Plastic Tube Sealing Machine: The Complete Buying Guide In 2025

Sealing tubes is not just science but also an art. The sealing of tubes required careful adjustment of seal parameters which is achieved by the plastic tube sealing machine. It creates strong and aesthetically pleasing tube seals that promote the marketability of products.

The plastic tube sealing machine is the master of precision and accuracy. No product recall and substandard seals are possible with a plastic tube sealing machine. It generates optimized results that bring huge profits for businesses.

Are you looking for the highest quality yet cost-effective plastic tube sealing machine? Then first, carefully go through this guide to acquire knowledge about certain facts about the plastic tube sealing machine.

1.What is a Plastic Tube Sealing Machine?

Allpack Plastic Tube Sealing Machine

A plastic tube sealing machine is a type of packaging equipment that is used for tightly sealing and securing plastic tubes. It dose up different product materials inside the squeezable tubes and seals its opening to prevent product leakage.

By sealing tubes, this machine assures superior product quality. It fuses the plastic layers to ensure that the inner content of the tubes remains intact. Plastic tube sealing machine seals products in such a way that it promotes anti-counterfeiting and anti-tampering efforts. This equipment is useful for packing a broad variety of products like creams, gels, pastes, ointments, glues, etc in the tubes.

2.Why Plastic Tube Sealing Machine is Significant in Industries?

Plastic tube sealing is significant in industries because it is more advantageous in every aspect than hand-filling. It brings profitability and success to businesses. It is the perfect solution to all problems that arise with hand filling. Here is a list of benefits of the plastic tube sealing machine.

Fill Precision

Fill Precision of Plastic Tube Sealing Machine- Picture Courtesy: JDA Progress

One of the top advantages of a plastic tube sealing machine is its fill precision. Filling by hand is filled with filling and sealing errors. This results in precious product loss and product recall if the product is underfilled. However, the plastic tube sealing machine has automated filling systems that allow it to attain filling precision in every batch.

Versatility For Processing

Versatility For Processing by Plastic Tube Sealing Machine

With its simple and fast change of parts, this machine can easily carry out the job of filling tubes of diverse shapes and sizes. It is a versatile and flexible machine suitable for industries, filling different volumes of products and sealing different shaped tubes.

User-Friendly Controls

User-friendly Controls of Plastic Tube Sealing Machine- Picture Courtesy: PKN Packaging News

The plastic tube sealing machine has integrated user-friendly controls like an HMI touch screen by which users can swiftly program and set inputs like fill volume, seal pressure, seal temperature, and speed of the turntable. Pre-saved data recipes allow users to change format with just one click of a finger.

High Speed

High Speed Plastic Tube Sealing Machine

One of the biggest advantages of utilizing a plastic tube sealing machine in production is its high speed. It operates at extremely high speeds, thereby, filling and sealing numerous plastic tubes in one setting. High speed means high production efficiency, this in turn translates to more profits.

Hygienic Design

Hygienic Design of Plastic Tube Sealing Machine

The plastic tube sealing machine has a sanitary hygienic design, meaning it is constructed with top-quality materials that are easily cleaned. Due to its clean design, this machine has zero chance of product contamination. Hence, it abides by different safe and hygienic industrial standards making it the favorite of numerous manufacturers.

High Shelf Life

High Shelf Life

A plastic tube sealing machine as the name indicates, is used to seal the plastic tubes. This sealing increases the shelf-life of the products by completely enclosing them, which not only prevents their leakage but also keeps them safe

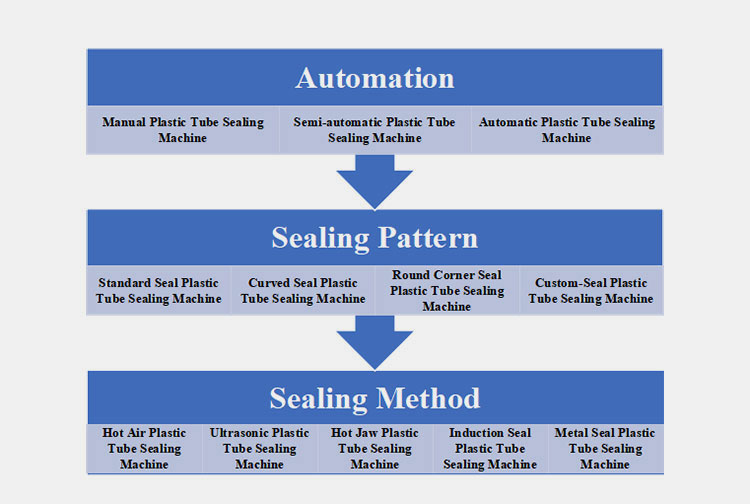

3.What are the Kinds of the Plastic Tube Sealing Machine?

Plastic Tube Sealing Machine Types

There are different kinds of plastic tube sealing machines in the market. These machines create huge confusion when making a selection. Hence, we are detailing different kinds of plastic tube sealing machines so you will choose the right machine type.

According to Automation

Manual Plastic Tube Sealing Machine

Manual Plastic Tube Sealing Machine

It is a small compact unit, consisting of handles and a lever for plastic tube sealing. This type of plastic tube sealing is one of the simplest tube sealing units, having a smaller price bag. This machine requires labor for loading and unloading the plastic tubes. It seals one tube in one go. A manual plastic tube sealing machine is easily accommodated on desktops.

Semi-automatic Plastic Tube Sealing Machine

Allpack Semi-automatic Plastic Tube Sealing Machine

It is a compact unit with a smaller footprint than an automatic plastic tube sealing machine. It has more productivity than a manual plastic tube sealing machine. This machine is seen in medium-sized productions. It comes with HMI so program options are easily adjusted without the need for high training. This machine is labor-intensive, as operators have to carry out the job of loading and unloading tubes.

Automatic Plastic Tube Sealing Machine

Allpack Automatic Plastic Tube Sealing Machine

It is a larger-sized machine, that automatically carries out the loading, unloading, filling, and sealing of the plastic tubes. Although it is a costly option, it has more productivity because of its automated and high-tech controls. It is a perfect solution for larger productions as it has a minimal rate of error in filling and sealing.

According to the Sealing Pattern

Standard Seal Plastic Tube Sealing Machine

Allpack Standard Seal Plastic Tube Sealing Machine

This type of plastic tube sealing machine creates a standard type of seal having straight-line designs. Standard seal plastic tube sealing machine forms seals with straight distinct corners.

Curved Seal Plastic Tube Sealing Machine

Curved Seal Plastic Tube Sealing Machine

This machine joins the plastic edges in such a way that curve seals are formed. This machine creates a curved arc-type seal. The corners of these seals are round, so preventing the risk of cutting, which is possible with sharp corners of tubes.

Round Corner Seal Plastic Tube Sealing Machine

Round Corner Seal Plastic Tube Sealing Machine

It creates seals in such a way that they resemble an oblong shape with round corners. It creates straight-line seals with round-shaped edges.

Custom-Seal Plastic Tube Sealing Machine

Custom-Seal Plastic Tube Sealing Machine

This machine is customized to create unique shape seals like half curves or seals with euro slots. This type of plastic tube sealing machine is mostly used in the cosmetic industry to boost the presentation and marketability of cosmetic tubes.

According to the Sealing Method

Hot Air Plastic Tube Sealing Machine

Hot Air Plastic Tube Sealing Machine

This machine uses hot air for sealing plastic tubes. It is a quick and versatile machine handling a variety of plastic tubes. Hot air in this machine increases the temperature of the plastic tube to make it ductile and cold sealing jaws using chilled water closes the ends shut. However, it requires more changes of parts for handling different-sized tubes.

Ultrasonic Plastic Tube Sealing Machine

Ultrasonic Plastic Tube Sealing Machine

This type of plastic tube sealing machine uses high-frequency ultrasonic vibration to hermetically seal and fuse tube ends. The vibrations lead to the heating and melting of the seal end. The plastic tubes are passed between the sealing horn and anvil that maintain and form the seal. This machine has slower productivity than a hot air plastic tube sealing machine. But it needs lesser replacement of parts when processing different-sized tubes.

Hot Jaw Plastic Tube Sealing Machine

Hot Jaw Plastic Tube Sealing Machine

This machine uses high pressure and temperature to crimp seal the exterior of the tube. High temperature at the exterior side transfers to the inner tube ends and hot jaws or crimp jaws exert pressure to shut the tubes. This machine requires more time for sealing the tube and has lower efficiency than other methods.

Induction Seal Plastic Tube Sealing Machine

Induction Seal Plastic Tube Sealing Machine

This machine uses a high-frequency electromagnetic field to heat and melts the aluminum or plastic materials and then seal the lids or ends of the plastic tube. This machine creates tamper-evident strong seals. It creates clean seals without burning the material which is possible when using a hot air plastic tube sealing machine.

Metal Seal Plastic Tube Sealing Machine

Metal Seal Plastic Tube Sealing Machine

This type of plastic tube sealing machine is used to flatten and crimp seal the metal tubes. This machine creates different kinds of sealing like single fold, double fold, saddle fold, and triple fold to form sealing of metal tubes.

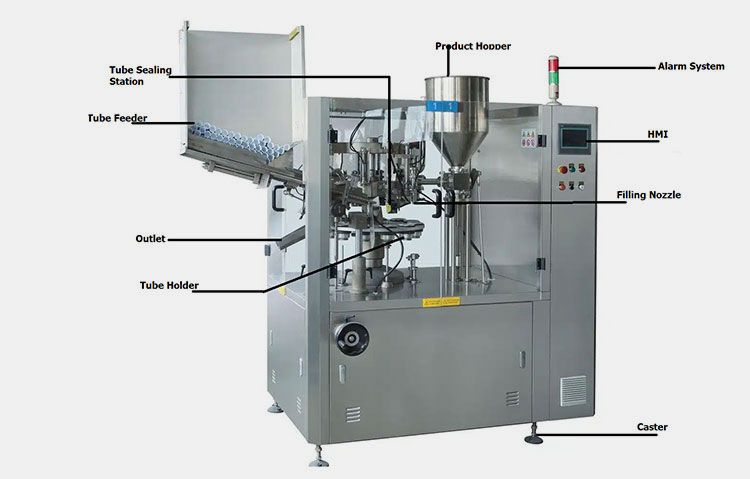

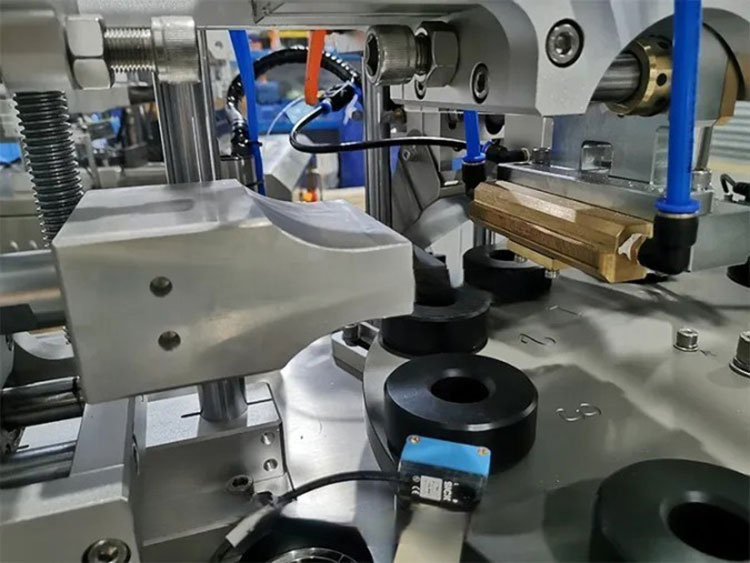

4.What is the Structural Design of Plastic Tube Sealing Machine?

Different parts that are featured in the plastic tube sealing machine are penned below:

Parts of Plastic Tube Sealing Machine

| Product Hopper | It is a conical shape component that is typically featured at the upper side of the plastic tube sealing machine. Its main task is to hold the product for continuous running operation. |

| Tube Sealing Station | It is the part of the machine that uses ultrasonic vibrations, electromagnetic current, and heat to melt and seal the layers of the tube. |

| Tube Feeder | It is a rectangular-shaped device found on the upper side of the machine. It is used to store numerous tubes. It loads tubes one by one in the tube holder. |

| Tube Outlet | It is an elongated chute-like device in which tubes are ejected after completing filling and sealing. |

| Tube Holder | It is a hollow cavity that resembles a pocket in which tubes are placed for secure filling and sealing. It prevents the falling of the tube and keeps them in place. |

| Caster | It is a stand-like structure that holds the full weight of the machine. It stabilizes the machine and keeps it leveled. |

| Alarm System | It is a safety component that flashes lights and creates sound to inform operators about the problems of the machine like tube jamming, low tube numbers in the tube holders, etc. |

| HMI | It is an interactive display screen that is used for swift and convenient programming of the machine operation. |

| Filling Nozzle | It is a cylindrical tube pipe-like device, whose main job is to dose the product inside the tube. It is connected to the hopper by the hose pipes. For drip-free dispensing of the products, the filling nozzles are elongated to reach the bottom of the tube. |

5.What is the Working of a Plastic Tube Sealing Machine?

The working steps of a plastic tube sealing machine are simple and act in synchronicity to perform flawless tube filling and sealing. Here is a list of steps that are executed in working of plastic tube sealing machine.

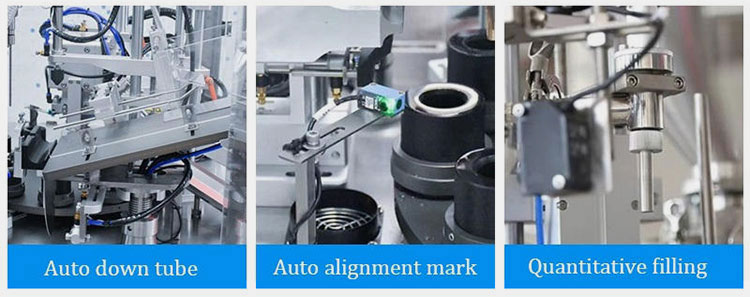

| Plastic Tube Loading

First, the empty tubes are placed in the tube feeder. This tube feeder is high and automatically loads the empty tubes in the tube holder using a high-quality mark sensor. This mark sensor detects the marking present on the tubes and places the tubes in the right orientation based on their marking. |

Plastic Tube Loading- Picture Courtesy: Norden Machinery AB |

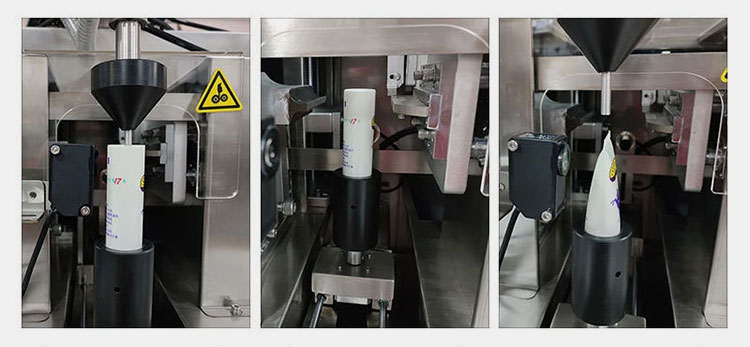

| Plastic Tube Filling

Immediately upon the detection of the tube under the filling nozzle, the product dispensing starts under the direction of the signaling by the PLC system. |

Plastic Tube Filling- Picture Courtesy: Makwell |

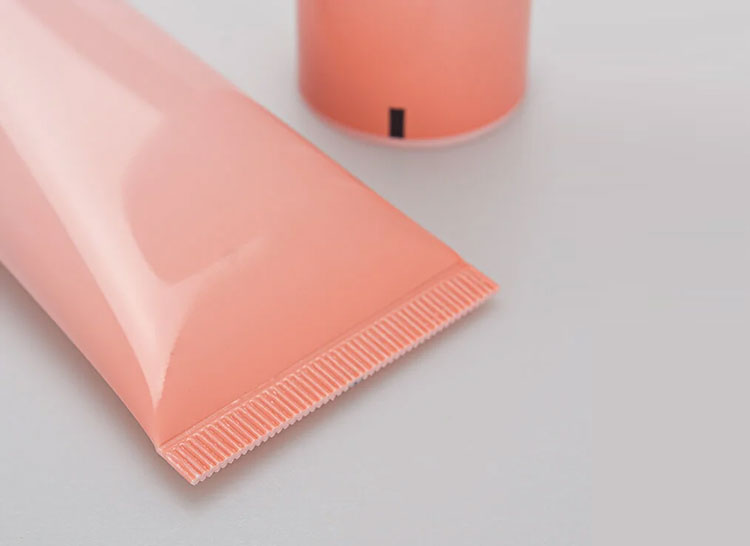

| Plastic Tube Sealing

In the next step, high heat from hot air melts the seal ends of the tube. These melted ends are joined using pressure provided by the sealing jaws. It creates strong hermetic sealing. The cooled water is employed at the same time to provide the seal ends with a smooth finish. |

Plastic Tube Sealing |

| Plastic Tube Trimming

At this station, excess tube material is cut by the high-shear cutting blades. Some kinds of plastic tube sealing machines employ laser for cutting the edges of plastic tubes. The laser precisely and smoothly cuts the tube ends. |

Plastic Tube Trimming |

| Plastic Tube Ejection

Finally, filled and sealed tubes are unloaded from the machine using a small outlet or a chute. |

Plastic Tube Ejection |

6.What are the Industrial Uses of the Plastic Tube Sealing Machine?

A plastic tube sealing machine is an efficient, quick, adaptable, and robust unit. It is used in various industries for filling and sealing different kinds of consumable items in sturdy tubes. Some of the basic industrial uses of the plastic tube sealing machine is discussed below:

Cosmetic Industry

Use of Plastic Tube Sealing Machine in Cosmetic Industry

Looks and product presentations are two things that play a significant role in the cosmetic industry, so this industry employs a plastic tube sealing machine because it improves the visual appeal of numerous cosmetic products, for instance, foundation, mascara, face wash, blushes, dyes, mask, lip gloss, sunscreen, serum, etc.

Personal Care Industry

Use of Plastic Tube Sealing Machine in Personal Care Industry

Plastic tube sealing machine is a prime part of the personal care industry because several personal care products like toothpaste, gels, shampoo, body wash, soaps, conditioners, and many more are available in the tube format. This machine is used for securely sealing such products in durable plastic tubes.

Pharmaceutical Industry

Use of Plastic Tube Sealing Machine in Pharmaceutical Industry

In the pharmaceutical industry, this machine is utilized for safely and hygienically packing different kinds of pharmaceutical creams, gels, ointment, burn salves, analgesics, dermal lotions, eye drops, and medicated adhesives. This machine with its sanitary design is involved in contamination-free packaging and sealing of pharmaceutical products.

Food and Beverage Industry

Use of Plastic Tube Sealing Machine in Food Industry- Picture Courtesy: News| Norden

Different food items require hygienic loading inside the tubes and that is where a plastic tube sealing machine plays a chief role. It seals food products like condiments, pastes, oils, ketchup, sauces, dressings, spreads, and jams in secure squeezable plastic tubes.

Chemical Industry

Use of Plastic Tube Sealing Machine in Chemical Industry- Picture Courtesy: Envato Elements

Different chemicals like sealants, adhesives, caulks, grease, inks, lubricants, and fuel oil require robust packaging that is leak-proof. Hence, these chemicals are securely packed inside the tough plastic tubes by the plastic tube sealing machine. These tubes are airtightly and completely sealed by this machine to prevent leakage of damaging chemicals.

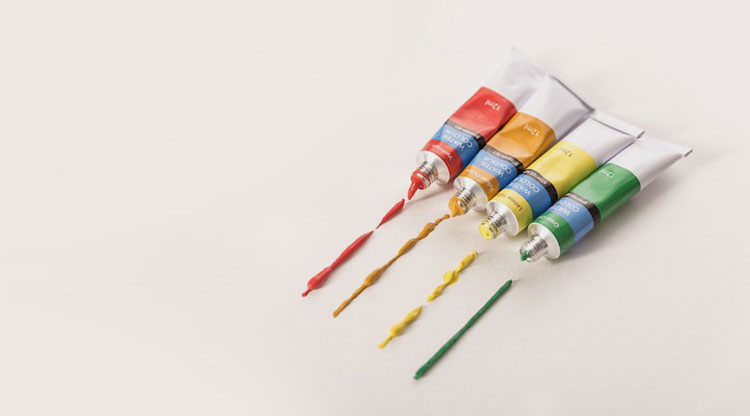

Paint Industry

Use of Plastic Tube Sealing Machine in Paint Industry

Yes, a plastic tube sealing machine is also employed in the paint and coating industry to seal the oil and water-based paints inside the vibrant and colorful paint tubes. This machine also packs different kinds of coating and oily emulsion in the plastic tubes.

7.What is the Sealing Temperature of a Plastic Tube Sealing Machine?

Sealing Temperature of Plastic Tube Sealing Machine- Picture Courtesy: Makewell

The sealing temperature is dependent upon various factors like the nature of the plastic material, for example, PE plastic needs a low sealing temperature of about 250°F - 350°F for sealing while PP plastic requires a high temperature of 300°F - 400°F for bonding.

In a hot jaw plastic tube sealing machine materials are directly heated, so a high temperature of about 200-500°F is used for sealing. In induction seal plastic tube sealing machine materials are indirectly heated by electromagnetic induction, so a temperature of 150°F - 250°F for bonding the plastic material.

8.What is the Dwell Time of Plastic Tube Sealing Machine?

Tube Sealing- Picture Courtesy: The Tube Council

The dwell time of the plastic tube sealing machine means the duration in which hot air, heated jaws, or ultrasonic waves remain in contact with the plastic tube. It is the time amount during which temperature and pressure are applied to the plastic tube for sealing.

Proper duration of dwell time is very critical in the correct melting and bonding of plastic tubes. It is necessary for forming an operative seal. Inadequate dwell time for sealing results in weak and poor seals that may cause products to leak from the plastic tubes while high dwell time may result in the burning of tube materials.

Hence, it is an essential parameter for plastic tube sealing, influencing the quality and efficacy of the seal.

9.What are Other Materials Processed by Plastic Tube Sealing Machine Beside Plastic?

The plastic tube sealing machine can handle a broad range of materials besides plastic. Here is a breakdown of some common materials handled by a plastic tube sealing machine.

Aluminum Laminate

Allpack Aluminum Laminate Plastic Tube Sealing Machine

It is created by layers of plastic and aluminum. It combines properties of both aluminum and plastics like toughness, durability, and, ductility. These aluminum laminate tubes are used in the food and pharmaceutical industry for the packaging of gels and pastes.

Composite Paper

Composite Paper Tubes- Picture Courtesy: TOPPAN

These are formed with plastic and paper layers. It is ductile and strong like plastic and has a smooth finish of the paper. These tubes are gaining traction because they are easily recyclable and offer sustainability.

Aluminum

Aluminum Tubes

These materials are processed by the plastic tube sealing machine in the cosmetic and personal care industry. Aluminum imparts these tubes a premium and luxurious look and attracts high-end users.

10.How To Maintain Plastic Tube Sealing Machine?

Maintenance of Plastic Tube Sealing Machine

Adherence to a regular maintenance schedule of the plastic tube sealing machine brings many fruitful results, like optimal machine performance and long operational life. These are some tips to keep your equipment in top condition.

| Cleaning Regularly | Clean thoroughly the exterior, frame, sealing area, filling nozzles, etc with a clean cloth and mild cleaning agent to remove the product and plastic tube material buildup that decreases sealing efficiency. |

| Calibration | Check and calibrate the sensors, heating elements, and pressure gauge. |

| Alignment | Align and level filling and sealing components to ensure they are properly positioned on the plastic sealing tubes. |

| Lubrication | Lubricate all the mobile joints and moving parts of the machine to prevent frictional buildup and overheating of the plastic tube sealing machine. |

| Full Examination | Examine all the machine parts like electric components, safety alarms, and pneumatic systems thoroughly for wear and tear and replace them if needed. |

| Software Update | Check and update the software of the machine if available. |

11.What are the Common Challenges of Sealing in the Plastic Tube Sealing Machine? How to Overcome Them?

The plastic tube sealing machine can face some unanticipated challenges that may result in loss of productivity and packaging. Here is a list of common challenges encountered by the plastic tube sealing machine.

Challenges in Heat Sealing

Challenges in Heat Sealing

When the machine is started for the day, sealing jaws takes more time to heat and melt the plastic tubes. Also, these sealing jaws remain heated after the machine shuts down, making it difficult to clean the machine. Products like salads, spreads, etc also leak from the tubes because of the heating process.

Solution

These challenges can be overcome by the ultrasonic seal plastic tube sealing machine. It easily seals the plastic tube at the molecular level using an ultrasonic seal horn. It quickly seals products without any leakage. Moreover, it is easier to clean this type of plastic tube sealing machine.

Plastic Tube Material Stick to Sealing Jaws

Plastic Tube Material Stick to Sealing Jaws

Sometimes, the tube material adheres to the sealing jaws even after lowering the temperature. It is because of the high sealing temperature and also because the tube material is not compatible with the machine. Sometimes, leftover product on the sealing jaws also causes the material to stick.

Solution

Lower the sealing temperature, as mentioned in the plastic tube sealing machine manual. This problem could be resolved using non-stick sealing jaws and using materials that are compatible with machine components. Also, cleaning the sealing jaws leads to less material adherence.

Uneven Tube Seals

Uneven Tube Seals

Sometimes, there is variation in seal consistency from plastic tube to tube. There are differences in the shapes and patterns of seals. This problem is due to old and defective sealing jaws. Improper levelling of sealing jaws with plastic tubes can also cause uneven seals. Poor sealing pressure and distorted sealing plates can also produce variations in seals.

Solution

Replace old and damaged sealing jaws. Properly align sealing jaws and ensure uniform pressure distribution. Check for distortion in the sealing plates and replace them if necessary to prevent the problem of uneven sealing.

Scorching of Plastic Tubes

Scorching of Plastic Tubes

The materials of plastic tubes get burned due to high sealing temperatures and increased sealing time. If the sealing jaws are dirty and uncleaned, they are also the cause of the scorching of plastic tubes.

Solution

This problem is resolved by decreasing the sealing temperature and also reducing the dwell time. Properly cleaning the sealing jaws solves the problem of plastic tube burning.

Conclusion

Now it's time to wrap up the blog about the plastic tube sealing machine. Hopefully, you have found this piece of writing informative and engaging. A plastic tube sealing machine is a one-time solution to all your problems in filling and sealing. It is a sophisticated piece of equipment, carefully sealing the tubes to prevent product leakage. Planning this machine for your production? We Allpack are here to provide you with the best deals. Message us for machine purchase quote and other questions.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide