Coating Machine in Pharmaceutical Industry: The Complete Buying Guide In 2025

Every pharmaceutical industry needs a solution to coat solid dosage formulation. Do you know the reason?

This is an important process step ensuring that tablet or capsule is meeting patient compliance in the term of masking taste and enhancing colors and other in-taking high demands.

With our vast experience on dealing coating machine in pharmaceutical industry; we have designed a combined effort and expertise to create the guide on ‘Coating Machine in Pharmaceutical Industry’.

Please read on to explore about this significant equipment.

1.What Is Coating Machine In Pharmaceutical Industry?

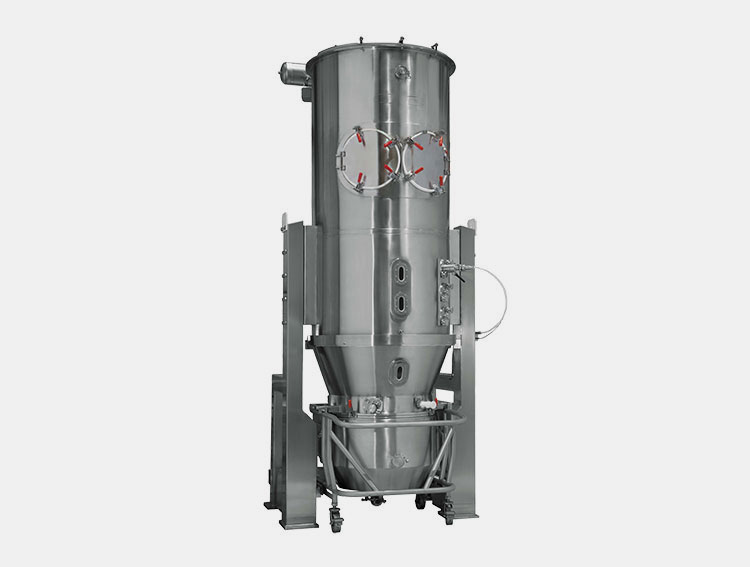

Coating Machine In Pharmaceutical Industry- Picture Courtesy: Aipak

The coating machine in pharmaceutical industry is used to coat a dosage form i.e., granules, tablets, capsule with coating material which is either sugar or film solution over the outer surface to achieve certain required actions.

The machine is designed with simple to complex form, small to large in structure to bring an even distribution of coating material over coating bed. The machine is specifically used in pharmaceutical industry as to achieve desirable results upon reaction of drugs at a specific target site.

A coating machine in pharmaceutical industry is a simple to use machine with certain limitations that everyone must consider (discussed later part of the blog).

2.When Coating Machine In Pharmaceutical Industry Developed?

Concept of Coating Initiated in the Early 1800s

Initially, the concept of coating began with Rhazes using psyllium seeds to hinder its bitter taste. It was later reported by Avicenna.

In 1838, Garot used gelatin to coat pills. The poisonous tablets were specially coated to prevent unintentional consumption. In 1842, sugar coating was introduced, and in 1950, the sugar coating technique was considerably used with coating machine in pharmaceutical industry.

The same technique was employed in food industries to coat candies. Today sugar coating and film coating processes using coating machine in pharmaceutical industry are the most prevalent techniques across the globe.

3.Why Do You Need Coating Machine In Pharmaceutical Industry?

The pharmaceutical solid dosage formulations are susceptible to degradation by external environment factors. Therefore, you always need to coat them for extra protection. Besides this, the emergence of coating machine in pharmaceutical industry is always in demand due to the following reasons:

Improving Shelf Life

Coating machine in pharmaceutical industry extends drugs shelf life

Coating machine in pharmaceutical industry is used to extend and stabilize the shelf life of solid dosage form by forming a protecting layer against its interaction with external physical parameters like light, moisture, air, etc.,

Masking Bad Taste

No bitter taste with coating machine in pharmaceutical industry

Previously, it was a problem when taking solid dosage forms. In fact, for many patients, ingesting a tablet or capsule was intolerable due to its taste. A coating machine in pharmaceutical industry is high in demand due to masking the bad or bitter taste of medicines.

Masking Bad Odor

No bad odor

Many solid medicines are presented with bad odor, coating machine in pharmaceutical industry masks unbearable odor by firm coating over dosage form.

Smooth & Polished Appearance

Glossy appearance

You can enjoy the smooth shape and shiny/ glossy appearance of pharmaceutical solid dosage form with the dexterity of coating machine in pharmaceutical industry.

Dosage Identification

Better dose identification

By different coating color, marking, identification code helps in identifying the right dosage.

Patient Compliance

High Patient Compliance

The attractive appearance of medication directly encourages patients to accept medication of the prescribed regimen.

Control Release of Active Pharmaceutical Ingredients

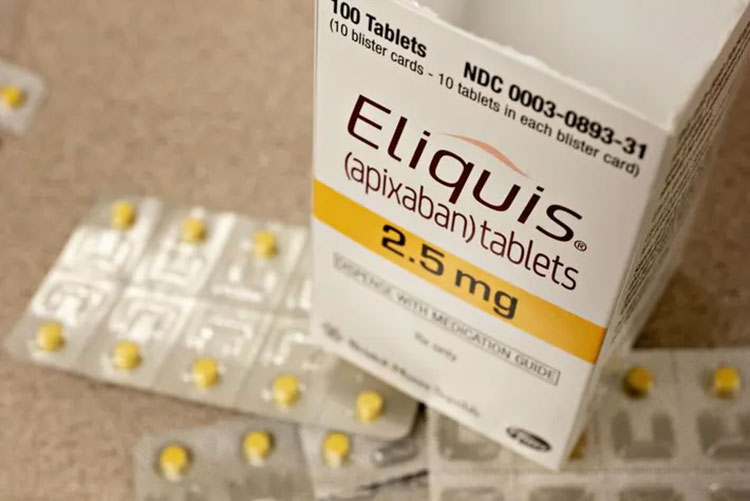

Controlled release medications- Picture Courtesy: Kanjivaram

The coating machine in the pharmaceutical industry is used to manufacture dosage formulations based on various different sites of release, time of release, or target site release.

Protecting the Gastric Mucosal Layer

Safe Medication for patients- Picture Courtesy: The medicine Maker

Dosage form without coating can directly interfere with internal gastric mucosal and damage the inner lining causing pain and bleeding if medication is used for a longer time. That’s why coating machine in the pharmaceutical industry is used to minimize this flaw in dosage form.

4.What Is The Scope Of Coating Machine In Pharmaceutical Industry?

Apart from pharmaceuticals, a coating machine has a broad scope of applications in various other industries. Some of them are discussed below:

| Industry | Description | Picture |

| Foods | The machine is frequently used in food industry for coating products such as chocolate, coffee beans, candies, nuts, and gummies. This is done to enhance appearance, texture and taste. |  |

| Automotive | To enhance protective coating of tools and parts of automotive components. A coating machine is utilized for improve corrosive resistant layer and extends the shelf life and durability of the parts of vehicles. |  |

| Fabric | Coating and coloring of dyes on textiles and material relevant to fabrics are done by coating machine. |  |

| Electronic | Electronic components, tools, switches, connectors, and other materials are coated using coating machine for enhancing appearance and make them more durable. |  |

| Chemical | Various chemical granules and tablets are coated by using coating machine. |  |

| Agriculture | The shiny glossy appearance of fertilizers, pesticides, insecticides, seeds, and relevant products is done by a coating machine. |  |

| Nutraceuticals | Multivitamins, capsules or tablet supplements, trace elements, minerals, proteins, enzymes, and probiotics in the form of solid dosage forms are usually presented with smooth textured and flavored coat. A coating machine is the robust machine that has widely applications in nutraceuticals. |  |

| Homeopathic & Herbal | Various granules, tablets, capsules are manufactured in this field are suggested to be coat to increase patient compliance and improved marketability. You can’t ignore coating machine while they are manufacturing. |  |

5.What Are The Types Of Coating Machine In Pharmaceutical Industry?

There are many types of coating machine in pharmaceutical industry.

For example,

Standard Coating Machine in Pharmaceutical Industry

You can also call it a conventional or traditional coating pan which was commonly used in pharmaceutical industries for the coating of dosage forms.

This machine is designed in a manner where a rotary circular pan which is also known as a drum is responsible for coating of dosage form.

An ideal diameter of a coating drum is about 6–80 inches which is commonly titled at the angle of 45 degrees.

An electric motor which is fitted horizontally inside the drum causing tumbling of coating bed.

The standard coating machine in pharmaceutical industry is further classified into the following:

Pellegrini/ Baffled Diffuser Pan

Pellegrini Coating Machine- Picture Courtesy: Aron

A standard pan with added Pellegrini baffled diffuser to improve drying and tumbling of coating by even distribution of warm and hot air.

The tablet bed was successfully achieved with an even distribution of material by drying air over entire material.

Immersion Sword

Allpack Immersion Sword Coating Machine

As the name indicates, a long sword like spray nozzle is subjected to deliver a hot air over the tablet bed.

This process is ideal for getting high drying from apparatus. This coating is relatively offering high speed coating due to the circulation of airflow in the middle of the coating bed because a sword is embedded in the coating material.

Immersion Tube System

Immersion Tube System- Picture Courtesy: ipharm

This type is accompanied by another additional tube in the coating bed with provides coating solution and dry hot air simultaneously.

The design of the machine is done in such as manner where heated air leaves the solution an upward direction. The drying and efficiency of machine is more enhanced than conventional pan simply by inclusion of an immersion tube.

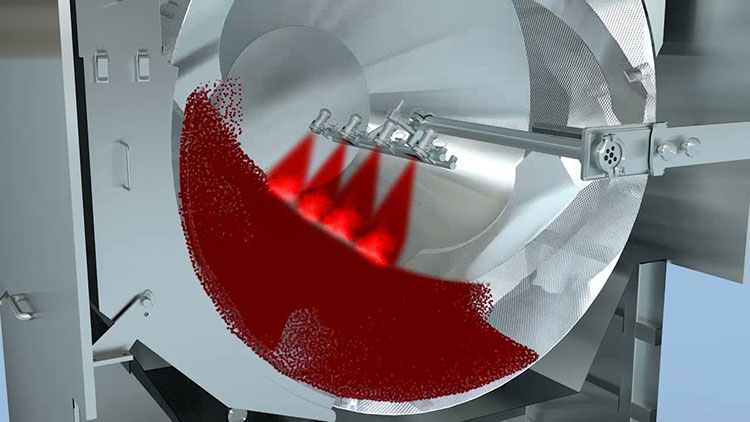

Perforated Coating Machine in Pharmaceutical Industry

Perforated coating machine in pharmaceutical industry- Picture Courtesy: Freund Vector

This technique is widely accepted by pharmaceuticals industries which is composed of full, partial perforated coating drum. Likewise, standard coating pan, this machine is also composed of rotating drum with horizontal axis and is equipped with an atomizer spray with an airflow inlet at the top of the pan.

Due to high air flow pockets, and high capability to deal tablets for coating, this machine is more promising than other coating machines.

There are three designs of perforated coating pans in pharmaceutical industry:

AccelaCota System

AccelaCota System

This is a fully perforated pan where the hot blowing of air is passed from upward direction which goes downward over coating bed and the exhausted air leaves the unit from bottom by plenum. The baffle in the rotary drum is responsible for complete tumbling of dosage form to ensure free mixing of coating and effective drying.

Dria Coater Pan

Dria Coater Pan

The coating pan is accompanied by perforated ribs featured on the inner periphery of the drum. In this machine, the basic working is like accelacota , but hot air flow from downward to upward direction. The exhausted air is flowed at the back of the machine and eventually leave the unit.

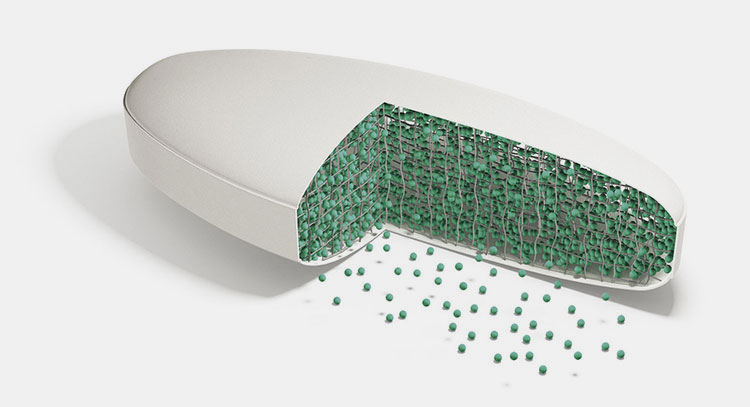

Fluidized Bed Coating Machine in Pharmaceutical Industry

Fluidized Bed Coating Machine- Picture Courtesy: Abbot mitre

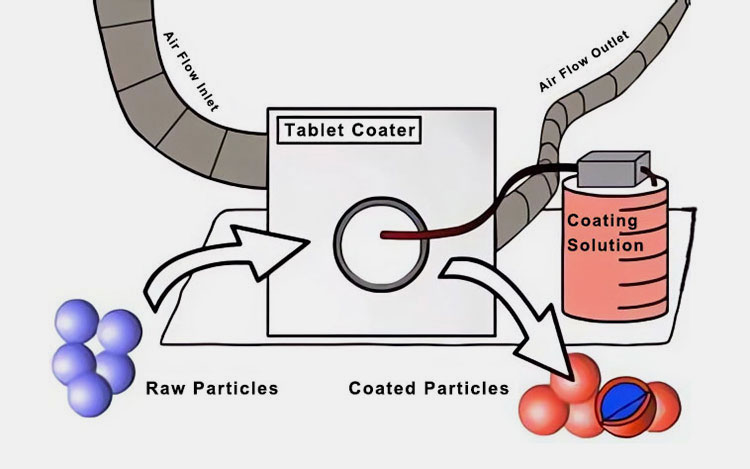

This machine is responsible for the fluidization of coating particles. It follows the fluidization working principle with an increased air concentration that enters the column and raises the tablets or capsule or any material in the air to carrying out coating procedure.

The machine has a vertical cylinder where dosage form is suspended and spray nozzles that sprays the coating material. The materials are dried via an upthrust of hot air. The fluidization phenomenon occur which causes dosage form to move upward and downward.

Coating machine in pharmaceutical industry Based on Pressure

On the basis of pressure system, the coating machine in pharmaceutical industry is categorized into two types:

High-Pressure Airless System

High-Pressure Airless System

This machine pump out coating solution without need of air, means the coating solution is sprayed out using a very high pressure which is up to 250,300 psig. The machine is featured with small nozzle about 0.0090 to 02 inches.

The size of the orifice and fluid pressure is regulating the rate of atomization and spray.

Low-Pressure Air-Atomized System

Low-Pressure Air-Atomized System

This unit utilizes a low pressure of 550 psig via a 0.020-inch larger orifice. The fluid cap orifice, air pressure, and air cap are responsible for modulating spray rate and atomization.

6.What are the Major Parts of Coating Machine in Pharmaceutical Industry?

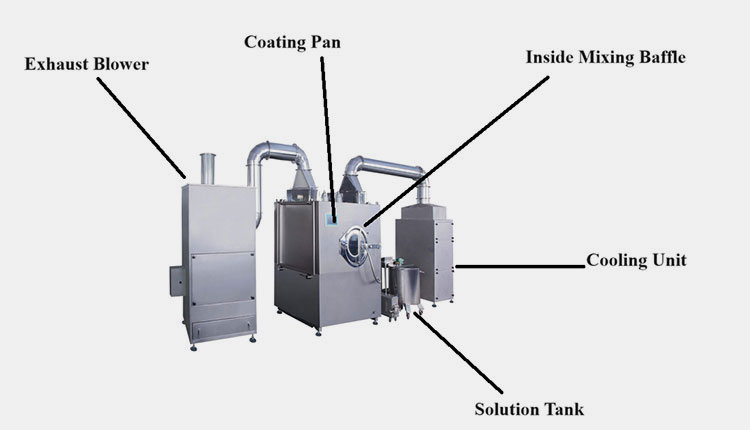

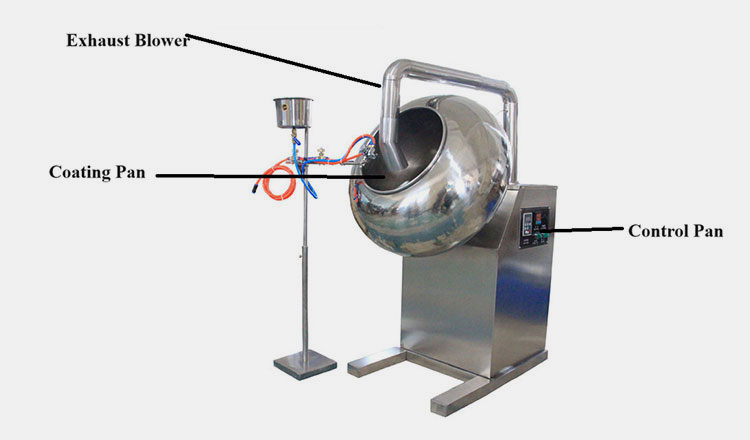

Allpack Coating Machine In Pharmaceutical Industry

Exhaust Blower

The exhaust blower is responsible for eliminating humidity or moisture content generated during coating process.

Coating Pan

The coating pan is used to adjust the coating bed and rotating continuously for even coating of solution over coating bed.

Inside Mixing Baffle

This is presented inside the coating drum or coating pan for uniform mixing and even blowing of air for equal distribution of coating solution.

Solution Tank

The coating solution is stored in a solution tank which is sprayed over the coating bed using spray nozzle. This tank is responsible for maintaining the complete and uninterrupted flow of solution.

Control Panel

The operating keys, and protocol parameters, for example, rate of rotation, rate of spray, temperature modulation, and other variables are controlled by a control panel.

Cooling Unit

This unit allows a controlled flow of air to cool down the inside temperature required for coated material.

7.What are the major Process steps of Coating Machine in Pharmaceutical Industry?

The working steps of coating machine in pharmaceutical industry are described below:

STEP 1: Preparation

Preparation

The preparation involved with the formulation of coating and identification of the batch. This is an essential step where the overall result is based, it will assure consistency in throughput.

STEP 2: Loading

Loading of Dosage formulation inside coating machine

Loading of subjected dosage formulation is loaded into the coating machine by the help of manual handling or machine hopper. This is a subtle process where smooth loading of dosage form takes place to avoid damage to surfaces.

STEP 3: Heating

Heating

| Application | Temperature | |

| °C | °F

122 |

|

| Heating | 50 | |

This step is carried out to minimize the moisture inside the drum and make the coating bed warm up to the required temperatures. Now your product is ready to coat.

STEP 4: Spraying

Coating Spraying- Picture Courtesy: Spraying System

| Application | Temperature | |

| °C | °F | |

| Tablet Coating | 70 – 90 | 158 – 194 |

After warming, atomization is carried out by the help of a spray gun over the coating bed. The solution is sprayed using a peristaltic pump set inside the spray gun offering a finest layer of coating solution with uniform distribution of spray particles over each part of the object.

STEP 5: Drying

Drying- Picture Courtesy: Syntegon

| Application | Temperature | |

| °C | °F | |

| Drying | 40 – 60 | 158 – 194 |

Heat drying is carried out to evaporate solvent molecules presented in the coated solution and dries the surface. In a result, you can get a smooth coating.

STEP 6: Repetition

Repetition- Picture Courtesy: Fluid Handling Pro

Now, once again spraying and drying procedure is repeated to get the optimum thickness of coating bed.

STEP 7: Cooling

Cooling

| Application | Temperature |

| Cooling | Typically Room Temperature |

Once you achieved the desirable coating, stop the process and allow the coating bed to cool down via continuous rotation of coating drum. This is done to prevent clumping between coating particles.

STEP 8: Discharging

Discharging- Picture Courtesy: TabletCapsule

After the procedure, the coated dosage formulation is discharged from the coating machine manually or by conveyor unit.

8.How Coating Machine In Pharmaceutical Industry Impacts On Release Of Dosage?

A coating machine in pharmaceutical industry has a great impact on releasing action of different solid dosage form by affecting profile, bioavailability, target site of action. There are certain specialized and commonly used solid dosage forms with variant delivery times and sites.

Sustained Release (SR)

Sustained Release (SR)- Picture Courtesy:Unguent

The name tells everything, it releases drugs in an extended time and coating is applied to design formulation that can maintain the action of active ingredients in the bloodstream. The coating machine in pharmaceutical industry is used to make drug with modified release kinetics and offering a steady and sustain releasing with time.

Enteric Coatings

Enteric Coated Tablet- Picture Courtesy: Formasup

Enteric word is commonly used for intestine. There are many drugs that can destroyed by the action of stomach enzymes. Therefore, coating machine in pharmaceutical industry is used to prevent the degradation of drugs by forming a coat which resists gastric enzymes and release drug safely in the intestine as it dissolves in an alkaline pH.

Immediate Release (IR) Formulations

IR formulation- Picture Courtesy: Pharma Excipient

A coating machine in pharmaceutical industry is beneficial to manufacture drug that offers an immediate releasing action once it reaches to target site and protects its from environmental factors like light, moisture, etc.,

Targeted Drug Delivery

Targeted Release Tablet- Picture Courtesy: Forbes

To achieve target drug delivery, a coating machine in pharmaceutical industry is used to engineer specialized coating in order to get a targeted drug delivery at a specified site of action. For example, inflamed cells, brain cells, cancerous cells etc., This is required as the minimum drug can specifically reaches and offering maximum efficacy.

Extended Release

Extended-Release Medicines- Picture Courtesy: Novant Health

To release a longer duration of action and high effectivity, an extended-release drugs are formulated. For that, coating machine in pharmaceutical industry use various specific polymer matrices that are designed to diffused with drugs and ensure extended releases.

9.What Polymers Used For Coating Machine In Pharmaceutical Industry?

Polymeric Formulation Used In Coating Machine In Pharmaceutical Industry

For coating of drugs, different combinations of polymers are used to alter the drug delivery and modify the action time and specific sites. The polymers with purposes are mentioned below:

| Polymer | Purpose |

| Ethyl Cellulose | Offering Sustained release |

| Eudragit RS 30 D (alone and in combination with ammonia methacrylate) | Offering Sustained release |

| Kollicoat SR 30 D | Offering Sustained release |

| HPMC acetate succinate | Offering Enteric coating |

| Cellulose acetate phthalate (CAP) | Offering Enteric coating |

| Eudragit L 30 D 55 | Offering Enteric coating |

| Eudragit FS 30 D | Offering Enteric coating |

| Chitosan | Offering Coating |

| EC, Shellac, Cellulose Acetate Trimellate | Used for Film Coating |

Classification Courtesy: National Library of Medicine

10.What Factors Affect the Quality Of Products Using Coating Machine In Pharmaceutical Industry?

There are certain factors that can affect the overall quality of a drug, therefore when using a coating machine in pharmaceutical industry you must avoid those parameters. For example:

Coating machine in pharmaceutical industry- Picture Courtesy: L.B Bohle

| Drying Procedure

|

This is pretty sure that efficacy and effectivity of coated drug can be affected if its coating is not dried sufficiently. Because an inadequate and uneven coating surfaces can progress the defects and batch failure. |

| Viscosity of liquid

|

Every liquid used in coating has various concentrations of viscosity. It affects the coalescence of the droplet during coating process. Knowing and managing the viscosities of coating liquid is helpful in obtaining an even coating when using a coating machine in pharmaceutical industry. |

| Uniform distribution of coating Particles

|

It is essential to maintain a consistent quality by considering surface tensions, wetting properties, and spreading action of coating to achieve an even thickness of coating. |

| Process Parameters

|

The distance between coating bed and nozzle, rate of coating spray, temperature, drying time, flow of air, have high impact on coating of drug. Therefore, it is essential to not ignore for desirable characteristic of drug. |

| Coating Material Quality

|

The composition of coating is very important which includes rheological properties, particle sizes, molecular bonding, that cumulatively impacts on coating of drug. |

| Equipment Features

|

The features of coating pan, spraying properties, and its maintenance can overall impacts on the coating properties of drug. The regular cleaning and calibration of the machine ensures a promising outcome of substrate. |

11.What Is the Commonly Used Coat Of Coating Machine In Pharmaceutical Industry?

There are various types of coating solutions that are coated over oral solid dosage forms offer significantly improved properties to medicines and patient compliance.

When it comes to patient compliance and demand, there are various coating compositions that are used in coating machine in the pharmaceutical industry. They include:

Sugar Coating

Sugar coating

Do you love ingesting medicines from a pharmacy that tastes sweet? No doubt, after few minutes, you possibly feel some bitterness.

This is the reason; a sugar coating is done for easy gulping of medicines to enhance sweetness and mask bitterness of solid dosage form. This coating formulation needs skilled manipulation which mostly requires 3 to 5 days and involves application of sugar molecules such as glucose, sucrose, based solution within coating machine in the pharmaceutical industry.

This includes sub -sealing, sub-coating, smoothing, coloring, polishing, and final printing.

Film Coating

Film coating

A film coating is a procedure where a thin polymeric layer is coated over drugs which ranges from 20 and 100 µm to oral solid dosage form to alter its releasing properties that we already discussed above. This is a one-step coating process with a fast application as compared to sugar coating with a lesser margin in weight increase.

The components used in film coating are polymers, plasticizers, opacifiers, and vehicles.

Compression Coating

Compressed coating- picture Courtesy : pharma specialist

This is similar to sugar and film coating where core or already coated tablets are compressed with excipients to protect drug against environmental conditions.

12.How To Clean and Maintain A Coating Machine In Pharmaceutical Industry?

As coating solutions are frequently used in coating machine in the pharmaceutical industry; you will have to frequently clean and maintain the machine to extend its quality life and quality of coating process.

Conventional Method

Conventional method

As polymeric solution and sugar solutions cleans easily. Thus, it is difficult to picked or identify left over inside the coating machine initially. Therefore, one time cleaning with water is not sufficient.

The cleaning process mostly involves two-step washing with high alkaline detergent to clean polymers and acidic detergents to clear insoluble particles stick inside the pan and circulatory pipes. In the larger equipment, manual scrubbing is also done to eliminate pigments.

WIP & CIP Method

WIP and CIP Cleaning- picture Courtesy: Tabletcapsule

For equipment designs like fluidized bed coating machine, the regular cleaning after every batch is mandatory which is occurred by Wash in Place and Cleaning in Place methods. WIP method is partially automatic where you need to open some parts of the machine for cleaning, whereas CIP automatically cleanses inner parts of the machine with opening via high flow of hot water and air to ensure greater cleaning results.

13.What Are the Flaws Of Coating Machine In Pharmaceutical Industry? How To Solve Them?

Blistering

| Flaw | Definition | Possible Reason | Treatment |

| Blistering | When coating over the surface of solid dosage form detaches or swelled, it forms a blister. | The common reason of coating blistering is high heat, entrapment of the gases during coating, high air spray | The condition could be treated with proper designing of protocol, using machine setting that offer mild drying, modulate air temperature. |

Chipping- Picture Courtesy: Colorcon

| Flaw | Definition | Possible Reason | Treatment |

| Chipping

|

In this condition, the coating over the surface of the dosage formulation become dented, cracked, chipped, or broken into around the edges to form a sub-standard shape. | When a coating machine in pharmaceutical industry coats with slow speed of rotation or slow flow of fluidized air in coating pan, it results in chipping. | You must be very careful during pre-heating, regulate the coating speed, and do not let over-dry the coating bed. It is helpful to encourage minimizing chipping problems. |

Picking

Picking- Picture Courtesy: Colorcon

| Flaw | Definition | Possible Reason | Treatment |

| Picking/ Sticking/ Adhering

|

This is a common problem where coating on the solid dosage form are adhere and may broke or erupted. | The possible reason of picking of tablets or capsule is due to the wet coating or insufficient air drying. | When coating machine in pharmaceutical industry dealt with an optimized condition such as reduced volume of coating solution, modulated temperature, and corrected air drying time; the picking can be overcome. |

Tablet to Tablet color variation- Picture Courtesy: Colorcon

| Flaw | Definition | Possible Reason | Treatment |

| Variation in coating appearance | The coating surrounding solid dosage form are uneven appearance and showing color defects. | This is due to improper dispersion of coating solution and variation in spraying. | For this, reform the coating solution, use proper concentration of plasticizer, polymers, and associated additives. Use correct size particles and proper distance between coating bed and nozzle. |

14.What Are Essential Parameters You Must Know For Coating Machine In Pharmaceutical Industry?

There are certain factors that must be considered during the usage of coating machine in pharmaceutical industry to ensure batch to batch quality and a consistent output.

Inlet Air Temperature and Relative Humidity

Temperature and Relative Humidity

This is well known that’s inlet air temperature should be enough to evaporate solvents quickly to make the coating evenly dry. Similarly, if moisture content or amount of moisture is present in the air can affect the drying process which causes the sticking of tablets or capsules. Whereas too low humidity causes cracking or peeling. Therefore, relative humidity must be optimized.

Formulation of Coating Solution

Formulation Design

The design of the coating solution is a mixture of syrups, polymers, plasticizers, etc., each component must be properly added and carefully controlled to be compatible with the tablet and coating machine.

Spray Rate

Coating spray rate

If the rate of spray is low, there’s less coating or thin coating applied over the coating bed. While too high a rate can also result in thick layer. Both are unfavorable which results in sticking or capping.

Spray Distance

Spray Distance

Determine the distance between the spray gun and the coating bed and the distance between spray guns, must be adjusted to ensure the coating solution adequately reaches without causing pooling.

Pan Speed

A coating machine in pharmaceutical industry- Picture courtesy: European pharma

If the rate of pan rotation is too high or too low can result in defects like mottling, streak formation, or uniform coating. A high pan speed causes a thin coating while low speed results in the thickness of the coating.

Conclusion

Oral solid dosage forms (OSD) activity becomes more enhanced with coating applications. That’s why coating machine in pharmaceutical industry is hooked to great value and supports countless benefits. Today, Allpack as an expert supports major industry players across the globe and shares rich expertise related to coating machines and their applications on OSD. With Allpack, you can enjoy the complete range of coating machines to scale up your production facility. Our team is ready to serve you.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide