Top 20 Food Processing Industry Trends In 2025

Do you know what current evolutions are there in technology and its integration with food processing industry? The trends show that the consumption of raw ingredients to its final food processing stage has completely evolved with advancement in technology. Food processing industry has now been able to preserve food for longer periods and provide quality products to the customers. With complete survey and research, following are the top 20 food processing industry trends in 2024

1.AI Based Processing

AI In Food Processing - Picture Courtesy: ResearchGate

With the advancement in technology, AI (Artificial Intelligence) has become the most popular way to do critical thinking and getting real time results. AI these days is used to enhance the efficiency of food processing and to develop new techniques for controlling the quality of food. Using AI less wastage is observed and also the food processing is balanced by continuous checking all its parameters.

AI process and algorithms are best while using them in predicting the required optimal maintenance and schedules it accordingly. This modern technique is well suitable for optimization of product supply chain cycle where are the demand and forecasting can easily be done by applying various methods of AI. From food processing to food preservation, all methods are modified currently due to the innovations in AI.

2.Robotic Food Processing

Evolution Of Robotics In Food Processing - Picture Courtesy: Zenoot

For repetitive task performance in food processing industry with high quality and precision, robotic operations are being used as a global industry revolution trend. Highly automated machines with user friendly algorithms are present in these robots that are robust in their process and perform dedicated jobs assigned to them.

Robots are used from the initial stage of food processing including plant plugging to food picking. The tasks are performed in a uniform way one after another without any disturbance. Modern robotic technology is involved in cleaning of the planting surface and also performs their packing. Industry 4.0 relates these robotic sources as their main weapons to be used for food industry processes.

3.Renewed Focus On Sustainability

Sustainable Development In Food Processing

The researches and studies in industry 4.0 tend to reduce carbon footprints and involve food processing techniques to produce less wastage. The focus on sustainability has slightly changed in trend as modern food processing methods are environment friendly and obey the rules to make eco-friendly products.

These practices and strategies are globally used for energy efficient production and having sustainable sources. The major portion supporting industrial trends in sustainability as it holds a greater importance in both environment and product safety.

4.Green Food Processing

Food Processing Trends - Picture Courtesy: World EDU

Modern days green food processing techniques decreases the total consumption of energy and also emphasis on the usage of resources that are generated from renewable resources. Minimum wastage is produced as a result of these green food processing methods.

Industry has been evolved by using aseptic way of packaging, applying edible coating and transformation in food irritation processes that result in greater shelf life of food products. The quality of food remains the same by using these green food processing techniques and also has the same feeling while consuming them as compare to a readily made product.

5.Supply Chain Disruptions

Supply Chain Process In Food Processing

As global transportation and product forecasting being a challenge in the current scenario, food processing industry is now using advanced methods to reduce its supply chain disruption. Critical and analytical thinking with all mathematical calculation has been a focus of all food processing industries that has led to monitor their product while they are travelled globally.

Also, an approach has been developed to judge the requirement of food products so that better forecasting can been done and supply chain disruptions can be minimized at the last moment.

6.Plant Based Foods

The Rise Of Plant Based Food Processing - Picture Courtesy: CRB Group

Where preservation of plant-based food and its seasonal production was a problem in past, modern advancement in technology has streamlined in food processing industry. Modern in-house and field produced plant-based foods are same in smell and appearance to that of produced by animals. These products are used directly as an alternative to dairy products where the taste remains the same.

Plant meat as an example of a startup that manufactures plant-based food that replicates to the products made up of meat. This food processing industry has less carbon footprints and has an opportunity to be delivered globally. All of the processed food has bulk of protein, mineral, fiber and vitamin contents that support in consumers healthy nature.

7.3D Printing Of Food

3D Printed In Food Processing - Picture Courtesy: GrabCAD Blog

3D food printing is a sustainable way to think beyond imaginations. It helps in design high class food structures that completely correlate with natural ones. According to the need of consumer, ingredients of any food product including sugar, protein, fiber or etc. can be managed and formulate using 3D food processing methods.

3D food printing supports environmental conditions and has less carbon footprints and also minimizes food wastage. High level of expertise is required in this regard which leads to greater cost reduction and efficient food processing results.

8.Food Waste Management

Waste Management In Food Processing Industry - Picture Courtesy: BioEnergy Consult

While facing food wastage problem in traditional processing techniques, industry revolution has minimized this to a greater level and manages it efficiently. The importance of food waste management in industry processing is due to its focus on consuming every last particle of leftover as a resource and enters in back to the system. This results in a sustainable policy related to the environment and also saves a lot of cost that preciously entered in food waste. This managing mode has enhanced packaging techniques as well that the food can be preserved for a longer period.

An example of food waste management is the digestion transform due to anaerobic conditions. This method gives support in rise of good bacterial and viral substitutes in food that turns the food into biogas. This biogas is then collected and utilized according to its requirement. A modern-day technique also involves in educating customers regarding products that are near to their expiry. Offers are also given on such production just due to early consumption of these products and to manage food waste.

9.Pet Food Processing

Pet Food Processing

People these days are verily involved in having pets and looking after them properly. As to give them proper health conditions the global demand in highly effective and healthy pet food processing has increased drastically.

To cater this increase in demand, advanced food processing techniques are being used to have people nutritious food with balanced diet in it. The packaging of these products is done in a way that greater number of customers can be attracted towards it.

10.Clean Labels

Clean Labels In Food Processing - Picture Courtesy: Grande CIG

Clean labels basically support the consumer to get better knowledge regarding the food product, the ingredients involved in its processing and the credibility of its manufacturer. The seriousness of any manufacturer related to the manufacturing of product and its environmental effects can also been judged through this clean label techniques.

Clean label method also builds a trustworthy relationship between the consumer and manufacturer by disclosure of all product related information. This can directly cause increase in the economical factor of any manufacturer that follows clean label industrial trends.

11.Cannabis Processing

Cannabis Processing - Picture Courtesy: Sustainable Cannabis Coalition

Earlier cannabis processing faced a lot of legal and traditional problems but since this process has been legalized, the world is now looking for new opportunities in this field. It is commonly referred to the food or drinkable product that has decarboxylated cannabinoids in it. This infusion has better health care results and produces food products that are highly delicious to eat.

Cannabis products have diverse applications with many advantages related to nutrients. The decarboxylated cannabinoids is used in various products like deserts, pizza and also in foundation of many cuisines.

12.Ethnic Cuisine

Savoring The Ethnic Cuisine

With increasing global demands of ethnic foods study shows that the market of $ 90 Billion USD in 2023 will drastically increase to $ 142 Billion USD in 2030. The increase indicates that globally ethnic cuisine is opted by many manufacturers and consumers with sauces and spices as their main ingredients.

Consumers from different backgrounds are now the main focus of many manufacturers and due to this ethnic cuisine is their main focus taking consumer preference on priority. The consumption market of ethnic cuisine is rapidly growing with a CAGR of 8.10% and providing customers with great satisfaction while using these products.

13.Longer Product Freshness

Improved Methods Food Companies Use - Picture Courtesy: AZ Big Media

Traditionally, food packaging has been a challenge for manufacturers as it plays an important role product safety and freshness. Eco-friendly and biodegradable packaging are used to keep the product fresh for a longer period and will improve more in future with continuous improvements in it.

In the modern world, food product manufacturers credibility directly depends on the freshness of product and different technologies are doing this work for them. The composite material used helps product to maintain its freshness which was not possible just 20 to 30 years back.

14.Sustainable Packaging

Sustainable Food Packaging - Picture Courtesy: Earth.org

Modern day trends show that sustainable packaging keeps the product 10 times more secure and fresh as compare to the methods that were used previously. Sustainable packaging allows manufacturers to make their product stand out and support in producing environment friendly products.

Both biodegradable and composite packaging materials can be recycled and reused that makes the process economical too. Packaging techniques will grew more in future as each of the food processing industry is in a rush to beat its competitor.

15.Product Traceability

Food Traceability - Picture Courtesy: Wipotec

One of the leading factors of food processing industry trend that helps the consumer to select the best product is its traceability feature. The global implementation of traceability was just $ 14 Billion USD in 2020 and is expected to rise to $ 24 Billion USD till 2026. This shows how consumers are concerned regarding the quality of food.

The use of IoT and its implementation helps fast tracking of products during the process and also helps it tracing even after it leaves the production facility. Global supply chain model is using product traceability as the customer now has greater awareness the benefits of products and the alternates present in the market.

16.Investment In Automation

Automation In Food Industry - Picture Courtesy: SP Automation & Robotics

It has always been a challenge in current conditions to meet the global demand and have consistent efficiency in each product. Industries now have shifted their processes entirely towards automation and industry 4.0 revolution supports it boundlessly. This not only increases the productivity but also keeps the quality same in each of the product.

Usages of AI, robotics and their integral processes have greater implementation in food industry to support the growth of any manufacturer. In future the labor cost will be minimized near to zero and the manufacturer with greater usage of automation will be the one to lead the global market.

17.Stocking Of Food Products

Food Inventory Management - Picture Courtesy: Zebra Technologies

Manual registers, pages, dairies and notebooks in which the inventory was managed have now been overruled by modern inventory managing systems. Manufacturers, retailers, store keepers and suppliers have exponentially moved towards modern inventory managing techniques and maintaining their stocks efficiently.

Industrial revolution has made inventory and stock management that much easy that its overview can be taken within a second not by counting them for long hours. No chance of error or uniformity can be occurred with these modern inventory management systems.

18.Smart Manufacturing

Smart Food Manufacturing- Picture Courtesy: Food Business Insight

Changing of process setups and production lines has now been just a click away. Any modifications in products can easily be done by using smart food manufacturing process where highly sensitive sensors and predictive analytical skills based on IoT support in improving the system efficiency.

All the process steps can be monitored in real time and depending upon their close lookup further decisions can be taken easily. Smart food manufacturing helps products traceability within the system and also during its supply chain. Systems have now moved from ERP to SAP to make it more user-friendly.

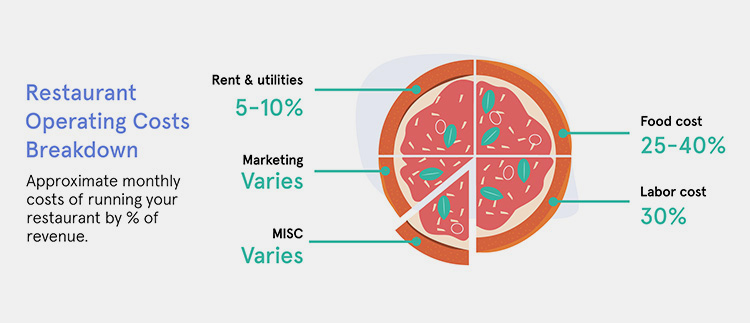

19.Food Operational Cost

Food Operating Cost - Picture Courtesy: 7Shifts

Being involved in food processing industry is never an easy job to do. It requires high operational cost with many critical values involved in it. Modern technologies and revolution has decreased the operational cost to a greater margin with energy saving, automation, reducing labor cost, increasing social media marketing campaign and other relevant factors.

Adopting global eco-friendly policies and R&D is supporting in reduction of food operational cost. These costs will be reduced as it will only depend on one time initial investments in future.

20.Alternative Proteins

Exploring The Alternative Protein Food Source - Picture Courtesy: Technology Networks

Advancement in technology has made people able to produce fermented proteins using different types of microorganisms. This fermented protein works as an alternate in making food, meat and farming substitute which can be consumed globally. Many other protein alternatives are used to help human life get the most from it.

Proteins grown from plants and other organism are sustainable to use and have equal or more level of nutrients as compare to those which were traditionally produced. Many industries are getting benefit from this aspect of advancement and meeting global demand in a new way.

Conclusion

Each passing year is bringing advancement and new trends in food processing industry depending upon the developments made in it. Food processing trends in modern industrial revolution are much efficient and economical. The advancement in processes are producing environment friendly results and meeting the expectations of customers. The market still is too big to grow and possibly a lot of changes in these trends can be observed in future years. We hope you enjoyed the article ' Top 20 food processing industry trends in 2024'; still you have question? Allpack is here to answer, message us now.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide