Pill Pressing Machine: The Complete Buying Guide In 2025

Are you looking for a dynamic solution to increase your tableting process? Is the pill fabrication process harder for you? Do you want to improve pill quality? Then consider installing pill pressing machine.

Picture Courtesy: Keppy Family Chiropractic

Pill pressing machines are a vital part of different industries, especially the pharmaceutical industry. The pill pressing machine is a favored tool for many industries because of its accelerated pill manufacturing and also for its improved quality of pill pill-making process.

In this article, you will find all the answers to your queries regarding the pill pressing machine. This informative article will discuss benefits, applications, working principles, types, and many more about the pill pressing machine.

1.Define A Pill Pressing Machine?

Pill Pressing Machine- Picture Courtesy: Fette Compacting

A pill pressing machine is the most important machine that is used for compacting and changing powders and granules into tablets. This machine is also referred to as a tablet press machine in the industrial sector. It produces consistent quality and diverse-sized tablets depending upon its tooling devices.

It is majorly seen in the pharmaceutical and cosmetic industry for creating tablets from precise powder formulation and granulation blends. It delivers top-notch results because of its excellent accuracy and high productivity.

2.Why is Pill Pressing Machine Significant in Industries?

Pill pressing machine is significant in industries because they offer better output rates than the traditional and old methods of pill pressing. It is cost-effective, as it consumes less energy. Some of the benefits of this manufacturing unit are detailed below:

Versatility in Shapes and Sizes

Versatility in Shapes and Sizes

A pill pressing machine is the best invention of science because it offers versatility and flexibility in tablet production. It does not produce a single type of product instead it produces diverse shapes of pills for increasing patient compliance. Unique shapes of tablets tempt patients to take their tablets.

Excellent and Superior Tablet Quality

Excellent and Superior Tablet Quality

Manufacturers of pill pressing machine routinely perform several tests to ensure their machines meet the highest possible standard of quality and performance. Thus, the pill pressing process by this machine creates top-quality tablets. Quality tablets ensure better therapeutic responses in patients.

Increased Outputs

Increased Outputs

With the help of pill pressing machine, manufacturers fabricate large quantities of tablets at increasingly high speeds. Using this machine also saves valuable time and increases the productivity of the production line. Furthermore, only not does this machine save time, but it also saves the quantities of formulation, resulting in lower wastage.

Hygienic Processing

Hygienic Processing

The machine is constructed with stainless steel materials that are corrosion and rust-resistant. This material offers a sanitary design to the pill pressing machine, making it easier to clean the machine. This feature allows hygienic and sanitary conditions during the tablet pressing process.

Uniformity in Shapes and Sizes of Tablet

Uniformity in Shapes and Sizes of Tablet

Manual labor does not produce uniform-sized and shaped tablets. There is always variation in the tablets created by manual labor. However, the pill pressing machine is an advanced piece of technology, creating consistent-sized and shaped tablets every time. There are no minute differences in the tablets formed by pill pressing machine.

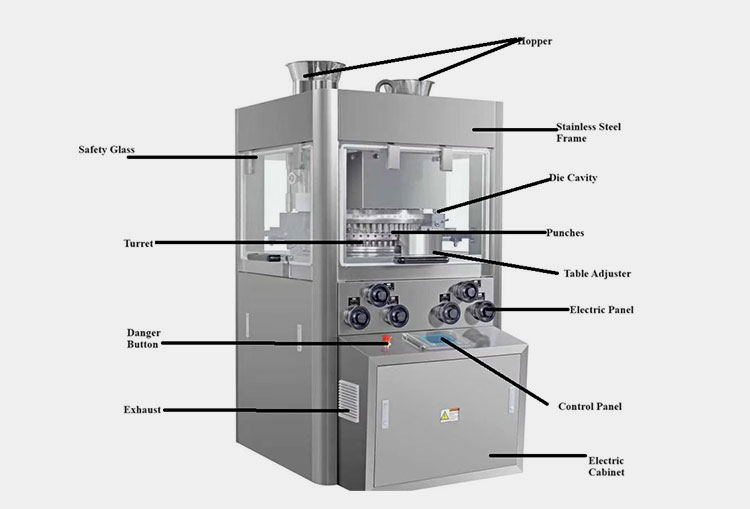

3.What are the Basic Parts of Pill Pressing Machine?

The basic parts of pill pressing machine are discussed below:

Parts of Allpack Pill Pressing Machine

| Hopper | It is the central part of the feeding system that houses large quantities of raw materials for making pills. It is an enclosed part that prevents the entry of other foreign objects to minimize the chances of contamination. |

| Stainless Steel Frame | The frame is made from stainless steel materials that are robust and long-lasting material. The frame offers support and stability to different machine parts. |

| Die Cavity | This part of the pill pressing machine allows the entry of the formulation materials through its hollow interior. It is constructed according to the shapes of pills and is easily interchanged for making different pills. |

| Punches | Punches come in pairs that are upper and lower punches. These punches move up and down to compact powders into pills. By their movement, they exert the necessary force for the compression. |

| Table Adjuster | For maintaining the level of powders in the pill pressing machine, a table adjuster is employed. With this part, excess materials are removed from the machine. |

| Electric Panel | It is the dashboard for different electric switches. It is used for adjusting powering options. |

| Control Panel | For controlling different parts of the pill pressing machine, the control panel is used. It regulates all the processes like the speed of the turret, movement of upper and lower punch, temperature, pressure, etc. It is used to input all the program parameters easily, lowering the burden on the workforce. |

| Electric Cabinet | Different electric appliances that are used for powering the machine are present in the electric box. |

| Safety Glass | It is an enclosed barrier surrounding the pill pressing machine and is made with organic glass. It is a safeguard system that protects the interior of the machine. It also allows operators to see the progress of the tableting process. |

| Turret | This part holds the die cavity, upper and lower punch. The motion of the turret is essential for the entry of the raw materials and also for the removal of formed pills. |

| Danger Button | This button is an emergency stop button that is used in case of machine malfunctioning and emergencies. It instantly turns off the machine without waiting for the normal turnoff process. |

| Exhaust | It is part of the ventilation system. The hot air or other fumes are discharged from the machine through exhaust. |

4.What are the Industrial Uses of Pill Pressing Machine?

Pill pressing machine have diverse industrial uses in different production lines. Many industries lean towards this machine because of its accuracy and high productivity. Some of the industrial uses of this machine are:

Pharmaceutical Industry

Use of Pill Pressing Machine in Pharmaceutical Industry

First and foremost, a pill pressing machine is utilized in the pharmaceutical industry to form bulk quantities of tablets. This machine produces consistent dosage pills by accurately and precisely compacting powders into pills. This enables pharmaceutical industries to deliver accurate dosages to patients.

Nutraceutical Industry

Use of Pill Pressing Machine in Nutraceutical Industry

Beside the pharmaceutical industry, the nutraceutical industry also employs pill pressing machine. It transforms different types of vitamins, minerals, and dietary powders into desired pills. Uniform quality nutraceutical pills are pressed by this machine and are regularly utilized by the patients to boost their health and immune systems.

Confectionery Industry

Use of Pill Pressing Machine in Confectionery Industry

Yes, the confectionery industry also utilized this precious invention to form different kinds of candies, toffees, mints, bounties, and beans. Pill pressing machine is known for its high speed, versatility, and uniformity in the confectionery industry.

Chemical Industry

Use of Pill Pressing Machine in Chemical Industry- Picture Courtesy: www.vensten.ru

Pill pressing machine is regularly found in the chemical industry and it creates different kinds of chemical pills like chlorine and phenyl tablets. Moreover, this machine is also used for fabricating fertilizer and pesticide pills in the agriculture industry.

Cosmetic Industry

Use of Pill Pressing Machine in Cosmetic Industry

When it comes to cosmetic tablets, a pill pressing machine is popular in the cosmetic industry as it forms aesthetically pleasing tablets. These pills are applied both externally and internally to boost human health and beauty. This machine also creates fizzy bath bombs that are used as body wash.

5.What is the Working Principle of Pill Pressing Machine?

The working principle of pill pressing machine is divided into four major steps that are:

| Filling

In the first stage, the raw materials (powders or granules) are deposited in the pill pressing machine hopper after their treatment with the roller compaction. These rollers are used for acquiring granular materials. This powder blend from the hopper goes to the turret for loading inside the die cavity. |

Filling |

| Metering

This stage is essential in obtaining the right-sized tablets. At this stage, excess powder materials are discharged from the turret. The uniformity in tablets is achieved by the lower punch also called dosage cam. |

Metering- Picture Courtesy: Ipharmachine |

| Compression

The compression of granules into tablets is achieved by the upper and lower punches. These punches come together to exert high-pressure force to form a tablet. The upper punch moves down while at the same time, the lower punch is raised upward to compress the powders. The hardness and thickness of tablets are dependent upon the distance between two punches. If two punches are close to each other, the formed pill will be hard and thin. If they are far apart from each other, the compressed pill will be soft and thick. |

Compression of Tablet- Picture Courtesy: US Validation Services |

| Ejection

The ejection or discharge of tablets from the pill pressing machine is carried out by the upward movement of the upper punch and by the downward movement of the lower punch. This leads to forcing the pill upward to the exterior of the die cavity. The take-off blade then removes tablets from the turntable towards the collection bin. |

Tablet Ejection- Picture Courtesy: Fette Compactin |

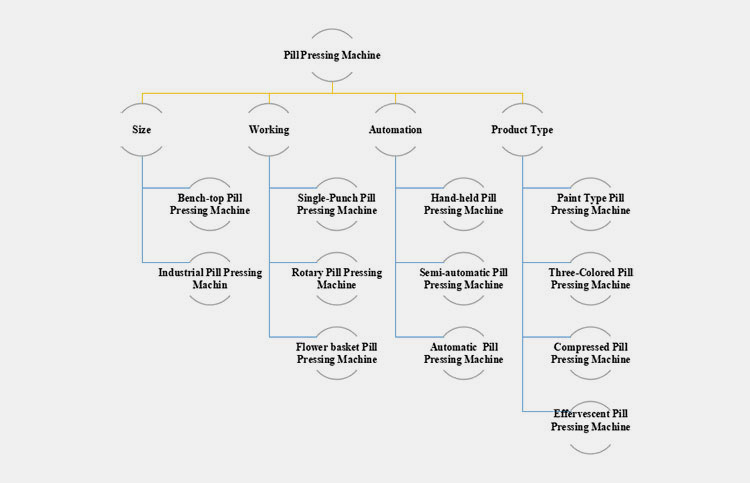

6.What are the Types of Pill Pressing Machine?

There are different types of pill pressing machine such as:

According to Size

Bench-top Pill Pressing Machine

Bench-top Pill Pressing Machine

It is a small, compact machine with a reduced footprint and is easily accommodated on the desktop. It consists of a single punch, hence, it has lower productivity. Unlike other, single-punch pill pressing machines, this system is fully enclosed and has a high raw material utilization rate.

Industrial Pill Pressing Machine

Allpack Industrial Pill Pressing Machine

It is a high-speed pill pressing machine used in various industries. Due to its high speed, it has an increased output rate that is usually around 300,000 tablets per hour. It not only produces round-shaped tablets but also forms special types of tablets. It processes fine powders but does not process moisture-prone materials.

According to Working

Single-Punch Pill Pressing Machine

Single-Punch Pill Pressing Machine

This type of pill pressing machine is the major component of small-scale industries because of its minimal output rate. It produces one tablet per cycle because of having only a single punch and one die cavity. Its compression capability is about 55-90 tablets per minute. It also has smaller space needs.

Rotary Pill Pressing Machine

Allpack Rotary Pill Pressing Machine

This kind of pill pressing machine is favoured among industries because it contains multiple punches arranged on a rotary turret. The rotary turret continuously moves up and down to load feed substances in the die cavity. This machine can form more tablets per minute because of its multiple punches. It can create versatile pills differing in their shapes and sizes.

Flower Basket Pill Pressing Machine

Allpack Flower Basket Pill Pressing Machine

It is used in smaller productions and research institutes that need a lower output rate. The flower basket pill pressing machine uses force feed as well as compression principles for smoothly creating the pills. This machine has the appearance of a flower, hence the name flower basket pill pressing machine.

It produces both regular and irregularly shaped tablets. It is easily installed on the desktops. The flower basket pill pressing machine exerts high pressure to create bigger-sized tablets.

According to Automation

Hand-held Pill Pressing Machine

Hand-held Pill Pressing Machine- Picture Courtesy: LFA Tablet Presses

It is a small pill pressing machine that is easily held in hands. It is used in home-based settings to produce different kinds of supplement pills. It has straight forward construction with two handles and a cavity in which powder is stored to produce tablets. The handles exert force for compressing powders.

Semi-automatic Pill Pressing Machine

Allpack Semi-automatic Pill Pressing Machine

It is a single punch machine that has a motor fitted in it. This machine has a semi-automatic mode of operation as although the feeding of granular material and discharge of powders is done by the operators, the compression is performed by the pressure force provided by the upper punch. The movement of the punch is powered by the motor.

Automatic Pill Pressing Machine

Allpack Automatic Pill Pressing Machine

It is a large industrial unit, comprising multiple punches that move simultaneously to output numerous tablets during one cycle. The automatic pill pressing machine has an automatic mode of operation in which feeding, metering, compression, and loading are carried out by the machine independently.

According to Product Type

Paint Type Pill Pressing Machine

Paint Type Pill Pressing Machine

This machine is used to produce round-shaped tablets. It is a compact manufacturing unit producing fewer pills per minute. It is best for small-batch businesses. It contains about 15-19 pairs of punches. Paint type pill pressing machine has a powder suction device that controls the rate of dust generation

Three-Colored Pill Pressing Machine

Allpack Three-Colored Pill Pressing Machine

This machine is used to create pills of three colours. It is equipped with double press rollers and double impellers that increase the rate of flowability and feeding performance. These systems increase the filling accuracy. Moreover, its cleaning and maintenance is easy.

Compressed Pill Pressing Machine

Allpack Compressed Pill Pressing Machine

This type of pill pressing machine is used in the food industry for compressing biscuit powders into biscuits. High pressure is applied on the biscuit powders by the upper and lower punches to undergo compression. These biscuits have extended shelf-life and they have freshness for a longer time.

Effervescent Pill Pressing Machine

Allpack Effervescent Pill Pressing Machine

This pill pressing machine is used to produce effervescent and aromatic pills. It has the same working principle as that of other pill pressing machines. It has advanced technology and is operated with the latest rotary system. It produces big-diameter, fizzy, fragrant pills.

7.What Shapes and Sizes of Tablets Are Pressed by Pill Pressing Machine?

Pill pressing machine press different shapes of tablets such as:

| Round Pills

It is a typical shape of pills. These shaped pills are the most common type of pills. These are circular with no corners. These pills are easily produced by regular-shaped tooling. Moreover, these pills are easily shallowed because they do not contain sharp corners. |

Round Pills |

| Oval Pills

It is the second most frequently available shape of pill. It has an egg or elliptical shape. They have a large surface area than the round pills. So, these can incorporate larger dosages of drugs. Buccal and sublingual pills are available in oval shape. |

Oval Pills |

| Oblong Pills

These pills have rectangular shape but with rounded corners. This shape is also called a capsule shape. |

Oblong Pills |

| Diamond Pills

These pills are shaped like two triangles fused. Reproductive disorders are treated by diamond shape pills. |

Diamond Pills- Picture Courtesy: Healthline |

| Triangular Pills

These pills are triangular with three distinct corners. Ecstasy drugs and drugs for psychosis come in triangular pills. |

Triangular Pills |

| Square Pills

They have four equal sides and four corners. Square pills treat asthma. |

Square Pills- Picture Courtesy: Verywell Mind |

| Heart Pills

These often come as tiny hearts and are utilized for curing heart disorders. |

Heart Pills- Picture Courtesy: ColourBox |

| Kidney Pills

These pills are in bean or kidney shape. They are used for treating blood pressure. |

Kidney Pills |

| Pentagon Pills

These pills have five distinct corners. These shaped pills are also called shield-shaped pills. These are often used for treating psychiatric disorders. |

Pentagon Pills- Picture Courtesy: self.com |

| Core Rod Pills

These pills have tiny circular holes inside them. |

Core Rod Pills |

| Special Shape Pills

These pills are chewable and are available in star, animal, fruit, etc., shapes. These pills are used for treating mineral deficiencies. |

Special Shape Pills- Picture Courtesy: Medic |

Size of Pills

Pills have different sizes, generally, pills are in the range from 1mm to 22 mm. It is recommended by the FDA that pill size must not exceed 22 mm. This is because larger-sized tablets do not pass through the pharynx.

| Mini Sized Pills

These contain intermediate-acting drugs and are in the size of 1 mm to 5 mm. Buccal and sublingual pills are mini pills. |

Mini-Sized Pills- Picture Courtesy: TwentyEight Health |

| Standard Size Pills

Standard pills have dimensions larger than 5 mm but smaller than 22 mm. Many pain-relieving drugs and antibiotics fall under this category. |

Standard Size Pills |

| Large Sized Tablet

Effervescent tablets have a larger size which is about 1 inch or 25.4 mm. Pills for ingestion do not come in larger sizes. |

Large Sized Tablet- Picture Courtesy:cblive.net |

8.What Tablets Can Be Produced from Pill Pressing Machine?

Pill pressing machine can produce diverse types of tablets like:

Medicine Pills

Medicine Pills

These are also called tablets and are routinely used forms of medication. It is consumed orally and has precise and accurate dosages of drugs. They have longer consumable life and lower chances of spoilage.

Single Layer Pill

Single Layer Pill

It is a routinely used form of medication and it has one layer of the drug so, are also called a single-dose drug. It contains a uniform blend of active pharmaceutical ingredients and excipients.

Multi-layer Pills

Multi-layer Pills- Picture Courtesy: RÖLTGEN

It is a special form of pill having multiple layers of active ingredients with different release times. Multi-layer pills also combine different incompatible drugs into a single pill. Different layers of drugs in this pill are shown in different colours.

Chewable Pills

Chewable Pills- Picture Courtesy: Making.com

These pills are not directly swallowed, rather they are first chewed into smaller pieces before ingestion. These are alternative forms of medication and are usually available as nutrient supplements. These chewable pills have an appetizing taste, smell, and colour.

Effervescent Pills

Effervescent Pills- Picture Courtesy: Ocean Property

These pills are another form of medicine pills. These are not ingested instead they are dissolved in water, emitting carbon-dioxide bubbles, and form a fizzy solution. Vitamins, minerals or other pharmaceutical drugs are available as effervescent pills.

Laundry Pills

Laundry Pills- Picture Courtesy: Urban Ethos

Pill pressing machine also compresses detergent and other cleaning agent granules to form laundry pills. These pills are used for washing clothes.

9.Does Pill Pressing Machine Offer Tooling Flexibility?

Tooling in Pill Pressing Machine

Yes, tooling versatility is one of the important benefits of the pill pressing machine. Toolings are important components of pill pressing machine and are called pill press tooling. Tooling is the dies and punches in the pill pressing machine that fashions different shapes of tablets.

Different toolings have different shapes and sizes like normal round, oval, rectangular, and diamond. Moreover, they come with different embedded markings and logos by which different tablets are shaped. Regular tooling creates round-shaped pills. Special shapes or labels on the tooling fashion uniquely designed pills. This will help the manufacturer to overcome the issue of counterfeiting.

10.Are There Different Turrets in Pill Pressing Machine?

Turret in Pill Pressing Machine- Picture Courtesy: Elizabeth Companies

There are versatile turrets available in the pill pressing machine. These can be changed according to the design of the tooling. Turrets are interchanged by simply changing their base. This is an easy way to create turret adaptability in the pill pressing machine.

Besides tooling, turrets are important in the pill pressing operation because they are used for holding both the punch and die cavity. Different numbers of turrets ranging from 15-75 are used in the pill pressing machine. The number of turrets depends upon the size, structure, and productivity of the machine.

11.How to Maintain Pill Pressing Machine?

Maintenance of Pill Pressing Machine

For efficient operation and long-lasting machine life, it is a must to maintain the pill pressing machine properly. Maintenance increases machine efficiency and reduces downtime. Here is the maintenance schedule just for you:

| Daily Maintenance | First, gently clean all the external surfaces of the machine like its frame to remove granule buildup and pill residues. Visually inspect every part of the machine for damage. Tighten loose bolts. Add lubricant if required. |

| Weekly Maintenance | Clean the machine fully once a week with mild detergent. Pay special attention to machine turret, punches, die, and cam. Oil every mobile part of the machine. |

| Monthly Maintenance | Conduct a thorough examination of the machine parts. Consider replacement parts if the damage is excessive. Calibrate machine pressure gauge and heating devices. Test the machine safety components and check their working order. |

| Yearly Maintenance | Replace the parts that show severe damage. Check the working condition of mechanical parts like motors, gears, bearings, etc. Inspect the working order of electric parts like wires, relays, cables, switches, etc. Replace them if needed. |

12.Does the Pill Pressing Machine Comply with Industrial Regulations?

The answer is yes, pill pressing machine complies with industrial regulations to increase the safety of the operator and the quality of pills. These industrial regulations are:

GMP

GMP

This stands for good manufacturing practices. These certifications are vital for pill pressing machine. It ensures that this machine is manufactured following quality standards. It ensures that this machine has ease in cleaning and prevention of cross-contamination, and it processes uniform quality pills.

FDA

FDA

Pill pressing machine is manufactured and designed per the guidelines of the FDA. Also, the operation and maintenance of this machine comply with the regulations of the FDA.

CE

CE

These certification in important for machine sold in the European Union and they ensures the safety and performance of the pill pressing machine. This certification states that the pill pressing machine meets the desired attribute and safety code of conduct.

ISO

ISO

Pill pressing machine fulfils the required guidelines, safety regulations, and quality assurance tests imposed by the ISO. It is a fundamental certification recognized globally.

FAT

FAT - Picture Courtesy: pharmaguideline

This machine also fulfills the required protocols imposed by the factory acceptance test. It verifies that the working principle of this machine is safe and hygienic.

13.What are Common Problems in Pill Pressing Machine? How To Remedy Them?

Common problems in pill pressing machine are due to mechanical issues and formulation errors. However, these problems are easily resolved by understanding them and their causes. Some tips and tricks to resolve them are:

Sticking of Pills

Sticking of Pills- Picture Courtesy: Tianjiu

Sticking occurs when the raw feed sticks to the exterior of punches due to the presence of granules clump.

| Causes | Remedy |

| It can occur due to high water content in the formulation and also due to non-uniform punch shape. | Reformulate the formulation by adding binder and lubricant. Coat anti-stick agents on the surface of punches. Decrease the moisture content in the formulation. |

Capping

Capping of Pills- Picture Courtesy: Romaco

It is defined as the incomplete separation of the top part of the pill from the rest of the body.

| Causes | Remedy |

| The capping issue is caused because of air trapped inside the pill during the compaction process. This could be due to poor compression forces, leading to poor bonding. Lack of binder in pill formulation. Non-uniform distribution of feed because of insufficient granule flow. | Increase the compression force for sufficient bonding between granules. Add a binder to the formulation to increase its cohesivity. Decrease the granule size to enhance their flowability. |

Lamination

Lamination of Pill- Picture Courtesy: Scientist Live

It is defined as the splitting of pills into different horizontal layers.

| Causes | Remedy |

| Poor bonding between the granules. High moisture content decreases the stickiness between the granules. Air entrapment also decreases the adhesive between granule layers. Poor compression force also results in poor bonding. | Uniformly distributing water content, binder, and granule size increases the bonding between layers. Decrease the water content between granules. Eliminate air by using granulating devices. Increase compaction pressure to optimize the compression process. |

Cracking

Cracking of Pills- Picture Courtesy: Coloron

Visible breaks on the surface of the pills is known as cracking.

| Causes | Remedy |

| Reduced cohesivity due to lower concentration of the binder. High compression force is exerted on the pills. Inadequate lubricant in the pill formulation. | Increase the concentration of the binder. Lower the compression force. Increase the concentration of lubricant. |

Non-Uniformity in Weight of Pills

Non-Uniformity in Weight of Pills

There is inconsistency in the weight of pills across different batches.

| Causes | Remedy |

| Inadequate blending of the formulation. There is inconsistency in the size, density, and distribution of granules. Poor flowability of granules in the die cavity. High or low compression force. | Properly blend formulation before tableting. Lower the variation in sizes, density, and distribution of granules. Increase the flow characteristics of granules. Ensure adequate compression force during tableting. |

14.What are the Consideration Factors You Should Know When Buying Pill Pressing Machine?

Pill pressing machine come with a hefty price, so consider several factors to make your investment worth investing in. A list of important things that must be pondered on before purchase.

Ponder on Production Capacity

Production Capacity

Production capacity is determined by the number of pills produced by the pill pressing machine per hour, which is in turn related to the motor, station, and number of tooling devices. The higher the speed of the motor, the higher will be the production capacity.

Calculate Your Budget

Budget

Secondly, after considering your production capacity, calculate the budget required for purchasing the pill pressing machine. It is important because high-speed industrial pill pressing machine has higher price tags. Also, you should not compromise on quality while checking the machine that fits your budget.

Determine the Shape and Size of Pills

Shape and Size of Pills

Pills are available in various shapes and sizes, so determine your desired shape and size. These two parameters will determine the type of tooling. The latter is specific for the particular shape and size of pills.

Go For Reputed Manufacturer

Reputed Manufacturer

Positive reviews are the measure of the trust of consumers in the quality of service and products. Thus, go for a manufacturer that offers the highest quality products and services by looking through its reviews.

Conclusion

No pharmaceutical industry is completed without a pill pressing machine. It is a superb machine commonly employed in pharmaceutical and nutraceutical industries because of its pill-forming characteristics. It is a versatile and precise equipment, producing a higher number of tablets per batch. If you require such equipment, then without delay contact our Allpack customer care, as we have the best pill pressing machine that will aid you in creating excellent quality pills.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide