Suppository Filling And Sealing Machine: The Complete Buying Guide In 2025

People are of different nature with distinct proclivities, phobias, and choices in every phase of their lives. Similar is the case when they are dealing with any disease or illness but don't want to take medication in conventional oral dosage form like tablets or capsules. That's why, multitude of other ways for effective drug delivery have been introduced among which suppository is the popular one.

For their remarkable packaging a Suppository Filling And Sealing Machine is employed to deal with the intricate task of suppository filling and packaging. The fame of suppository dosage form is gaining momentum as it not only helps you to switch the drug taking way but also carry substantial benefits for your health. So, be ready to know in detail everything about a suppository filling and sealing machine!

1.What Is Meant By Suppository?

Rectal suppository with shell- Picture Courtesy: cgskincare.co.uk

Suppository is a type of solid medication dosage which is taken through the opening of human body other than oral route such as rectum, urethra, or vagina. It is characterized by round, bullet, or cone shape.

As many people find it difficult to take drugs orally, and most of the medications have adverse effects on human body when get into contact with intestinal acids, therefore, suppositories are designed to be released into body with good pace.

2.Define Suppository Filling And Sealing Machine?

Allpack- Middle Speed Suppository Production Line(U Type)

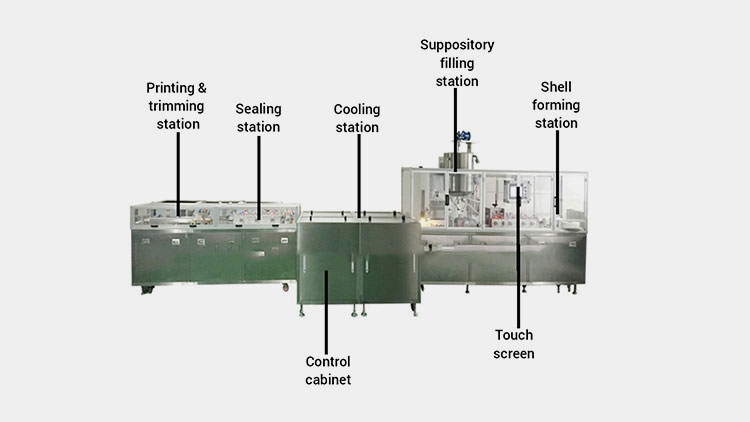

A suppository filling and sealing machine is a state-of-the-art machine employed to accomplish the function of suppository filling and sealing. The machine is an assembly of several advanced units which together form the production line for suppository filling and sealing.

This machine or production line is meant to support several steps for the finishing of suppository that encompasses shell forming, suppository filling, cooling, strip printing, and trimming. In this way, it follows an automatic processing which ultimately leads to high production, precision, and reduction of waste.

3.Enlist The Various Features Of A Suppository Filling And Sealing Machine?

A suppository filling and sealing machine come up with lots of advanced features and benefits which are enumerated below:

High Automation

High automation icon

The machine is equipped with fully automatic technology that is controlled by intuitive PLC control panel. Thus, the machine is monitored and controlled by using this touch screen. Apart from that, in case of emergency the alarm will display red light and loud noise and the machine will be stopped through emergency stop.

Production Efficiency

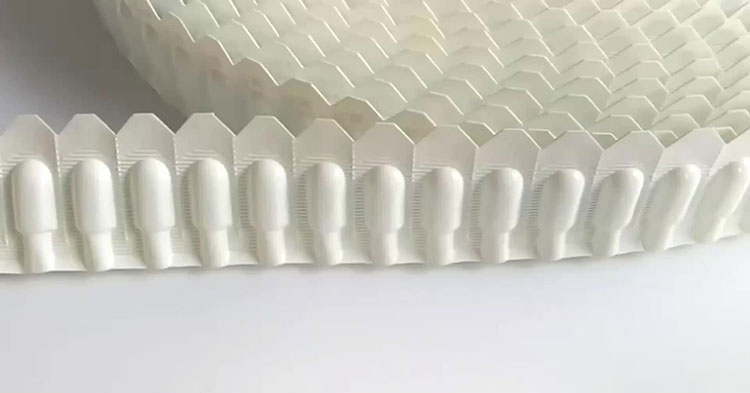

Large continuous suppository strip

Enhanced production efficiency is one of the critical advantages of a suppository filling and sealing machine. It enables you to produce up to 12000 suppository units just in an hour.

Ultimate Precision

Precisely packed suppository strip- Picture Courtesy: wellandgood.com

Precision is yet another attribute of the machine which can be seen both in terms of accurate filling and packaging. For instance, the volumetric pump filling make sure to weigh and dispense the exact amount of suppository into shells, while as, the intermittent strip packaging sections greatly help in the homogeneous packaging of suppository strips.

Low Maintenance

As the machine follows automatic way for functioning, operator is only required to set the basic parameters and monitor the process with no manual intervention. Therefore, little maintenance is needed for the machine.

Multi Tasking

Multi tasking presentation idea- Picture Courtesy: Clockwise

A suppository filling and sealing machine offers multitasking services which covers not only the suppository filling and sealing but encompasses suppository shell forming, printing, trimming, cutting, and material weighing. Moreover, it is widely applicable in multiple sectors such as food, cosmetic, and pharmaceutical industries.

Enclosed Structure

Allpack- Medium Speed Suppository Production Line(Linear)

Another most important attribute of the machine is its enclosed structure and compact body which takes only a decent floor space. Moreover, the protected window installed over the entire machine keep the inside operation intact from external environment.

4.Explain The Working Principles Of A Suppository Filling And Sealing Machine?

A suppository filling and sealing machine undertake multiple tasks due to which it has long procedure. However, this process is simple and do not hold complex phenomena if broken down into few principles as explained below:

Machine Feeding

Film roll feeding into machine- Picture Courtesy: Aipak Pharmaceutical Equipment

The very first working phase of the machine is feeding. Here, the material bucket of the suppository filling and sealing machine is supplied with liquid suppository medication and the film rolls are fed into the shell/ strip forming station.

Machine Setting

Secondly, it is significant to set the parameters of each section of the machine. It will include the speed of film unwinding device, the temperature of strip forming molds, temperature of material tank, dosage amount of suppository, cooling segment adjustment, and customization of data printing etc.

Strip Forming

Strip forming- Picture Courtesy: Aipak Pharmaceutical Equipment

When the above-mentioned steps are accomplished in a well manner, the machine is ready to be started. After it is powered on, the unwinding of film from corresponding rolls will be initiated for strip formation. The unfurled film then enters into the preheated molds where they are molded into strip by using heated blow.

Suppository Filling

Suppository filling- Picture Courtesy: Aipak Pharmaceutical Equipment

Once formed, the suppository strips will be pushed for their filling with suppository dosage. At this point, first the suppository dosage is measured by the machine through pump and then precisely filled into the empty molds or strips via filling heads.

Suppository Cooling

Suppository cooling- Picture Courtesy: Aipak Pharmaceutical Equipment

Moving forward, the filled suppository strip enter the cooling tunnel where multiple guiding rollers guide their path. Similarly, the continuous suppository strip is arranged in a way that long time is spent inside the tunnel to cool down. For this purpose, the air cooler fans disseminate the low temperature generated by the water chiller in entire cooling tunnel. Consequently, the suppository gets cool down and turned into solid state from liquid one.

Suppository Strip Sealing

Suppository strip sealing- Picture Courtesy: Aipak Pharmaceutical Equipment

In this phase, suppository strip passes by the preheated molds to get their top heated and ready for melting. Right after that, the strip is passes under the heated sealing tail which bind together the opening of strip and creates strong sealing.

Suppository Strip Printing

Suppository strip printing- Picture Courtesy: Aipak Pharmaceutical Equipment

When suppository strip gets sealed, it is printed with four lines to make a set which is then helpful in their splitting phase. The number of lines can be customized and increased or decreased as per the manufacturer needs. Along with this, an obligatory printing of information over strips such as batch no, expiration date, and manufacturing date is also realized in this step.

Suppository Strip Trimming

Suppository strip trimming- Picture Courtesy: Aipak Pharmaceutical Equipment

Finally, the extra part over the strips is trimmed by the machine by using horizontal blade. At the same time, continuous strip of suppository is bifurcated into sets. Therefore, sets of suppository strips are made via cutting.

Suppository Discharging

Suppository discharging- Picture Courtesy: Aipak Pharmaceutical Equipment

At last, when every step gets completed, the finished suppository strips are ejected out of the machine through discharge chute into a collection container or adjoined auxiliary machine for secondary packaging.

5.Describe The Components Of A Suppository Filling And Sealing Machine?

For such an extensive and sophisticated machine, it is obvious to have several parts for achieving the long process of suppository filling and sealing. Therefore, in below paragraphs, you will know the different components which makes up the suppository filling and sealing machine along with their functions:

Touch Screen

Touch screen is a human machine interface that consists of several input and output tools through which user set commands into the machine. These commands are then taken into the machine according to which the operation of machine is carried out.

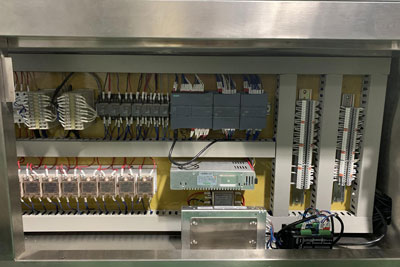

Control Cabinet

Control cabinet is a large robust body located in the base of the machine under each station. It encases all the electrical connections of the machine which are in form of wires, fuses, and other gadgets.

Shell Forming Station

Shell forming station constitute the very first part of suppository filling and sealing machine. Its main task is to form plastic shells for suppository packaging by using following components:

Film Roll:Film roll is a stock of film which may be of three types such as PVC, PE, and PVC + PE. Two film rolls are supplied to the machine for feeding the machine with material needed for creating shells.

Film Unwind Part:It includes the film roll holders and unwinding rollers which when move in rotary direction result in film unwinding from film roll.

Forming Molds:Forming molds are hollow places made in metallic device which stand parallel to each other.

Blowing System:Blowing system is the combination of heat with air system which are responsible to turn the flat film into conical or special shapes during shell formation process.

Suppository Filling Station

It is another crucial part of the machine where actual process of liquid suppository filling into shells takes place. This segment has further parts including:

Material Tank:It is a large capacity material hopper where large volume of liquid suppository medication is temporarily poured to supply machine with it during operation. Inside material tank is the stirrer and motor driven agitator whose continuous movement keep mixing the material to avoid lumps.

Filling Pump:Filling pump is a device located under the material bucket through which the amount of suppository for each dosage is measured.

Circulation Pump:Circulation pumps maintain the temperature of material in tank as well as during the suppository filling into shells.

Filling Heads:Long narrow nozzles which are attached to the hopper on top and dispense material into shells are known as filling heads.

Cooling Station

This segment of a suppository filling and sealing machine basically perform the task of cooling down suppositories by using several tools comprising:

Cooling Tunnels:There are two large cooling tunnels in the machine which provide adequate space and time for cooling down the suppositories.

Cooling Fans:Inside the cooling tunnels are fitted air cooler fans which helps in dispersing low temperature to reach every suppository.

Water Chiller:Water chiller is a device which is used to produce low temperature inside tunnels.

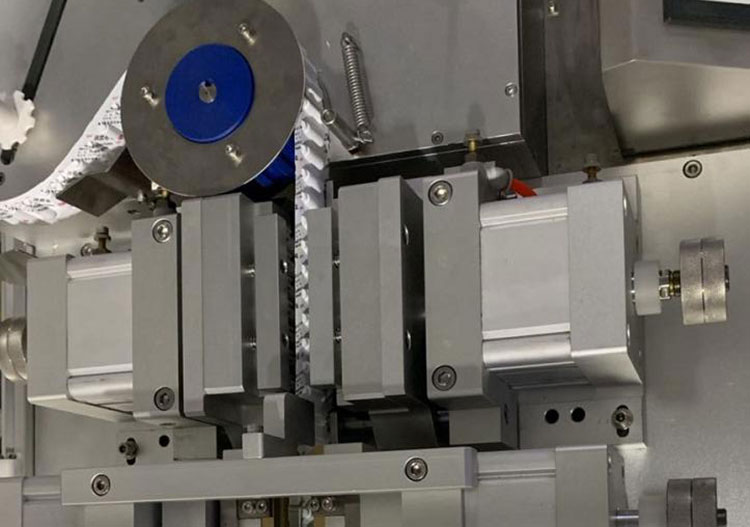

Sealing Station

Sealing or closing station is an area of the machine where the opening of filled suppository shells are tightly sealed by bringing in use the two components:

Preheating Mold:It is responsible to reheat the suppository filled strips for effective sealing.

Pneumatic Sealing box:Pneumatic sealing box is a part which create a stringent sealing over the strip.

Printing & Trimming Station

This section constitutes the last part of machine where necessary coding and cutting of continuous strip take place. It has few parts which include:

Inkjet Printer:Inkjet printers imprint the necessary information such a as batch no, manufacturing and, and expiration date over strips. It can also be customized to print line on every set of strips for desired cutting.

Cutting Blades:Cutting blades can be divided into two categories: horizontal blade which trim the additional part from the top of strip and the vertical sharp blade which split the suppository shells into sets.

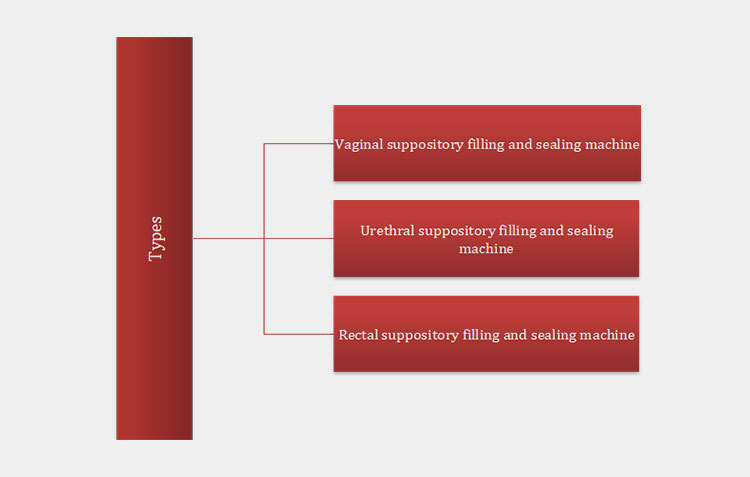

6.Are There Any Types Of A Suppository Filling And Sealing Machine?

Suppository filling and sealing machine can be classified into three types according to their function. These are explained below in detail:

Vaginal Suppository Filling And Sealing Machine

Allpack- High Speed Suppository Production Line(Linear Type)

Vaginal suppository filling and sealing machine is designed to create vaginal suppositories with its specialized features and capabilities. These suppositories get easily dissolved in vagina as a result of the warmth of body.

Specifications

The machine can make solid oval shape vaginal suppositories from liquid medication. The size of vaginal suppositories is often kept small for easy insertion and placement.

Applications

The machine deals with all kinds of suppositories which are meant for treating vagina related illness or disorders such as contraceptive suppositories made for birth control and other vaginal suppositories used for treating fungal infections.

Urethral Suppository Filling And Sealing Machine

Allpack- Medium Speed Suppository Production Line(Linear)

As the name indicates, this type of suppository filling and sealing machine is especially tailored to meet all the requirements necessary for making urethral suppositories.

Specifications

As far as the specifications of machine is concerned, so, the machine can design urethral suppositories in three distinct dosages including 250 µg, 500 µg, and 1000 µg. Apart from this, there are three dimensions followed by the machine to make conventional small size MUSE urethral suppositories which are 1.4mm diameter and 3mm to 6mm in length.

Applications

You can produce any urethral suppositories by using this machine. The common example includes alprostadil which is erectile dysfunction medication.

Rectal Suppository Filling And Sealing Machine

Allpack- Middle Speed Suppository Production Line(U Type)

The third and last type is rectal suppository filling and sealing machine, a sophisticated machine created to form rectal suppositories through its flexible functioning.

Specifications

The machine produces round shape rectal suppositories with a tip having bullet type end for quick insertion and offers 1 inch long size for rectal suppositories.

Applications

The popular rectal suppositories processed by the machine encompasses Therevac, Dulcolax and Magic bullet.

7.What Are The Uses Of A Suppository Filling And Sealing Machine?

When it comes to discuss the uses of a suppository filling and sealing machine, there are multiple sectors where the applicability of the machine can be found. So, let's delve deep into these areas and explore how they apply this machine:

Pharmaceutical Industry

Doctor holding a stethoscope- Picture Courtesy: thebump.com

Pharmaceutical industry is the most prominent sector where a suppository filling and sealing machine is popularly used for making suppository medication to treat various illnesses associated with vagina, rectal, and urethra such as fungal infection or rectal itching etc.

Food Industry

Various dietary supplements- Picture Courtesy: inspirededibles.ca

It is a matter of fact that in modern world, doctors around the globe prefer prescribing healthy drugs to patients in form of supplements which are often derived from nutrients found in herbs and food. These suppositories mostly do not have any side effects and support gentle release into body without showing any adverse reaction. Similarly, the machine can be used in food or herbal industries for making relevant suppositories.

Cosmetic Industry

Various cosmetic products- Picture Courtesy: thebeautylookbook.com

There is a debate on whether suppository filling and sealing machine can be used in cosmetic industry or not. However, these concerns have been addressed and now it is claimed that all those suppositories which are meant for cleansing, freshening, or lubrication of vagina come under cosmetic industry. Therefore, this sector is the right place for using suppository filling and sealing machine.

8.What Quality Standards Should A Suppository Filling And Sealing Machine Should Meet With?

Suppository filling and sealing machine is designed to deal with highly sensitive medication which require exceptional safety both in terms of processing material and packaging. Therefore, it is pertinent that the machine must adhere certain quality standards which will guarantee its structural integrity and hygiene with respect to material processing.

ISO certification icon- Picture Courtesy: online-tesis.com

Among these quality standards, the most popular one includes ISO which is an international standard but have presence on local level to validate the goods quality followed by GMP that is meant for determining the material quality for machine construction such as 304/ 316 stainless steel.

Apart from these, certain other certifications such as FDA, CE, and CPGP ensure that the machine you are intending to purchase is of food grade quality and will sustain the materials of various nature while preserving their sterility.

9.How To Clean And Maintain A Suppository Filling And Sealing Machine?

Cleaning and maintenance are very important for keeping your machine on right track. Therefore, never avoid regular care for your suppository filling and sealing machine. You can take few steps for the routine maintenance of the machine which will surely enhance its working life as well as performance. These are as follows:

Maintenance tools m- Picture Courtesy: Homecare24

Cleaning:As the structure of suppository filling and sealing machine is large comprising many sections, so, you need to clean each part separately. First, disassemble the parts such a as hopper, filling nozzles, and preheating molds for washing. Secondly, wipe the rest of the parts with wet cloth like the touch screen, glass window, and sensors etc.

Maintenance:Maintenance will include both structural adjustment and internal setting. The former require accurate placement and positioning of different parts of the machine in their exact location and their tightening through screws and nuts. While as, the internal setting includes fixing of temperature, dosage, and printing information etc., through touch screen penal.

Parts Changeover:It is obvious, that after a long working time, any part of device of your machine might get dysfunctional. It does not mean the machine is out of order rather you simply need to replace the damaged parts with new functional one.

Lubrication:Last but not least, it is lubrication that keeps your machine in smooth running condition. So, make sure to keep your machine lubricated and avoid spontaneous friction and wear.

10.What Are The Common Problems Of A Suppository Filling And Sealing Machine Also Give Solutions?

Whenever you use any electronic or mechanical machine, it is for sure that spontaneous errors may hinder your way for successful operation. Similar is the case with a suppository filling and sealing machine. If so, then why use this machine? Oh wait! Just take a pause!

These problems are not going to riun your material or waste your money, rather they are general and can be tackled with same general countermeasures. So, let's know what these are!

| i. Machine starting issue | ||

Displaying electrical connection of suppository filling and sealing machine- Picture Courtesy: Aipak Pharmaceutical Equipment |

Cause:

Incorrect connection between different units of the machine Poor connection to power Error in safety stop button |

Solution:

Make sure each unit if Machi is well connected Replug the switch for correct connection and regulation of power Check the safety button by turning it on and off |

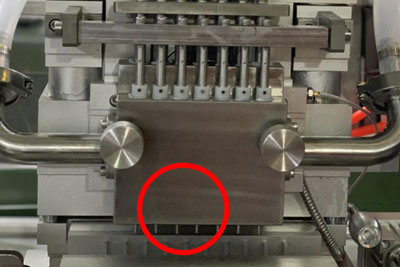

| ii. Blockage of suppository filling nozzles | ||

Encircled suppository filling nozzles- Picture Courtesy: Aipak Pharmaceutical Equipment |

Cause:

The temperature of material tank is low creating lumps which stuck in nozzle Inaccurate speed of agitator and stirrer Dirty filling nozzles |

Solution:

Adjust the temperature of material tank as per the requirement of material nature Adjust the speed of agitator and stirrer Clean the filling heads |

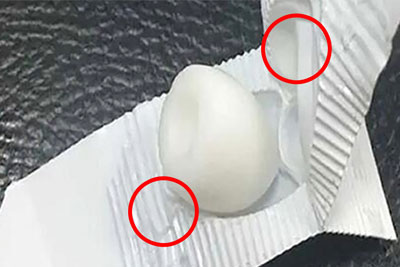

| iii. Improperly formed shells | ||

Highlighting forming errors of suppository shell |

Cause:

Temperature is insufficient to heat the film Too high temperature deform the exact shape of shells Inaccurate stay timing of film in molds |

Solution:

Increase the temperature to suitable level and connect the terminals of heater to molds Reduce the mold temperature to desirable level Adjust the stay timing of film during shell formation |

| iv. Sealing error | ||

Displaying sealing of suppository strip- Picture Courtesy: Aipak Pharmaceutical Equipment |

Cause:

Low sealing temperature causes weak seal Dirty sealing tail creates partial seal |

Solution:

Increase the sealing temperature for effective sealing Clean the sealing tail |

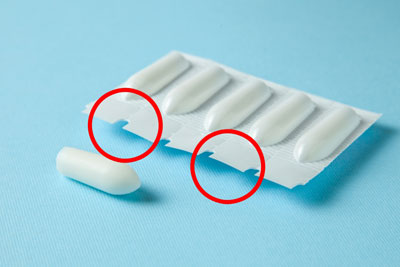

| v. Cutting errors | ||

Marked trimmed edges of suppository strip- Picture Courtes: vetmedicspharmacy.com |

Cause:

Low pressure of blades may create suppository strips of rough edges The blades are loose which result in shaking and insufficient application of pressure The sensor may be unable to detect the mark/ line on suppository strip during cutting |

Solution:

Increase the pressure of blades Tight the blades for allowing adequate force to split suppository strips Clean the sensor if polluted and correct its position. |

11.Factors To Look For When Choosing A Suppository Filling And Sealing Machine?

Every entrepreneur has a dream to incorporate in their production line the best possible machines, so, they will make best use of it. Similarly, it is crucial to consider several factors when choosing a suppository filling and sealing machine. Some of these are as follows:

Type of Suppository

Different shapes & sizes of suppositories

The very first thing to look for is the type of suppository you want to process by using this machine. For instance, whether you are intending to produce urethral suppositories, vaginal suppositories, or rectal suppositories. Determining this will help you choose the machine that is suitable to your concerned type of suppositories.

Capacity

Suppository shells- Picture Courtesy: phoenixnewtimes.com

Another factor is to examine the capacity of your current production which will lead you to opt for the compatible machine. In addition, suppository filling and sealing machine are available in medium to large and extra-large production capacities.

Cost

Cost accounting- Picture Courtesy: forbes.com

When considering cost, you need to keep in mind both the initial purchasing cost as well as the cost of its maintenance and potential downtime. Therefore, it will enable you to buy a machine that is under your range.

Durability

Durability of the machine is very important to check when selecting a suppository filling and sealing machine. For this, you can check the quality certifications of the machine as well as the machine buildup.

Conclusion

To conclude this buying guide about a Suppository Filling And Sealing Machine we are sure that it has provided you a valuable insight regarding the purpose, significance, types, and applications of the machine. The importance of machine can never be denied in this era but can be appreciated. So, what are you thinking about? To opt for a suppository filling and sealing machine or wishing to get further assistance in selecting the best option? In both cases, we are here to help you out. You just have to approach us via given link!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide