Coffee Powder 3 Side Sealing Packing Machine: The Complete Buying Guide In 2025

We know- coffee makes you alert and more focused! However, you can enjoy the freshness and aromatic essence of the coffee if it is stored properly.

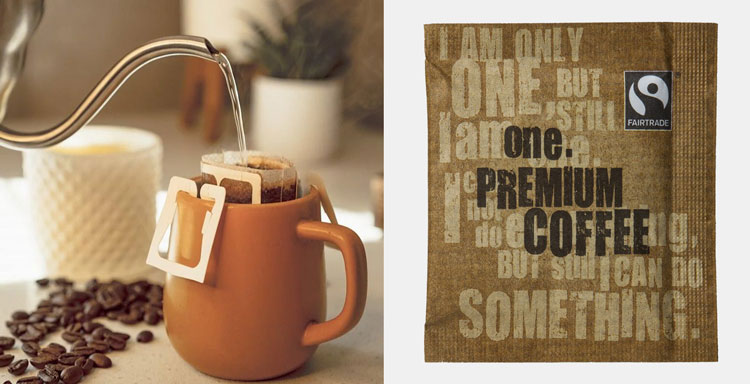

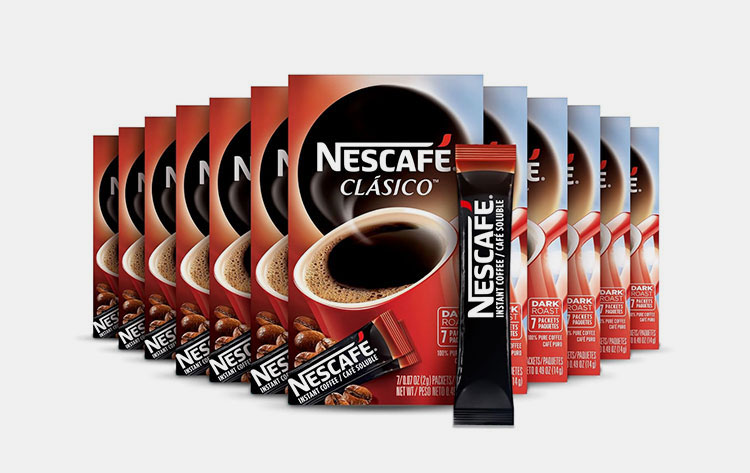

Yes, coffee powder is an absolutely magical brew you can put in a purse or bag and can carry anywhere. This is how a coffee powder 3 side sealing packing machine facilitates an amazing job as provides a small and convenient sachet efficiently.

Picture Courtesy: The Laughing Pug Coffee

Your coffee is absolutely safe if it is stored in 3 side sealing packing sachets as it helps in controlling temperature, oxygen, moisture, and other unwanted physical and chemical conditions to prevent oxidation and degradation of volatile substances of the coffee.

For all manufacturers or investors, this is a great place for you because ‘Coffee Powder 3 Side Sealing Packing Machine: The Complete Buying Guide In 2024’ is all about new and basic information related to this machine.

1.Define Coffee Powder 3 Side Sealing Packing Machine?

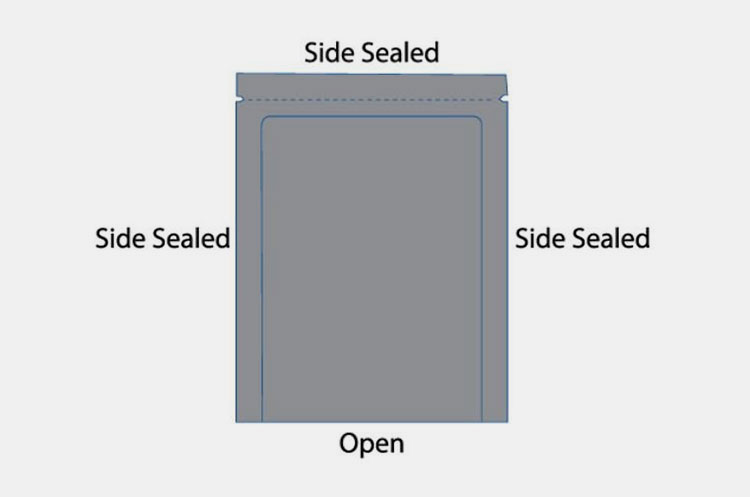

Coffee Powder 3 Side Sealing Packing

It is not possible to enjoy a cup of coffee without thanking the coffee powder 3 side sealing packing machine.

A coffee powder 3 side sealing packing machine is a great machine that helps you in creating coffee powder packs with easy filling and without mess. Coffee powder is basically stored in an airtight sealed pack to taste and look like freshly filtered coffee so it preserves a real taste which is perfect!

Well, for every brand there must be modified packs, some can be sachet, whereas some can prefer stick packs. Therefore, a coffee powder 3 side sealing packing machine is a magical equipment for you that transforms powder into great packing in a shorter time.

2.Why is coffee Powder 3 side sealing packing machine significant?

When it comes to coffee freshness which is significantly important for coffee lovers, a coffee powder 3 side sealing packing machine stands out as a game changer. This advanced technology not only has raised the quality of coffee but approaching an absolute solution to persistent technical packaging problems.

Coffee Powder 3 Side Sealing Packing Machine- Picture Courtesy: MST pack

| Specialty in Coffee Powder Packing

Not every packing machine is meant to deal with proper filling and sealing procedures. Without a coffee powder 3 side sealing packing machine, you are limited to approaching the exact format. This machine gives you all you are looking for by just adjusting the film and the touch of a button. |

Provide Fresh Coffee Powder

In the 1700s, the coffee powder was packed in the sacks which were most often a greased leather or with beeswax covering. It is replaced by a coffee powder 3 side sealing packing machine which features ait tight packing that leaves coffee powder fresh for a long time and maintains its taste. |

| Consistency

A highly programmed machine that is equipped with pre-determined specifications to approach advanced processing for coffee powder packing, so there’s absolutely no room for error that boosting your product quality. |

Safety

Safety is a real concern when using a coffee powder 3 side sealing packing machine. The process may involve powder; therefore dust may progress and often cause some issues. But, I am not saying this machine is harmful, instead, you can enjoy anti-dust features in many advanced machines to make you safe when operating it. |

| Robust & Reliable Processes

Your coffee powder 3 side sealing packing machine can run coffee powder of various flowability and textures. You can treat your packing production with a robust and reliable machine present in the market with amazing endless processing features. |

Beautiful Coffee Packing

A coffee powder holds the freshness of real constituents if packed in a controlled way. The machine has in-built air-tight sealing features that keep the coffee powder intact and preserved to give you fresh product each time. |

3.What is the working of coffee powder 3 side sealing packing machine?

The Coffee Powder 3 Side Sealing Packing Machine Working Steps Demonstration

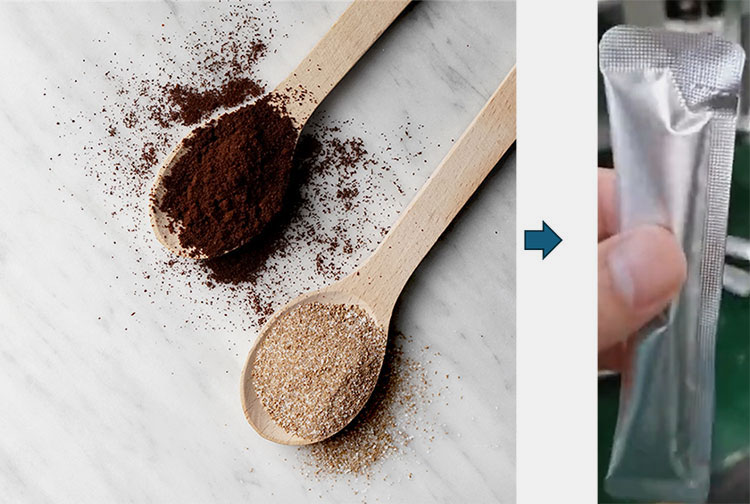

A coffee powder 3 side sealing packing machine is designed into the following major steps; I have tried to generate simple images for your understanding. Let’s check it out.

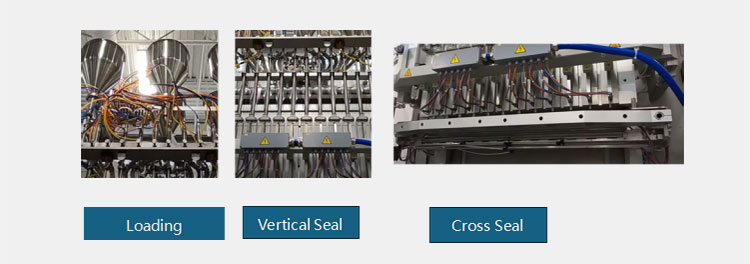

STEP-1: Loading & Filling Formation

To begin the process, you will need to fill the required materials into each specified compartment of the machine. The machine is equipped with a hopper (sometimes with hoppers), the hopper is meant to fill the lane which is presented just below and supports the material flow into each pack.

As you’re filling coffee powder, therefore the machine is fitted with an auger filler to regulate the powder material.

Illustration of coffee powder 3 side sealing packing machine- Picture Courtesy: Vikingmasek

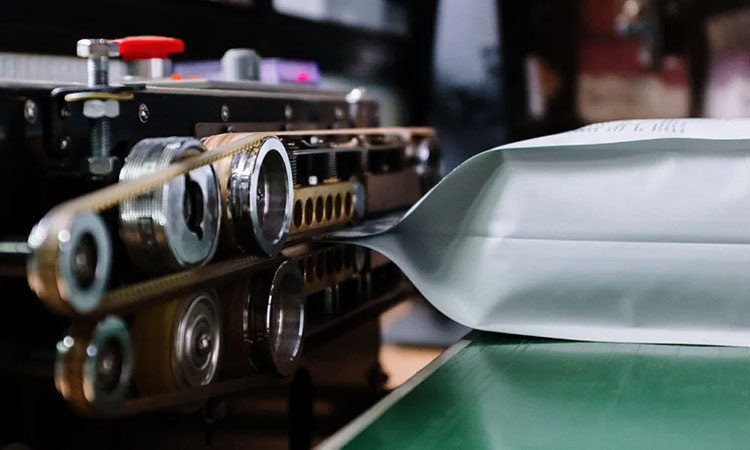

Pack Formation

The film unwinds and wraps around the former to acquire the shape of the packaging. This is mainly supported by an assembly that guides the passing of the film sheet so sealing takes place accordingly. For example, vertical and cross-seal.

Vertical seal

3 side sealing packing sketch- Picture Courtesy: Tedpc

A coffee packaging is formed into two basic sealing bars which are designed in a vertical fashion that assists in bonding the packet by pressing hot sealing bars which quickly creates a strong seal at the edge.

Do not worry about the temperatures as it is basically controlled by PLC which is fed by you depending on the requirement of the particular material you are using.

It is a precise and safe method without any deviation or heat fluctuations.

Cross- Seal

This sealing bar is designed to punch high-temperature seal using a cross-sectional or horizontal direction which offers bonding of the packaging. In this case, it will seal one end of the pack while the other seal is done after the filling of the material.

STEP-2: Filling Coffee

The lane is connected to formed packets for the coffee and is responsible for the filling of small amounts of coffee powder into packaging respectively. The appropriate concentration of the powder is filled with the help of auger filler; after the filling, another seal is done to pack the coffee powder entirely. It continues to move down toward the cutting section where sharp blades or knives remove the chain of packets one by one by punching concomitantly.

STEP -3: Pack Discharge

This is the right time when you receive a finished form packaging from the coffee powder 3 side sealing packing machine. In some machines, the user integrates a conveyor to move the subtle flow process of prepared packaging, whereas, some users load them directly in a collector and remove the containers when it fills each time.

Nowadays, you can find a new feature of weighing each prepared coffee pack at the end of the creation. It helps to obtain an accurate filled concentration of coffee prior to moving to the next stages.

4.What are the types of coffee powder 3 side sealing packing machine?

The classification of the coffee powder 3 side sealing packing machine is mentioned below:

Vertical Coffee Powder Machine 3 Side Sealing Packing Machine

Allpack 338A3 High-speed vertical coffee powder 3 side sealing packing machine

This machine is suitable for packaging coffee powder and other materials possessing free-flowing and non-free-flowing properties. With a machine you can enjoy fast, and user-friendly processing that works precisely using a vertical fashion. This means when you fit the film, its opening, forming, filling, sealing, and cutting, all functions take place using one flow which is from top-to bottom or vertical direction.

The machine has easy loading and adjustable parameters that can be run longer to achieve high productivity without downtime.

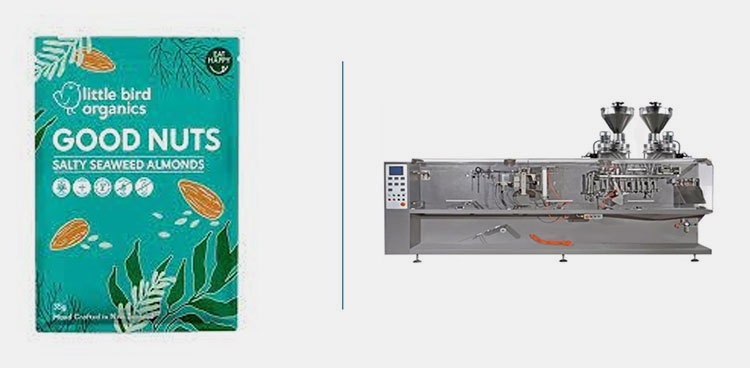

Horizontal Coffee Powder Machine 3 Side Sealing Packing Machine

Allpack Automatic Coffee Powder Machine 3 Side Sealing Packing Machine

This machine has adopted high speed coffee packaging methodology followed by rotary working system. A quick and automatic operating system that allows a shorter film formation and filling time with additional time saving features.

These improved elements allow you to operate it for large production capacities. Using this machine you to generate a single pack as well as multiple coffee powder packaging at one time.

With a horizontal coffee powder 3 side sealing packing machine you can attain high speed production which is about 400 to 1200 pack each minute.

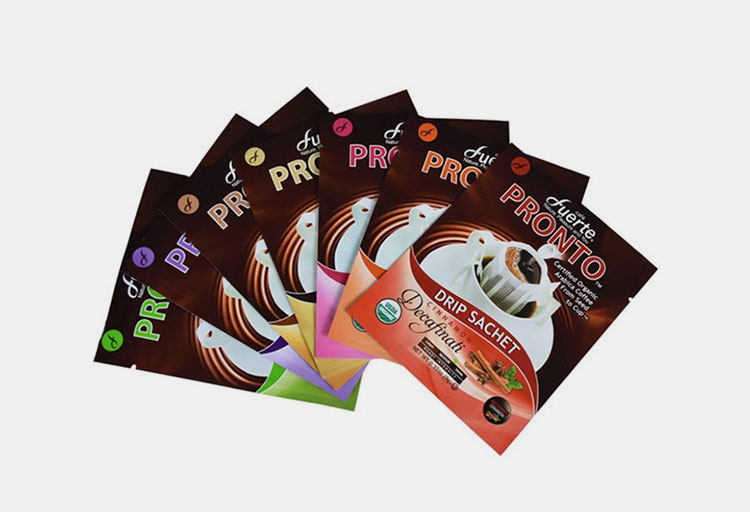

Stick Coffee Powder 3 Side Sealing Packing Machine

Coffee Powder 3 Side Sealing Packing Machine

The coffee powder 3 side sealing stick packing is an incredibly flexible solution that perfectly allows you to create coffee packaging on 3 side sealing which follows a narrow and thin formatting that ultimately looks like a stick. That’s why it is known as a stick packing machine.

This machine is additionally advanced equipment ensuring that you can attain coffee powder packing with high production capacity. This is due to its excellent design which offers multi-lane pathways for powder as well as film formation.

Single Lane Coffee Powder 3 Side Sealing Packing Machine

Allpack SN-60AK Single Lane Coffee Powder 3 Side Sealing Packing Machine

Here, Allpack is presenting an amazing and compact solution for coffee powder filling procedure. This is an economical machine which is very pocket friendly as well as user friendly.

The machine offers you automatic features and is equipped with a single lane for forming, filling, and sealing purposes. You can use this machine for other powder applications also that’s why it has broad usages.

Multi-Lane Coffee Powder 3 Side Sealing Packing Machine

Allpack Multi-Lane Coffee Powder 3 Side Sealing Packing Machine

This is a complete coffee powder 3 side sealing packing machine that provides you broad spectrum material filling range. Allpack multilane machine is equipped with several lanes for the formation, filling, and sealing of the coffee powder packs which is driven with a servo motor adopting auger filler for the filling process.

This machine comparatively provides you high production rate and ease in operation. A controlled mechanism with 100% user and environment safety is implemented by this machine.

5.What is an Intermittent and Continuous Coffee Powder 3 Side Sealing Packing Machine?

Aipak Coffee Powder 3 side sealing packing machine

The coffee powder 3 side sealing packing machine features two important working properties which are either based on intermittent or continuous principles.

An intermittent coffee powder 3 side sealing machine that follows break-ins during its operation. In this machine, after sometimes, parts halt movement after creating a particular set of packing. The movement of the film stops proceeding so sealers also stop. This machine is of high significance if when you do not require speed at regular intervals.

A Continuous coffee powder 3 side sealing machine is an essential object when you need a high speed as the machine’s reel never halts; both sealers operate continuously without the occurrence of breaks.

Well, the continuous machine offers high degree of benefits over intermittent as it is fast, can produce more sealed packs per minute.

6.Where do you need coffee powder 3 side sealing packing machine?

A coffee powder 3 side sealing packing machine is used across the manufacturing field for its excellent packing properties. The common fields of its applications are mentioned below:

Food Industry

Food industry – Picture Courtesy: Greatist

Food products always require airtight packaging and efficient materials which act as a strong barrier against moisture and those elements that affect its freshness. A coffee powder 3 side sealing packing machine ensures excellent packing of food products like tea, sugars, salts, snacks, crackers, chips, grains, and other important substances such as flavoring agents, essences, etc.,

Chemical Industry

Applications in Chemical Industry- Picture Courtesy: The Tennessean

Well, in commercial industries like chemicals which include manufacturing and packing of products such as powder detergents, powder cleaners, and anti-mold, anti-septic preparation which are single serve dispensed and marketed using coffee powder 3 side sealing packing machine.

Pet Care Industry

Pet- related products- Picture Courtesy: News Medical

A secure packing of pet related products such as supplements, antibiotics, pain killers, as well as food products like crackers, snacks, sweets, and pet grooming products are packed using a coffee powder 3 side sealing packing machine.

Agricultural Industry

The Agricultural Industry

Various agricultural field related products that are included as herbicides, insecticides, and pesticides are stored and packed in 3 side seal packs. They are most often packed in various sizes, shapes, and various random formats. A coffee powder 3 side sealing packing machine is suitable for carrying out this procedure in the agriculture industry which is why it is highly applicable in this sector.

Medicine Sector

Pharmaceutical Applications

This includes the pharmaceutical industry and pharmacies where several health related items require a safe and high standard machine for the packing of dosage forms such as powders, and granules in 3 side seal pack by using a coffee powder 3 side sealing packing machine.

Cosmetic Sector

Cosmetic Sector

The packing of cosmetic products such as powders and granules mostly requires 3 side sealing pack for suitable packing and ease of transportation. A coffee powder 3 side sealing packing machine is an ideal addition to carry these tasks under high safety standards.

Condiment and Spices Industry

Condiments and Spices

An inert storage and transporting way to keep spices, and condiments as fresh as possible is achieved by using a coffee powder 3 side sealing machine. By using this machine, the manufacturer claims that their product may remain fresh for a longer time (from 6 months to 24 months).

7.What is the structural design of a coffee powder 3 side sealing packing machine?

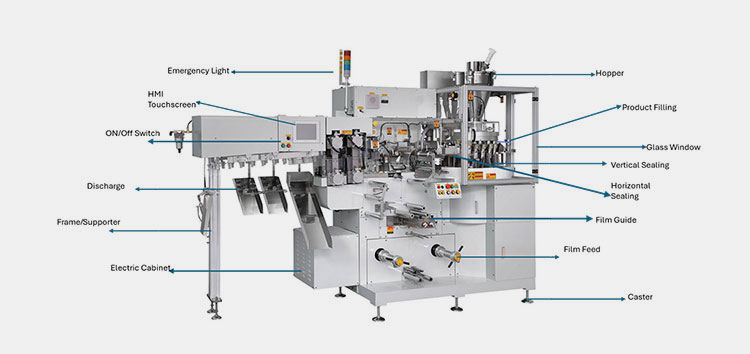

Structural Demonstration of Allpack APK-889 Ultra-high speed Coffee Powder 3 side sealing packing machine

Hopper: You can store the coffee powder in the hopper which is capable of dispensing an accurate amount of product when the machine needs its supply. A hopper is mostly accompanied by an auger filling system for powders.

Product Filling: This is composed of small funnel types of containers that weigh and fills the desirable amount of coffee powder into each prepared pack in a controlled manner.

Glass window: Your machine is promising user safety. This is meant to control the blowing of powder and maintain an anti-dust working environment additionally allowing you to visualize the process as well.

Vertical Sealing: This hot temperature controlled sealing bars are meant to join the film vertically.

Horizontal sealing: A cross-sectional sealing bar that mostly ensures sealing of packing via horizontal side.

Emergency Light: A coffee powder 3 side sealing packing machine is a safeguard equipment for you as it can sense an emergency situation and blow on the ‘red light’ to alert you prior to any mishaps. Similarly, the yellow light is for ‘alertness’ and the green light is meant for a smooth processing system.

HMI Touchscreen: A human-machine interface that allows you to feed in protocol by using an available monitor and put the keys by just clicking on the screen. It can allow you to add temperature requirements, speed of the process, number of coffee packaging, type of sealing, amount of powder and so on.

On/Off Switch: you can on and off the machine simply by using these keys.

Film Guide: These available supporting units ensure flexible attachment or placement of the film and its movement throughout the production process. It ensures that movement is seamless without jamming or wrinkling the film.

Film Feed: You can hook the film roll by using a film feed which is equipped in the front side of the machine to assure a flexible supply of the film.

Caster: During process, a coffee powder 3 side sealing packing machine never moves or vibrates., this is all because of the caster which helps the machine to stand strong and firmly with the ground. You can reposition and install the machine by moving these casters by unlocking them.

Frame: The structural firmness of the coffee powder 3 side sealing packing machine is mainly controlled by a stainless steel frame which keeps intact all the parts of the machine.

Electric Cabinet: Electrical wiring, parts, and motor is compact inside the cabinet to maintain user safety.

8.Coffee Powder 3 side sealing packing machine: How does it Keep the product Fresh in All types of climatic conditions?

Picture Courtesy: Solution Pack

Built to withstand the coffee powder or food products completely fresh and intact for a long. The coffee powder 3 side sealing packing machine has a superior design and robust construction with an excellent advanced processor that allows you the following significant features which offer the following important tasks to extend coffee powder shelf life in every climatic condition.

Air-Tight Sealing: The valuable construction of the machine ensures end-to-end and edge-to-edge sealing minimizing chances of involvement of the external physical environment inside the packaging.

Gas Flush System: As you know, oxygen might be the culprit behind the progression of oxidation and microbial growth inside the packaging. The new technique has combat this problem by introducing a gas flush system which eliminates the presence of oxygen inside packaging and preserves the product for a longer time.

Strong Barrier Packaging Materials: A coffee powder 3 side sealing packing machine is mainly utilized with materials that are mostly made up of aluminum, polyethylene, polypropylene, and nylon, which are proven to possess a strong barrier and anti-puncturing properties that keep protected against moisture as well as against external factors to keep coffee stay long and fresh.

9.How to maintain the Coffee powder 3 side sealing packing machine to extend its shelf life?

Coffee powder 3 side sealing packing machine- Picture Courtesy: Tranexteint

Once you purchase the machine, it should be your prime motive to enhance the machine’s high performance and longevity. One of the important objectives must be to keep it clean because a clean tool can simply work better and give a perfect quality coffee powder pack for further transportation and storage.

There are the following steps you should take consider for machine maintenance:

Remember to keep machine connections and energy away and it must be isolated from electrical components for your safety. First of all, check the hopper and lanes and make it dust-free by using compressed air which blows away all remaining particles inside the lanes.

Clean the sealing bars and cutting knives to offer you sharp binding and cutting output. For this, you can clean them using a cloth and brush. You should use a heat-resistant protective gloves when managing sharp and heated objects. We would recommend going through our demo videos to get aware of the machine’s parts.

The movable parts must be lubricated to make them flexible during operation. It directly extends machine life as well as improving excellent performance.

You should follow the ‘daily’, ‘weekly’, ‘quarterly’, and ‘annual’ maintenance planner to enjoy machine processing as purchased newly.

10.What Type of Bags are produced by A Coffee Powder 3 Side Sealing Packing Machine?

A coffee powder 3 side sealing packing machine is able to produce the mentioned below packaging styles making it the popular choice among the consumers.

The Popular Packing Styles by Coffee Powder 3 Side Sealing Packing Machine

The following below are the 3 side sealing packing styles generated by the machine:

|

Three Side Seals Bag with Easy Open Three Side Seals Bag with Easy Open- Picture Courtesy: PMF This is the basic formatting style produced by the machine with three side sealing packing featured with an opening notch to facilitate the consumer for flexible opening of the coffee pack. The tear notch is mostly created during the formation of the pack where a cutting die is responsible for punching a tear notch at the end of the packet. |

Three Side Seals Bag with Euro Hole Punch

Three Side Seals Bag with Euro Hole Punch- Picture Courtesy: Pouch Direct A euro hole is a punch on the top of the pack that is mainly used to hang the pack. It offers a great display by using a punching tool equipped by the machine. |

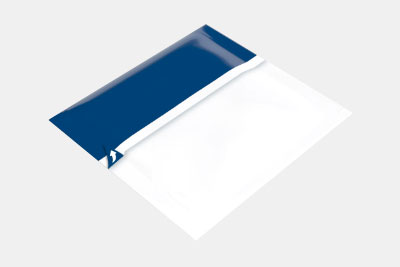

| Three Side Sealing Packing with Zip

Three side sealing packing with a zipper- Picture Courtesy: Chia HSIANG This is mostly pre-applied before pack formation which allows you to open and reclose the 3 side sealing packing, so you can use it multiple times which is mainly used for food and non-food product packing. |

Customized Three Side Sealing Packing

Customized Three Side Sealing Packing- Picture Courtesy: Chia HSIANG This machine uses a combine’s features to provide a three side sealing packing with random, irregular, or customized formatting which is used in various industrial packing. |

11.What Are the Reasons for Coffee Packing Going Bad? What Are the Possible Challenges & Solutions of Coffee Powder 3 Side Sealing Packing Machine?

Running a coffee packing business is not a piece of cake, although a coffee powder 3 side sealing packing machine has eased this challenging task, however, there are still some difficulties hooked to this processing field. What are those we have discussed below:

Insufficient sealing time

Insufficient sealing time- Picture Courtesy: mtpak

When you put the machine on high packing speed; sometimes you don’t provide a sufficient sealing time to packing therefore it progresses to leakage due to failure in the sealing and weak sealing strength which bursts the packing later and wastage your product.

How to Countermeasure it?

We would suggest improving temperature differences between films and optimizing the sealing properties of heat sealers.

Assess the sealing time for each film you use to attain high-strength sealing.

Clean the sealing bars that may cause defective sealing as residue can affect the proper sealing when uncleaned and calibrate the machine.

Seal failure caused by static electricity

Coffee powder 3 side sealing packing machine

First, understand this term, this is a stationary electric charge without the presence of any electrical applications. This is mostly caused by attractive or catching dust or unwanted particles' stickiness and may cause sparking or crackling. This can cause wrinkling of the film edges and display poor presentation.

How to Countermeasure it?

Don't worry if you are facing this problem! To prevent this issue, you can use a static eliminator that can nullify the static electricity. This is mostly attached to the machine around the forming tube prior sealing process. It keeps the process preventing against accumulation of static electricity.

Film Tension Failure

Coffee powder 3 side sealing packing machine

You have seen in our videos that the feeding unit is supported by feed screws which supply proper facilitation of the film. Sometimes it fails to do this, you can consider it as tension failure which results in wrinkling and failure of film tightness. So the packing process gets affected, producing uneven expansion of the film, and forming poor quality packaging.

How to Countermeasure it?

Adjust the feeding screws, place the film, and assemble it properly around every channel to allow easy and flexible movement during the formation, filling, and sealing process. Moreover, it is recommended to adjust the take-up shaft which helps in the movement of the film throughout the process. Correct the setting of the machine using a PLC unit.

Edge breakage

Sealing bar of coffee powder 3 side sealing packing machine

Too high sealing temperature of the machine results in the edge breakage of the coffee packing which can result in product waste as well as the quality of the packing.

How to Countermeasure it?

This problem can be avoided by determining the thermal and sealing pressure applied on the film and determining the sealing time given to the pack. You can modulate the parameters and induce the setting compatible with the film. Moreover, reduce the sealing and heating bar temperature to attain the right force and heat required by the film.

12.What are things to consider when buying a coffee powder 3 side sealing packing machine?

Coffee powder 3 side sealing packing machine

There are a bunch of valid reasons why you may consider buying a coffee powder 3 side sealing packing machine for packing coffee powder. This is not to ignore that your expanding business needs should be catered with lowering the labor cost and increasing production speed to handle the production demand. Therefore, an unreliable machine may cost you badly. There are certain mentioned factors you should consider when planning to purchase the equipment.

Gas Flushing Properties

Fresh Coffee Powder- Picture Courtesy: Naati Grain

It is the ability of the machine to flush out the presence of oxygen inside the packing that will keep the coffee powder fresh for a longer time with long lasting and the best taste ever. The coffee powder minimum recommendation is less than 2% and this should be you desired goal to select the machine that must offer flushing oxygen level to keep high-quality product.

Machine Run Rate

coffee powder 3 side sealing packing machine

When buying a coffee powder 3 side sealing packing machine, it is literally natural thought that you are not only subjecting to fulfill your demand but want to purchase the solution that must have the ability to meet expected production requirements as well. This is very important for you to estimate your long term production outcome and put investment in such a machine that can directly lead your business toward success and can fulfill your future run rate also.

Quality of the Coffee 3 side sealing packing

High Quality Product Packing

Your future machine must be capable of representing your product, your brand, and your first impression to the end -user. Therefore, you must look sealing and working features that the coffee powder 3 side sealing packing machine offers to its consumers to obtain an unobstructed process.

Gas Tight & Strong Sealant

Coffee powder 3 side sealing packing machine

No matter what formatting your machine provides you; you must look for equipment that offers you air-tight packing with firm sealing to keep your product for long periods of time and during transportation across the globe.

Conclusion

Having the support of a quick and reliable coffee powder 3 side sealing machine is an exclusive technology that can maximize your effectiveness in the production line. This is a very crucial tool that has demonstrated a huge consumer satisfaction as it provides peace of mind throughout the packing process. Allpack with a team of knowledgeable members is ready to assist you with the machine covering all the necessary aspects related to it. If you want to purchase this machine now, please contact our team! Trust me, our team members will help you to make your choice easier. Happy Shopping!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide