Granular Packing Machine: The Complete Buying Guide In 2025

Do you know food granules are a rich source of nutrients? To uphold their nutrients, they are packed inside tough containers. A specialized machine carries out this job and is known as a granular packing machine.

It fills food granules, seeds, spices, herbs, and pulses so that they reach safe and sound to the end-users. It is a cost-effective machine, carrying plentiful profits for the enterprises.

Now let’s delve into the blog post “Granular Packing Machine: The Complete Buying Guide In 2024” to discover what makes a granular packing machine an outclass instrumentation of the world.

1.What are Granules?

Granules

Granules are small compact masses of particles that have either fine or coarse surfaces. These are solid and have varying sizes. Granules are round or irregular in shape.

Granules are found in different industries like salt, sugar, pulses, and rice grains are examples of grains in the food industry. Fertilizers and detergents are chemical granules. In the plastic industry, plastic resins are processed to create plastic granules that form plastic materials.

In the pharmaceutical industry, granules are assembled by the drug powders during the granulation process. These pharmaceutical granules are utilized in tablet compression and capsule encapsulation.

2.How to Define a Granular Packing Machine?

Granular Packing Machine

A granular packing machine is a specialized piece of equipment that wraps the granules in a protective covering. This machine contains and encloses the granules in the packaging materials for their ease of transportation, handling, retailing, storage, and marketing.

Due to this wrapping, granules retain their nutritional quality and structural integrity and they do not get spoiled by environmental and biological deteriorating agents.

Hence, a granular packing machine is an efficient machine that easily performs the tasks of fabricating packaging containers, dispensing materials, and sealing the packaging containers.

3.What are the Pros of a Granular Packing Machine?

Granular packing machine has an edge over manual filling due to its various useful pros. These viabilities fetch tons of monetary benefits for the ventures. Here is a list of pros of the granular packing machine:

Say No to Packing Error

Say No to Packing Errors with Granular Packing Machine

One pro that makes the granular packing machine the preferred choice of manufacturers is its accuracy and precision. Filling precision is important as it lowers the chances of product recalls and increases users' trust in the packaging quality of brands. With a granular packing machine, there is no over and under-filling. So, using this machine you can say goodbye to packaging errors.

Say Yes to Production Efficiency

Say Yes to Production Efficiency with Granular Packing Machine

With a granular packing machine, you can save time, because it easily packs a greater number of granules in less time. It automates the packing procedures that improve the output speed and production capacity. These features save valuable time, allowing production to deliver more products to market.

More Protection by Packing

More Protection by Packing

Consistent granular packing can boost product protection at numerous levels. By packing granules accurately, the granular packing machine prevents the possibility of damage to products. Airtightly sealed granules are saved from biological culprits and environmental agents, increasing their retail life.

Consistent Packing for Shelf-life

Consistent Packing for Shelf-life with a Granular Packaging Machine- Picture Courtesy: Packaging of the World

A granular packing machine packs products consistently and seamlessly which is not possible with hand packing. Consistent packing is more appealing to users which tempts them to purchase the said product.

Lower Packaging Material

Lower Packaging Material with a Granular Packaging Machine- Picture Courtesy: Dieline

The granular packing machine is economical in its use of packaging film. It uses an accurate amount of packaging film and precisely folds, seals, and cuts the film in a preset manner. This reduces the packaging film wastage.

4.Where Granular Packing Machine is Found?

Applications of Granular Packing Machine

A granular packing machine is a versatile machine, seen in every industry that performs granular packing. Some significant industrial uses of this machine are:

Pharmaceutical Industry

Use of Granular Packing Machine in Pharmaceutical Industry

In pharmaceutical manufacturing, the packing of granules is important. Therefore, a granular packing machine is commonly used for dispensing granular medications in pouches and bottles. This machine also dispenses granules formed during dry and wet granules in large bags for offsite table and capsule manufacturing.

Agriculture Industry

Use of Granular Packing Machine in Agriculture Industry

In the agriculture industry, the granular packing machine proficiently performs the packing of seeds, fertilizers, pesticides, organic manure etc. It carefully packs said products without degrading their structural composition.

Food Industry

Use of Granular Packing Machine in Food Industry

Granules are one of the biggest food groups. Hence, a granular packing machine has a central role in packing granular foods like rice, pulses, beans, salt, sugar, soy, lentils, peas, cereals, nuts, dry fruits, coffee beans, tea leaves, flour grains, and many more. This machine seamlessly packs food granules.

Snack and Confectionary Products

Use of Granular Packing Machine in the Confectionery Industry

Snacks and confectionery products like chips, gummies, Choco balls, bounties, popcorn, toffee, and many more are granular and these products are easily and effortlessly packed by the granular packing machine.

Pet Food Industry

Use of Granular Packing Machine in Pet Food Industry

Granular packing machine is pivotal in the pet food industry because it ensures accuracy and precision in pet food filling. This machine hygienically and cleanly dispenses kibbles, pet treats, and pet candies inside sturdy pouches that averts possibilities of contamination.

Chemical Industry

Use of Granular Packing Machine in Chemical Industry

In the chemical industry, the granular packing machine safely and securely fills different phenyl balls, cleaning agents, detergents, bath bombs, etc. in pouches and other packaging containers. By automatically packing chemicals, this machine prevents health risks.

5.What Parts Form a Granular Packing Machine?

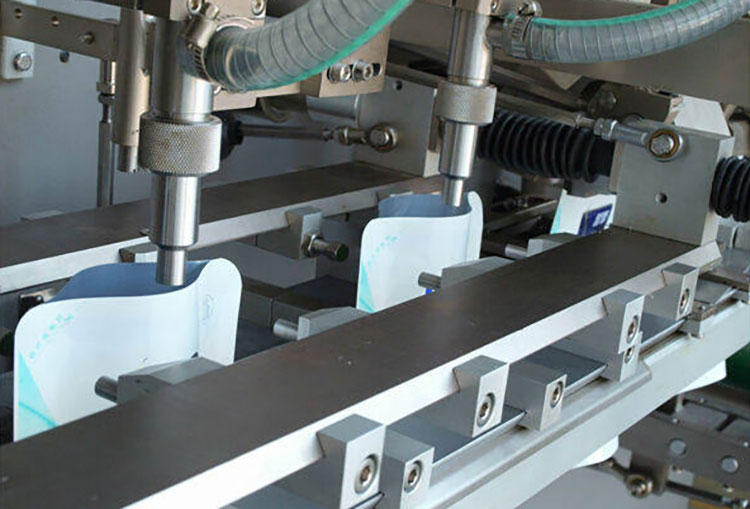

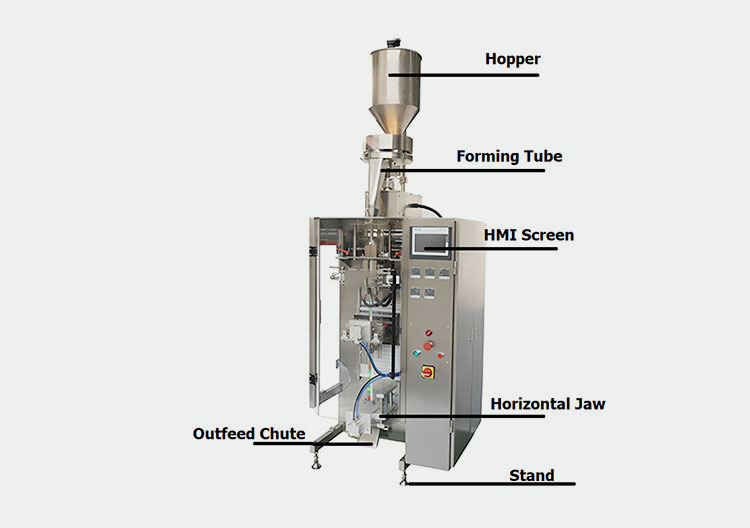

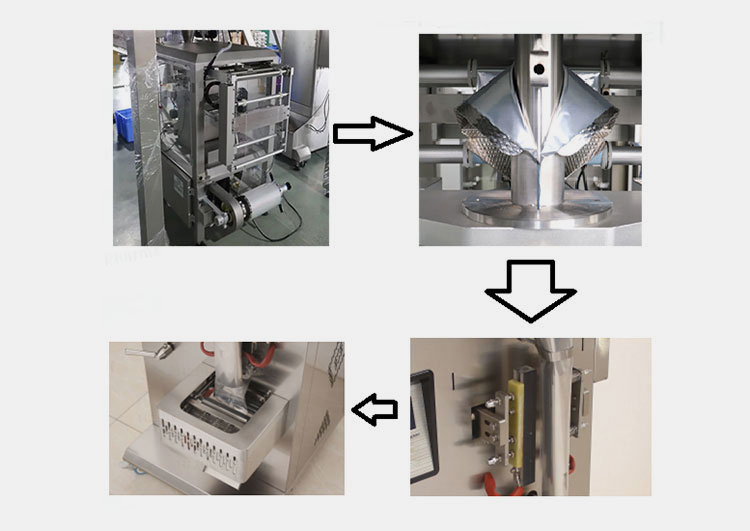

Both Pictures Represents Part of the Allpack Granular Packing Machine

| Hopper | It is a conical part that usually stores huge amounts of granules for speedy operations. |

| Forming Tube | This part changes packaging film into pouches by doubling, wrapping, and sealing, |

| HMI Screen | It is a smart screen panel that allows operators to see the progress of the machine in remote settings without supervising it. Moreover, this panel is present in the modern granular packing machine and by interacting operators can easily input parameters. |

| Horizontal Sealing Jaws | It is a heated sealing bar that melts and joins the top and bottom seams of the pouch or sachet. |

| Outfeed Chute | It is a small chute in which the finished pouches or sachets are collected after sealing and cutting. |

| Stand | It is the bar that balances, stabilizes, and levels the machine. |

| Platform | A large granular packing machine is stabilized with the platform. It offers support to the machine and helps in leveling it. |

| Elevator | It is a vertical conveyor-like structure that transports the materials, such as granules or grains to the filling devices. |

| Multi-head Weigher | This part is used for feeding granules in the pouches. It is made of many heads; each is used for simultaneously filling the pouch. |

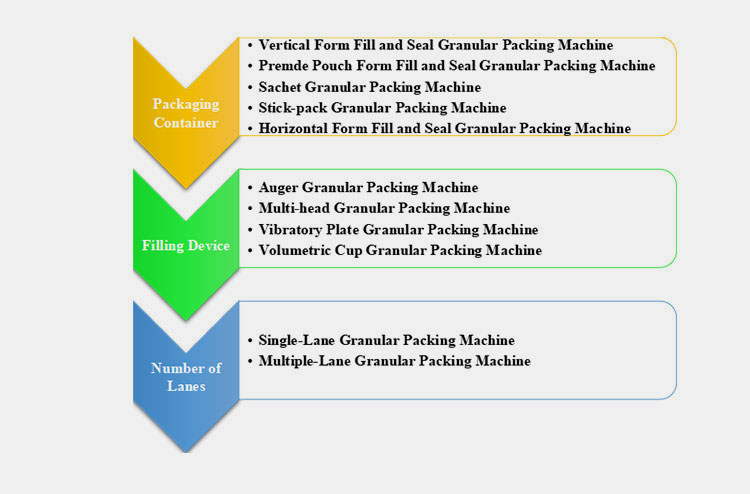

6.How Can You Classify a Granular Packing Machine?

Classification of granular packing machine is somewhat complicated, but we are giving an outline chart and its explanation for your ease of understanding:

According to Packaging Container

Vertical Form Fill and Seal Granular Packing Machine

Vertical Form Fill and Seal Granular Packing Machine

It is the most common type of granular packing machine. This machine is the most economical unit and usually fills multiple servings of granular products. VFFS granular packing machine is a versatile and adaptable machine that has flexibility in its packaging material and product type processing.

Premade Pouch Form Fill and Seal Granular Packing Machine

Premade Pouch Form Fill and Seal Granular Packing Machine

This device as the name indicates, fills already-made pouches. This machine has a carousel that holds numerous bags at various units. The movement of the carousel allows the pouches to pass through different opening, filling, and sealing stations. It operates with higher speeds allowing it to fill multiple pouches per minute.

Sachet Granular Packing Machine

Allpack Sachet Granular Packing Machine

This machine is on the smaller end of the spectrum, needing smaller room for installation and setup. It fills and seals smaller sachets, usually sealed at 3 or 4 seams. The sachet granular packing machine dispenses a one-time serving of the granules in sachets.

Stick-pack Granular Packing Machine

Allpack Stick-pack Granular Packing Machine

It comprises multiple lanes and can form, fill, and seal numerous stick packs in one cycle. It usually has a higher output capacity than its sachet granular packing machine sibling. It also seals stick at 3 or 4 ends. It requires more room for installation.

Horizontal Form, Fill, and Seal Granular Packing Machine

Horizontal Form, Fill, and Seal Granular Packing Machine

This type of machine forms and fills pouches by cutting the packaging pouch from a large roll of pouches. The filling devices load product inside the packing pouch. The packaging process in this machine happens in the horizontal direction. It has higher productivity but it needs more floor space for its packing operation.

According to Filling Device

Auger Granular Packing Machine

Allpack Auger Granular Packing Machine

It fills dry powders and granular products in the packaging containers. It has an auger screw that rotates and moves the products from the hopper to the auger plates from where they flow to the filling nozzles. Control systems in this device regulate the rotational speed of screws. Auger granular packing machine is an enclosed system that has contamination-free dispensing.

Multi-head Granular Packing Machine

Multi-head Granular Packing Machine

It consists of multi-channel hoppers and the weight of granular products inside the hoppers is measured by the load cells. These channels simultaneously dispense inside the pouches when the weight calculated by the load cells matches the preset weight on the machine’s HMI.

Vibratory Plate Granular Packing Machine

Vibratory Plate Granular Packing Machine

It is also termed a vibratory feed granular packing machine. It fills granular products into the container by the constant vibration of the vibratory plates. These plates located underneath the product hopper move the granules. Due to the lower agitation of granular products in this machine, there is a lesser chance of dust generation in this device.

Volumetric Cup Granular Packing Machine

Volumetric Cup Granular Packing Machine

This machine easily fills the granular products as they are free-flowing and move without clumping. The calibrated cups present below the hopper store small amounts of granular products from where they are loaded inside the container. It uses leveling devices to accurately feed inside the containers.

Number of Lanes

Single-Lane Granular Packing Machine

Single-Lane Granular Packing Machine

This type of machine consists of only one lane that forms, fills, and seals one sachet or stick in one go. It has slower processing than its multi-lane counterpart. However, it is a compact forming unit that is a more budget-friendly option for smaller industries.

Multiple-Lane Granular Packing Machine

Multiple-Lane Granular Packing Machine

It consists of four up to twenty lanes that fabricate, load, and seal several sachets or sticks in one cycle. It packs at must faster speed, thus is well-liked by many big brands. It has the latest technology and more parts, henceforth; it needs more space for its installation and operation.

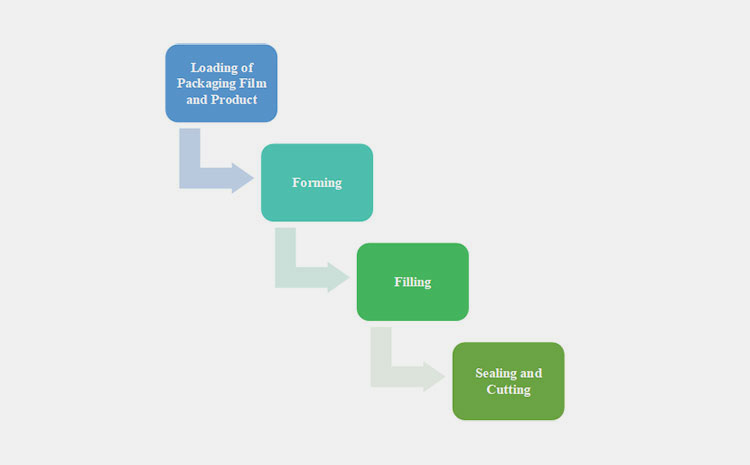

7.What are the Working Steps of a Granular Packing Machine?

The working steps are simple and precise. Different machines have different working steps. These working steps based on machine type are given below:

Working on Form, Fill, and Seal Machine

Form, Fill, and Seal Machine

Working of Form, Fill, and Seal Machine

Loading of Packaging Film

At the start, a large roll of packaging film is inserted into the film holder and also huge quantities of granular products are placed inside the hopper.

Forming

After moving on rollers, the films travel to a conical forming tube that converts the film into the pouch. It is aided by the vertical sealer that seals the side seams of the pouch.

Filling

After forming, the product is gradually loaded inside the pouch with the aid of filling devices. These devices measure and dispense an accurate quantity of products inside the pouch.

Sealing and Cutting

In the end, a horizontal sealer fuses the top seam of the pouch while a sharp cutter located in the middle of the sealing jaws trims away the edges to disjoin two consecutive pouches.

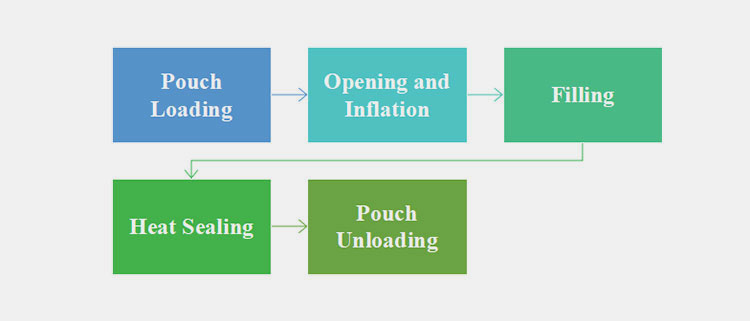

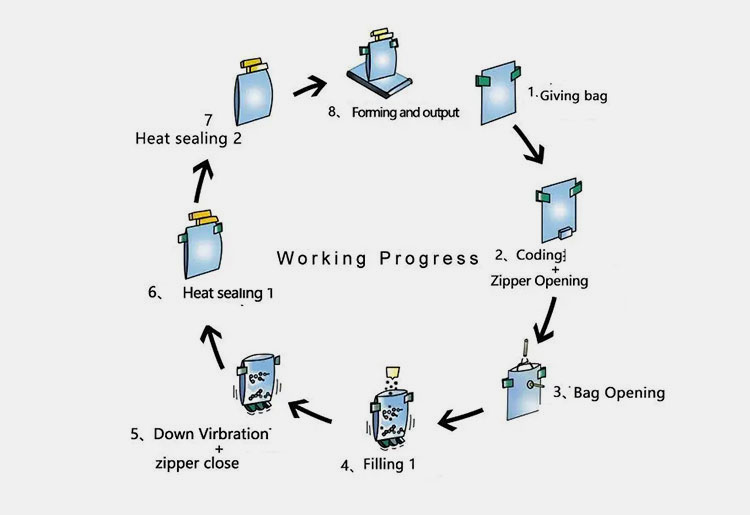

Working of Premade Pouch Granule Packing Machine

Premade Pouch Granule Packing Machine

Working of Premade Pouch Granule Packing Machine

Pouch Loading

At the start, a large stack of bags is loaded on the bag magazine. The products are also stored in the hopper at the beginning of the operation.

Opening and Inflation

The grippers carry these empty pouches one after the other and take them to the opening area, where the zippers (if present) are opened. This pouch is inflated with compressed air so that granules are easily loaded inside the pouches.

Filling

After inflation, the products with the vibration or other movements of filling devices are moved to the filling nozzles. Then, these products are dispensed inside the pouch.

Heat Sealing

In the next step, the zippers of the pouches are closed. Using heat and pressure, the upper side of the pouch is tightly sealed using sealing bars.

Pouch Unloading

The finished pouches are discharged into an outfeed chute or conveyor from where they are moved to secondary packaging units.

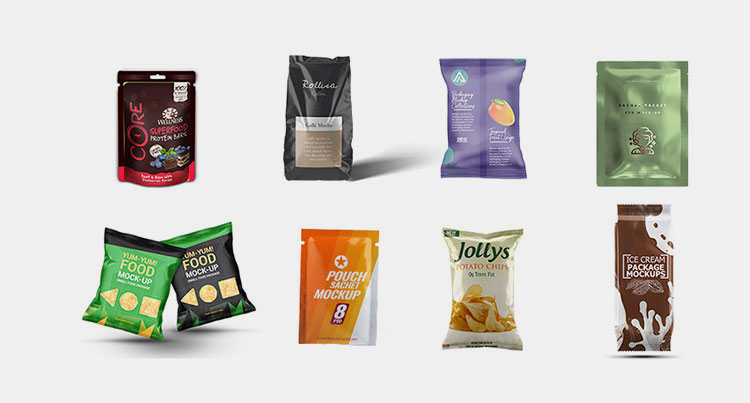

8.Can a Granular Packing Machine Handle Different Bag Designs?

Yes, this machine can easily handle different bag designs, for instance:

| Standup Pouch

It is the most common pouch design handled by a pouch packaging machine. It has bottom gussets that allow this pouch to stand upright on the retail shelves. This feature boosts marketability. |

Standup Pouch |

| Zipper Pouch

It is like a standup pouch with a zipper on the top. This zipper provides users ease of re-closing the pouch after use. |

Zipper Pouch |

| Pillow Pouch

It has three seals- top, bottom, and central- that give this pouch a pillow-like shape. A pillow pouch is also termed a T-seal pouch. It is the most economical retail pouch. |

Pillow Pouch- Picture Courtesy: Spack Machine |

| Side-Gusset Pouch

It has side folding that swell on filling. Hence; it can store more products. It has folding at the bottom and thus does not have a flat base for its stability. |

Side-Gusset Pouch |

| Flat Block Pouch

It is also known as a flat bottom and box pouch because of its box-like shape. It has a flat base on which this pouch easily stands. It has more room for printing and marketability. Moreover, flat bottom pouch stores more quantities of granular products. |

Flat Bottom Pouch- Picture Courtesy: Roastar |

| Pyramid Pouch

It is a triangular-shaped pouch, often storing small quantities of products. Its unique shape attracts more customers. It is used for storing tea leaves and coffee beans. |

Pyramid Pouch |

| Sachet

It is a rectangular or square-shaped sachet. It packs a small serving of the granules and is sealed at three or four sides. |

Sachet- Picture Courtesy: Polysack |

| Stick pack

It is a tubular-shaped pack, sealed at three sides-central, bottom, and top. It also packs one-serve of the granular products. |

Stick pack- Picture Courtesy: Packaging World Insights |

9.Is the Granular Packing Machine User-friendly?

Yes, a granular packing machine is very user-friendly. By adding the granular packing machine in businesses, the brands decrease the burden on their workforce, as hand packing is monotonous, hectic, and tiring, often resulting in work-related injuries.

HMI Touch Screen

HMI Touch Screen- Picture Courtesy: Assembly Magazine

However, a granular packing machine easily carries out its responsibility and needs just the programming of HMI from operators. This HMI is an interactive touch screen on which users can adjust fill parameters, pouch length, number of pouches and other machine protocols with just a finger swipe.

Moreover, it is quite easy to troubleshoot this machine because HMI self-diagnoses machine problems and also outputs recommendations to fix the problems.

Intelligent Design

Intelligent Design of Granular Packing Machine-Picture Courtesy: Packaging Digest

This machine has a simple design and minimal changeovers that increase user-friendliness. The granular packing machine is operated with slight training. It also has safety features like guard rails, safety doors, and emergency stop buttons which contribute to its user-friendliness.

10.What Materials Are Used for Constructing a Granular Packing Machine?

Different materials are used for constructing the granular packing machine which provides the highest durability and corrosion resistance. These materials are discussed below:

Stainless Steel

Stainless steel make up of Granular Packing Machine

It is the most commonly used material. It is usually used for making filling devices, frames, and other structural components. This material is convenient to clean, tough, sturdy, and robust. Furthermore, this material is GMP compliant.

Food-Grade Material

Food-Grade Material

The parts that directly encounter food products like hoppers, filling pipes, and filling nozzles are made with food-grade materials like stainless steel or food-grade plastics. These materials are non-toxic and do not leach harmful chemicals into the food products.

Glass or Plastics

Glass Safety Door

The safety doors in the granular packing machine are either made with glass or clear plastics to allow end-users to view the granular packing operation.

11.Does Granular Packing Machine Contribute to Eco-Friendly Efforts?

Granular Packing Machine

Due to concerns about environmental conservation, more and more manufacturers demand eco-friendly granular packing machines. In short words, this machine contributes heavily to eco-friendly efforts by some simple processes like:

A granular packing machine uses packaging film at a controlled rate, consequently, there is less waste of packaging materials. Nowadays, more and more granular packing machines are utilizing recyclable and compostable film for pouch formation. Some machines fill reusable pouches. These features increase its eco-friendliness.

This machine also contributes to sustainability efforts by accurately and precisely dosing the granular products in the packaging containers. It does not spill and lose material, thus reducing product wastage.

Granular packing machine has high energy efficiency which means they save energy while running. This lowers fuel consumption and results in reduced carbon emissions in turn promoting eco-friendly efforts.

12.Tips and Tricks- How Can You Troubleshoot Granular Packing Machine?

Yes, occasional problems can occur in the granular packing machine that could be the source of overwhelmingness for the manufacturers and operators alike but they are easily resolved with some tips and tricks. Here are some common problems and their troubleshooting:

Equipment Generates Dust

Equipment Generates Dust

Sometimes the granular packing machine produces a high amount of dust that could spark.

Cause

- The granular product produces dust.

- Improper measures of containing the material.

Solution

- Check the characteristics of materials and install dust control devices.

- Use closed devices like auger fillers to avoid dust generation.

Inadequate Sealing of Packaging Container

Inadequate Sealing of Packaging Container

The sachet, pouch, or stick pack may have improper sealing that could lead to product leakage.

Cause

- Insufficient sealing temperature.

- Poor sealing pressure.

- Damaged or faulty sealing bars or heating elements.

Solution

Increase the sealing temperature to ensure proper sealing.

Increase the sealing pressure.

Replace or repair old and faulty sealing jaws and sealing elements.

Machine Fails to Run or Stop Without Warning

Machine Fails to Run or Stop Without Warning

Sometimes, the machine fails to start or stop running without any notice.

Cause

- Presence of undesired objects, dust, leftover product, or sticky residue in the machine.

- Different components like PLC systems, sensors, etc. may be defective.

Solution

- Thoroughly clean all the machine parts.

- Check for faults in components and if possible, replace them.

Tearing of Packaging Film

Tearing of Packaging Film- Picture Courtesy: Hefei Zengran Intelligent Packaging Technology

Sometimes, the packaging film rips or gets slashed.

Cause

- Packaging film is not properly aligned on the rollers or other machine parts.

- High film tension can also cause ripping.

Solution

- Properly align the film on the rollers.

- Reduce the film tension.

Uneven Weighing and Filling of Granules

Uneven Weighing and Filling of Granules- Picture Courtesy: Rockwell Automation

Sometimes, there are inconsistencies in the fill weight and volumes of the granules.

Cause

- Defective filling or weighing devices.

- Nozzles are dirty or clogged.

- Filling devices out of calibration.

- Incorrect settings of fill parameters.

- Wet granules clump together and cause bridging.

Solution

- Replace worn-out filling devices.

- Clean the filling nozzles.

- Recalibrate filling devices.

- Reset the fill parameters.

- Dry the granules before filling.

Conclusion

The granular packing machine is a popular invention of modern times, packing seeds, grains, rice, spices, cereals and many more products. Efficiency, speed, productivity, and accuracy are a few of the important pros of a granular packing machine. Integration of such machines can bring fruitful results for enterprises. Now are you tempted to procure a granular packing machine? We, Allpack have a comprehensive catalogue of machines. If you are tight on budget! We have a solution just for you. Email or message us with your queries. We will help you with your selection.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide