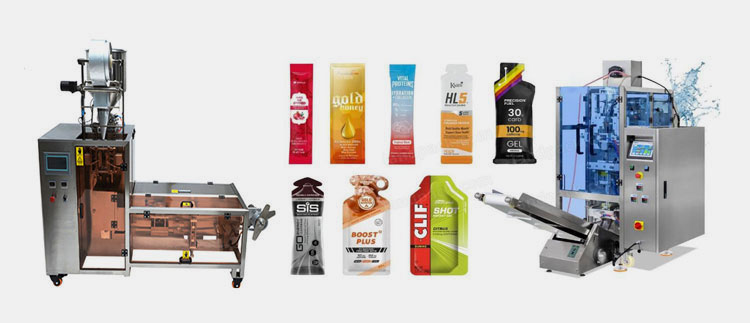

Horizontal Irregular Shape Sachet Packaging Machine:The Complete Buying Guide In 2025

Did you know, a careful product packaging plays a significant role in sustaining the longevity of your product value? Indeed, this is essential to adhere to health guidelines when it comes to food or medicinal products. A horizontal irregular shape sachet packaging machine is an advanced machine that meets not only consumers’ but manufacturers' demands to comply with high standards in product’s packaging. If you’re planning to invest in this machine; please go through the article! We promise it will be useful to read.

1.What is a Horizontal Irregular Shape Sachet Packaging Machine?

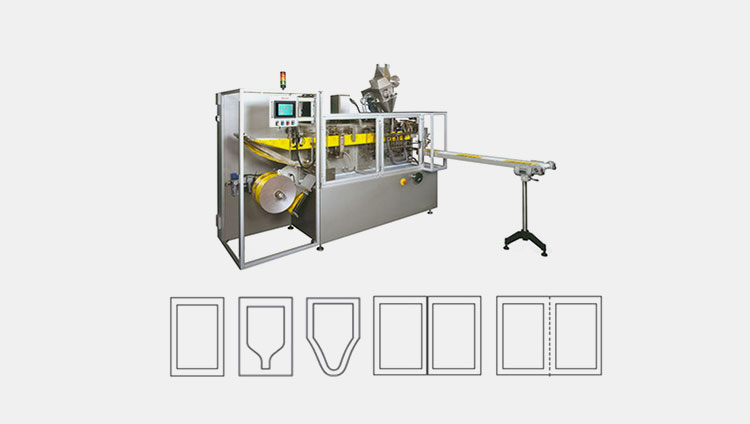

Horizontal Irregular Shape Sachet Packaging Machine

Horizontal irregular shape sachet packaging machine is an equipment that works horizontally in the manner in which the products are incorporated into the equipment horizontally for conducting the packaging process.

It is suited to make, insert and seal sachets that are aberrant in conformation, meanwhile making sure that the packaging material is specifically chosen according to your product.

Industries that have products that are designless require special or customized styles of packaging, which can be seamlessly carried out by this machine. It enables dynamic and definite packaging formats that can not be applicable by enclosing it in regular shaped packaging materials, giving the consumer a different experience in various items.

2.What are the industrial uses of the Horizontal Irregular Shape Sachet Packaging Machine?

The industrial applications of horizontal irregular shape sachet packaging machine are discussed below:

Food Industry

Horizontal Irregular Shape Sachet Packaging machine uses in Food industry

You might have seen eye catching wrappers that have variety of delicious snacks, biscuits and other edible items that are packaged in horizontal style of flow wrapping material. That’s what is done by this machine!

Bakery Industry

Irregular shaped sachet in bakery

Bakery items such as pastries, cakes , biscuits, cookies, and some other baked goods are custom packaged involving the use of this equipment.

Frozen Food Industry

Irregular shaped sachet in Frozen food products

Automatically wrapped in any form of packaging can be carried out for frozen food items as well , such as frozen ready to eat meals, vegetables, fruits, seafood etc.

Confectionery Industry

Irregular shaped sachet in confectionery packaging

Confectioners find amazing styles of packaging formats to grab consumers by packaging of different products such as candies, chocolates, gummies, chewing gums, etc with the help of this equipment.

Pharmaceutical Industry

Irregular shaped sachet in Pharma products

Pharmaceutical industry finds its purpose in the employment of horizontal irregular sachet filling machine by using it for packaging of blister packs, medicine strips, bandages, and some other medical products and devices.

Cosmetics and Personal Care Industry

Irregular shaped sachet in cosmetic and personal care items

When it comes to taking care of your beauty and hygiene, cosmetics and personal care industry makes sure to deliver your good quality product that has extremely precise packaging that is conducted by this machine. Horizontal wrapping can be found enclosing soaps, shampoo sachets, lotions and creams, hair care products etc.

Hardware and Tools Industry

Irregular shaped sachet in hardware items packaging

Hardware and tool items like small nuts, screws, bolts, and packing of other tools that serve mechanical and electrical purposes are automatically wrapped by this machine.

Household Products

Various household items needs irregular shape sachet packaging machine

Household items need horizontal irregular shaped packaging such as that of cleaning tissues or wet wipes , disposable items, and some other household used products.

3.What are the Advantages of a Horizontal Irregular Shape Sachet Packaging Machine?

Works for All Shapes

Excellent machine for versatile packaging

As mentioned earlier, it suits its purpose across many industries and has multiple applications. So it’s evident that this machine will work to cover up any shape of your product as per your customized design requirement.

Super Fast and Non-Stop

Horizontal Irregular Shape Sachet Packaging Machine : Offering fast operation

You don’t need to worry about your package getting loose or inaccurate sealing, as products processed by this machine can seal securely , keeping your inside item safe from any damage. One great benefit it holds is that it can handle packaging process efficiently with quick rate of progression, wrapping up hundreds of products in one hour!

Saves Material and Earth

An eco-friendly solution is now in your town

This equipment serves to sustain Earth’s ecological environment by reducing material wastage. It only uses appropriately required material for your packaging, saving resources and making the whole procedure eco-friendly.

Looks Really Good on Shelves

You can promote business via irregular shape sachet packaging machine

The products that are tailor designed by this machine attracts customers by appealing product packaging placed on shelves.

Can Team Up with Other Machines

Machine offers high integration

It has the functional capability to work integrated with any production line, interlinked to team up with other machines to result in one smooth operating system.

Reduces Costs and Works Smart

You will spend less with horizontal irregular shape sachet filling machine

Due to it’s smart automation and work efficiency it cuts down on labor cost and speedily produces packaging to give good production throughput.

4.What is the Structure of a Horizontal Irregular Shape Sachet Packaging Machine?

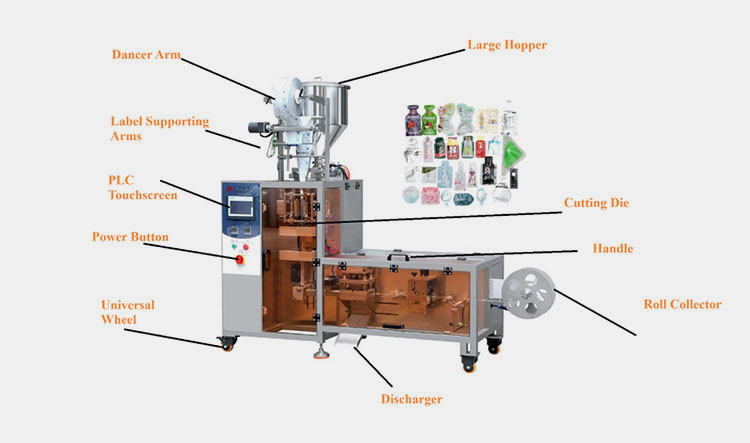

Parts of horizontal irregular shape sachet packaging machine

Large Hopper

The large hopper provides the storehouse for raw materials that are supposed to be filled in packaging process. Materials like granules or powders are kept in supply here so that production is not discontinued.

Dancer Arm

This part is easily adjustable in terms of maintaining the packaging material’s movement through the horizontal irregular sachet filling machine. Dancer arm takes over the control of packaging material, deciding how much tight or loose it must be, avoiding tearing or irregularities in packaging.

Label Supporting Arms

Label supporting arms function in coordination with dancer arm, dictating the proper maintenance, orientation and shape of sachets as it moves through different steps of packaging.

PLC Touchscreen

PLC screen device is the operator facilitator in order to instruct and feed settings that will control and analyse the working procedure.

Cutting Die

Cutting die is a component that will design, shape and selectively cut your desired sizes of sachets from the packaging material into individual and accurately measured sachet packets each.

Power Button

The power button is the main switch control for operating overall functions of your equipment. It enables the electrical power supply , letting the packaging process to start or stop.

Handle

Handle is a lever that lets the user to manually see the inside parts of your machine whether it is the cutting die, label supporter or any other components. This allows easiness for the technician to make any changes or handle it during its repairing.

Roll Collector

Roll collector is a part that carries the used bundle of packaging film rolls and keeps your working area tidy , facilitating it’s easy discarding.

Universal Wheel

A universal wheel is the driving wheel that lets the equipment to be transported around the industry anywhere it is required. It gives mobility to the machine, letting the users to easily reposition as required.

Discharger

The discharger releases the final packaged sachets from the machine, making sure the last discharging phase is smooth so that it can process for next step in production.

5.What is the Working of a Horizontal Irregular Shape Sachet Packaging Machine?

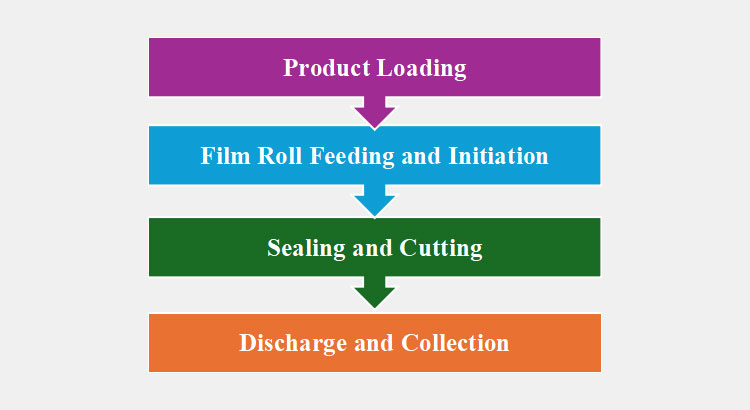

Horizontal Irregular Shape Sachet Packaging Machine

To understand the working of the machine, we have divided the working step in the following steps. We hope it will be more helpful.

Workflow of Horizontal Irregular Shape Sachet Packaging Machine

| Step 1: Product Loading | The machine is equipped with a large hopper where you can manually introduce the feeding material. The material could anything in raw form such as granules, semi-solid, solids, powder or various other product. |

| Step 2: Film Roll Feeding and Initiation | A film roll is adjusted on the dancer arm, this film roll starts opening or unwinding upon system initiation. The mechanism is basically relying on the formation and insertion of product inside each formed individual sachet. An unwind roll starts forming sachet and the product enters inside.For irregular shape product the system is associated with various factors including cutting and collecting of film and label roll respectively. |

| Step 3: Sealing and Cutting | A formed and filled sachet is now sealed by heat sealers followed by an even cutting of formed packed material. here, a cutting die is responsible for giving the desirable shape of an irregular sachet. |

| Step 4: Discharge and Collection | The prepared and packed product perfectly leaves the unit via the discharger of the machine and unwanted material is collected in a controlled way over the roll collector. Upon finishing the process you can remove the collector from the machine for disposing off. |

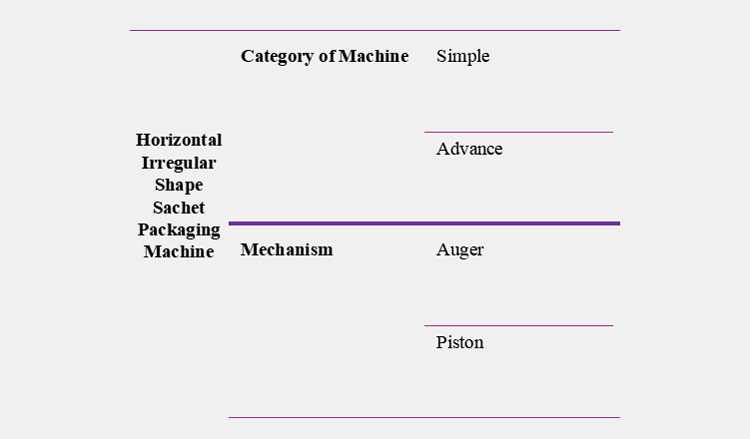

6.What is the Classification of Horizontal Irregular Shape Sachet Packaging Machine?

The classification of horizontal irregular shape sachet packaging machine is given below:

Classification of Horizontal Irregular Shape Sachet Packaging Machine

Based on Type of Machine

This type includes different features of horizontal irregular shaped sachet packaging machine. such as:

Standard Horizontal Irregular Shape Sachet Packaging Machine

Standard Horizontal Irregular Shape Sachet Packaging Machine

This category involved simple and the most basic responsibilities and properties of the machine to produced irregular shaped sachets. A simple machine but extremely protective as entire cables and wire are designed with well-hidden cabinet following electrical standards. This is easy to handle machine with simple operatability and pocket friendly properties.

Advanced Horizontal Irregular Shape Sachet Packaging Machine

Advance Horizontal Irregular Shape Sachet Packaging Machine

The additional and most advanced features involved with this machine which is mostly used in larger capacities production companies. The machine is involved with an air expansion shaft used for unwinding of the film to form an individual sachet or pouch, using high controlled PID temperature controller mode an easy and error free sachet formation take place with vertical and horizontal sealing.

Based on Filling Mechanism

This category of horizontal irregular shape sachet packaging machine is designed to pack specific products needs specialized filling system.

Auger Filling Horizontal Irregular Shape Sachet Machine

Auger Filling Horizontal Irregular Shape Sachet Machine

This is commonly used type which is used to fill dry powders, granular material, in irregular shape sachets. This machine is require to avoid spreading of dust and powdery particles in working environment.

Piston Horizontal Irregular Shape Sachet Packaging Machine

Piston Horizontal Irregular Shape Sachet Packaging Machine

If you’re packing liquid, semi- liquid or viscous formulation, it is considered as a suitable option to use as a piston is responsible for accurate filling of volume in irregular sachet.

7.What is the Sealing & Closure Type of Horizontal Irregular Shape Sachet Packaging Machine?

A horizontal irregular shape sachet packaging machine features various sealing types that is depending upon manufacturer choice and machine type.

Sealing Type

The following sealing type of the machine is described below:

Impulse Sealing

Impulse sealing for Horizontal Irregular Shape Sachet Packaging Machine

This type of sealing is basically used for the packaging of materials that are sensitive in nature so an impulse wave can protect it against harsh heating. A very fast and short impulse of heat wave can swiftly create a seal around the sachet.

Heat Sealing

Heat sealing for Horizontal Irregular Shape Sachet Packaging Machine

This is the most commonly used sealing type where heat sealers are responsible to bring the sealing around the edges of the sachet to create a firm and tamper evident closing.

Ultrasonic Sealing

Ultrasonic sealing for Horizontal Irregular Shape Sachet Packaging Machine

This is also frequently used method where ultrasonic heat wave can cause sealing around the sachet.

Cold Sealing

Cold sealing for Horizontal Irregular Shape Sachet Packaging Machine

In this type, heat energy is not utilized, though a firm pressure is supplied over the sealing area to produce strong adhesion. This type of sealing is mainly used for those products that are heat-sensitive.

Closure Type

The closure type of horizontal irregular shape sachet packaging is discussed below:

Tear Notch Closure

Tear Notch Closure

The type of closure normally designed to allow user an easy opening or tearing the sachet to get the product.

Zipper Seal

Zipper Seal

A modern closures of sachet where user can utilizes the sachet multiple times simply by opening and zipping the sachet.

Cap or Screw Cap or Spouted nozzle

Cap or Screw Cap or Spouted nozzle

This is also a modernized way of closure which is mostly used in food industries to secure and reuse the product by screwing the cap over the neck of the sachet. Mostly liquid or semi solid products’s sachets are designed with spouted nozzles to secure product when use and avoid chances of spillage.

8.What is the Filling Type of Horizontal Irregular Shape Sachet Packaging Machine?

| Pneumatic Filling | In pneumatic filling, controlled pressurized air is involved in the filling process which allows correctable and accurate filling capacities. |

| Volumetric Filling | An accurately measured amount of product that is to be dispensed is consistently filled into each packaging sachet. Examples of volumetric fillers are piston and rotary type of fillers. |

| Gravity Filling | Gravimetric filling enables the product to fall freely following the law of gravity, suitable for products that are liquid or powders. |

| Auger Filling | Auger fillers incorporate the use of auger screws which fills powders or granules into sachets by precise measurement. |

| Net Weight Filling | Once your desired amount is filled into the package, it is weighed and measured to ensure that your product is present in the specific net weight. |

| Positive Displacement Filling | This includes the use of a working device to dispense a certain quantity of product into the packaging material ensuring that it is accurately displaced. |

| Peristaltic Pump Filling | In this type of filling, peristaltic nozzle are used to pour out liquid products offering good precision in control over avoiding product’s contamination. |

| Magnetic Filling | Magnetic filling is conducted by the help of magnetic fields is used majorly for controlled filling of such products which are magnetic in nature or iron containing materials. |

| Servo-Driven Filling | The servo-powered filling uses servo motors to precisely manage and balance the filling process, providing adaptability and precision. |

| Pressure Filling | Pressure-based filling regulates the filling procedure based on the pressure within the product storage device, making it suitable for thick liquids. |

| Vacuum Filling | Vacuum-based filling generates a vacuum to suck in fluids, particularly useful for filling containers with a slender neck. |

| Cup Filling | Cup-based filling situates pre-determined volume cups or containers under a filling nozzle, guaranteeing each cup receives the intended quantity. |

9.What Kind of Sachet Shape The Machine Can Offer?

Horizontal Irregular Shape Sachet Packaging Machine

The shape list of a horizontal Irregular shape sachet packaging is so broad. Some of the very commonly formed shapes are mentioned in:

| Name | Description | Picture |

| Arches or Fingers Like Projection Shaped Sachet | Machine is capable to create finger and sharp projection shape that is mostly used form and pack items involved hygiene and user’s protection, such as gloves, foot covers, etc |  |

| Circular/ Convex Shaped Sachets | This is target irregular sachets frequently used to packaging of various items. This is the portable and convenient packets once can carry everywhere easily. |  |

| Rectangular Shaped Sachet | Single used portable irregular sachets are manufactured by this machine to boost more aesthetics of your brand. This is the most appealing shape that helps in storing adequate amount product in a smaller pack. |  |

| Heart Shape | Individual irregular sachets can be prepared to store formulate in beautiful heart shape. It is mostly used in packing of gift products or items related to improve aesthetics when displayed for marketing. |  |

| Bowl Shape/Concave Shape Sachet | An appealing bowl or concave shaped sachet is another addition which is commonly used for packaging of spices or condiment can be prepared by this machine. This way of packaging has grabbed the attention of many producers and consumers worldwide as it creates finest aesthetic of your product. |  |

10.What is the Difference Between Horizontal & Vertical Irregular Shape Sachet Packaging Machine?

Difference Between Horizontal & Vertical Irregular Shape Sachet Packaging Machine

| Contrasting Factors | Horizontal Irregular Shape Sachet Packaging Machine | Vertical Irregular Shape Sachet Packaging Machine |

| Shape of Sachets | Horizontal style shape with broader dimension of width. | Vertical style of shape with greater length. |

| Accommodation size | Occupies larger floor area due to it’s horizontal style of equipment. | Usually minimal area is taken by the machine due to it’s vertical positioning. |

| Sealing Side | Seals are created or placed on the edges of the sachet. | Seals are generally applied over the top or bottom line of the sachet. |

| Product Movement Through Machine | Products are delivered horizontally through the equipment for conducting packaging. | Products get transferred vertically through the system for packaging process. |

| Application In Industries | - Food items and drinkables, Beauty and Self Care, Medicinal industries. | - Medicinal, Eatables like Snack items, Chemicals and Powderous substances. |

| Machine Configuration | Parts like packaging material , filling type, and sealing section are all basically arranged in horizontal manner. | Parts are arranged vertically, with a persistent vertical style of transferring. |

11.How To Maintain A Horizontal Irregular Shape Sachet Packaging Machine?

Horizontal Irregular Shape Sachet Packaging Machine

| Daily Routine Cleaning

|

A strictly followed daily cleaning routine should be objectified, depending on how often the machine is brought in usage and what is it’s production capacity. You can maintain daily or weekly, or even shifts based cleaning. |

| Empty and Clean Hopper

|

The large hopper device should be properly emptied with any residual remains of any material previously present in it. Then it must be cleaned effectively to avoid chances of contamination amongst other products processing. |

| Cleaning the Dancer Arm and Label Supporting Arms | Wipe the dancer's arm and label supporting arms with a tidy and wet piece of fabric. Then take off any dirt or residue substance from it’s surfaces to maintain good operability of these parts. |

| Cleaning Cutting Die | Take out the cutting die component separately and then clean it , removing any unwanted particles or dirt . |

| Analyse and Clean Roll Collector | Check the roll collector for any deposited dust or particles, and take off any old packaging film bundle that might be present. |

| Checking of Seals and Joints | Monitor thoroughly the sealing and joining parts for any presence of error or damage, or signs of wearing or rust that might have developed over time. Properly clean and oil these areas to enable good functionality. |

12.What are the basic problems and Solutions of Horizontal Irregular Shape Sachet Packaging Machine?

The common problems associated with a horizontal irregular shape sachet packaging machine are mentioned below:

Leakage of Edges Due to Improper Sealing

| The cause of this problem is due the following reasons:

High Temperature burns the film and cause leakage. Due to pressure differences inside and outside the film may cause incomplete or incorrect sealing. |

It is recommended to use a pyrometer. This tool is helpful in the proper assessment of temperature.

Reduce or regulate the temperature of the heating jaws. Regulate the pressure difference inside and outside the packaging. |

Bubble Or Wrinkled Sealing

| This is a very common problem and can be caused by two basic reasons:

When you use the equipment after a long time, so temperature calibration is required if not this could result in uncontrollable temperature. Second reason is dirt or dust at sealing jaws that can normally an embossed sealing which is mostly not required at edges. |

The following problems can be rectified:

By changing the sealing jaws or correcting them Regulation and calibration of heating jaws can be a good solution. Regular monitoring, cleaning, and maintenance of the machine can be helpful to combat the problem. |

Blockade or Jamming of Sachet Film

| This is a very common problem can be caused by:

Misalignment of the roller supporters and channels. Incorrect adjustment of the film roll. Obstacle in film roll pathway. |

The following problems can be rectified by monitoring:

Alignment of the roller supporters and correct the settings. Reset and Start the program again to check the process. Correct the adjustment of the film roll. Clear the obstruction and recheck if the system ensures smooth feeding of the film roll. |

13.A Horizontal Irregular Shape Sachet Packaging Machine: What do you need?

Before buying a horizontal irregular sachet packaging machine, you must ensure that what would be your specified requirements according to the different products that will be catered by this machine. Let’s go through some of them below:

Type of Product

A product shape must be assessed

Depending upon the category and type of your product, whether it is solid, liquid, powder or granular in texture, and what size and weight it receives will decide the choices of features of equipment that would be required for packaging.

Speed Requirements

Production speed specifications

One major factor for determining the packaging machine’s output requirement is it’s rate of production. Certain products need to be filled at a quick speed ensuring multiple number of sachets are delivered per hour or day.

Budget

Assessment of budget is significant

You must have the idea of budget your industry can afford , keeping in mind return on investment and what type of machines can you accommodate in your production line.

Quantity of Product

Product Capacity

The quantity of product that would be filled by your equipment is another necessary factor to be looked upon, which means what will be the production volume and size of your machine, and that relates obviously to it’s speed.

Labeling Requirements

Label specifications

You must also know if any specific labeling system must be integrated in the line or if certain labeling requirements must be fulfilled by the machine.

Conclusion

Horizontal irregular shape sachet packaging machine is advanced and the most popular machine as it is a gateway to achieve random, customize and attractive packaging of sachet and pouches in no time. The colorful, dynamic addition in your packaging line is indeed playing a promising role to enhance your business. If you want to purchase this excellent addition in your production line; then don’t think more; Just send us message to start new journey of success. We hope this article is suitable for deciding what’s your choice, so contact Allpack advisory Team to start discussions and Buying Support. Happy Shopping!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide