Oil 3 Side Seal Packaging Machine: The Complete FAQ Guide In 2025

Oil is a vital ingredient in culinary. Oil is not only used in dishes but also has cosmetic and medical purposes. Nutritional benefits, flavor, and quality of the oil are preserved by the oil 3 side seal packaging machine.

Oil 3 side seal packaging machine is utilized in the food, cosmetic, and nutraceutical industries because it makes cost-effective, minimal space, and easily packed 3 side seal packaging. It revolutionizes the oil packaging process through its efficiency, versatility, and automation.

If you’re looking for a solution to improve production then an oil 3 side seal packaging machine is the best option. But before going out to purchase this machine, first read this informative FAQ guide to get acquainted with the different elements of the oil 3 side seal packaging machine.

1.What is an Oil 3 Side Seal Packaging Machine?

Oil 3 Side Seal Packaging Machine- Picture Courtesy: Western Packing

Oil 3 side seal packaging machine is a state-of-the-art piece of equipment solely designed for packaging oils. It makes three seals at three seams of the oil packaging. It hermetically seals the top, bottom, and one vertical seam or it seals the top, and two vertical seams.

This machine has a prime place in the food industry because it automates the filling and sealing functions in the oil packaging. It processes and packs various types of oils, differing in their viscosities and chemical composition.

2.Why is Oil 3 Side Seal Packaging Machine Advantageous for Production?

Oil 3 side seal packaging machine is associated with a wide range of benefits for the production. It ascertains the quality and integrity of oil products. Some of its common advantages are penned below:

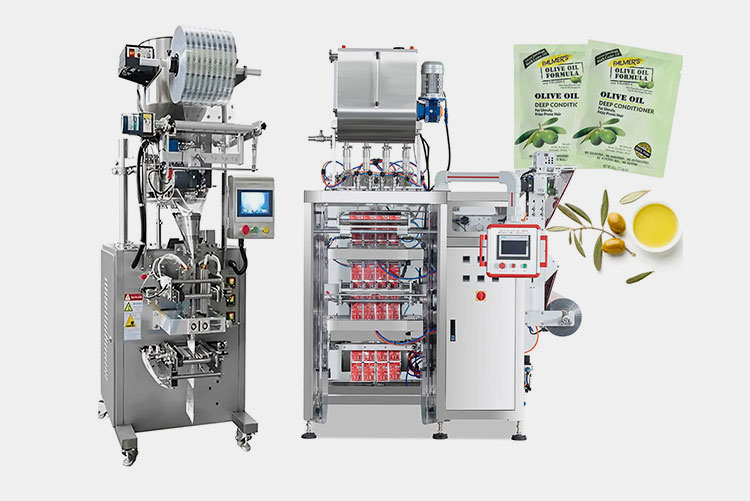

Increased Automation and Speed

Increased Automation and Speed- Picture Courtesy: Asian Flex Pack

High and medium-scale industries are working consistently to deliver high-quality results. This is where the oil 3 side seal packaging machine shows its value. Due to its automation, it packs numerous products with minimal human intervention. It efficiently packages oils at increasingly high speeds.

Consistently High-Quality Results

Consistently High-Quality Results- Picture Courtesy: Behance

Different units are fitted in the oil 3 side seal packaging machine to detect errors at every step. Hence, the oil 3 side seal packaging machine presents high-quality packaging results in every cycle.

With its precise and accurate filling devices, there is no fill variation from batch to batch, consequently, this machine is approved by the industrial sectors.

Improved Protection

Improved Protection- Picture Courtesy: Keeko

One of the top aims of the oil 3 side seal packaging machine is to offer oils a high level of protection by packaging them. It prevents the chances of oil contamination and protects them from elements like air, moisture, heat, and sunlight. Oil 3 side seal packaging machine completely secure inside the packaging and prevents their leakage.

Multi-Tasking

Multi-Tasking- Picture Courtesy: Pinterest

Another interesting advantage of the oil 3 side seal packaging machine is an allrounder machine, capably fulfilling the numerous tasks of forming, filling, and sealing in one machine. It saves operators from the hassle of going from machine to machine for carrying out different steps.

Customization and Versatility

Customization and Versatility- Picture Courtesy: Pakona

The oil 3 side seal packaging machine also has significance in the industries because it can pack numerous oil packing, differing in sizes and styles. Different industries have their specialties, so, this machine is tailored according to the production needs. This machine is easily configured to allow businesses to output oil packaging of different styles and volumes.

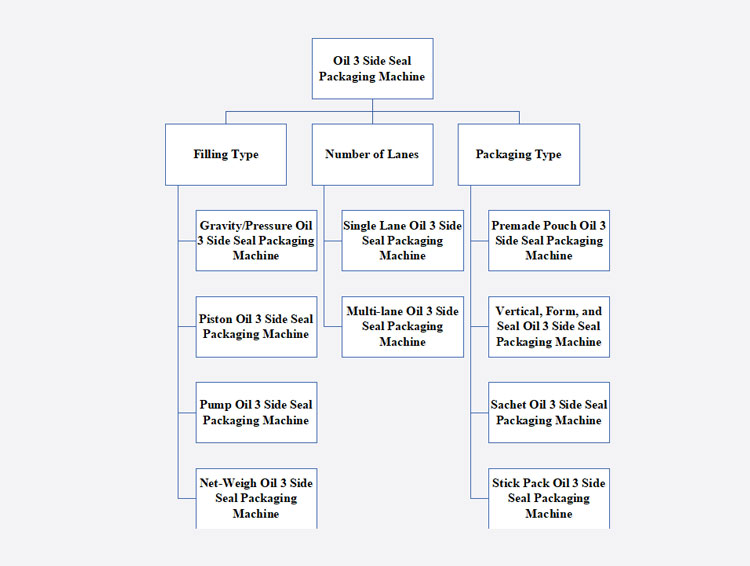

3.What are the Categories of Oil 3 Side Seal Packaging Machine?

Oil 3 side seal packaging machine comes in various shapes and sizes. So, we are explaining the categories below:

According to the Filling Type

Gravity/Pressure Oil 3 Side Seal Packaging Machine

Gravity/Pressure Oil 3 Side Seal Packaging Machine

It is a straightforward type of oil 3 side seal packaging machine with simple design construction. Thus, it has minimal maintenance, it comes with a hopper and filling valve that are the main part of the machine. It fills oils by the pressure differences or by gravity. This machine is generally used for thinner viscosity of oils.

Piston Oil 3 Side Seal Packaging Machine

Piston Oil 3 Side Seal Packaging Machine

It consists of the piston and cylinder which are the chief parts of the piston oil 3 side seal packaging machine. The oils are deposited in the container by the movement of a piston in the cylinder. This machine is useful for filling both thinner and thicker consistency liquids. It is known for its increased speed and extreme accuracy.

Pump Oil 3 Side Seal Packaging Machine

Pump Oil 3 Side Seal Packaging Machine

It is equipped with multiple kinds of pumps that fulfil the job of dispensing oils in 3 side seal packaging by their rotation. The pumps present in the pump oil 3 side seal packaging machine are cavity, gear, lobe, and rotor pumps. It can process any type of oil whether thinner or thicker viscosity.

Net-Weigh Oil 3 Side Seal Packaging Machine

Net-Weigh Oil 3 Side Seal Packaging Machine

This machine is renowned in different industries because it fills oils by their weight instead of their volume. It is equipped with scale and load cells that measure sand dose oils accurately. It is usually suited for filling products in bulk quantities.

According to Number of Lanes

Single Lane Oil 3 Side Seal Packaging Machine

Single-lane Oil 3 Side Seal Packaging Machine

As the name suggests, it consists of just one lane with which it forms, fills, and seals one sachet or stick pack in one cycle. It is a compact design machine with a minimal footprint. It is easy to clean and maintain the single-lane oil 3 side seal packaging machine.

Multi-lane Oil 3 Side Seal Packaging Machine

Allpack Multi-lane Oil 3 Side Seal Packaging Machine

This machine has high productivity because it has more than one lane usually about 2, 4, 8, and 16. Thus, it can produce many sachets and stick packs in one setting. It needs more space in the production because of its larger footprint. It is difficult to clean and maintain this manufacturing unit.

According to the Packaging Type

Premade Pouch Oil 3 Side Seal Packaging Machine

Premade Pouch Oil 3 Side Seal Packaging Machine

This machine processes already-made pouches, so it fills and seals multiple pouches in one go. It continuously processes oil pouches so it does not stop filling oils, consequently, it operates at much higher speeds. It has a rotary-type configuration because it is designed with a circular turntable.

Vertical, Form, and Seal Oil 3 Side Seal Packaging Machine

Vertical, Form, and Seal Oil 3 Side Seal Packaging Machine

It is a compact unit, needing less room for installation and setup. It is a cost-effective unit that increases its popularity in the industrial sector. It is a customizable machine because it uses packaging film for forming pouches, consequently, the packaging sectors tailor this machine according to their needs.

Sachet Oil 3 Side Sal Packaging Machine

Sachet Oil 3 Side Sal Packaging Machine

This machine features one or more lanes and its processing speed is dependent upon its number of lanes. It makes small sachets having a single serving of oils. Sachet oil 3 side seal packaging delivers optimal quality with its versatility and accuracy. It performs packaging operations in the vertical direction.

Stick Pack Oil 3 Side Seal Packaging Machine

Allpack Stick Pack Oil 3 Side Seal Packaging Machine

This machine has increased productivity because of its greater number of lanes. It is usually found in large-scale ventures because of its high processing rates. It can form a long tubular stick pack containing a one-time serving of the oils.

4.What are the Working Steps of Oil 3 Side Seal Packaging Machine?

Each component of this machine plays a specific role in the efficient and harmonious working of the oil 3 side seal packaging machine. Here is the detail of important steps that occur in this machine.

| Film Loading and Pulling

In the beginning, a large film role is positioned on the films’ unwinding disk. The film is guided over the rollers and the dancer’s arm. |

Film Loading and Pulling |

| Oil Loading

The bulk volume of the oil is stored in the hopper located at the top. This step is essential for the smooth packaging of oils. |

Oil Loading |

| Bag Formation

The bag is formed by the forming tube when the film arrives at the forming station. This film is doubled and wrapped to fabricate the bag. |

Bag Formation |

| Vertical Sealing and Filling

The vertical jaws seal the vertical seams of the folded film. The oils are then dispensed inside the newly formed packaging. |

Vertical Sealing |

| Horizontal Sealing

In this step, the top end is sealed using horizontal jaws using heat and pressure. |

Horizontal Sealing |

| Cutting

In the final steps, an integrated cutter present between the sealing jaws cuts the two joined 3-side sealing packaging from each other via its sharp edge. |

Cutting |

5.What Packaging Styles are Produced by Oil 3 Side Seal Packaging Machine?

Oils are available in all kinds of packaging styles and these packaging styles are processed by oil 3 side seal packaging machine. The complete list of these packaging styles is discussed below:

Spout Pouches

Spout Pouch- Picture Courtesy: scholleipn.com

This pouch is sealed at three sides and it has a nozzle at its top edge. This nozzle offers users ease of pouring oils. Spout pouches decrease the spillage and thus, wastage of oils.

Pillow Pouches

Pillow Pouches- Picture Courtesy: Blue Mockup

It is also called a T-seal pouch due to its back seal that runs along its middle on the backside. It has a pillow-like shape because of its distinct corners. It is an economic pouch style.

3 Side Sachet

3 Side Sachet- Picture Courtesy: Behance

As the name suggests, this sachet has a similar design to that of 3 side seal pouch. The difference between three three-sided seal pouches and three-sided seal sachets is that the latter usually packs one serve of the oils.

Stick Pack

Stick Pack- Picture Courtesy: The Grocer

It has a central seal and a distinct top and bottom seal. It is a long tubular structure that has more length than width. It also houses a single serving of the oils.

6.Howthe Oil 3 Side Seal Packaging Machine and the Oil 4 Side Seal Packaging Machine are Different from Each Other?

Oil 3 Side Seal Packaging Machine and Oil 4 Side Seal Packaging Machine

Oil 3 side seal packaging machine and oil 4 side seal packaging machine are vastly different from each other based on their production of different style pouches. The differences in these machines are listed below:

| Features | Oil 3 Side Seal Packaging Machine | Oil 4 Side Seal Packaging Machine |

| Sealing Sides | This machine seals the upper and two vertical seams of the pouches or sachets. | It seals two horizontal and two vertical seams of the pouches or sachets. It seals a total of 4 sides, hence, the name oil 4 side seal packaging machine. |

| Appearance | The pouches produced by this machine have a flat bottom. | The pouches produced by this machine are sealed bottom. |

| Cost-Effective | Oil 3 side seal packaging machine is a budget-friendly option because of its simpler design. | It is costly because of its complicated sealing mechanism. |

| Uses | It usually packs small quantities of the oils. | It packs large quantities of oils. |

| Tamper-Evident Seals | It creates less tamper-evident seals. | It forms more tamper-evident and leak-proof seals. |

7.What Type of Oils are Packed by Oil 3 Side Seal Packaging Machine?

Oil 3 side seal packaging machine is a versatile and flexible machine, packing both edible and non-edible oils in 3 side seal packaging. The details of these oils are given below:

| Edible Oils

These oils are the favorite of many consumers, and these oils are directly consumed. Their examples are olive oil, sunflower oil, canola oil, coconut oil, etc. |

Cooking Oils |

| Cooking Oils

These types of oils are included in culinary dishes because of their light and mild flavors. These include canola oil, soyabean oil, and, palm oils |

Cooking Oils- Picture Courtesy: BajarHaat |

| Specialty Oils

These oils are included in different cosines because of their characteristics and unique flavor. These oils boost the flavour of dishes. They include herb-infused oils and truffle oils. |

Specialty Oils |

| Essential Oils

These oils are acquiring traction day by day because of their diverse utilization in aromatherapy, personal care, and cosmetic items. |

Essential Oils |

| Nutraceutical Oils

These oils are consumed because of their health-boosting benefits, like fish oils are a rich source of omega-3 fatty acids. |

Nutraceutical Oils- Picture Courtesy: Carlson Labs |

| Cannabis Oils

These oils are packed in the pharmaceutical industry by oil 3 side seal packaging machine. They are used for treating psychiatric disorders, pain, and inflammation. |

Cannabis Oils- Picture Courtesy: Magna Cosmetics |

8.What are the Accessories Included with Oil 3 Side Seal Packaging Machine?

The accessories included with the oil 3 side seal packaging machine are discussed below:

Product Hopper with Agitator

Product Hopper with Agitator- Picture Courtesy: National Bulk Equipment

This hopper is useful when filling oils with high viscosity. The agitator allows to achieve steady oil flow during the packaging process.

Filling Nozzle Set

Filling Nozzle Set

Some types of oil 3 side seal packaging machines come with interchangeable filling nozzles. These nozzles are useful when processing oil pouches of different sizes.

Date Coding Printers

Date Coding Printers

For printing expiry dates and bar codes on the packaging film, the date coding printer is featured in this machine.

Safety Guard Rail

Safety Guard Rail

A safety guard rail is also present in oil 3 side seal packaging machine to prevent unintentional machine contact while the machine is running. It is beneficial for safety purposes as it reduces the chances of electric shock

9.Does the Oil 3 Side Seal Packaging Machine Comply with Industrial Regulations?

Yes, the oil 3 side seal packaging machine complies with industrial regulations such as:

| CE Certification

This type of certification is required by oil 3 side seal packaging machines sold in European countries. This certification shows that this machine meets all safety and occupational standards. |

CE Certification |

| GMP Certification

This certification indicates that the oil 3 side seal packaging machine is produced under the guidelines issued by good manufacturing protocols. It ensures superior quality oil packaging by oil 3 side seal packaging machine. |

GMP Certification |

| FDA Certification

This certification is necessary if the machine is manufactured and used in the United States. FDA compliance is vital for machines involved in the food and medical sectors. |

FDA Certification |

| ISO Certification

This certificate indicates manufacturers are committed to implementing quality management protocols during machine production. It ensures consistent quality of oil 3 side seal packaging machine. |

ISO Certification |

| ATEX Certification

This certification is necessary for the machine processing explosive and inflammable oils. It denotes that an oil 3 side seal packaging machine is produced with explosion-proof parts. |

ATEX Certification |

| HACCP Certification

This certification is important for the machine packaging of edible oils. It ascertains the safety of edible oils as well as operators and reduces the chances of oil contamination. |

HACCP Certification- Picture Courtesy: www.bharatagritech.com |

10.What are the Issues Faced by the Oil 3 Side Seal Packaging Machine?

Oil 3 side seal packaging machine, an engineering marvel faces some unexpected issues that delay production. But there is no need to worry as these problems are easily resolved by the mentioned tips below.

Filling Inaccuracies

Filling Inaccuracies- Picture Courtesy: EDPOL Food & Innovation Sp. z o.o.

Packaging containers are over and underfilled. This issue is due to poor calibration of the filling devices. Old or defective nozzles are also the reason for fill inaccuracies. Changes in oil viscosities also cause fill variations.

Solution

This problem is solved by calibrating filling devices and by changing old nozzles. Sometimes, this issue is solved by changing the fill parameters based on oil viscosities.

Presence of Air Bubbles in the Seal

Presence of Air Bubbles in the Seal- Picture Courtesy: Behance

Sometimes, tiny air bubbles are seen in the seals of 3 side seal packaging. The presence of air during the sealing process creates air bubbles in the seals. It negatively impacts the quality of oil packaging.

Solution

To prevent air bubbles in the seals, ensure that the vacuum and air pressure are according to the manufacturer’s instructions. Also, ascertain there are no folding or creases in the packaging film.

Weak Seals of Packaging

Weak Seals of Packaging

There is a weakness or loss of seal integrity after the sealing process. This issue is due to inconsistent seal temperature and pressure. Weak seals are also caused by unclean, defective or damaged sealing bars.

Solution

This problem is corrected by ensuring adequate pressure and temperature during the sealing process. Moreover, by cleaning and replacing sealing jaws, this problem is resolved.

Inconsistencies in the Packaging Dimensions

Variation in sealing edges of packaging

Sometimes, there are differences in the lengths of pouches created by the oil 3 side seal packaging machine. This issue is caused placement error of the film roll on the holder and improper alignment of forming and cutting devices. Moreover, it is also due to programming errors like wrong input of length parameters.

Solution

This error is solved by correctly inputting the pouch length parameter on the machine HMI. Correctly positioning the film roll and aligning the forming and cutting device also solves this problem.

Conclusion

This FAQ guide about oil 3 side seal packaging is informative and it covers every aspect of this machine. This machine is an amazing addition to the production lines and boosts the efficiency and profitability of the machine. By following the tips mentioned in this FAQ guide, you can package edible and non-edible oils in your business. So, without further ado, contact Allpack customer care to acquire state-of-the-art machines at discounted rates. Happy Shopping.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide