Multi-Row Powder Packaging Machine: The Complete Buying Guide In 2024

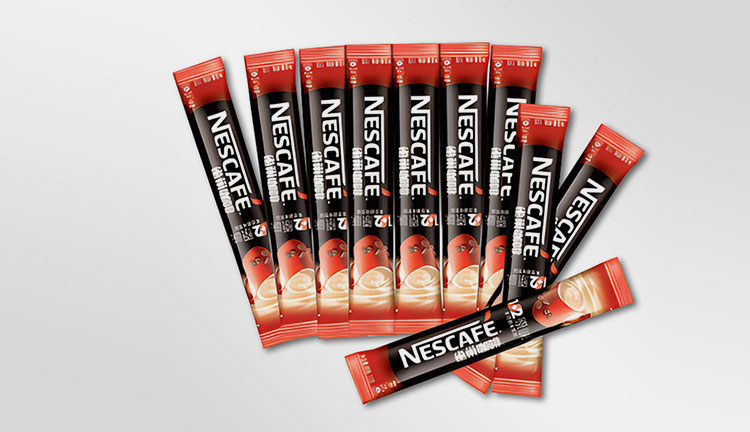

Whether it's instant coffee powder, sugar, salt, or calcium powder stick packaging is the most popular style. The reason is its extremely convenient method of usage, occupying less space, and is cost-effective. Therefore, stick packaging is the most preferred way on part of customer as well as producers. However, when the demand gets higher most of the time manufacturers struggle to meet their customers' expectations.

In this way a Multi-Row Powder Packaging Machine has been introduced into the field to facilitate quick packaging of various powders. This machine is beneficial in every possible way. Gone are the days when production was dependent upon labours. Now, the use of a single machine assists you and benefits you in every possible way. So, let's start reading this buying guide and you will discover range of information about Multi-Row Powder Packaging Machine!

1.What Is Multi-Row Powder Packaging Machine?

Allpack- APK 4-480 Multilane stick packing machine for powder

Multi-row powder packaging machine is an automatic machine with brilliant features to pack various types of food and non-food powders into multiple stick packs including cocoa powder, milk powder, protein powder, and others.

The machine uses number of channels for forming bags from film and then filling each bag with exact amount of powder that has been set by the operator in machine. So, this machine is considered a highly remarkable invention that aids you in extending your production efficiency while maintaining packaging accuracy and products safety.

2.Enumerate The Features Of A Multi-Row Powder Packaging Machine?

Multi-row powder packaging machine comes up with advance features and automatic technology which enable it to give you an outstanding performance in terms of efficiency, packaging accuracy, and versatility. Below are some of its crucial attributes:

High Efficiency

Bulk of stick packs

By using multi-lane bag forming and filling stations, this machine finishes multiple powder bags in the single run. Therefore, various packaging steps including bag forming, filling, sealing, coding, and cutting are realized in extraordinary efficient way.

Automatic Functioning

Displaying automatic system of multi-row powder packaging machine- Picture Courtesy: chengyipacking.com

Multi-row powder packaging machine is designed with automatic technology where it fully supports the entire processing automatically and is controlled by a single chip microcomputer. Therefore, its operation is safe and convenient.

Hygienic

Hygienic stainless steel part of multi-row powder packaging machine- Picture Courtesy: chengyipacking.com

The machine is made up of durable stainless steel with anti-bacterial and corrosion resistant layer over the parts of machine which are in contact with material like hopper and filling heads.

High Precision

Precisely packed powder sachets- Picture Courtesy: popsugar.com

As the machine has fitted in it the high precision photocell sensor which guide the accurate marking on film, so, the cutting and sealing of packages are carried out at precise position. Moreover, the auger filler combined with highly sensitive metering device stop machine from over and under-filling.

Low Maintenance

Multi-row powder packaging machine has low maintenance and operating cost due to its automatic technology and computerized system which works independently once set by the operator.

Customization & Resilience

Various customized stick packs along with different powders- Picture Courtesy: coretamp.com

No doubt a multi-row powder packaging machine is best known for its resilience and flexibility both in terms of powders packed and bags sealed. For instance, you can pack free-flowing powders, non-free flowing powders, and different designs of bags and sachets by using the single machine.

3.What Products Can You Pack By A Multi-Row Powder Packaging Machine?

Myriad of powders can be easily packed by a multi-row powder packaging machine including:

Instant Drink Powders

Various fruit juice powdered stick packs with juice bottles

All kinds of solid instant drinks in form of powders are suitable to be packed by a multi-row powder packaging machine including coffee powder, juice powder, glucose powder, and soda powder etc.

Milk Powder

Milk powder presentation idea- Picture Courtesy: ruchikrandhap.com

Milk powder is one of the most notable ingredients that will always be packed by a multi-row powder packaging machine whether it's for baby use, adult use, or meant for use as additive in tea.

Seasoning Powders

Seasoning solutions display- Picture Courtesy: etsy.com

Seasoning powders refers to the powdered condiments such as salt, pepper, and chilli etc., which adds to the taste of cuisines. That's why, their packing in small stick packs and sachets is carried out on large scale by a multi-row powder packaging machine.

Protein & Herbal Powders

Moringa herbal powder in bowl- Picture Courtesy: Healthline

The use of protein and herbal powders is now common among people of all ages. Therefore, you can easily pack various kinds of herbal powders by using this machine.

Detergent Powder

Detergent powder with filled scoop- Picture Courtesy: familyhandyman.com

Detergent powder is made up of mixture of chemical powders which needs to be properly handle till its use. So, this multi-row powder packaging machine is best applicable to perform this task responsibly.

Cosmetic Powders

Woman holding gelatin powder stick pack- Picture Courtesy: lookfantastic.com

All kinds of cosmetic powders such as bleach powder, facial mask powder, talc powder, and pearl powder are best suitable to be packed by a multi-row powder packaging machine with great precision.

Medicine Powder

Various probiotic powder stick packs

Most of the medicated drugs are now delivered in form of powders such as calcium powder, nutritional powder, and probiotic powder etc. Ergo, multi-row powder packaging machine is used for these powders.

Pet Powders

Pet supplement powder bag

Pet powders, made for feeding and treating dogs and cats etc., can also be packed by this machine.

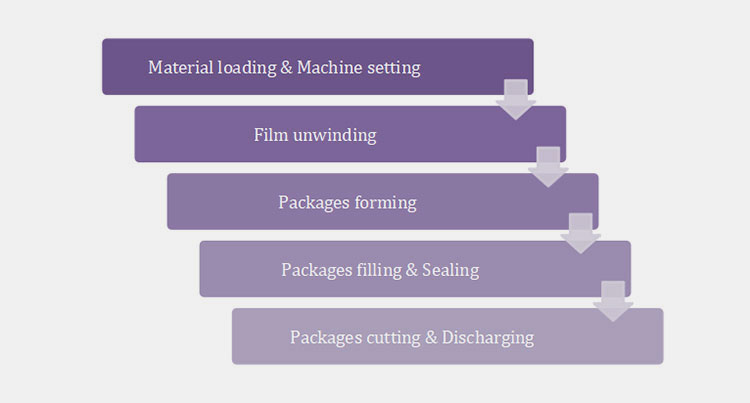

4.How To Operate A Multi-Row Powder Packaging Machine?

Let's explore how a multi-row powder packaging machine works by looking into the details step-by-step!

Material Loading

Powder loaded in hopper- Picture Courtesy: chengyipacking.com

The very initial step you need to take for operating the multi-row powder packaging machine is loading the machine with adequate amount of powder into hopper and placing the film roll in holder.

Machine Setting

Touch screen control panel for setting machine- Picture Courtesy: chengyipacking.com

The second step involves setting the parameters of machine including the amount of powder to be filled in each package, the speed of auger, coding data, sealing temperature, and the length of packages etc., through touch screen display.

Film Unwinding

chengyipacking.com

Now, when the material is loaded into machine, the operator will switch on the machine which will result in energizing every part of it. Similarly, the film will start unwinding from a film roll through multiple guiding rollers to uphold the tension and preclude wrinkles.

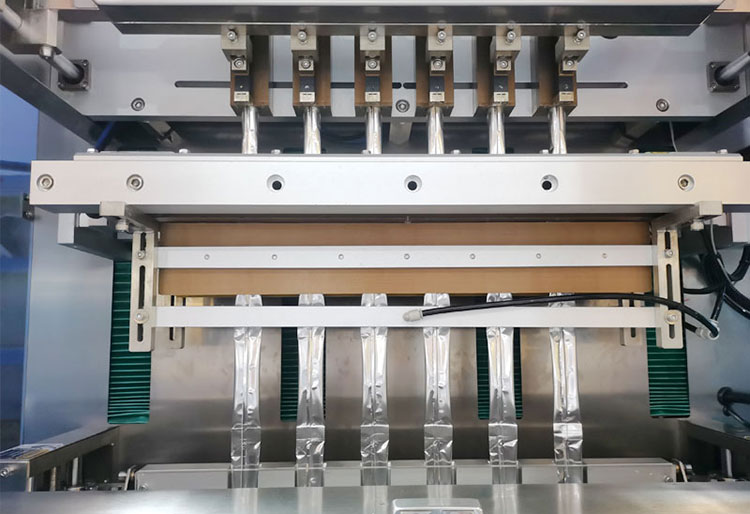

Packages Forming

Packages forming- Picture Courtesy: chengyipacking.com

Moving forward, the single film will be separated into number of individual films for forming individual packages. These film layers are then longitudinally fitted around the bag forming tubes who turn the flat films into packages by creating the back vertical sealing. Afterwards, the packages are collectively sealed from bottom via horizontal sealing device.

Packages Filling & Sealing

Stick packs filling & sealing process- Picture Courtesy: chengyipacking.com

When the packages are formed, the most crucial step of packages filling with powder is carried out in a way that precision measuring device accurately weigh the required amount of powder and dispense it into different packages. At the same time, filled packages are sealed from top using horizontal sealing.

Packages Cutting & Discharging

Discharging of multiple stick packs through conveyor- Picture Courtesy: chengyipacking.com

Finally, the continuous strip of packages is cut into individual units by using a sharp blade or cutting knife. These units of packages are then discharged by the machine through a conveyor belt for collecting into container or conveying for further packaging into boxes or bags.

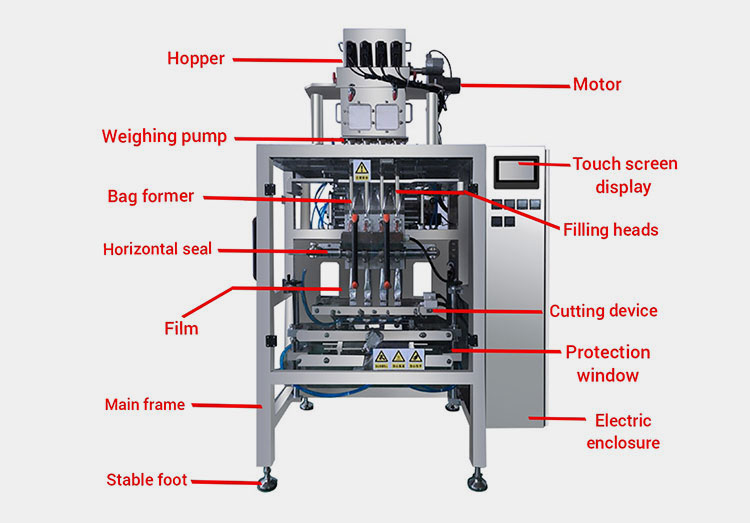

5.Describe The Structure Of A Multi-Row Powder Packaging Machine?

The structure of a multi-row powder packaging machine is made up of different components. These components are described below:

Structure of Multi Line Powder Stick Packing Machine- Picture Courtesy: coretamp.com

Hopper

Hopper is a large size stainless steel pot located on the top of machine to hold bulk of powder and supply it to machine during operation.

Motor

Motor is another significant part of a multi-row powder packaging machine situated on the top left side of machine. It energizes the machine to run different components such a as auger for mixing and filling powders etc.

Weighing Pump

There is a device naming weighing pump who is placed right below the hopper. Its major function is to measure the exact amount of powder which is meant to be filled in each package.

Touch Screen Display

It is the most important part of a multi-row powder packaging machine characterized by an intuitive touch screen panel with colored display. This device provide multiple types of information regarding the volume of powder, length of bags, and temperature of sealing etc. Hence, operator set commands and control the machine through this device.

Filling Heads

Filling heads are small and long narrow stainless-steel nozzles through which powder is transferred from weighing pump into the multiple bags.

Bag Former

Bag former refers to the number of conical metallic tools pla Ed around multiple columns. They are useful in forming different stick packs and sachets where the layer of film is drawn around each bag former.

Horizontal Seal

Horizontal seal is another essential component of a multi-row powder packaging machine which is used to seal the bottom and top of the bags by using heat.

Film

Film is a thin layer of plastic, paper, aluminum, or combination of them which is used to form bags and packages for holding powders. The long layer of film is stacked on a tool and attached to the back side of a multi-row powder packaging machine from where the film is transferred towards forming station.

Cutting Device

Cutting device is also known as knife which is made up of stainless steel with having sharp edges used to split two joined stick packs or sachets through cutting.

Protection Window

Multi-row powder packaging machine has a protection window made up of transparent glass. Therefore, it protects the entire processing of bag forming, filling, sealing, and cutting in a safe environment on one hand, while as, enabling easy way for user to administer the operation.

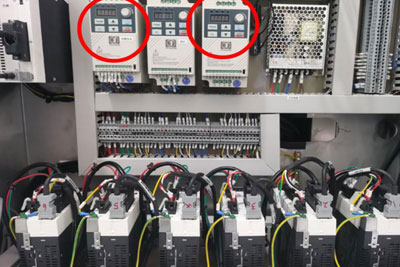

Electric Enclosure

Electric enclosure is a box type tool where all the electrical components of a multi-row powder packaging machine including wires, fuses, and circuit breakers are fitted. It thus ensures the safe working of machine.

Main Frame

The main frame of a multi-row powder packaging machine includes all the supporting tools and devices to which all other parts are attached. The main frame of machine is made up of 304 stainless steel.

Stable Foot

There are 4 stable feet attached to the machine which make it stand on surface.

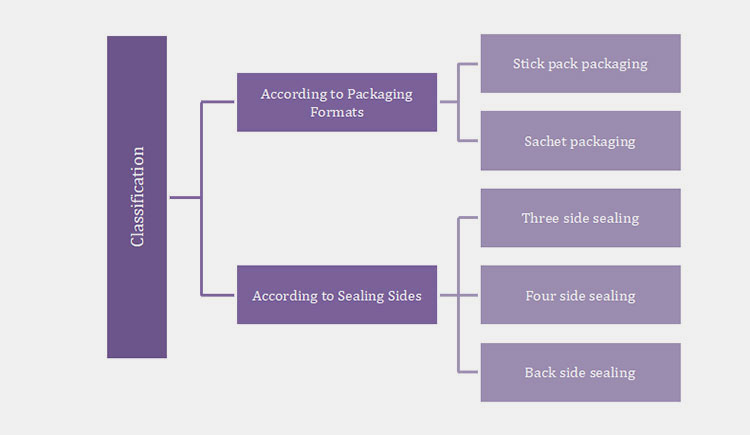

6.What Is The Classification Of A Multi-Row Powder Packaging Machine?

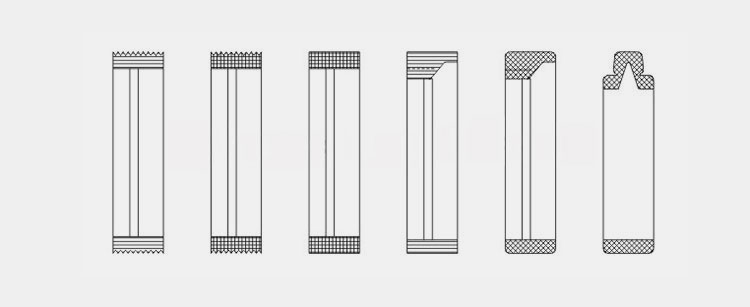

Multi-row powder packaging machine can be classified into two types on the basis of packaging format. These two types are described in detail in the upcoming paragraphs:

According to Packaging Format

Multi Line Powder Stick Packing Machine

Multi Line Powder Stick Packing Machine- Picture Courtesy: coretamp.com

Multi-row powder stick packaging machine is an intelligent machine designed with innovative features to cope up with all kinds of free-flowing and non-free flowing powders into number of stick packs. It can be also linked with other machines to carry out secondary packaging task.

Structure

The structure of machine composite with parts including a hopper, weighing pump, control system, bag former, horizontal seal, cutting device, filling heads, and overall body.

Working Process

It follows straight forward way of packaging by unwinding the film from roll and turning it into individual stick packs. After the forming of stick packs gets completed, they are filled with precise amount of powders, sealed tightly, and discharged out of machine after the splitting of continuous strip of stick packs is done.

Packaging Format

Various stick packs- Picture Courtesy: chengyipacking.com

This machine is known for its most popular packaging format which is stick pack. Stick pack is long, narrow package highly recommended for delivering single serving powders in catering, cosmetic, and pharmaceutical industries.

Multi Line Sachet Powder Packing Machine

Sachet Packing Machine for Powder- Picture Courtesy: senieer.com

Multi-row powder sachet packaging machine is another type of machine employed to pack eclectic powders into square shaped sachets. The machine has high output ratio and good precision level in packing powders.

Structure

The body of machine is a bit complex with multiple parts accounting for its construction including 304 stainless steel body, touch screen panel with various knobs and switches, electric enclosure, film roll, bag forming and associated mechanism for filling and sealing etc.

Working Process

Its working process is similar to that of stick pack powder packaging machine provided that the length and sealing are same. Therefore, it follows the main steps of material loading, sachet forming, filling, coding, sealing, cutting, and discharging etc.

Packaging Format

Various sachets- Picture Courtesy: chengyipacking.com

It has a most commonly used packaging format of sachets which are square in shape or sometime resembling rectangular shape often used in chemical, pesticide, food, and healthcare industries.

According to Sealing Sides

Multi-Row 3 Side Sealing Powder Packaging Machine

Multi row 3 side sealing powder packaging machine- Picture Courtesy: chengyipacking.com

As the name indicates, this type of multi-row powder packaging machine is capable of packing 3 side sealed packages for powders used in pharmaceutical, beauty care, daily chemical, and food industry. It uses single layer of film.

Structure

It is an assembly of several tools and units including feeding station, weighing mechanism, control system, and the most prominent part which is the side bag formers along with horizontal seal and cutting blades.

Working Process

Working process of 3 side sealing powder packaging machine- Picture Courtesy: chengyipacking.com

It pulls the film from roll and turn the film around bag former in a way that their opened sides are joined on the right side of machine instead of combining on the back side. Therefore, the longitudinal sealing form the sealing of one side. While as, the bottom sealing and top sealing after powder filling results in the formation of 3-sided sealed finished powder packages.

Multi Row 4 Side Sealing Powder Packaging Machine

Multi Row 4 Side Sealing Powder Packaging Machine- Picture Courtesy: chengyipacking.com

Multi row 4 side sealing powder packaging machine is unique design machine that come up with 4 side sealing. So, no matter what type of powders you process or packaging material you use, this machine will perfectly pack these packages by creating stringent sealing from all sides.

Structure

The structure of a multi row 4 side sealing powder packaging machine is different from other machines in a way that its bag forming device is not conical like other machines, rather it uses double layer of film.

Working Process

It simply works by unwinding the dual film layers from separate film rollers in back and front manner. Afterwards, these two film layers are sealed vertically and horizontally in bottom. When powder is filled into these packages, the top horizontal seal is realized.

Multi-Row Back Side Powder Packaging Machine

Multi-Row Back Side Powder Packaging Machine

Another type of a multi-row powder packaging machine is on the basis of back side sealing. It also uses single film for forming stick packs and sachets. Therefore, it is mostly used for instant coffee, milkshake powder, and facial powder etc.

Structure

Its body is distinguished by other types of multi-row powder packaging machine due to its conical bag forming devices located around tubular filling heads.

Working Process

It process is simple that initiate with film dispensing around the bag formers. During this phase, the back longitudinal side is sealed followed by lower horizontal sealing. Similarly, precisely measured powders are filled in individual sachets, they are sealed from top, and ultimately, discharged out of the machine after splitting.

7.Compare The Multi-Row Powder Packaging Machine With Other Types Of Multi-Row Packaging Machine?

Powders, granules, and liquids are 3 most essential materials that come in different characteristics. Therefore, their packaging involves different machines which we have compared for your ease:

| No | Dimensions | Multi-Row Powder Packaging Machine | Multi-Row Granule Packaging Machine | Multi-Row Liquid Packaging Machine |

| 1 | Definition | Multi-row powder packaging machine is multi channel machine used to pack powders. | Multi-row granule packaging machine designed to accurately pack granules into various packages. | Multi-row liquid packaging machine is created to carry out the smooth packaging of liquids. |

| 2 | Weighing & filling system | According to the type of powders, it uses short auger screw measurement alone or with vibrantion device to avoid accumulation of powders. | It employs drawer type measuring cup or swing type measuring cup in accordance with granules size and nature. | It utilizes magnetic pump metering, Peristaltis pump, ceramic pump, or piston pump metering in accordance with material specifications. |

| 3 | Packaging formats | Stick pack and sachet. | Stick pack and sachet. | Stick pack and sachet. |

| 4 | Sealing | 3 side sealing, 4 side sealing, and back side sealing. | 3 side sealing, 4 side sealing, and back side sealing. | 3 side sealing, 4 side sealing and back side sealing. |

| 5 | Application | Free flowing and adhesive powders including milk powder, coffee powder, seasoning powders, and medicine powder etc. | All granulated materials such as grains, corn flakes, nuts, pet food, and candies etc. | All kinds of free flowing and viscous liquid substances encompassing honey, ketchup, gel, and shampoo etc. |

| 6 | Picture |

Allpack- APK 4-480 Multilane stick packing machine for powder |

Allpack- APK 6-480 Multilane stick packing machine for granule |

Allpack- APK 8-480 Multilane stick packing machine for liquid |

8.How Multi-Row Powder Packaging Machine Differs From That Of Single Row Powder Packaging Machine?

Both the multi-row powder packaging machine and single row powder packaging machine are used for the same purpose of packing various powders into stick packs and sachets. However, there are major distinctions between both which are highlighted below for your clear understanding:

| No | Features | Multi-Row Powder Packaging Machine | Single Row Powder Packaging Machine |

| 1 | Specifications | Multi-row powder packaging machine uses multiple channels for making and filling packages. | This machine utilizes a single channel for forming, filling, and sealing of packages. |

| 2 | Structure | Its structure is complex with many heavy-duty components. | While as, single row powder packaging machine has small footprint with few parts. |

| 3 | Automation | It is fully automatic in technology. | On the other hand, it is available both in fully automatic and semi-automatic technology. |

| 4 | Capacity | The machine gives you exceptional production efficiency. | In contrast, you will get small to medium level of production by using this machine. |

| 5 | Cost | The machine is expensive with high initial cost. | On the other hand, it is cost-effective with low initial expenses. |

| 6 | Picture |

Allpack- APK 4-480 Multilane stick packing machine for powder |

Allpack- APK 2-220 Automatic Vertical Single Lane Powder Stick Packing Machine |

9.Where A Multi-Row Powder Packaging Machine Can Be Used?

Multi-row powder packaging machine play a highly significant role in different modern industries. Some of the prominent industries where this machine is regularly used are explored below:

Food Sector

Tea stick packs- Picture Courtesy: chengyipacking.com

Food is inevitable for human survival; therefore, modern day technology is introduced to facilitate this necessity in the most convenient way. In this way, products like salt, sugar, pepper, instant coffee powder, tea powder, and milk powder are often delivered in small amount for traveling and outing for which this multi-row powder packaging machine is employed.

Pharmaceutical Sector

Patient mixing urinary tract health supplement into water glass- Picture Courtesy: uqora.com

Pharmaceutical industry is yet another notable field where bulk of drugs and medicine are produced in form of powder whose instant usage can help patients treat their ills in an easy way. Therefore, a multi-row powder packaging machine is best suitable in this sector.

Nutraceutical Sector

Nutritional powder in stick packs- Picture Courtesy: drinkhydrant.com

The people's preference to treat their deficiency of energy, protein, and calcium is now turned towards using instant nutritional and protein powders on daily basis. Therefore, they used to carry with themselves small packets of powders in their pockets which is indeed an outcome of using this multi-row powder packaging machine in nutraceucal industry.

Cosmetic Sector

Various cosmetics- Picture Courtesy: sephora.com

Another significant application of a multi-row powder packaging machine is cosmetic industry. Probably, it is for sure that you have used bleach powder, facial powder, and hair color powder in bags and sachets which are produced by this machine.

Daily Chemical Industry

Detergent powder with towels

Daily chemical industry is a sector where products like detergent powder, dish washing powder, and floor cleaning powder are manufactured and packed. Therefore, for packing these numerous powders, a multi-row powder packaging machine is utilized in this field.

10.How To Determine The Safety And Quality Of A Multi-Row Powder Packaging Machine?

As multi-row powder packaging machine is meant to be used for both food and non-food powders which include the most sensitive materials like drugs whose minor exposition to harmful particulates can cause health hazards.

That's why, it is always important to make sure the safety and quality of a multi-row powder packaging machine. In this way, few well-known standards are established whose compliance guarantee the machine's quality. These include:

Quality importance icon- Picture Courtesy: 123rf.com

ISO:International Organization for Standardization is an international organization that publishes safety regulations for machines and products across the globe.

GMP:Good Manufacturing Practices is another platform that peculiarly administer the safety of structural material of multi-row powder packaging machine such as it must be made up of 304, 304L, 316, or 316L stainless steel.

FDA:Food and Drug Administration is USA based agency created to hold check on drugs and associated equipment for whether they comply all the essential regulations required for public health and safety.

CE:CE is the certification allotted to all those goods and products who adhere the primary safety regulation set by European Union, so, that they will get an opportunity to sell their products in European Union.

11.Enlist The Procedure For Regular Cleaning And Maintenance Of A Multi-Row Powder Packaging Machine?

Multi-row powder packaging machine is meant to produce large number of finished bags and sachets; therefore, its long-lasting working life is essential which can be only maintained through regular care. This care will include its regular cleaning, lubrication, and parts changeover etc. For this, follow the upcoming guidelines:

Operator maintaining a machine- Picture Courtesy: mes.com.sg

Cleaning:Cleaning of a multi-row powder packaging machine is obligatory for safe and hygienic packaging. Therefore, you need to disassemble the parts of machine from hopper to filling heads and sealing jaws.

Afterwards, wash the hopper, filling heads, and sealing jaws with non-acidic moderate hot water. Dry these comments by wiping with a clean cloth. The cleaning of other parts like control panel, transparent window, and coding device etc., should be carried out through wiping using a moist cloth.

Lubrication:All the transmission and movable parts are in constant working phase whenever you operate the machine. So, long term working can lead to running-in and friction of these parts. Therefore, it is recommended to add lubricating oil periodically.

Parts Changeover:It is a matter of fact, that continuous working of a multi-row powder packaging machine result in the damage or worn out of some tools. However, these parts do not make your machine useless, rather their simple changeover with new ones will give your machine a new life.

Internal Inspection:Before starting operation, it is necessary to perform inspection of the machine internal system such as the air source, power supply, temperature of sealing jaws, amount of material for weighing, and coding data adjustment etc.

12.Give Remedies To Solve The Problems Of A Multi-Row Powder Packaging Machine?

Spontaneous inconsistencies during the working of a multi-row powder packaging machine often leads to reduced packaging efficiency and precision. To avoid these circumstances, it is recommended to take measures in advance for tackling these issues. For this consider the table below:

| i. Sudden tripping of machine during operation | ||

Highlighted power supply system- Picture Courtesy: chengyipacking.com |

Cause:

Incoming power issue. Insufficient voltage of electricity. |

Solution:

Make sure the machine is property plugged in. Ensure that electric board is supplying adequate voltage. |

| ii. The length of packages is unparalleled | ||

Displaying the difference between length of stick packs- Picture Courtesy: chengyipacking.com |

Cause:

The input parameters for bag length are wrong. Bag forming and cutting parts are improperly positioned. Bag forming and cutting tools are damaged. |

Solution:

Adjust the bag length parameters through PLC. Level the bag forming and cutting units properly. Replace the tools with new ones. |

| iii. Inconsistencies in powder filling into bags | ||

Indicating the accumulated powder in hopper- Picture Courtesy: chengyipacking.com |

Cause:

The powder is wet which make it accumulate. The speed of auger is low. Blockage of the filling heads. |

Solution:

Make sure to load dry powder inside the hopper. Increase the speed of auger to suitable level for uniform filling. Clean the filling head by removing debris. |

| iv. Improper tracking of the film | ||

Encircled film roll holder- Picture Courtesy: chengyipacking.com |

Cause:

Uneven dancer's arm and film pulling rollers. Inaccurately positioned film roll. Tension of film roll holder. |

Solution:

Make the dancer's arm and film pulling rollers parallel to each other. Locate the film roll in right place. Lubricate the moving film holder to reduce tension. |

| v. Weak, partial, or burned sealing of bags | ||

Encircled sealing side of various stick packs- Picture Courtesy: chengyipacking.com |

Cause:

Temperature is too low or too high. Low sealing tension. Contaminated sealing bars. Worn out sealing jaws. |

Solution:

Adjust the sealing temperature to suitable level. Increase sealing pressure. Clean the sealing bars. Replace sealing jaws. |

13.Tips For Purchasing An Effective Multi-Row Powder Packaging Machine?

Purchasing an efficacious multi-row powder packaging machine is the dream of every manufacturer but at the same time most of them confront some doubts and difficulties in selecting the right one. So, we have tried to make this step an enjoyable for you through following tips:

Type of Machine

Various stick packs with different types of sealing- Picture Courtesy: chengyipacking.com

Now, after reading the classification of a multi-row powder packaging machine, it will be clear to you that how many types existed in the market. So, you need to choose the machine which suits you the most in terms of efficiency like number of lanes the machine have, the packaging format it follows, and most importantly, the type of sealing which it supports.

Vendor Reputation

Getting an experienced and reputable supplier is as important as the machine itself. It is because a reputable vendor will provide you with customer service and remote support to understand and troubleshoot the machine when needed.

Cost

Finding cost- Picture Courtesy: thomasnet.com

Another critical tip for you to consider the cost from every angle, as a multi-row powder packaging machine is a heavy-duty machine which indicates its high value. So, with any large purchase, you will consider not only the initial cost of machine but its maintenance charges. Hence, if you find it expensive then secondhand machine will be cost-effective.

Warranty

Warranty banner image- Picture Courtesy: brennancorp.com

Warranty provides the guarantee about products, therefore, a multi-row powder packaging machine you are going to purchase should have a warranty which can be of 1-3 years.

Conclusion

Let's wind up this informative buying guide about a Multi-Row Powder Packaging Machine with few reminders. We are sure this guide was helpful for your and resolve the puzzles of confusion that existed in your mind regarding a multi-row powder packaging machine. Now, when you have finally explored its different aspects, it is better to opt the write machine for your lucrative business. If you are still struggling to trust which supplier, then we recommend you to consider Allpack which is having over 11 years of experience in this field. Not only that but offer you with 1 year of warranty. Contact us for further information!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide