Liquid Packaging Essentials: 3 Important Details You Must Know

Dealing with packaging of liquid formulation is always tricky and requires a lot of expertise. Do you know why? Because there are more chances of spillage, equating temperatures, dealing with viscosities, and much more. Therefore, having proper knowledge about liquid packaging equipment, the type of packaging required, capacity, and application is paramount.

Stepping into liquid packaging production?

Try making this plan as stress-free as possible. Today, liquid packaging has gained a lot of attention and high market demand due to frequent usage in pharma, food, beverage, and many other industries.

Be awesome and make the liquid packaging process simplify. Here we have elaborated Liquid Packaging Essentials: 3 Important Details You Must Know; the purpose of designing the article to deal with your inner stress and making the project easy for you. So read and try implementing the points.

1.Never Ignore Temperature Regulation

Several Liquid Packaging Are Temperature Sensitive- Picture Courtesy: meghmani dye

For any liquid packaging, considering the right temperature associated with a respective product is really important to maintain the quality and potency of the ingredients.

This is the foremost factor that every liquid packaging has to pass through transportation, shipping, and other delivery methods.

Therefore, the packaging material must be of a kind that can preserve the internal environment as favorable as required.

| Medicine | Food | Nutraceuticals | Cosmetics | |

| Ambient Temperature | 15°C - 25°C | 15°C - 25°C | 15°C - 25°C | 15°C - 25°C |

| Refrigerated Temperature | 2°C - 8°C | 2°C - 4°C | 2°C - 8°C | 2°C - 8°C |

| Freezing Temperature | Below 0°C (-15—40) | Below 0°C | Below 0°C | Below 0°C |

A table demonstrates different temperature essential for liquid packaging- Source: Specialist Pharmacist Service

The change in temperature can mess up the quality of the inside product. For instance, there are various medicinal products that are sensitive to external environmental conditions. You need to keep its temperature maintained. The ambient temperature for medicinal products is preferred between 15ºC and 25ºC” or “below 30ºC” . Similarly, the refrigerated items must be between 2 and 8ºC. These medicines are commonly referred to as “cold chain” medicines or “fridge lines”. Those liquid products are prone to go bad early ultimately wasting a huge amount of money, and energy, and affecting the health system.

Therefore, for liquid packaging, you must consider the necessity of the temperature of the particular packaging item to control the environment and use the packaging material that is best fit for your formulation to deliver promising products.

Things To Do!

Temperature-controlled liquid packaging essentially protects the perishable liquid items from destabilization, change in potency, taste, and other relevant parameters. It is important to keep liquid packaging insulated against the mentioned factors.

Not only does it lose its valuable potency and efficacy but so called it puts your formulation in a danger zone to progress microbes inside and lead to food poisoning upon ingestion.

Therefore, for liquid packaging follow the points:

Insulated Liquid Packaging

PLA liquid Packaging

There are various insulated liquid packaging that can keep your business awesome as it will keep the temperature well controlled during transit. For example, using PLA or Polylactic acid packaging which has thermal insulating properties that can keep the temperature around 4ºC for up to 30 hours then can rise to 25 to 30ºC. This packaging is safe and does not contaminate or releasing unwanted fumes. That’s why it is popular in food, pharmaceutical, nutraceutical industries.

Use Temperature Indicator

Temperature Indicator Strip

Today, you can find high-technology color-changing temperature indicators used as liquid packaging essentials that are not only indicating but known as effective sensors by highlighting unacceptable temperature range exposure. This is beneficial as it helps in satisfactory deliveries, helps in storage under various climate conditions, and accurate demonstration of temperature even in below -18C, or temperatures between -3C and 10C.

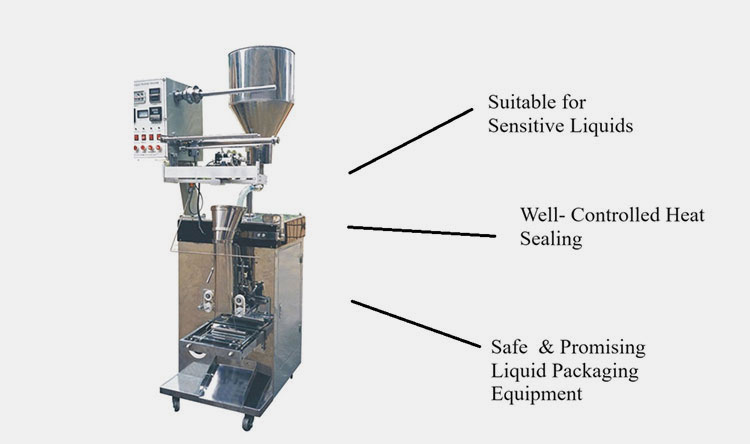

Well-Controlled Liquid Packaging Machine

Allpack Liquid Packaging Machine

A good liquid packaging machine is also significant for liquid packaging which should specifically feature temperature controlling properties and be capable of dealing with various products packaging for sensitive pharmaceuticals, drinking, and other liquid packaging.

2.Knowing about Liquid Particle Size

In some liquid preparations, you will observe various particle sizes suspended in them. This is known as suspension.

On the other hand, formulations like condiments, salads, and similar products are also composed of suspended particulates. The filling of such items requires much concentration as they cause clogging of the filling passage inside the machine.

Therefore, you must assess the nature of particles and the type of working principle used by the machine. The commonly used particle sizes in liquids used in the chart below:

| Type of Liquid | Particle Size |

| Suspension | Greater than 100nm |

| Solution | Less than 1 nm |

| Colloid | Less than 100 nm but greater than 1nm |

| Granules Aggregate | Greater than 1000 µm |

| Coarse Particle | Size varying from 100 µm to 1000 µm |

Table is referred from Boomeria.org

Allpack semi-automatic piston filler is recommended for liquid with various suspended particulate.

For those particles that are composed of a large surface area, the liquid packaging can be done using a ‘piston filler’ which features a unique filling nozzle that helps in addressing the easy flowability of such items.

Moreover, this filler is appreciated for using products like salad, jams, and relevant foodstuffs as it ensures that molecules with larger surface area can be dealt with easily. This is because a piston can push and accelerated the process very well. The material stored in the hopper can be received and pushed using piston pressure.

Suspended Particles in the Mixture- Picture Courtesy: DayNatural

Some particles are suspended in the liquid due to the high thickness of liquids, for filling them you need to constantly stir the solution to keep liquid solution uniform and well-dispersed.

It is essential to ensure that a uniform and even number of particulates are filled and packed inside the filling material. This can be achieved by constant agitation and stirring processes to bring their products with tremendous output. Also, it minimizes the settling of particulates bottom of the hopper or tank.

Things to Do!

Nevertheless, dealing with liquids with various particles size is challenging but side by side there are various types of equipment came into emergent that can break large particles and make them up to your requirements and make the process easier.

Use Homogenizer or Mixers

Allpack Vacuum Emulsifying Mixer for Uniform dispersion of particles with high-speed shear

When making suspension in food and pharmaceuticals, manufacturers are frequently demanding machines like cone mills, rotor stators, emulsifying mixer homogenizers, and ultra-sonic homogenizers.

The homogenizers work by using shear forces, impaction or cavitation (reducing particle sizes). Each of these machines gives you promising output with a high guarantee that the liquid solution is packed with uniform and equal distribution of particle sizes.

3.Viscosity of Liquid Solution & Packaging

Viscous Liquid Products

If liquid resists flow and shows thickness, it is known as viscosity. This means, it is internal friction develops inside the molecules of fluids so you can feel thickness which is termed as a viscous liquid.

Well, what viscosity has to do with packaging?

This is very important known as products with high viscosity resist motion and exert more internal pressure than normal liquids. It does not flow and pack more easily as you expect. Similarly, liquids with lower viscosity molecules tend to flow more easily and form less friction when packaging them.

Therefore, every manufacturer must know the viscosity of the liquids they pack. For that we are giving a mathematical formula, which is helpful in measuring the viscosity of the products. Such as:

Viscosity = Shear Stress / Shear Rate

or

μ = τ / γ

The unit of viscosity is expressed in ‘centipoise or cps.

There are standard viscosity of water which is ‘1cps’. Similarly, the viscosity of the honey shows a viscosity approximately 10,000 cps, while mustards or ketchup demonstrates a viscosity ranges between 50,000 - 70,000 cps.

The viscosity ranges must be known to you as during packaging more viscous liquid consumes greater time inside the machine’s circulatory units to reach final dispensing into the packaging material. Therefore, you should be able to select the machine that must be capable to run, and inducing the pressure to flow liquids smoothly till packaging without over or under-flowing liquids.

Things to Do!

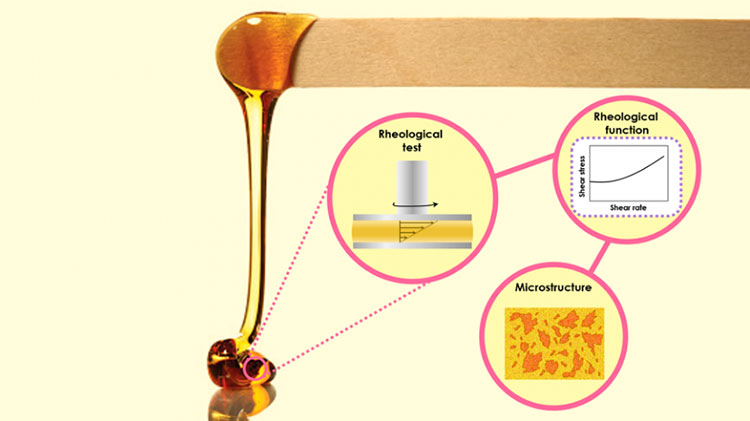

You Should Know Viscosity Measurement

The rheology is very important- picture Courtesy: College of London

It is measured by a specialized device known as ‘viscometer and rheometer.

A viscometer is used to measure Newtonian liquids in which viscosity is not dependent on shear forces such as water, urine, etc., whereas a rheometer is used to measure non-Newtonian fluid, where liquids change their viscosity depending upon pressure or stress applied. For example, kinds of ketchup, sauces, etc.

That’s why it is recommended to shake the bottle of ketchup or viscous solutions as its viscosity becomes decreases upon good shaking. The liquid packaging viscosity is affected by heat, that’s why it is recommended to warm syrups with high thickness to make less viscous during packaging in industrial packaging.

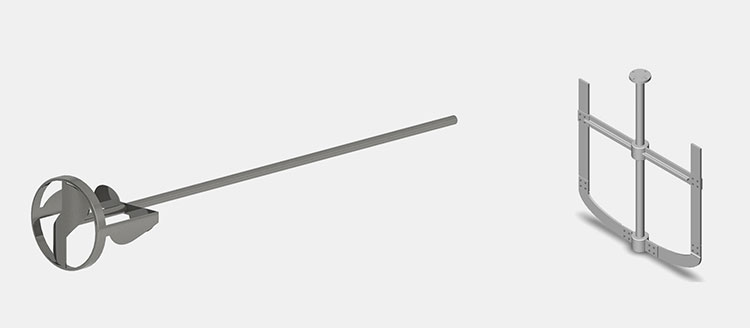

Using A Good Mixing Equipment

Mixing Liquid- Picture Courtesy: Elephango

As mentioned above, mixing can lower the thickness or viscosity of the liquids, therefore, blending time, agitator rate, and selection of impellers are very important which alter the characteristics of solutions.

A blending time and speed of agitation is significant that’s why choosing the right design and selection is paramount to achieve an efficient mixing speed.

High Shear Mixer Liquids- Picture Courtesy: Syntegon

For high-viscosity blending, use a low-shear impeller, it will maintain uniformity in the liquid tank and make cleared liquid flow. Whereas a high viscosity impeller is recommended for high viscous solutions to keep them uniform in the blending tank.

Impeller used for low (Propeller) and High (Anchor) Viscous Liquid

Low Viscous Liquid

A propeller and turbine impeller are used for mixing low viscous liquids to keep uniform consistency inside the liquid molecules.

High Viscous Liquids

An anchor impeller and Gate impeller is needed for mixing highly viscous liquids as they promote an axial flow and suitable for thick slurries.

Conclusion

It's time to automate your filling task by knowing ‘Liquid Packaging Essentials 3 Important Details You Must Know’. Whether you’re filling sauces, thick slurries, syrups, or elixirs, the modern liquid packaging machine has turned this difficult job pretty quickly and easily. However, if you consider the right supplying company like Allpack, it would make your decision ‘super-tremendous’. This is because Allpack cares for its customers by offering expert guidance and an amazing liquid filling line in a cost-effective way. Want to Make a quick Purchase? Please contact our team now.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide