Particle Filling Machine: The Complete Buying Guide In August 2025

Are you interested in buying a particle filling machine Does your industry involves filling of particles? Do you want to know more about a particle filling machine? Do you want related information regarding the operation and different types of a particle filling machine? This is the place where you can get all the related information that will support you in selecting the right type of machine. Read the complete guide to resolve your queries.

1.What Is A Particle Filling Machine?

Digital Control Particle Filling Machine

A particle filling machine is a piece of packaging equipment that accurately fills containers with products made up of small particles or granules. These particles could range from culinary items such as rice, grains, seeds or coffee beans to pharmaceutical products like pills or capsules. Most of the industries use particle filling machines to enhance their productivity and to make their products look pleasant.

2.What Are The Industrial Applications Of A Particle Filling Machine?

Particle filling machines are used in a variety of industries and sectors depending upon their usage. These machines are widely employed in following industries

Food Industry

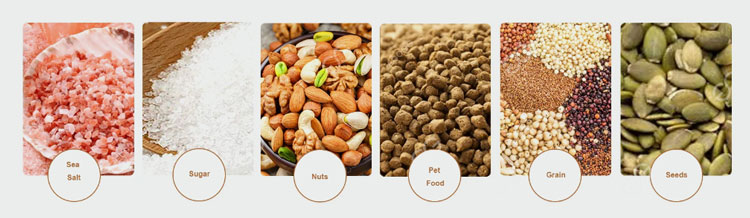

Food Particle Products

Particle filling machines are used to fill containers with a variety of food products including rice, grains, nuts, seeds, coffee beans, spices, and snack foods like popcorn or candies. These products are filled in a consistent manner to maintain the quality and freshness of product.

Pharmaceutical Industry

Capsule Filling - Picture Courtesy: Pharma Excipients

Pharmaceutical industry is one of the major particle filling machines using industry around the globe. These machines are used to fill capsules, tablets, pills, and other pharmaceutical items in granular or powdered form. Accurate dosage is maintained to secure the integrity of products using a particle filling machine.

Chemical Industry

Chemical Particle Packaging - Picture Courtesy: Finopack

Chemical industry also uses particle filling machines to fill containers with chemical goods like fertilizers, detergents, powdered additives, and other granular materials used in industrial processes. This increases the quality with accurate measurement of particles and minimizes the chances of spillage.

Agricultural industry

Particle Resin Coated Urea

As fine particles are also produced and used in agricultural industry, usage of particle filling machine is involved for their proper packaging and filling. Particle filling machines are used to package seeds, fertilizers, insecticides, and other agricultural supplies in both granular or powdered form.

Cosmetic Industry

Cosmetics Dispersants - Picture Courtesy: UL Prospector

Cosmetic products require greater care while filling and packaging as they are directly applied on human body. Particle filling machines are used in cosmetics industries to fill containers with items like powders, creams, lotions, and granular components. These products are further used in making makeup and skincare products.

3.What Are The Advantages Of A Particle Filling Machine?

Particle filling machines provide various benefits in industrial packaging processes:

Precision

Coffee Particles Packaging

The most important benefit that is gained from a particle filling machine is precise and accurate filling. These machines can fill particles in containers with high accuracy that results in consistent product weightsaccording to the requirements.

Efficiency

Rod Hutchinson Cooked Particles

Particle filling machines are mostly found with automatic operations. This automatic filling process gives higherproduction efficiency and throughput as compare to manual filling methods. Particle filling machine increases productivity with greater efficiency and gives cheaper labor expenses.

Versatility

Particle filling machines can also handle a wide range of materials in a single operating machine.The machine can support particles from fine powders to coarse granules making them appropriate for a variety of industries. These filled particles are then used in many industries including food, pharmaceuticals, chemicals, and cosmetics.

4.What Particles Can Be Filled And Sealed Using A Particle Filling Machine?

A particle filling machine can handle a wide range of particles, including

Food Products

Food Product Particle Filling Machine

Most of the food products including grains, nuts, seeds, coffee beans, dried fruits, spices, snack foods, and granular ingredients are efficiently filled using a particle filling machine.

Pharmaceutical Products

Capsule Particles - Picture Courtesy: Innopharma Technology

Pharmaceutical products like capsules, tablets, pills, granules, and powdered medications are filled with their respective particle material using a particle filling machine. These particles are filled in an accurate amount so that their chemical composition remains as per standard.

ChemicalAnd Agricultural Products

Chemical Particles

Products like fertilizers, pesticides, powdered additives, detergents, seeds (crop seeds), insecticides, and soil amendments are efficiently filled and packed using a particle filling machine.

Cosmetics

Cosmetics Particles Packaging- Picture Courtesy: Prooftag

Variety of cosmetic products like powders, creams, lotions, granular ingredients, and makeup products that are used as skin care products also use particle filling machines for their precise filling.

5.What Is The Working Procedure Of A Particle Filling Machine?

Working Steps Of An Automatic Particle Filling Machine

A particle filling machine works in a very simple and friendly manner. The machine typically operates in multiple steps including

Initially a particle filling machine is calibrated in accordance with the specifications of the product being filled. The calibration process includes altering parameters like filling volume, pace, and container size.

In the next step the particles are filled into the hopper of a particle filling machine. From here these particles are fed further into the filling chamber with consistent flow. Mechanisms such as vibratory feeders or augers are used to perform these filling of particles.

Once theparameters are set and the particles are feeded, the packaging containers are placed beneath the filling nozzle and the particles are allowed to enter in it. This mechanism precisely pours particles into the containers. The movement of containers is controlled by highly advanced controlled sensors.

Over and under filling of particles is prevented by a proper leveling mechanism found in some of the particle filling machines.

Once thefilling step gets completed the containers are moved to the sealing station where lids, caps, or seals are affixed to secure the contents. This technique guarantees that the product remains fresh, intact, and safe during storage and transit.

6.What Are The Different Types Of Particle Filling Machines Available Globally?

Particle filling machines are classified into several varieties, each of which is appropriate for a certain application or industry. Some common types of particle filling machines accessible globally are

Gravity Particle Filling Machine

Gravity Particle Filling Machine

Gravity particle filling machines utilize gravity to fill containers with particles in an efficient manner. The particles flow down from a hopper into the containers directly with the influence of gravity. The same mechanism is designed for the travelling of particles from container to the filling nozzle determining required speed and quantity for filling.

Auger Particle Filling Machine

Granule Auger Filler

In an auger particle filling machine, a rotating auger similar to a screw is used to discharge particles into container of different sizes and shapes. The auger draws particles from a hopper and feeds them into the containers, allowing for exact control over the filling quantity.

Vibratory Particle Filling Machine

Vibratory Particle Filling Machine

As the name suggest, vibratory particle filling machines use vibration to settle particles both in filling and packaging containers. This results in a constant and accurate filling of particles of different types. These types of machines are frequently used to fill unusually shaped containers or fragile products that require careful handling.

Vacuum Particle Filling Machine

Vacuum Particle Filler

Vacuum pressure is present in a vacuum particle filling machine to fill containers with particles. This vacuum pressure removes air from the containers and forms a vacuum in it. The vacuum surface is then used to attract particles inside it. This process is commonly used to fill powders and other fine particles produced in different types of industries.

7.What Are The Main Components Of A Particle Filling Machine?

Some of the main components of a particle filling machine are

Hopper

A hopper is present mostly at the top of a particle filling machine and used to store the particles that are fed into the system. The hopper may include agitators or vibrating feeders to maintain a continuous flow of particles to the filling mechanism.

Filling Mechanism

It is present inside a particle filling machine that dispenses particles into containers. Depending on the type of filling machine, this mechanism may be gravity-fed, auger-based, piston-driven, or use other means to precisely measure and dispense the particles.

Filling Nozzle

This is the main component of a particle filling machine that controls the flow of particles into packaging containers from the filling mechanism. Once the required limit of particles is collected, this filling nozzle dispenses it with specific speed. A filling nozzle may be modified to fit various container sizes and shapes.

Control Panel

A control panel allows the operator to set and alter the working parameters. The settings including filling quantity, speed, and container size can easily be adjusted from this control panel. Some of the control panel also include features like buttons, knobs, or touch screen controls that makes it user friendly.

Sealing Mechanism

Some of the particle filling machines also include sealing mechanism that is used to apply lids, caps, or seals onto the container to make the content secure. The sealing mechanism ensures that the product remains fresh, intact, and safe during storage and transportation.

Infrared Sensor

Infrared sensors are used to ensure quality control by sensing factors such as fill levels, seal integrity, and container presence. Highly automated and with greater sensing reliability, infrared sensors guarantee that the filling process is carried out in an accurate and consistent manner.

8.Which Packaging Containers Can Be Filled Using A Particle Filling Machine?

Various types of packaging containers are used to fill particles using a particle filling machine. Some of the most commonly used packaging containers are

Jars

Small Jars Filled With Blue Particles

Widely used particle filled jars made up of glass or plastic material are filled using a particle filling machine. These jars are filled with food, pharmaceutical and other supplements that can be seen and consumed easily.

Pouches

Insecticides Pouches

Pouches made up of plastic materials are widely used to fill granular particles using a particle filling machine. Food contents including grains, seeds and etc are filled in these pouches in a highly precise way.

Bags

Seed Bags

Just like pouches, bags of plastic and papers are filled with coffee, snacks, grains, seeds and pet foods using a particle filling machine. The filling and sealing of these materials is carried in an efficient manner so that no spillage or material wastage may occur.

Drums

Plastic Drums For Particle Filling

In large scale industries where particles are to be filled and supplied in large quantities, drums made up of plastic or metal are used to fill particles in them. Automatic particle filling machines are more compatible for these types of particle filling.

Bottles

Polystyrene Glass Bottle With Particles

Similar to jars, bottles of glass and metals are also filled with different types of particles using particle filling machine. Most of the bottles are transparent that makes the consumer more attractive towards the product. It also gives air tight sealing to maintain the freshness of particles.

9.What Are The Major Differences Between A Powder And A Particle Filling Machine?

Material Usage

The primary distinction between powder and particle filling machines is their handling qualities and applicability for specific materials. Powder filling machines are designed for fine powders and require characteristics such as dust containment systems to ensure correct filling, precision, and maintenance.

Particle filling machines, on the other hand, handle a broader range of items, such as granules and irregularly shaped particles, and may be more concerned with particle flow and distribution.

Accuracy And Precision

Powder filling machines require high accuracy and precision due to the aerated nature of powders. This requires high monitoring to block entrance of heavy particles to maintain the product content.

Whereas a particle filling machines provide more adaptability while still requiring accurate filling. As the particle count is first carried out in the filling container and then dispensed via filling nozzle, accuracy and precision is ensured in each of the container using a particle filling machine.

10.What Are The Auxiliary Machines Associated With A Particle Filling Machine?

Several auxiliary machines are widely used with particle filling machines to improve their efficiency, accuracy, and productivity. Some of them are

Conveyor Systems

Stainless Steel Bottle Conveyor Belt

Conveyor belts or other conveying system are frequently used along with a particle filling machine to transfer containers from loading to offloading. These conveyors pass the packaging containers through phases filling processes including loading, filling, sealing, and labeling.

Weigh Checker

Automatic Weighing Machine

Weigh checker are used to confirm the weight of filled containers and ensure that they fulfill the predefined weight criteria. This helps to ensure quality control and regulatory compliance.

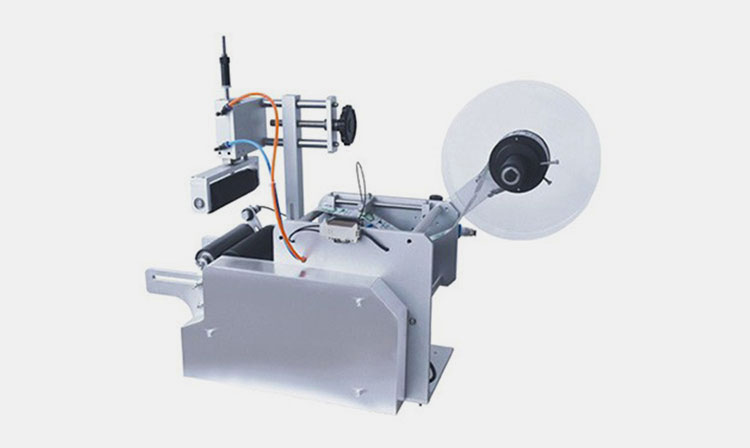

Labeling Machine

Semi-automatic Labeling Machine

Once the packaging containers are filled completely, the containers are sent to labeling machine where labels are applied on them. These labels contain complete information regarding the manufacturer and product that makes easier to the consumer to be familiar with the product.

11.How To Choose A Particle Filling Machine For Business?

It is always a difficult task to select the right type of particle filling machines for any production setup. Some of the factors to kept under consideration to choose a particle filling machine for a business are

Productivity

Productivity

The most important factor to choose a particle filling machine for your business is to determine your production volume and product attributes. This allows selecting a particle filling machine that best suits the productivity keeping future forecasting in view.

Structure

Digital Control Particle Filling Machine

Taking the structural design of a particle filling machine into account is also an important factor to choose. The filling mechanism, dependability, and compatibility of a particle filling machine are important keeping the covering area of process line in view.

Return On Investment

Return On Investment

Having professional guidance, before buying a particle filling machine the return on investment point is also important for any business. As soon as the ROI is achieved the machine can be profitable for any business.

Conclusion

A particle filling machine provides a flexible solution for a variety of industries, in accurate filling and packaging of different types of particles. It is always important to understand its operation, applications, and advantages choosing the best machine for your process .However, in order to find the best particle filling machine All Pack is always available to give you with comprehensive machine-related information and assist you in selecting the ideal product. If you still find any query contact our customer representatives that are available 24/7 for your guidance.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide