Pouch Filling Machine: The Complete Buying Guide in 2025

Today’s dynamic world of modernization and industrialization, the packaging field is revolutionized with innovative machines. A pouch filling machine is a versatile addition that bring this difficult task to fulfill with accuracy and much flexibility.

Planning to invest in buying a pouch filling machine, then we are here to enhance your money with offering promising solutions with proficiency. Yes, this blog is about extending your knowledge about pouch filling machine that will assist you in making a final and right decision prior buying any machine. Let’s start.

1.What is pouch filling machine?

Pouch Filling Machine

A solution for your industrial manufacturing of various types of products, yes! That’s what a pouch filling machine is!

A pouch filling machine is a robotic equipment that can fill multiple styles of pouches with your daily routine items ranging from food products, liquid beverages or chemicals, and any category of powderous material.

This machine works with efficiency making sure the packaging process runs accurately with consistency and high speed working. It helps businesses to adapt with time , ensuring that customers get timely delivery of their pouch filled products.

2.What are applications of pouch filling machine?

The applications of pouch filling machine is mentioned below:

Food Industry

Pouch filling machine in food industry

Food companies have been widely in use of a pouch filling machine in order to fill , seal and package snacks like chips, crackers, biscuits, candies, nuts etc. It can quickly fill large quantities of pouches with precision in weight, thereby effectively packaging your tasty treats.

Beverage Industry

Pouch filling machine uses in Beverage Industry

You might’ve seen creative and stylish packaging of your favorite beverages whether they’re powdered juice mixes, or ready to grab and go drinks, or even water! A pouch filling machine is utilized to fill liquids as well, speeding up the whole process.

Pharmaceuticals Industry

Pouches for Medicinal uses

Pharmaceutical products like supplement powders, or other medicated products are weighed with precision and filled in pouches with reliable dosage units. Pouch filling machine ensures that there is no error in dispensing them.

Cosmetics Industry

Pouch Filling Machine for Cosmetic Products

Interesting packaging designs made by a pouch filling machine helps the cosmetics industry to take it’s benefits too. A pouch filling machine is brought to package different styles and sizes of pouches with creams, lotions, or shampoo.

Household Products Industry

Pouch filling machine uses for Household Products- Picture Courtesy: LLife

Your daily use household cleaning chemicals such as laundry detergents, handwash, surface cleaners, dishwashing liquid etc can be filled using a pouch filling machine. Household products companies uses this equipment to reliably fill their products and make it ready for consumers purchase.

Agricultural Industry

Pouch Filling Machine in Agricultural Industry

Agricultural industry have been revolutionized involving the use of a pouch filling machine. This machine serves to fill their plant nutrients and fertilizers, pesticides and insecticides in small or large pouches so that farmers may conveniently take benefits of it.

Pet Food Industry

Pouch Filling Machine in Pet Industry- Picture Courtesy: QLM

Packaging of pet food whether dry or wet , can be safely carried out in pouches. These pouches are formed via the use of pouch filling machine which effectively ensures proper weighing and sealing so that your pets receive good quality treats.

3.What are benefits of pouch filling machine?

The benefits of pouch filling machine are mentioned in:

Quick Responsive Packaging

Pouch Filling machine- Picture Courtesy: Ocean Property

This equipment has a brilliant way to be productive, as it has quick response to the system fed settings of filling multiple number of pouches at a single time. You can easily forget the manual hassle of weighing and filling any product now!

Precision is priority

Highly Precise Filling by Pouch Filling Machine

How precision controlled processes do matter, you might surely know! For a pouch filling machine, accurate filling of your desired amount of product is a priority as it is characteristic of this machine to do so every time you carry out packaging.

No spillage stress

100% Accurate Ratio with Pouch Filling Machine

Unless your machine parts wear off or show some error, a pouch filling machine will dutifully ensure tidy and mess free proper filling of your products into their respective pouches. Whether it is a liquid product or a powderous substance, there are suitable type of fillers that help to assist the process without wasting or spillage.

Suitability and Adaptability

A Subtle machine to handle your products- Picture Courtesy: Process Plant

A pouch filling machine is creative enough to handle and manage any shapes and sizes of pouches, whether it is a doypack, pillow pouch or a small sachet pouch. It can fill many different sort of items and hence finds it’s applications across many industries.

Saves Time and Money

Pouch Filling Machine

This machine helps you cut down on your labor cost as it can efficiently take over the role of filling and sealing products manually, hence also saving your time in packaging process. This equipment makes your manufacturing quick and productive.

Always Reliable and Consistent

Pouch Filling Machine

We can say that you might definitely trust this equipment for reliable and consistent filling and packaging of your items. It has incorporated weighing and filling devices that measures with precision and fills the product properly inside the pouches.

Cool Packaging Styles

Pouch Filling Machine

Pouch Filling Machine can be inculcated with various customized or traditional options of packaging formats of pouches . It offers cool packaging styles that makes your brand uplifted and takes it’s position on supermarket shelves.

Built-in Health and Safety Protocols

Safe Construction of Pouch Filling Machine- Picture Courtesy: Retz

This equipment also has built-in safety parameters which makes sure that the operator is safe while working. It has designed characteristics that keeps the whole filling and packaging process clean and hygienic, ensuring that you receive unaltered state of product specially like food and pharmaceutical items that requires utmost safety.

4.How many types of a pouch filling machine?

The classification of pouch filling machine is described below:

Vertical Form Fill Seal (VFFS) Machine

Allpack VFFS Pouch Filling Machine

VFFS machines are suitable to make a vertical shape of pouch from a wounded roll of packaging film that can fill the product and then seal it close. It is a persistent procedure in which the film is unrolled and formed into pouch, the product is filled inside and then sealed. These all steps take place in a vertical manner and hence its name implies.

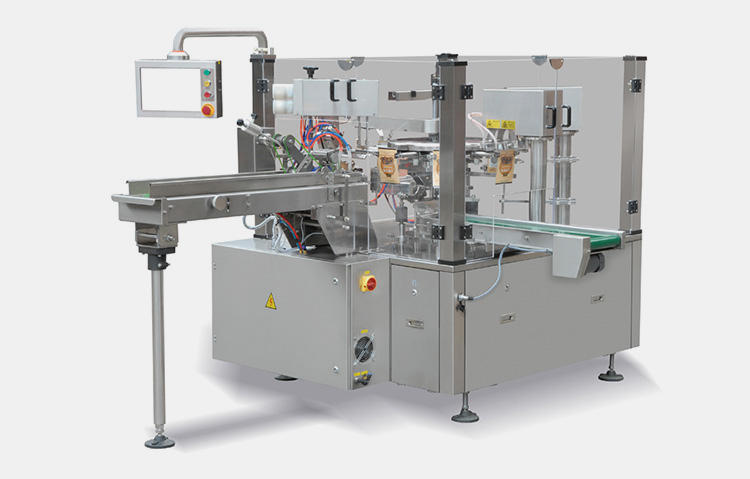

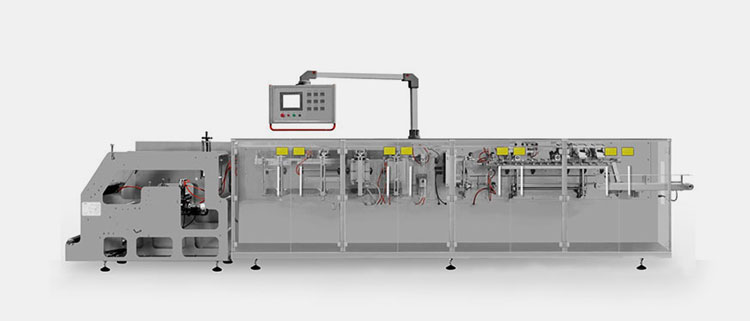

Horizontal Form Fill Seal (HFFS) Machine

Allpack HFFS Machine

HFFS machines are functioning similar to VFFS in their processing steps, but the difference that arises is that all takes place in a horizontal manner. The packaging material is unrolled from the film, made into a pouch shape and filled with the desired product, later to be sealed and dispensed. This machine is utilized for filling of heavyweight items.

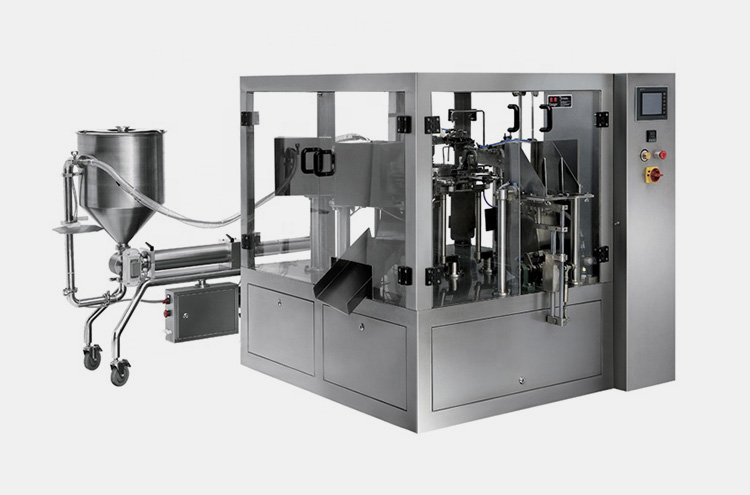

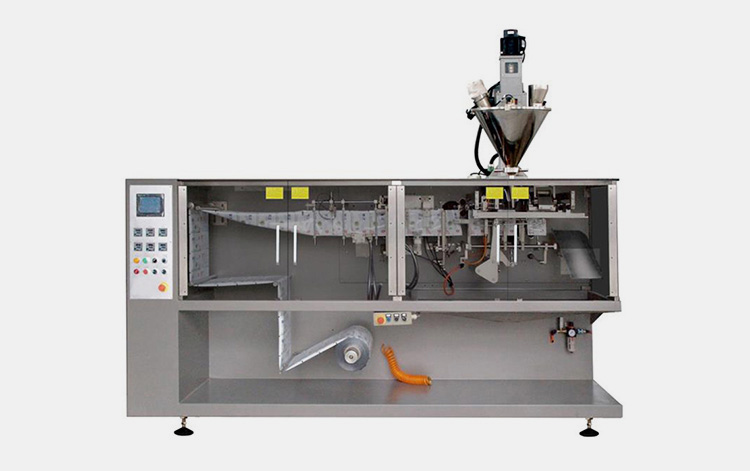

Pre-Made Pouch Filling Machine

Allpack Premade Pouch Filling Machine

A premade pouch filling machine is an innovation in pouch filling industries as it is loaded with already premade pouches that just need to be filled and packaged. It allows for more customized design approach and time saving productivity.

Sachet Filling Machine

Allpack Sachet Filling Machine

Sachets Filling Machine can make small single serving portions of pouches for variety of products. They perform by formation of sachets by cutting the shape of it using packaging film, and then the product is filled inside and sealed and later detached individually. They serve to be perfect for packaging of items like spices, powders, sauces and drink mixes.

Rotary Pouch Filling Machine

Allpack Rotary Pouch Filling Machine

Rotary pouch filling machine are intended for working at fast speed motion, as they function in circular pathway. Pouches that can be filled via this equipment are mostly fluids or semi fluids such as gels and pastes that are of higher viscosity. They move through different stations for the process of pouch filling and sealing.

Auger Pouch Filling Machine

Allpack Auger Pouch Filling Machine

Auger pouch filling machine is a system that has incorporated Auger filler which is a screw metric system that is fitted to pour out granular or powdered substances into pouches. It can accurately measure the amount of powder or granules that are to be filled into the pouches such as condiments, free flowing powders like flour, and even medicated products.

Volumetric Cup Pouch Filling Machine

Allpack Volumetric Cup Filling Machine for Granules and Other Products

Volumetric pouch fillers are those type of pouch filling machines that have precisely measuring cups that weighs and fills selected quantity of your items into respective pouches. These cups can be accommodated with items such as coffee grounds, snacks and granular products.

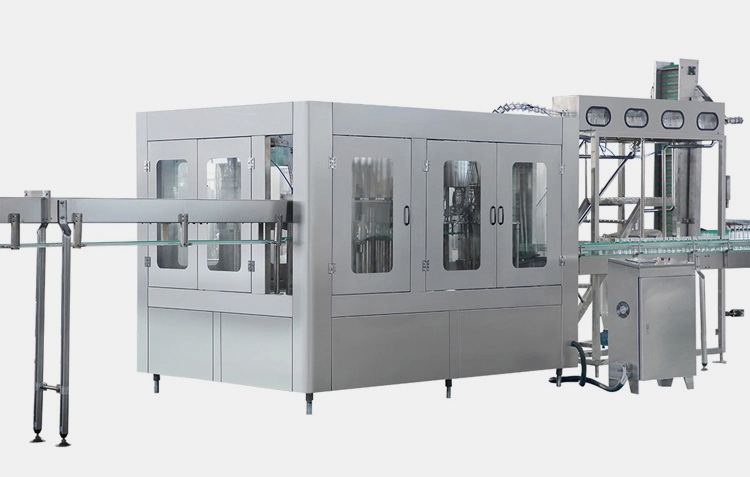

Liquid Filling Machine

Allpack Liquid Filling Machine

Liquid filling machines as the name suggests are manufactured to deliver liquid products using different techniques of filling like volumetric filling, piston filling, gravimetric filling or peristaltic nozzle filling. Applications that find it’s purpose are from food and beverages industry, pharmaceutical industry and cosmetics industry.

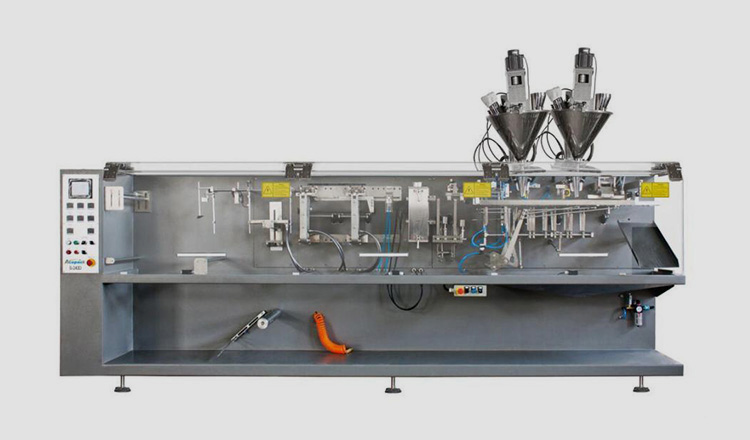

Continuous Pouch Filling Machine

Continuous Pouch Filling Machine

Continuous pouch filling machines can fill in a non-stop fashioned state, without taking breaks between each filing. The packaging film which is transformed into pouch positions from one station to another in order to fill and seal them. It permits high scale output with quick pace efficiency. Various items such a as snacks, fluids, and powders can be filled using this equipment.

Intermittent Pouch Filling Machine

Intermittent Pouch Filling Machine

A pouch filling machine that can function in a work and pause method is known as intermittent pouch filling machine. It gives the operator an accurate degree of control over the dispensing of products where reliable and careful handling of items are mandatory. Applications for this equipment are in pharmaceutical industry, nutraceutical industry, cosmetics industry and some high value products.

Multi-Lane Pouch Filling Machine

Allpack Multi-Lane Pouch Filling Machine

Multi lane pouch filling machine can be employed for filling various styles of pouches simultaneously. It is designed to have multiple lanes that function together, individually filling and sealing many pouches at a time. It is thus ideal to operate for high scale industries where large output is required in a shorter span of time. Usually small small-sized pouches such as stick packs, sachets packs are filled using this equipment from the pharmaceutical, food and cosmetics industry.

Single-Lane Pouch Filling Machine

Single lane pouch filling machine- Picture Courtesy: Aipak

Unlike multi-lane pouch filling machine, this equipment has only one lane that can handle one pouch at a time. Whole procedure of filling and sealing works sequentially. Although their speed is comparatively lower than the former machine, it has the flexibility of use in many purposes. Some common uses include filling of snacks, pet food, and personal care products.

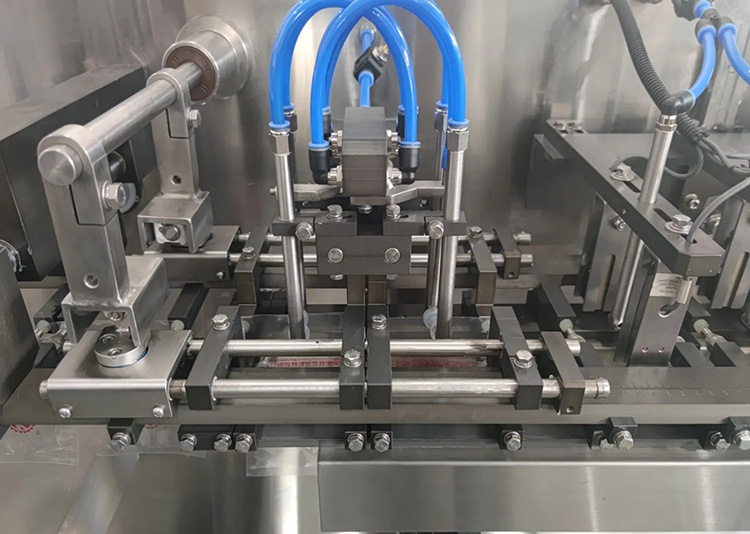

5.What are Parts of Pouch Filling Machine

Allpack Premade Pouch Filling Machine

Premade Pouch Filling Machine

| Hopper | A hopper is a storage device used to contain and hold the product that is to be later on filled into the pouch. It allows controlled flowing mechanism of material into respective pouches individually. |

| PLC Touch screen | The Programmable Logic Controller (PLC) is a touchscreen system that works as the control unit for this pouch filling machine. It lets the user to operate , check and analyse different parameters like filling amount, rate of filling, and other machine functions. |

| Power Switch | The power switch is a simple on or off switch that grants the electricity supply to the machine or stops it. It is a basic part required for starting and stopping the machine as needed. |

| Air Inflator | Air inflator is a component of pouch filling machine that can be used to fill air into pouches before the filling process. Inflating the pouches is necessary so that the pouches are in correct shape and configuration while filling process goes on. |

| Pouch Filler | Now this can be said as one vital part of pouch filling machine as the filling mechanism is totally dependent on it’s working. It fills the product into pouches based upon type of filler(auger filler, volumetric filler, piston filler) incorporated in the machine suitable for your respective type of product(liquid, powder, granules). |

| Conveyor for Product Discharge | Conveyor system is employed to carry away the filled pouch from the filling station for further processing or packaging. It ensures a smooth and easy proceeding of pouches for downstream operations. |

| Universal Wheel | The universal wheel, also known as caster wheels, allows the machine to be in movable condition . It allows the pouch filling machine to easily change direction and it’s location within a production facility for best outcome in efficiency and flexibility. |

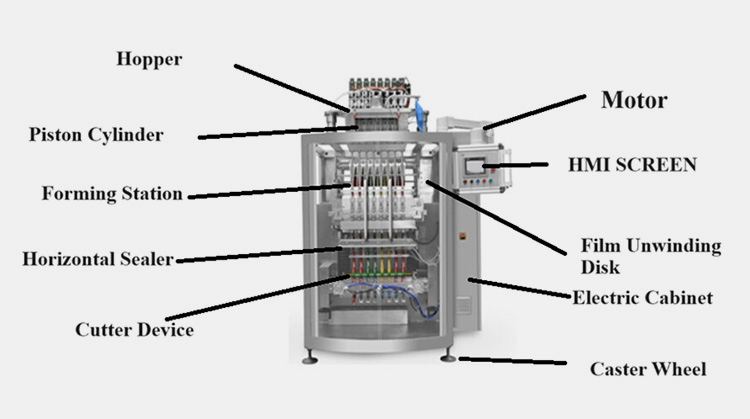

Pouch Filling Machine

Allpack Pouch Filling Machine

| Hopper | Same as above |

| Piston Cylinder | Piston cylinder can be said as filler component of the pouch filling machine . It is responsible for accurately weighing and dispensing a measured quantity of product into the pouches. |

| Motor

|

The motor enables the electromechanical supply needed to start functioning of various components of the pouch filling machine, such as the piston cylinder, conveyor belts, and other moving parts. |

| HMI Screen (Human-Machine Interface) | The HMI screen is the control system for the pouch filling machine. It allows the user to adjust and set the features of the machine, monitor it's performance, and make changes as intended for reliable operation. |

| Forming Station | The forming station is where the pouches are shaped and created from a roll of packaging material. It molds the material into the desired pouch shape before it is filled with the product. |

| Film Unwinding Disc | A film unwinding unit is supposed to let out the packaging material that is rolled into material handly . This is part of the packaging material which ensures convenient unrolling of the film or material used to create the pouches. |

| Horizontal Sealer | Horizontal sealer is type of sealer which can handle dispensing of products in a horizontal manner. It ensures the pouches are securely sealed to prevent leakage or contamination. |

| Electric Cabinet | The electric cabinet houses electrical components and controls that manage the various functions of the pouch filling machine. It provides a centralized and organized system for electrical connections. |

| Cutter Device | Cutter device is a component that is used in the last stage of pouch filling machine. It is responsible for individual separation of small sized pouches that are continuously made .by filling and sealing, and later detached from their roll. |

6.How a pouch filling machine works?

For working of pouch filling machine, we would consider two basic types of machines.

Pre-Made Pouch Filling Machine

Pre-Made Pouch Filling Machine

Step 1: Pouch Loading

Already made pouches are loaded into the magazine of the machine.

Step 2: Pouch Opening

Pouches are opened using strong air inflator and gripers.

Step 3: Pouch Filling

Material is filled in pouches from hopper.

Step 4: Pouch Sealing

Whether zipper or slider or heat sealers, the pouches are finally secured.

Film-Forming Pouch Filling Machine

Film-Forming Pouch Filling Machine

The film forming pouch filling machine is the one that forms the formation of pouch using a film sheet followed by simultaneous filling.

Step 1: Unwinding

When you adjust the film roll on the machine, it starts unwinding for the formation of a pouch.

Step 2: Formation of Pouch

The opened layer of a film crosses the tube forming section which assist to acquire the shape of the pouch. The process is taken by using ultrasonic heat, cold heat, or heat sealing etc.,

Step 3 Pouch Filling

Upon the formation of pouch, it is time to fill them from your product. Machine is capable of filling products belonging to various states such as liquid, powder, semi-solid, granular, etc. so it is filled in individual pouches.

Step 4: Sealing

The final sealing is taken place once pouches are filled.

Step 5: Cutting and Separation

The filled pouches are now separated by the help of sharp knives and making ready for final packaging.

7.What different Sealing Types does a pouch filling machine offers?

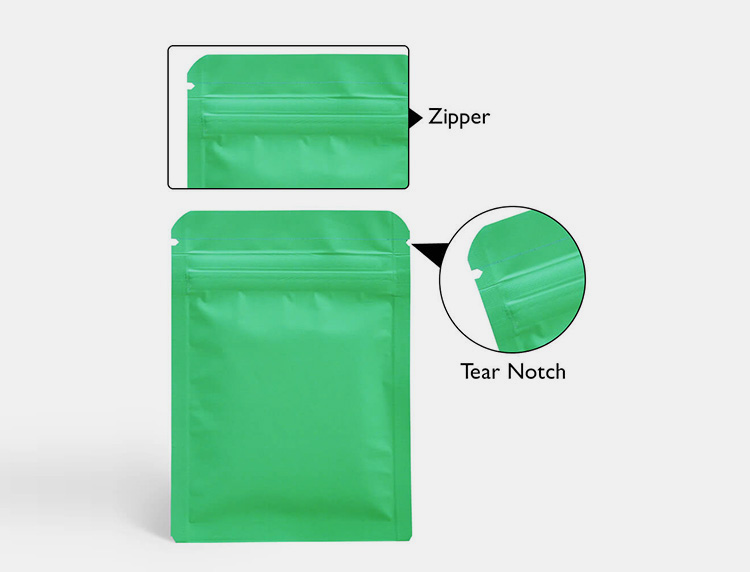

Zipper Sealing

Zipper Sealing

Zipper sealing offers reclosable feature for consumers to reuse the content of pouch again whenever they need and then close it back for locking its freshness. It’s general uses are for packing of snacks, pet food, frozen items and some other items.

Slider Sealing

Slider Sealing

Slider sealing mechanism is also very much similar in characteristic to zipper sealing, as both offers reclosable facility for it’s users. They are also used commonly in food industry.

Press-to-Close Sealing

Press to Close Sealing

This type of sealing uses pressure application to close the pouch when it is pressed. Applications of this sealing are in flexible packaging styles for products like cheese , frozen meat , fruits and veggies and also some snacks.

Heat Seal

Heat Sealing

Heat sealing is offered where reopening feature is not wanted for the product packed inside the pouch. It is a permanent seal which is formed using heat and can be used for single time use products.

Tear Notch Sealing

Tear Notch Sealing

Tear notch is a small slight cut feature designed onto the pouch which allows the consumer to easily tear and open the packaging. Common uses are found in powdered substances, spices, coffee and even some snacks food items.

Spout Sealing

Spout Sealing

Spouted pouch have a small nozzle like closure sealing that is made for dispensary of liquid products such a as paste like products, baby food, sauces and some beverages.

Tin Tie Sealing

Tin Tie Sealing

Tin tie sealing are consisted of wires that are added into the pouch opening which allows it to be opened or closed by simple twisting the tie. It is seen in bakery items and coffee bags packaging.

Velcro Sealing

Velcro Sealing

Velcro sealing are used once in a while for pouches that needs convenience of resealing. It is utilized by pouch packaging that contains small electronic components of hardware parts.

Double Zipper Sealing

Double Zipper Sealing

Double zipper sealing is an advanced state of zipper closure as it provides extra protective layer , keeping your food fresh and quality sustained. It is commonly used in big sized pouches for family snacks and other products.

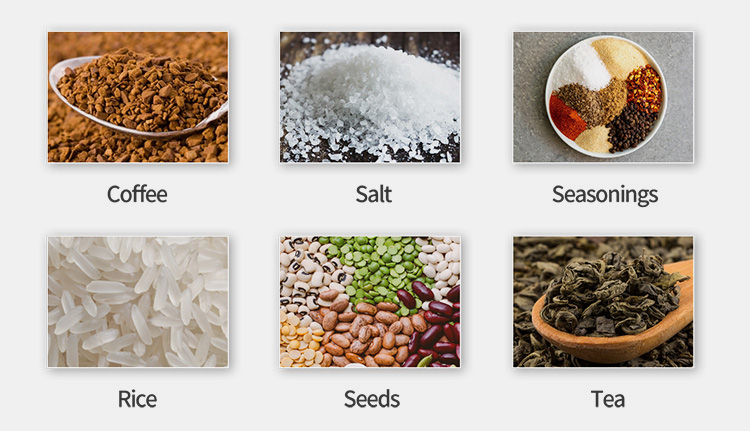

8.What Different Products A Pouch Filling Machine Fills?

Powder

Powders can be filled using Pouch Filling Machine

Powders can be efficiently filled or dispensed by a pouch filling machine as it has special auger fillers for this purpose. They usually belong from food and beverages industry, some are from pharmaceutical and nutraceutical industry, and few find applications from chemical industry and agricultural industry . Examples include coffee , tea , salt, sugar, spices and condiments, drink mixes, supplements, medicated dusting powders, antacid powders, fertilizers , pesticides etc.

Liquid

Liquid products can be easily filled using pouch filling machine

Liquids can also be interestingly filled into pouches by the occupation of a volumetric cup filler. These liquids are from food and beverages industry, chemical industry and even cosmetics industry. Examples are sauces like ketchup, chili sauce, mayonnaise, peanut butter, chocolate spread, liquid sweetener, milk samples, liquid fertilizer, dishwashing liquid, detergents , lotions and creams etc

Granular

Granular Products can be filled by Pouch Filling Machine

Pouch filling machines finds it’s purposes applicable for dispensing of granular products that mostly belong to food and beverages industry, pharmaceutical industry, and cosmetics industry. Free flowing granules like salt, sugar, black pepper, coffee grains and some chemical products like fertilizers, and household chemicals, wax granules, medicated granules etc.

9.What Is Difference Between Pouch Filling Machine & Pre Made Pouch Filling Machine?

Difference Between Pouch Filling Machine VS Premade Pouch Filling Machine

| Feature | Pouch Filling Machine | Pre-Made Pouch Filling Machine |

| Pouch Formation | A continuous roll of packaging film is responsible for shaping and forming of any style of pouches you want. | Pouch formation is not a problem here, as the machine is supplied with already formed pouches that can be handled using it. |

| Versatility | Multiple sizes, shapes and styles can be offered by a pouch filling machine. | As the pouches are fed into the machine in premade condition, the versatility becomes less. |

| Customization | Easy and flexible customization options are available that can provide you with different designs of pouches with different materials. | Customization is rarely possible as the machine works on premade pouches, restricting the design and material options. |

| Complexity of Operation | This process runs continuously working in forming, filling and sealing steps all by this single machine. | It’s main focus is on filling and sealing, as there is no need of pouch formation. |

| Production Efficiency | As it works at high speed it ensures greater production efficiency. | Production speed depends on effectively filling and sealing of pouches and not on the pouch forming. |

10.What type of pouch formatting a pouch filling machine can make?

The types of pouches are mentioned below:

| Stand-Up Pouch | Stand-up pouches also known as doypacks can stand upright in shelves allowing good display to the consumers attraction. It can be filled with various food items , pet food, personal care products. |  |

| Flat Pouch | Flat pouches can be laid down as they have no bottom support for standing and are simple style of packaging. It can pack products like powders items, liquids and few of single use products too. |  |

| Gusseted Pouch | Gusseted bags or pouches have an extra layer of space which allows additional filling of products and are suitable for packing heavy items like pet food, rice grains, and some other eatables. |  |

| Spouted Pouch | Spout pouches are suitable for easy pouring out of paste like or liquid substances as they have an inbuilt nozzle opening which can be used to deliver as much quantity as required. This allows the user for convenient usage. |  |

| Retort Pouch | Retort pouches are manufactured for those substances that need heat preservation oftenly for readymade food items like ready to eat meals , soups or sauces. It can handle high temperatures while cooking. |  |

| Shaped Pouch | Shaped pouches offer multiple designs ,shapes and sizes of customized and attractive packaging formats that appeal to customers and often used for good and effective brand marketing. |  |

| Slider Pouch | Pouches that have sliding mechanisms allows the consumer for easy and hassle free way to open or close the pouch. Its common uses are found by snacks, bakery items and some frozen foods. |  |

11.How to Prevent Downtime on a Pouch Filling Machine?

In order to cut down the time wastage that causes a hurdle in your production process, there are a few steps which you must follow to avoid the machine causing errors.

Prior To Machine Functioning

Allpack Pouch Filling Machine

- You must keep the machine powered on at least half hour prior to the equipment’s functioning and before turning the heating seal bar on.

- There must be no sign of any obstructive material or presence of dysfunctional parts related to product loading unit.

- All the switches must be accurately working.

During The Machine Functioning

Working Process of Pouch Filling Machine

- The bag feeding system must be appropriately working and there must be a sufficient supply of bags for pouch forming.

- Ensure that all the necessary components of the machine such as the printer, sealing bar, and other vital components are functional and reliable in working.

- Keep a check on HMI device for any display of error message.

On An Ongoing Basis

Insight View of Pouch Filling Machine

It’s mandatory for the proper working of the equipment that it has a maintained check and balance system by daily weekly or monthly monitoring and analysis of the systemic functional parts. It must be cleaned for any dirt or unwanted particles and a standard maintenance routine must be followed dutifully.

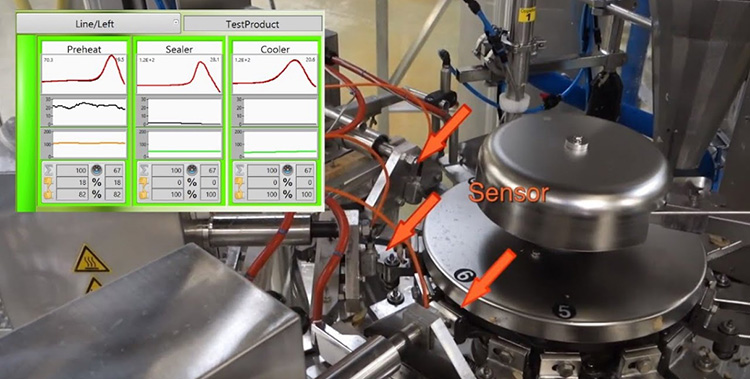

12.What are the problems and solutions with a pouch filling machine?

| Pouch Fail to Open

|

|

| Cause

The vacuum pad of the machine may break down. The bag is drooping or adjusted incorrectly. Repair of the filter may be not right to work. Incorrect machine’s timing. |

Solution

Maintain the ware and tare part of the machine. Correct the arranging of the premade pouches, for the FFS machine check the alignment of the film forming tube. Replace the filter of the machine Adjust the calibration of the machine. |

| A Defective Pouch Sealing

|

|

| Cause

The sealing bars must be exerting high temperature. Sealing bars are accompanied with wrong pressure. Sensor Malfunctioning Dirty or scratchy surface of the sealers. |

Solution

Maintain the temperature and adjust up to the sealing materials. Calibrate the pressure of sealing bars. Calibrate sensors and Clean them from dirt or dust. Clean and maintain the surface of the sealing to radiate uniform sealing heat. |

| Pouch Stickiness

|

|

| Cause

Due to high temperature and electricity, the pouches become stickier to each other. |

Solution

By using anti-static electric measure, the pouches become easy to separate and do not absorbed humidity. |

Conclusion

So, after reading the blog on ‘Pouch Filling Machine’ we’re 100% assured that you will be capable enough to select the right pouch design and the right pouch filling machine for your business. Whether you’re formulating solid, liquid, or semi-solid products; the available enrich options would make now easier for you to select the best. If you have any questions or machine machine-related purchase plan. Just Send Us a Quote. Allpack Team will be shortly to Reply you.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide