Tablet Counters: The Complete Buying Guide In 2024

Do you know why it important to count tablets before its packaging. Does your business involve manufacturing of different kinds of tablets? Does your business involve tablet counters for counting of tablets? Are you interested in buying a tablet counter to make your business more reliable and efficient? This is the right platform from where you will get all your queries solved related to tablet counters.

This buying guide will assist you in selecting the right type of tablet counter for your process and help you in understanding all its usages. Read the complete guide to solve your queries

1. What Are Tablet Counters?

Allpack Auto Counter 32 Channel Tablet Counter

A tablet counters are used in pharmaceutical, food, nutraceutical, cosmetics and chemical industries to count tablets of various sizes and shapes in bulk quantity. This equipment is highly versatile that it copes up with high productivity processes and gives fine and optimal results. The counter efficiently counts the number of tablets by the sensing of highly sensitive components present in it.

2.What Are The Industrial Applications Of Tablet Counters?

Tablet counters are equipped with perform detection, separation and counting of tablets on their own in a single operation. Due to this feature these counters are applied in many industries including:

Pharmaceutical Industry

Pharmaceutical Tablets – Picture Courtesy: Medicircle

Pharmaceutical industry is the greatest user of tablet counters as millions of tablets are produced on daily basis to meet the global requirement. These tablets are impossible to be counted and packaged manually and this is why tablet counters are efficiently applied in pharmaceutical industry. This also ensures accurate dosage formulation of tablets to maintain safety and health concerns.

Nutraceutical Industry

Nutraceutical Tablets – Picture Courtesy: Nutraceutical Companies

Global demand of tablets produced in nutraceutical industries is also growing day by day. This industry also uses tablet counters for accurate dispensing of tablets and to ensure that the required packaging quantity remains uniform in each package.

Chemical Industry

Dishwashing Detergent Tablets – Picture Courtesy: Minq

Similar to pharmaceutical and nutraceutical industries; tablets made up of chlorine that are used for cloths and laundry purpose, dishwashing foam tablets, chemical tablets are also counted using tablet counters. This maintains the overall performance of system and specifies the standard weight in each packaged bag.

Food Industry

Food Supplements– Picture Courtesy: The Guardian Nigeria

Candies, chocolates and gums that are sweet and flavored in nature also appear like tablets. These are manufactured in a way that their process line requires tablet counters to count them in a desired number. The counted candies are then filled in their respectively packaging.

Cosmetics Industry

Beauty Rose Cosmetics Tablets– Picture Courtesy: Tanie Cosmetics

Some of the cosmetic products used for skin, hair and body treatments are present in tablet form also. This is why cosmetics industry uses tablets counters to assist the packaging process and maintain the quality standards. Biotin skin care tablets, glutathione tablets are some of the cosmetics tablets counted using tablet counters.

3.What Are The Advantages Of Using Tablet Counters?

Some of the advantages of using tablet counters are

Precision And Accuracy

Precise Tablet Counting

Tablet counters are highly precise and accurate that they can count thousands of tablets without any error. The method executes proper precision and accuracy no matter what type of tablets are processed.

Efficiency

Efficient Tablet Counting – Picture Courtesy: Banner Engineering

Both process and time efficiency are provided using tablet counters in any processing system. This is a significant advantage of tablet counters as the increasing in demand is observed in the past two decades.

Consistency

Advantages Of Tablet Counters – Picture Courtesy: AIPAK

Tablet counters are always reliable to use it shows consistency and uniformity while managing large batches of tablets. The quantity of tablets remains same throughout the process and shows no deformation.

Adaptability

Advantages Of Tablet Counters – Picture Courtesy: iPharmachine

Different types and sizes are available these days. A single tablet counter being versatile equipment shows adaptability at a greater level and can easily manage these tablets. Just few settings are required to process variety of tablets in a single machine.

Visual Observations

Advantages Of Tablet Counters – Picture Courtesy: iPharmachine

Throughout the process, tablets can very clearly be seen in a tablet counter as it has transparent appearance. The operator can monitor all the progress from here and can easily judge any sort of problem in its smooth operation.

4.What Are The Sizes And Shapes Of Tablets That Undergo Tablet Counters?

Some of the tablet sizes and shapes that are counted using a tablet counter are:

Rectangle Shaped Tablets

Rectangle Tablets– Picture Courtesy: Drugs.com

Varieties of tablets are found in rectangle shape that are used to aid and diagnose different human diseases.

Oval Shaped Tablets

Oval Shape Medicine Tablets– Picture Courtesy: Freepik

Oval or egg type tablets are also manufactured in different types of industries. These are easily swallowed due to their cutting edge.

Square& Round Shaped Tablets

Square Shape Tablet– Picture Courtesy: Aipak

The most common shape of tablet available globally is a square and round shaped tablet. Different sizes of these tablets are used for the treatment of multiple diseases and are consumed easily. Food and cosmetics supplements are also mostly available in this shape.

Customized Shaped Tablets

Customized Size And Shapes Of Tablets– Picture Courtesy: Aipak

Other than ordinary shapes, different types of customized shapes including diamond, kidney, triangle, heart, special and core also undergo tablet counting using tablet counters. These shapes range between 10 mm to 50 mm and are directly supported by a tablet counter.

5.What Is The Working Principle Of Tablet Counters?

Working Of Tablet Counters

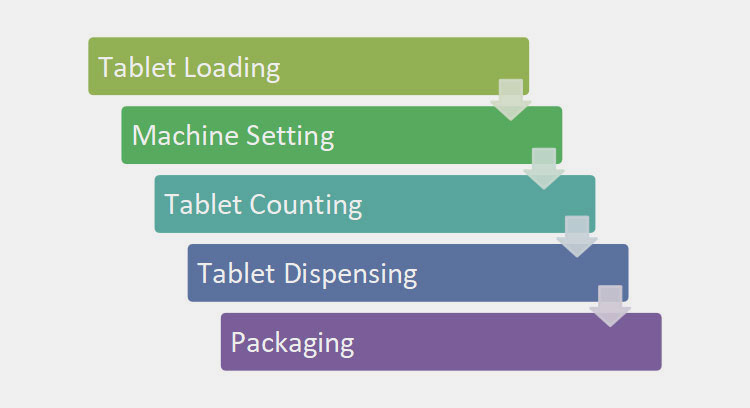

A tablet counter works in following working steps:

STEP 1: Tablet Loading

Initially the tablets are loaded in bulk amount into the counter’s hopper present at the top of it. The volume remains defined as standard and from here these tablets are moved to the loading and filling lines.

STEP 2: Machine Setting

Simultaneously, the setting of machine is also carried out by the operator related to its speed, counting number, loading speed and etc. These are all adjusted manually according to the requirement.

STEP 3: Tablet Counting

Once the setting is done, the tablets are moved towards the counting area where these tablets are first aligned and then counted using special sensors and actuators. Each of the column of tray gets its aligned tablets and the counting operation remain on until the last one is detected.

STEP 4: Tablet Dispensing

Some of the tablet counters dispense the counted tablets via conveying system while the other have a depositing process where specific number of tablets are collected to make packaging easier.

STEP 5: Packaging

The collected tablets are either filled in different types of bottles or are placed in blister packaging machine for blister formation.

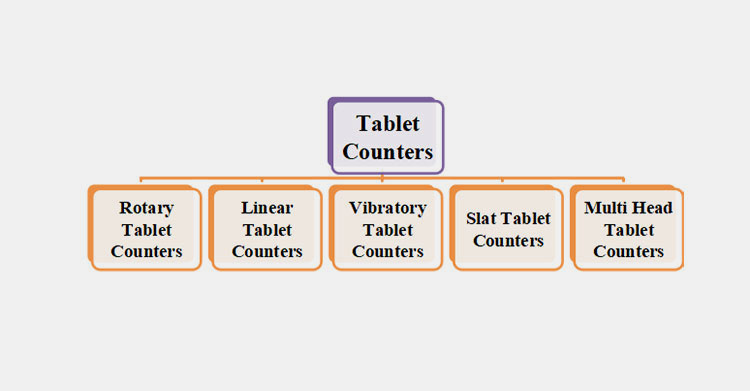

6.What Are The Types Of Tablet Counters Available Globally?

Tablet counters are mostly classified on the basis of their working principle and automation level. Both of the features are integrated with each other to perform the task efficiently. Some of the types of tablet counters are:

According To Their Automation Level

Types Of Tablet Counters

Fully Automatic Tablet Counters

Allpack Fully Automatic Tablet Counters

Fully automatic tablet counters are the most advanced type of tablets counters as it counts millions of tablets in just a fraction of time. These tablet counters are used in large scale industries where complete process is based on automation and no manual intervention is required. Bottles ranging from 100 to 200 can easily be filled using these tablet counters in just a minute.

Semi-Automatic Tablet Counters

Allpack Semi-Automatic Tablet Counters

Both manual and automatic processes are involved in semi-automatic tablet counters. These are preferable for medium scale industries where the productivity remains moderate. The operator is responsible to load and unload the tablets whereas the counting process is complete carried out automatically. Bottles up to 100 can easily be filled in a minute using semi-automatic tablet counters.

Manual Tablet Counters

Manual Tablet Counters

Manual tablet counters involve complete operator efficiency as it depends directly on it. A minor possibility of error always remains in this type of tablet counters due to manual processes. The productivity remains low and can fill up to 20 to 30 bottles in a minute only.

Laboratory Purpose Tablet Counters

Laboratory Digital Tablet Counters

Some of the tablet counters are also designed for laboratory or research and development purposes. These counters are used to count small amount of tablets to maintain accuracy and uniform formulation in various laboratory testing.

According To Their Working Principle

Rotary Tablet Counters

Rotary Tablet Counters

Rotary tablet counters are usually having rotating mechanism in their structure to count numbers of tablets. A disc rotates tablets in a guided path and counts them according to it. On exact standard number, the rotation stops and the tablets are discharged.

Linear Tablet Counters

Linear Tablet Counters

As the name suggests, tablets are allowed to move in a linear or straight path in linear tablet counters. The hopper releases tablets and their further movement is supported by a conveying system. All the tablets pass through photoelectric sensors that counts the total number of tablets directly. One achievement of desired number, the tablets are deposited into bottles of various sizes.

Vibratory Tablet Counters

Vibratory Tablet Counters

Vibratory tablet counters use vibration effect to move and count tablets of various types. Once the tablets are released from the hopper, a vibrating surface helps in their separation and uses sensors to detect their total count. The vibration tablet counters are mostly suitable for solid and fragile types of tablets that are easy to handle.

Slat Tablet Counters

Slat Tablet Counters

For specifically flat, square, and oblong shaped tablets, slat tablet counters are used because these tablets cannot be accommodated in other machines. The transportation of these tablets is carried out via conveyor belts and their surfaces are fed in a way that each channel is supported with accurate counting. Tablets of irregular shapes can also be counted using slat tablet counters.

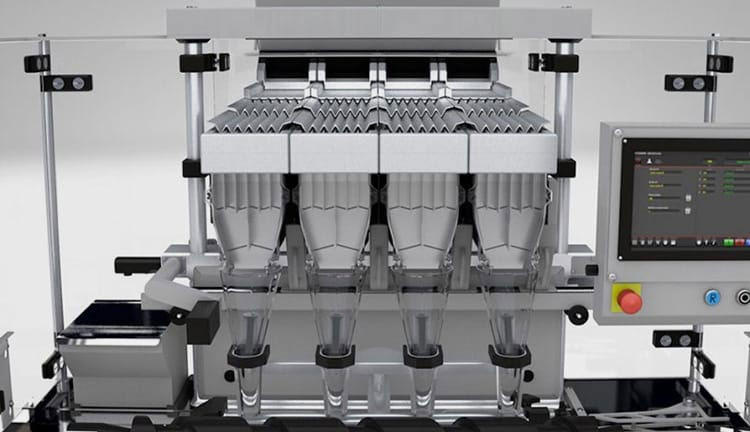

Multi Head Tablet Counters

Allpack Multi Head Tablet Counters

Most of the large-scale industries use multi head tablet counters due its their high productivity and efficiency. More than two heads are found in these machines that help in easy and quick filling of bottles. The throughput of multi head tablet counters is much higher as compare to those of single head tablet counters.

7.What Are The Main Components In Tablet Counters?

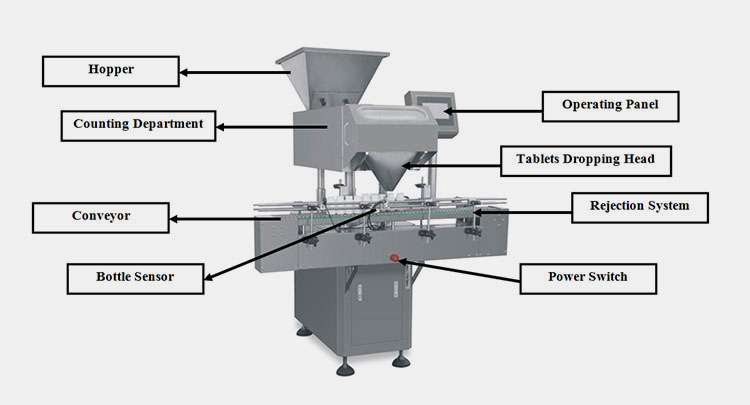

Components Of Allpack Automatic Tablet Counters

Hopper

This is the area from where the tablets are fed into the system. Hopper is mostly present at the top of tablet counters that have a broad opening at its upper side and a narrow one at bottom. From here the tables are inserted into the counting department in a synchronous manner.

Counting Department

This is the most important part of tablet counters where the tablets are counted with the help of highly sensitive photoelectric sensors. These sensors allow specific number of tablets into the tablet dropping head and switches off the valve opening once the desired number is achieved.

Conveyor

Conveying system is used for the movement of packaging material within tablet counters. These materials can be bags, pouches or bottles that are moved on the conveyor and filled once they reach the tablet dropping head.

Bottle Sensor

In tablet counters, bottle sensors are attached parallel with the conveyor that performs dual operation. Firstly, it detects the presence of bottle and secondly is activates the releasing sensor of tablet dropping head to fill the bottle with precise amount of tablets.

Operating Panel

An operating panel in tablet counters is the place that has a direct access to the operator. The operator monitors and controls all the processes taking place in tablet counters. The controlling parameters are also set via this operating panel.

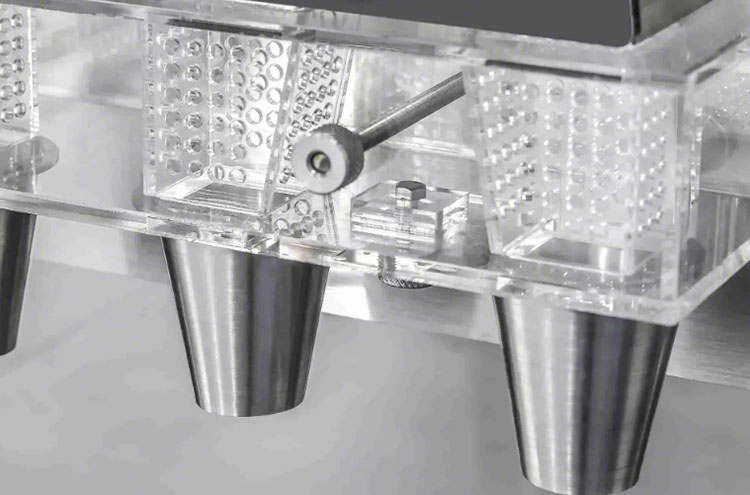

Tablets Dropping Head

Once the tablets are counted in sets in a tablet counting department, these are then moved towards the tablet dropping head. It is mostly conical in shape that makes the filling process easier and reliable.

Rejection System

In some of the tablet counters, rejection system can also be incorporate to check the quality and quantity of tablets. This system takes out faulty or improper tablets so that the process remains smooth and efficient.

Power Switch

Power switch is used to turn on off the power system of tablet counters. These are mostly present at the front to control the process and making its cut off easy during any unwanted circumstances.

8.What Are The Different Types Of Sensors And Actuators Used For Counting In Tablet Counters?

Most commonly used sensors and actuators for counting of tablets in tablet counters are:

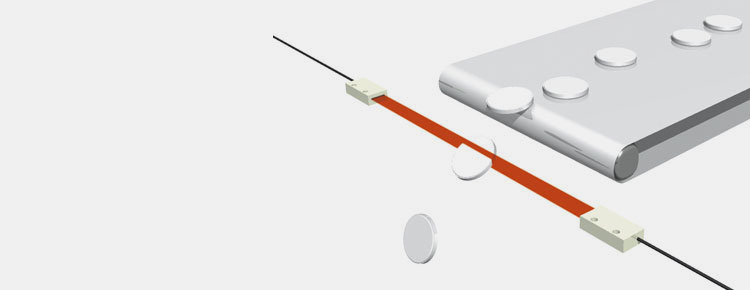

Photoelectric Sensors

Application Of Photoelectric Sensors In Tablet Counting – Picture Courtesy: Optex - FA

The most precise and accurate sensor used to count tablets are photoelectric sensors. These are positioned in a way that each of the tablets crossing the photoelectric beam gets detected and counts its presence.

Vibration Sensors

Vibration Sensors For Speed Calculating – Picture Courtesy: Ascendtech

Mostly vibration sensors are present in the counting department of tablet counters that are used to detect the mechanical movement of tablets. These sensors are ideal for tablets with fragile coating and for those that are difficult to be sense using photoelectric or optical radiations.

Infrared Sensors

Infrared Sensor For Tablet Counting

Infrared sensors are also like photoelectric sensors that are used for detecting tablets with the help of infrared light. This light does not get interfered with different colors and it ideal for counting colorful tablets.

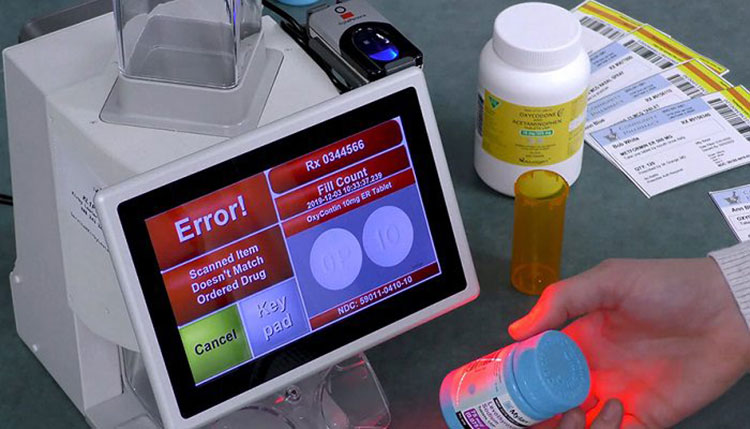

Weight Sensors

Pharmacy Tablet Counters – Picture Courtesy: Capsa Healthcare

Once the tablets are counted, weight sensors are there to calculate their required well both in individual condition and also when packaged in pouches, bags or bottles. This helps to produce uniform medication throughout the process.

9.What Are The Auxiliary Machines Present In The Production Line Along Of Tablet Counters?

The tablet counting processing line includes following auxiliary machines to support and excel its process:

Bottle Unscrambler

Allpack Semi-automatic Electronic Turntable Rotary Bottle Unscrambler

Bottle unscrambler is used to position the bottles into the conveying system that are to be filled with tablets ahead. This helps the bottles to remain controlled throughout the process in an aligned and sequential way.

Capping Machine

Allpack Bottle Capping Sealing Machine

Once the bottles are filled with the desired amount and weight of tablets, they undergo capping process where lid and cap in inserted on their tops. Different types of caps can easily be accommodated in a single capping machine.

Induction Sealer

Allpack Continuous Induction Sealing Machine

To ensure product safety and help it remain free from environmental effects, induction sealing is carried out of caps so that no air or environmental content can enter in its vicinity.

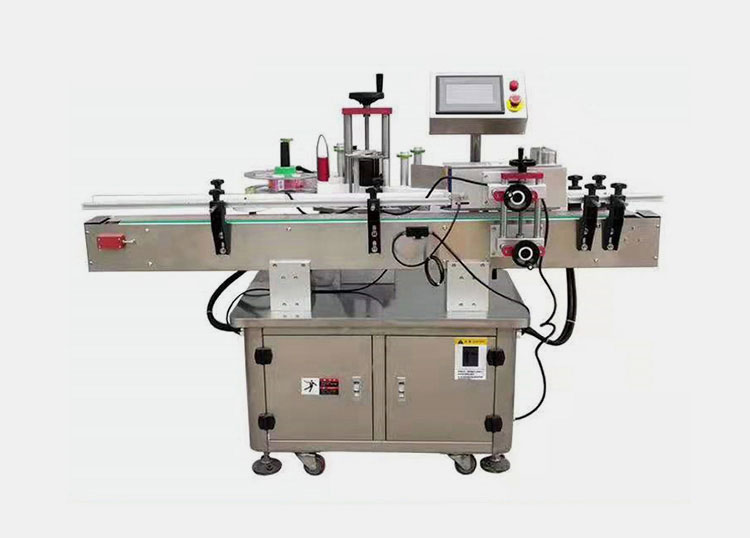

Labeling Machine

Allpack Bottle Labeling Machine

A labeling machine is used to apply labels on tablet bottles. These labels carry all product and manufacturer related information that can assist the consumer in getting all related information.

10.What Factors Can Affect The Efficiency Of Tablet Counters?

Efficient Tablet Counting - Picture Courtesy: Altrimex

The efficiency of tablet counters can affect when only two factors can be observed. Firstly, if the tablet does not holds the required characteristics as it is standardized or secondly if the sensors are not working properly. Tablets with different shape or color if mixed together can cause trouble in counting ability of tablet counter. Meanwhile the sensors also need to be monitored and calibrated timely to get authentic results.

11.How To Maintain Tablet Counters For Its Smooth Operation?

Some of the steps that should be taken to maintain smooth operations of tablet counters are:

Cleaning

Service And Support - Picture Courtesy: Kirby Lester

It is always important to clean tablet counters at the end of every batch process to make the machine contamination free and to increases it working life.

Lubricating

Lubrication Of Parts

To avoid rust in moveable parts of tablet counters, lubrication should be carried out on timely basis so that their movement can be done properly.

Maintenance Scheduling

Managing Maintenance Plan

For both predictive and preventive maintenance a properly should be prepared on monthly or yearly basis according to its standards. This will help in checking of all parts and change any of them if required.

Calibration

Calibrating Tablet Counters Sensors - Picture Courtesy: Scientific Industries

As variety of sensors are incorporated in tablet counters, it is always important to verify their operations and check their sensing ability. If any sort of error occurs, calibrate the specific sensor or replace it immediately to get efficient counting performance.

Conclusion

Tablet counters are highly reliable for counting tablets in a specific amount without any error. These tablets can easily be counted even if they are millions in number. But it is important to select the correct type of tablet counters to boost the productivity. We hope this buying guide has conveyed very informative points to you regarding tablet counters that you were looking for. Allpack is here to provide you complete assistance in selecting the right type of tablet counters. Do contact out customer representative available 24/7 for further information and guidance if required.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586