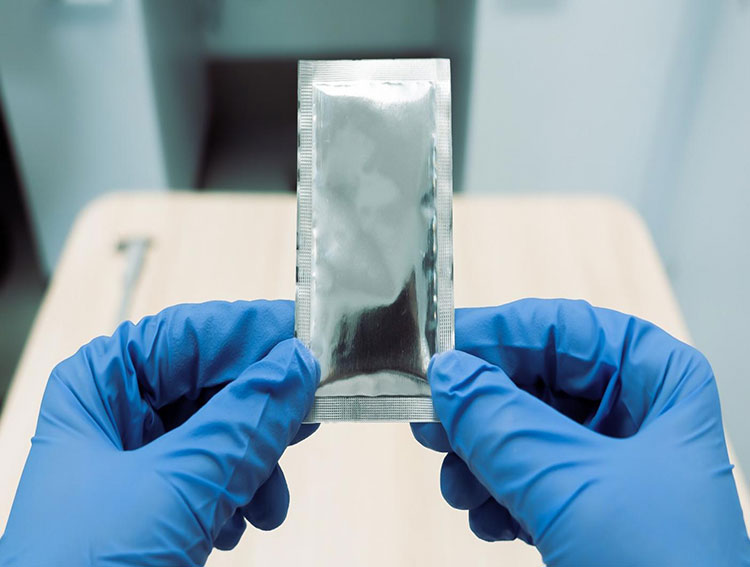

Aluminum Foil

Aluminum foil stick pack- Picture Courtesy: Universal Pack

Aluminum foil is another famous type of film used by a protein powder stick packing machine for forming stick packs. Aluminum foil has high barrier properties against light, heat as well as moisture, therefore, it is often used for products requiring longer shelf life such as protein powders, medicine powders, and food powders etc. Aluminum can also be used in multilayer with plastic or paper film to give the products additional strength.

Paper Film

Paper stick packs- Picture Courtesy: Creative Market

The third and most traditional packaging material type is paper film. Paper films are highly sustainable, environmentally friendly, and 100% compostable. However, due to their poor resistance to moisture, paper is often used along with plastic or aluminum layer for the protection of products being packed. Some common examples of paper film include kraft paper, glassine paper, and wax paper etc.

Biodegradable Films

Biodegradable stick pack- Picture Courtesy: chengyipacking.com

Keeping in view the growing environmental concerns, packaging industry has broaden the spectrum of packaging films and included in it the use of biodegradable films which greatly help in environmental sustainability by natural breakdown process. One such example is Polylactic acid (PLA) which is derived from renewable resource such as cornstarch.

4.What Popular Protein Powders Are Processed By A Protein Powder Stick Packing Machine?

There are wide range of protein powders available in market today. Each comes with unique advantages and all of them can be packed in stick packs by using a protein powder stick packing machine. These include:

Whey Protein

Whey protein powder- Picture Courtesy: alphabitamins.com

Whey protein is one of the most popular types of protein powder derived from milk. It is a great source of amino acid leucine and is considered an effective booster for muscle building.

Casein Protein

Casein protein powder- Picture Courtesy: recoveryforathletes.com

Another notable type of protein powder which can be packed in stick packs is casein protein powder. It is also obtained from milk; however, it requires a bit longer time to digest than that of whey powder.

Soy Protein

Soy powder in spoon- Picture Courtesy: superfoodies.com

Soy protein is a plant-based protein available in powder form. It is rich in amino acids, glutamine and arginine; therefore, it is considered best for uplifting immunity, digestive system and brain function. However, with some health exceptions it must be taken with care.

Egg White Protein

Egg white protein powder- Picture Courtesy: unlimited-recipies.com

It is the most popular protein powder known for its benefits especially before workout. It is simply the dried white of egg which is turned into powder. Egg white protein powder can be consumed as a meal replacement smoothie; therefore, egg white protein powder is always preferred in stick packs form for ease and convenience.

Pea Protein

Pea protein powder- Picture Courtesy: syndicatedanalytics.com

Pea protein powder is another plant-based protein powder used by anyone who is allergic to diary products. It can be consumed by pairing with other light protein powder like rice or hemp protein due to its lower amino acid possession.

Hemp Protein

Hemp protein powder- Picture Courtesy: thebircherbar.com.au

Hemp protein is made from plant-based hemp seeds and is a good source of energy for all those who want to ramp up their protein intake without building their muscles. Hence, hemp protein powder can be perfectly packed into stick packs by using a protein powder stick packing machine.

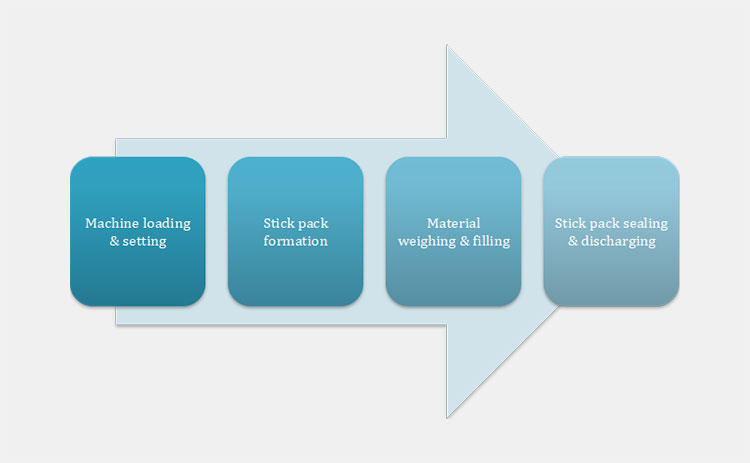

5.Explain The Working Principles Of A Protein Powder Stick Packing Machine?

The working process of a protein powder stick packing machine is faster and easier with few working principles in context. These are explained below:

Machine Loading & Setting

User setting machine- Picture Courtesy: Universal Pack

So, the process of a protein powder stick packing machine gets started with operator loading the hopper of machine with adequate amount of protein powder and placing a rollstock into film roll frame.

Once loaded, the user comes up with the associated important task of assigning the machine certain responsibilities regarding powder dosage, bag size, and sealing temperature etc., through contacting touch screen interface.

Stick Pack Forming

Stick pack formation- Picture Courtesy: Great Pack

Now, the operator will turn the machine on. As soon as the machine get power supply, motor will energize the various parts of machine including weighing system, film unwinding rollers, and heat-sealing jaws.

Firstly, the formation of stick packs will be carried out. The constant unwinding and its guiding through rollers will mobilize the film towards forming unit. Here, the film will be wrapped around conical bag former and turned into stick pack by heat sealing.

Material Weighing & Filling

Protein powder weighing & filling- Picture Courtesy: Great Pack

Upon forming, the stick packs are ready to be filled with protein powder. For this purpose, protein powder is first weighed by the machine through attached weighing system. Once, the required dosage of protein powder is weighed by the machine, it will be then poured into stick packs.

Stick Pack Sealing & Cutting

Stick pack sealing & cutting- Picture Courtesy: Great Pack

Later, the filled stick packs are moved towards sealing where a pair of heated sealing jaws come closer and create a strong sealing to the opening of stick packs. Afterwards, stick packs are separated into individual packages through sharp cutting blades.

Stick Pack Discharging

Stick packs discharging- Picture Courtesy: Universal Pack

At the end, finished protein powder stick packs are discharged from the machine through conveyor belt.

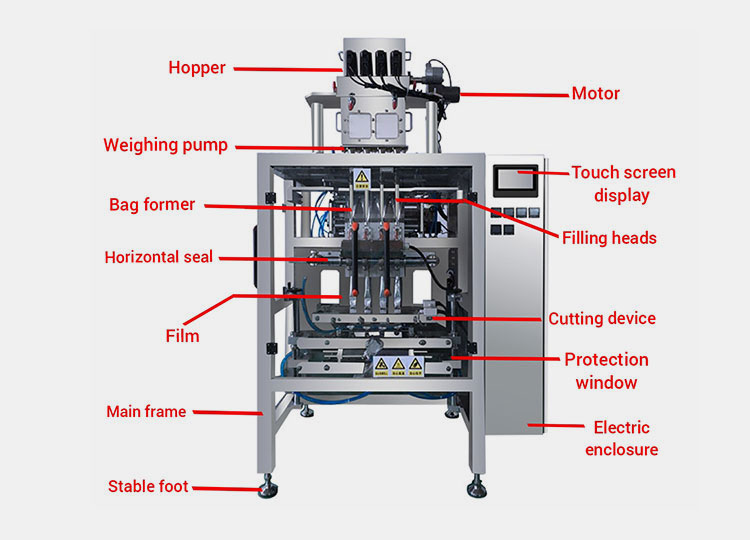

6.Describe The Structure Of A Protein Powder Stick Packing Machine?

The structure of a protein powder stick packing machine is precise, compact, and easily manageable. Its basic components are described below in detail:

Structure of Multi Line Powder Stick Packing Machine- Picture Courtesy: coretamp.com

Hopper:Hopper is a large size vacant container located on the top of machine. Its function is to hold the large volume of protein powder and gradually supply it to machine during operation.

Motor:Another important part of a protein powder stick packing machine is motor which regulates the different parts of machine when power supply to the machine is switched on.

Weighing Pump:Weighing pump is an integrated device attached to the machine. It is responsible for weighing and filling of accurate protein powder amount into each stick pack. The type of weighing pump or filling system vary according to the properties of protein powder such as auger filler, volumetric cup filler, and basculating filler etc.

Touch Screen Display:This tool is placed on the top right of machine. It helps in managing and monitoring of machine by displaying different options regarding machine functions.

Bag Former:Bag former is the core part of a protein powder stick packing machine due to its role for the formation of stick packs. It is attached with a collar on top. The conical bag former is used to wrap the film around it and turn it into uniform stick pack shape.

Filling Heads:Multiple filling heads are attached to the weighing pump which come into action for the final disposition of weighed protein powder into stick packs.

Horizontal Seal:Horizontal seal forms the top and bottom of stick packs. It seals the stick packs using heat and pressure. It works along vertical seal which is responsible to add longitudinal seal to stick packs.

Film:Film is a think layer of plastic, aluminum, laminated paper, or combination of these all. It is supplied to the machine in form of a rollstock to create stick packs.

Cutting Device:It is also known as cutting knife or cutting blade which is used to separate the stick packs before discharging.

Protection Window:A transparent window is placed around the workplace of machine for visibility and protection of ongoing process.

Main Frame:The main frame constitutes supporting structure of machine being made from stainless steel.

Electric Enclosure:It is a safety enclosure for keeping the electrical connections of machine.

Stable Foot:There are four stable feet attached to the machine which greatly helps in distributing the weight evenly on surface and avoid disequilibrium.

7.What Is The Classification Of A Protein Powder Stick Packing Machine?

Protein powder stick packing machine can be classified into two categories. These categories or types of machines are described below:

Single Lane Protein Powder Stick Packing Machine

Allpack- APK 2-220 Automatic Vertical Single Lane Powder Stick Packing Machine

Single lane protein powder stick packing machine refers to the small size, compact machine that is easily manageable and can be moved conveniently from one place to another. This machine is cost-effective while as the same time striving to fulfill your daily production targets with its automatic high-speed production of over 60 stick packs per minute.

The machine works by taking the single layer of film from roll and processing it through single conical bag former where it gets filled with protein and then passed through sealing and discharging phase.

This machine is best suitable for small to medium size industries dealing with powders such as laboratories, home based businesses, and small estates.

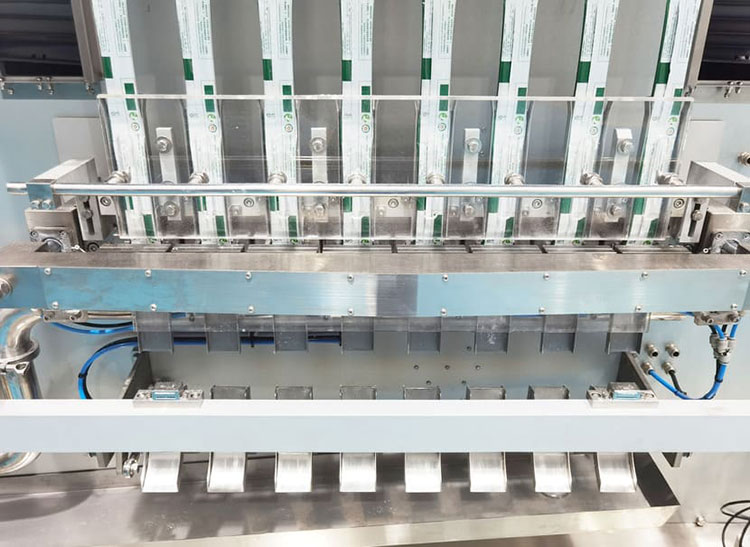

Multi-lane Protein Powder Packaging Machine

Allpack- APK Multilane stick packing machine for powder

Contrary to single lane, multi-lane protein powder stick packing machine is high power machine with multiple lanes being engaged in stick packs forming, filling, and sealing. Moreover, the machine has high output ratio. It can be found in 4-12 lanes with production output of over 500 stick packs per minute.

The working process of machine is automatic and continuous until the operator stops it or the desired number of stick packs are produced. The film is processed through multi channels, and the process end up with discharging of finished stick packs.

This type of heavy-duty machine is perfectly compatible to meet the needs of large to extra large industries in food, medical, and cosmetic sectors.

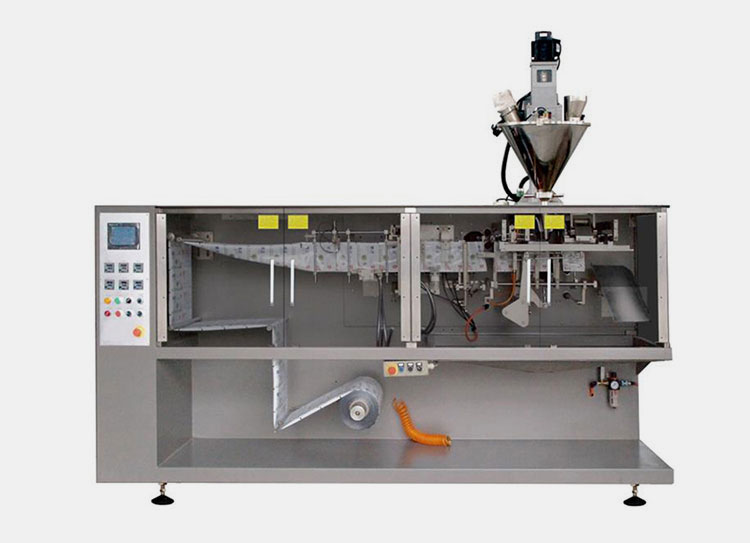

8.Differentiate Between Protein Powder Stick Packing Machine And Protein Powder Sachet Packing Machine?

Protein powder stick packing machine and protein powder sachet packing machine are both used for same purpose yet having certain differences prevailing between them. So, let's discover what these distinctions are!

| No | Factors | Protein Powder Stick Packing Machine | Protein Powder Sachet Packing Machine |

| 1 | Definition | It is a type of machine employed for creating stick packs and filling them with protein powder. | While as, this type of machine is used for packing protein powder in sachets. |

| 2 | Structure | The structure of machine is vertical body that stands up right on the floor covering less space. | In contrast, it has a horizontal structure, therefore, it covers more space than stick packing machine. |

| 3 | Working process | Its working process start from top and end at the bottom. | On the other hand, you will notice that this machine has a linear horizontal working process that start from one (left) side and get completed on the other (right) side. |

| 4 | Bag former | Its bag former is conical in shape around which film is wrapped for stick pack formation. | Contrary to that, sachet packing machine has a photocell and film guide for sachet formation. |

| 5 | Best for | This machine is best suitable for all the powders which are meant to be taken as on-the-go like protein powders, collagen powder, seasonings, coffee powder, and tea powder etc. | While as, protein powder sachet packing machine is good for products with a bit high volume such as milk powder, chocolate powder, and juice powder etc. |

| 6 | Picture |

Allpack- APK 2-220 Automatic Vertical Single Lane Powder Stick Packing Machine |

Allpack- APK-130 Automatic Horizontal Powder Sachet Machine |

9.Figure Out Are The Uses Of A Protein Powder Stick Packing Machine?

The uses of a protein powder stick packing machine are uncountable due to its adaptability and flexibility to cope up with powders of various characteristics. However, to give you a valuable but brief insight of the applications of this machine, we have highlighted some of the prominent sectors:

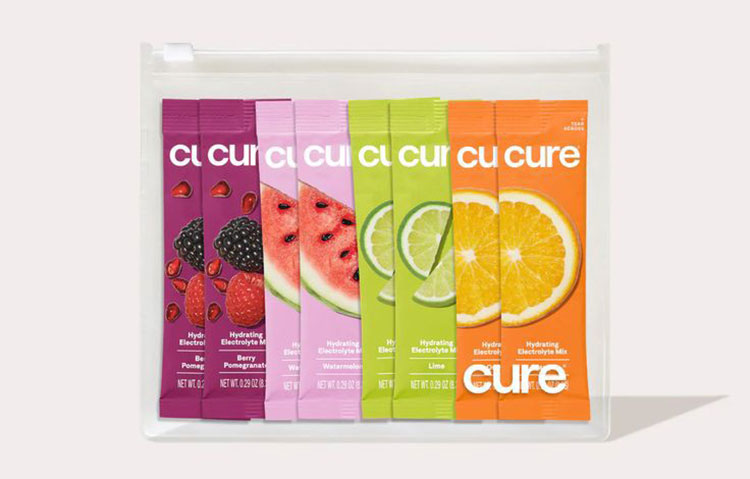

Beverage Industry

Multiple stick packs of fruit juice powder

Beverage industry is an area where products related to drinks are manufactured and processed. Similarly, these drinks are also available in solid powder form such as juice powder, energy drink powder, and milk mixers etc. To pack these beverage powders in beautiful stick packs, the help of a protein powder stick packing machine is taken.

Food Industry

Vegetable powder- Picture Courtesy: suncorefoods.com

Another comprehensive field where the presence of a protein powder stick packing machine can be found is food industry. Here, hundreds and thousands of powders including seasonings, milk powder, coffee powder, sugar, cocoa powder, and vegetable powders are processed on daily basis.

Agricultural Industry

Plant growing on soil- Picture Courtesy: World of IVY

In addition to food industry, another application of the machine is agricultural industry where the processing of powdered pesticides, soil, uracil chemicals, and fertilizers is carried out regularly. Therefore, this machine is helpful in enabling producers to pack these powders in small amount.

Medical Industry

Electrolyte mix protein powder stick packing presentation idea- Picture Courtesy: Ultima Replenisher

Protein powder stick packing machine is also playing a very significant role in medical industry to pack protein powder, calcium powder, supplement powder, and other medicated powders in stick packs.

Hardware Industry

Multiple colors plastic granules- Picture Courtesy: dreamstime.com

In hardware industry we often see the production and packaging of adhesive powders, pigments, metal powder, and plastic particulates. So, these all objects can be easily packed by using this wonderful protein powder stick packing machine.

10.What Are The Cleaning And Maintenance Requirements Of A Protein Powder Stick Packing Machine?

As long as you take care of your protein powder stick packing machine, it will never disappoint you and will be on right track. However, when you leave it to work only, it will start losing its efficiency, working quality, and packaging accuracy. So, make sure to be vigilant when it comes to the cleaning and maintenance of your machine.

Although, cleaning and maintenance methods should be described by the owner or manufacturer of machine, but still, you must show interest in undertaking the right way. In this way, we have explained a brief description. Consider it!

Operator maintaining machine- Picture Courtesy: Universal Pack

Cleaning

Before cleaning, properly turn off the machine by disconnecting the power supply.

Wear protection glasses and use a pair of gloves to keep yourself protected from debris.

Disassemble hopper, bag former, filling heads, and sealing jaws and clean them properly from all the possible accumulation of dirt and residues.

Use mild moist cloth for cleaning the machine interface, protection window, and other external components.

Maintenance

Tight all the nuts and screws of machine each time before starting operation.

Examine the components of machine during operation and identify the location if unusual noise is caused.

Check the movable parts of machine, rollers, and joints for accurate functioning and add lubrication to concerned parts for friction free functioning.

Replace the damaged and worn-out parts of machine timely to avoid further deterioration.

Regularly set the parameters of machine by resetting previous setting or regulating the saved one.

11.What Quality Standards Should A Protein Powder Stick Packing Machine Meet With?

A protein powder stick packing machine is meant to be used for food products like protein powder, meal replacement powder, and coffee powder etc. Although, it is applicable to non-food powders as well, it is obligatory for the machine to be a product of quality material. In this way, the machine must adhere to local and international quality standards to be in the line of quality equipment. These quality standards include:

Quality compliance icons- Picture Courtesy: Universal Pack

Current Good Manufacturing Practices (cGMP)

CGMP is a quality standard established by FDA to keep strict check on all the products which are direyor indirectly associated with food and drugs. Therefore, a protein powder stick packing machine complying cGMP's regulation will confirm the machine's high quality, strength, and safe hygienic condition.

International Organization for Standardization (ISO)

ISO is another organization having its presence on national and international level. It is essential for a machine to be certified by ISO to be eligible for food products.

Food And Drugs Administration (FDA)

FDA is American agency responsible for ensuring the safety, quality, and efficacy of all the goods and products which are related to food and drugs. Therefore, a protein powder stick packing machine must be certified by FDA.

Conformité Européenne (CE)

The french term Conformité Européenne translate to European Conformity which means that a protein powder stick packing machine which is meant to be exported to European Union countries or sell there, must have a CE mark over it. Hence, it is necessary for a machine to comply its rules and regulations.

12.Factors For Selecting The Best Protein Powder Stick Packing Machine?

A sea of questions starts floating in the mind when it is about to make a critical step for your business and one such step includes deciding the packing machine. Seems relatable? Then why not go for some simple factors! Let's mark important ones!

Speed

Large number of powder stick packs

When buying a protein powder stick packing machine must consider the speed of machine by questioning how fast the machine needs to be in order to meet specific production targets. It will help you determine not only the speed of machine but also your manufacturing level.

Filling System

Another significant factor is to examine the filling system which the machine is offering. For instance, whether it is volumetric cup filler or auger filler? Does it suit your current powder nature? Answering these questions will indeed be helpful for you.

Customization

Customized stick packs- Picture Courtesy: kollohealth.com

The time has gone when people used to be attached with same old things. The emerging trends are totally different where new and unique design packages appeal to the eyes in a something different way. So, make sure to check the machine's customization and adaptability to create variety of stick packs.

Cost

Estimating cost- Picture Courtesy: euronews.com

When you are on brink of revolutionizing your packaging mode, it is always suitable to pay attention to the expenditure this purchase will cause in both short and long term. It simply means to estimate the collective cost of machine which will include the original price of machine, the cost of packaging material, installation, and parts changeover etc.

Conclusion

To sum up, this buying guide about a Protein Powder Stick Packing Machine aims at identifying the machine significance in today's world and how it can bring positive change in your business. Meanwhile, you can attain further benefits by understanding its structure, functions, and applications which all are covered in this guide. So, if you are interested in purchasing a super efficient, fully automatic protein powder stick packing machine then don't forget to contact Allpack for getting the desired one! For further information visit our website.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide