Multi-lane Stick Packaging Machine: The Complete Buying Guide in 2025

Are you planning to revolutionize your business with an advance multi-lane stick packaging machine?

Everyone wishes to find a solution where entire program is controlled by an innovative operating system. Now you can enjoy your packaging business by simply purchasing multi lane stick packaging machine.

But, we would suggest you to look into this blog post where you can enjoy the major details about components, working, benefits, and other important parameters related to multi-lane stick packaging machine.

Let’s get into it!

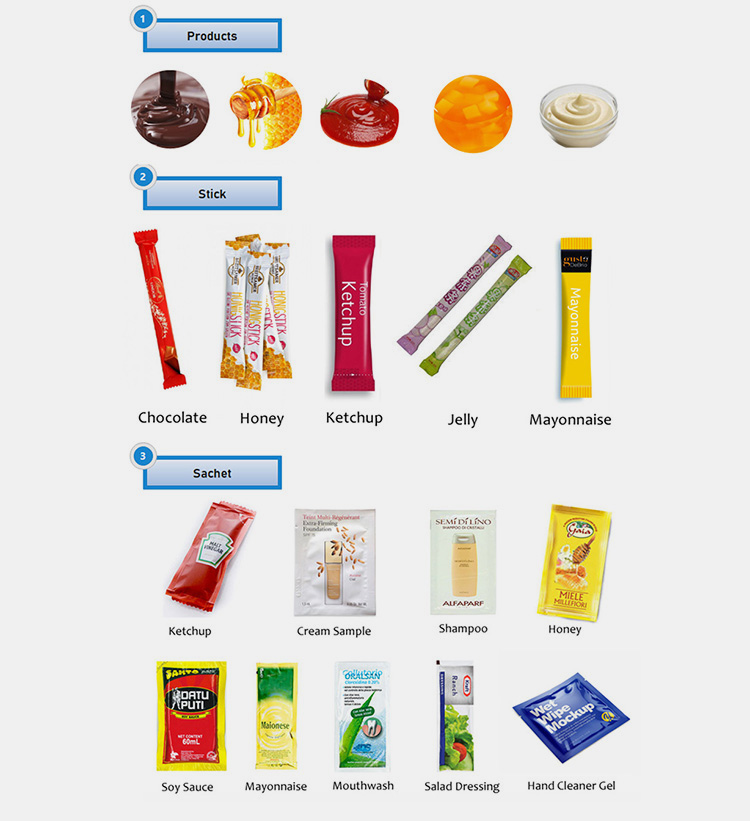

1.What Is Stick Packaging?

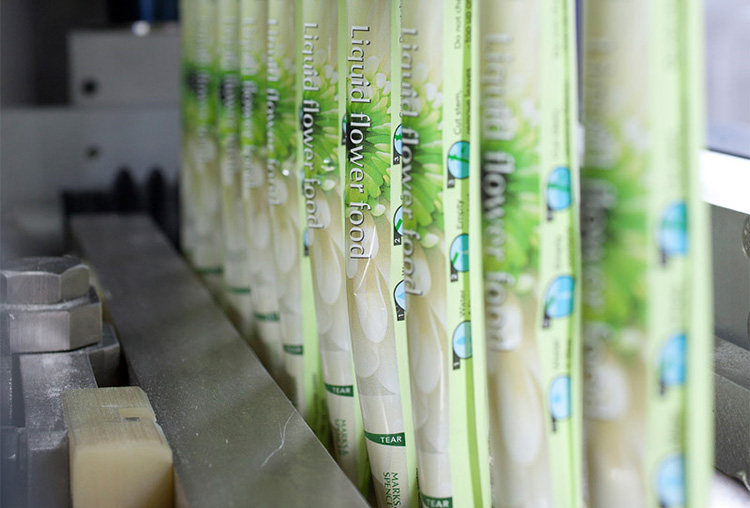

Stick Packaging- Picture Courtesy: Smith

The word ‘stick’ brings a central theme behind stick packaging; means your product is packed in a way it resembles a slim, elongated, sealed packet which is often referring a single serving to you. It is helpful to fill items that are mostly presented in a granular, powdery, gel, liquid, or beads form.

There are various industries across the globe performing stick packaging for convenience and high marketability. Moreover, the sizes of stick packaging may vary with different sealing properties.

2.What Is Multi-Lane Stick Packaging Machine?

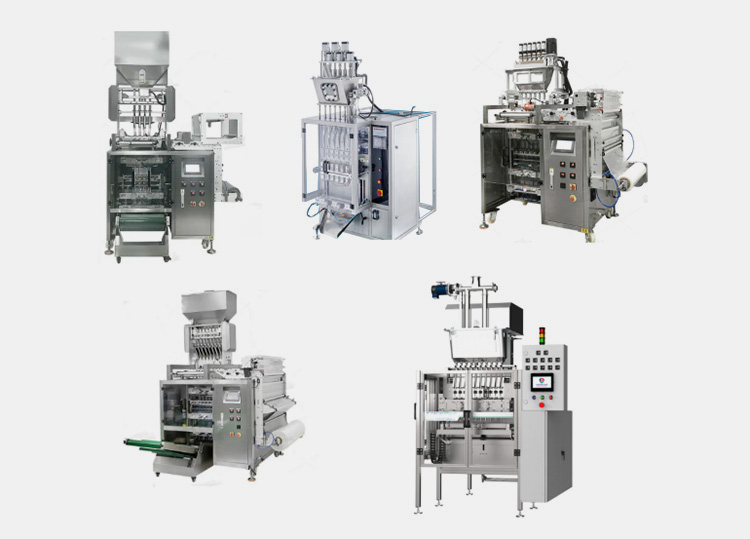

Multilane stick packaging machine

A multi-lane stick packaging machine is popular choice to make stick pack and fill them to secure product in a single serving offering a modern way to present the product with convenience.

As it names shows, a single machine is designed with multiple production lanes to make stick shaped sealed pack in multiple lanes at one time. This machine is mostly presented with the best features as it offers to manage a large production packaging that play a significant role in foods and non-foods industries to suit a broad range business need.

3.What are Benefits of Multi-Lane Stick Packaging Machine?

A multi-lane stick packaging which is known for its broad industrial benefits as a single machine is subjected form a stick packs with simultaneous action of filling and discharging. This ultimately making as an excellent choice for industrialists to add in production line. The key advantages of multi-lane stick packaging machine are described below:

Variations and Flexible Stick Packs Production

Greater variation & productivity

This machine is useful in the packaging of products belonging to various state of matters. Moreover, you can attain several sizes and capacity of stick packs in the fastest pace. You can count this machine as the most flexible one as at a one time you can run various product types which enhance high productivity to every manufacturer.

Say ‘No’ to Product Loss

Precise and Correct packaging

Due to greater and advanced technology and specification of multi-lane stick packaging machine; you can get precise and accurate amount of product into each filled packet. Therefore, the likelihood of product wastage become almost ‘zero’ when it comes to utilizing this machine, so it helps in cost-effectiveness.

High Protection & No Cross Contamination

No risk of cross-contamination

The multi-lane stick packaging machine provides you extremely reliable operation which enhances the greater protection to your product by firm sealing and securing from external environment. Side by side, no chances of cross contamination which commonly leads to progression of microbes and affects the shelf life of your products. Say hello to multi-lane stick packaging machine if you really want to enhance your business.

Space Savings

Allpack Compact Multi lane stick packaging machine

Indeed, using a multi-lane packaging machine is useful in the term of space saving as you can get high productivity as one time from a single machine which not only saves your time, money, but also your floor space. This is beneficial for those companies that is confined with a limited space or with congested operators’ production layout. Now your technicians can move here and there with ease when it comes to installing and operating multi-lane stick packaging machine.

Greater Portability

Allpack Multi Lane Stick Packaging Machine

This machine is especially designed to meet your needs and expectations. In every industry, there is high chance that you need to move your machine. Whether moving within vicinity or outside, a multi-lane stick packaging machine comply with ease of portability under strict hygiene requirements. Means you should not be worried if your machine is exposed to external environment; it will be offering perfect working properties.

Consistent Stick Packs Output

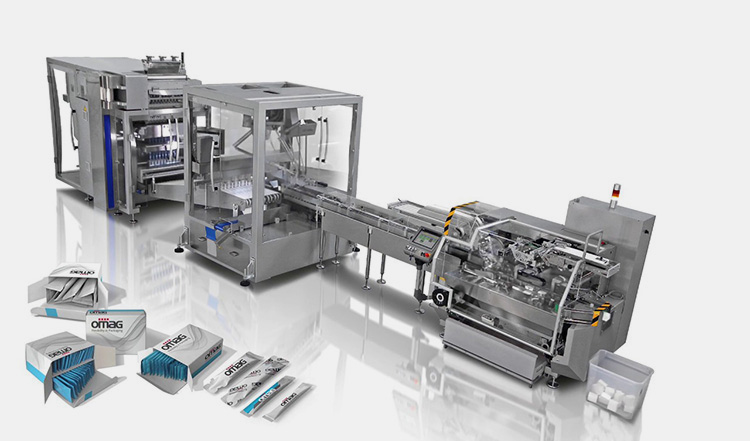

Omag complete stick packaging line- Picture Courtesy: packaging Machines

A multi-lane stick packaging machine is promising equipment provides a consistent and convenient output ensuring a uniform and even packaging of products with high quality and customer’s needs.

4.What is industrial application of multi-lane stick packaging machine?

Owing to its vast usage in many versatile applications and benefits, several industries take help utilizing a multi-lane stick packaging machine for their manufacturing purposes. Whether you need a stick package of food item or it is your personal care product, this packaging machine will serve you prominently! These industries are :

Food Industry

Need of multi lane stick packaging machine in food industry- Picture Courtesy: MERZ Verpackungsmaschinen

You might’ve come across stick packs that serve single portion packaging that contain edible products which are used as either condiments, sauces or flavour enhancers. A multi-lane stick packaging machine can be useful therefore to package your daily consumable items like instant coffee, tea, hot chocolate, salt, sugar, black or white pepper, red chilli powder, chicken powder, sauces etc.

Pharmaceutical Industry

Multi lane stick packaging machine

Single serving stick packs are required in pharmaceutical industry as well where controlled dose needs to be administered to a patient or where compounding becomes easily available as single dosages. Medicated products such as effervescent powder, supplements in the form of multivitamins, antacids, mouthwash etc can be packaged using this machine.

Beverage Industry

Multi lane stick packaging machine in beverage packaging

Beverage industry also utilizes multi-lane stick packaging machine for manufacturing packets of various flavored drink powders such as iced tea, energy boosters, chocolate or coffee powder, milk powder etc.

Cosmetic and personal care Industry

Applications of multi lane stick packaging machine for cosmetic and personal care items

Whether for your skin or hair care daily routine, a multi-lane stick packaging machine can pack single use cosmetic sample amount of these products. You can find lotions, creams, shampoo, conditioner and many other products that can be packed in stick packs.

Chemical Industry

Chemical products requires multi lane stick packaging machine for transporting & marketing

Chemical industry has also employed this machine for packaging single time use of detergents that are for your laundry or dishwashing purposes, household cleaning chemicals, handwash, agricultural products such as fertilizers or plant supplements.

Automotive Industry

Uses of multi lane stick packaging machine in automotive industry

Automotive industry packages small amounts of their promotional products such as stick packets of lubricant oils, and mechanical cleaning chemicals in individual use packaging.

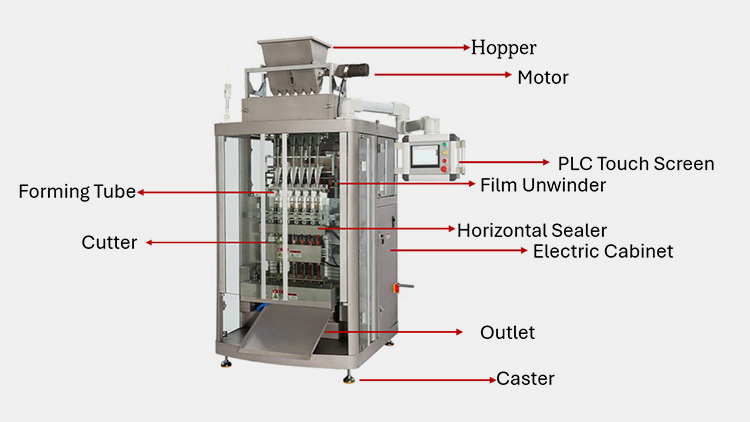

5.What are parts of multi-lane stick packaging machine?

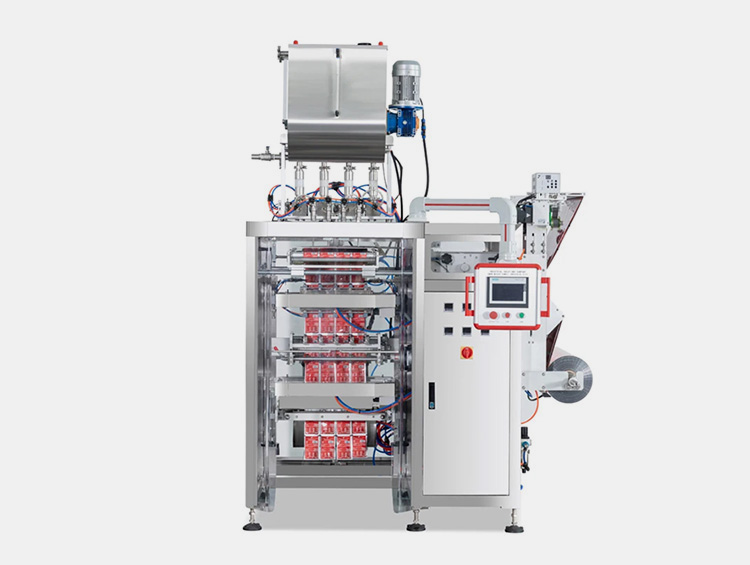

Allpack Multi-Lane Stick Packaging Machine

| Hopper | The hopper is like a big container that holds the material you want to package, such as powder or granules. It ensures a steady supply of the product for packaging. |

| Motor | the motor is the engine of the machine. It powers the different parts, making them move and work together to package the product |

| PLC Touchscreen | The PLC touchscreen is like a smart control panel with buttons you can touch. It helps you set up and control the machine. You can tell it how many packages to make and other important settings. |

| Film Unwinder | The film unwinder is where the packaging material (usually a roll of film) starts. It unrolls the film, so the machine can use it to make the individual packages. |

| Forming Tube | The forming tube shapes the flat packaging material into a tube or a long, narrow shape. This is where the product will go before it gets sealed. |

| Horizontal Sealer | The horizontal sealer is like a big press that seals the edges of the packaging material together, creating the sides of the individual packages. |

| Electric Cabinet | The electric cabinet is like the brain of the machine. It contains all the electrical components and wires needed for the machine to work correctly. |

| Cutter | The cutter is like a big knife that cuts the long tube of sealed packaging material into individual stick packs. This is where the final shape of the packages is formed. |

| Outlet | The outlet is where the finished stick packs come out. Once the packages are cut, they move out of the machine for further processing or packaging. |

| Caster | Casters are like wheels attached to the machine, making it easy to move around if needed. This helps in positioning the machine where it's most convenient for production. |

6.What is working of multi-lane stick packaging machine?

The operating steps of multi-lane stick packaging machine is involved in several important steps. The basic overview of those steps is mentioned in:

Feeding of Packaging Product

The raw materials must be fed in the hopper of multi-lane stick packaging machine which is mostly located at the topmost position of the unit that allows easy flowability of the material to carry an easy packaging process in each lane. The dispensing of the products takes place by means of either auger, volumetric, piston or other filler depending on your product type.

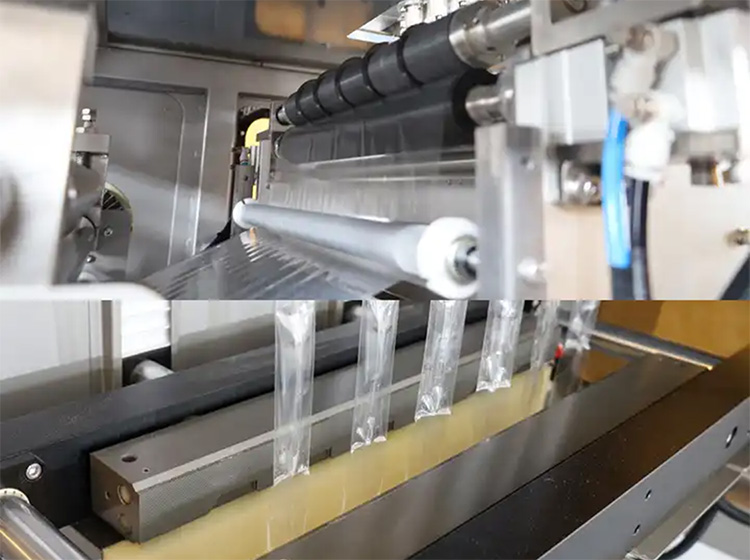

Unwinding of Film

A film rolls which is fixed in disc starts unwinding offering a necessary measurement of film needed for making of each stick pack. The entire system is based on the command transmitted by PLC of the machine.

Stick Pack Formation

The unwind film is wrapped around the collars of forming tube that helps in the making of justified shape via vertical and horizontal sealing.

Filling & Sealing

The product is entered into each stick pack followed by firm sealing ensuring greater integrity and security of items by no chances of leakage.

Separation & Discharge

The machine is accompanied by sharp knives that are meant to separate the stick pack into single packet. The prepared stick packet is discharged via the machine’s outlet.

7.What are the types of multi-lane stick packaging machine?

There are various models of a multi-lane stick packaging machine that are configured suitable according to handling different products and their industrial specific features.

We’ve outlined some of the types for you, which will help you in deciding which one fits for your requirement.

| Vertical Form Fill Seal (VFFS) Multi- Lane stick packaging machine | VFFS machines as their name implies can vertically produce, fill the product, and seal the stick packets. These are employed for processing products that have a pourable flowability, such as fluids or free-flowing powders. |  |

| Multi lane Stick Pack Machines with Auger Fill | These machines are incorporated with an auger filling system that precisely weighs and fills powdered or granular products into stick packets. |  |

| Multi lane Stick Pack Machines with Piston Fillers | A multi-lane stick packaging machine that has piston fillers are purposeful for dispensing accurate amount of liquids or thick flowing products. They assure that filling of individual stick packet are carried out with consistency in volume filled. |  |

| Multi lane Stick Pack Machines with Volumetric Fillers | The machine having volumetric fillers can weigh accurate volumes of your product that is to be filled , involving the use of a fixed volume section. This equipment is versatile as it can handle multiple type of items. |  |

| Continuous Motion Stick Pack Machines | This machine can function in a persistent manner which helps the manufacturers to receive good speed and effective productivity in the packaging process. |  |

8.What are different sealing options for Multi- Lane Stick Packaging Machine?

Multi-lane stick packaging machines gives diversity of sealing options which assures the safety and freshness of the packaged products. What type of sealing method you’ll select, depends on parameters such as the category of product, packaging material, and certain industry specifications.

| Thermetic Sealing | Thermetic sealing is one of the commonly utilized methods where heat is transferred to the packaging material to make a strong bond. This is achieved by various strategies, involving constant heat sealing or intermittent heat sealing. Thermetic sealing is appropriate for packaging materials, including laminates and films. |  |

| Ultrasonic Sealing | Ultrasonic sealing makes use of high- oscillating vibrations to develop a molecular connection among layers of the packaging material. This technique is operative for sealing few types of films and is usually selected for its characteristic to produce clean and well defined seals. |  |

| Cold Sealing | Cold sealing, also known as pressure-sensitive or self-sealing develops a sealing bond without the use of heat and instead it occupies the use of pressure to create a seal. This technique is appropriate for sealing of thermolabile products such as laminated films. |  |

| Impulse Sealing | Impulse sealing involves the use of applying electric current to a heating device for a short while which heats it quickly. Impulse sealing can package heat labile products such as thin films. |  |

| Continuous Band Sealing | Continuous band sealing carries out the sealing process by persistent sealing of the corners of a packaging material using a heated metal band. This type of sealing is applicable for creating durable and constant seals in a continuous packaging process. |  |

| Heated Air Sealing | In the heated air sealing process hot air stream is employed to melt the sides of packaging thus developing a strong sealing bond. It is generally used for some types of films and laminates. |  |

9.What is difference between single- lane and Multi-lane Stick Packaging Machine?

The basic variance between single-lane and multi-lane stick packaging machines is in their production output and their respective quantity of lanes they can function with simultaneously. Below are some differences mentioned:

Single lane stick packaging machine VS multi lane stick packaging machine

| Single Lane Stick Packaging machine | Multi-Lane Stick Packaging Machine | |

| Quantity of Lanes | It can deal with one lane at a time.

Appropriate for lesser production capacity industries. Generally employed by manufacturers operating at a small setup where speed and efficiency are not that mattered. |

It can function with multiple lanes at the same time.

Purposeful for greater production capacity industries. Ideally appropriate for use in such industries which have large scale setup requirements where efficiency and speed are very important. |

| Output Volume | Single-Lane Stick Packaging Machine can only handle selective volume of production for your packaged goods. Therefore it is appropriate for applications having small or medium output capacity. | Multi-lane Stick Packaging Machine can handle number of lanes simultaneously, improving production volume that is specifically used in industries requiring high speed manufacturing. |

| Production output and Efficiency | Comparatively it has lesser output compared to multi-lane machines.

Production is carried out in step-by-step processes, which may result in slower overall packaging speeds. |

Multi-lane stick packaging machine offers higher output due to the simultaneous processing of multiple lanes. |

| Footprint and Space Requirements | As discussed earlier, this equipment is suitable for small industries that doesn’t require much space for it’s fitting and occupancy. It has space saving design making it suitable for places with space constraints. | This machine configuration may require more space for installation and working due to its larger size as it accommodates multiple lanes. |

| Cost | The purchasing cost of this machine is lower as it has less production capacity and is only suitable for small setups. | It’s expensive cost requires high investment as it offers advanced benefits in terms of its capabilities. |

10.What are different cutting types a multi lane stick packaging machine offer?

| Round Cut

Round or circular cutting is indicated by placement of sharp rounded edge cuts along the corners of a stick pouch which gives it a smooth finishing look. |

Straight Cutting

Cutting blades of the multi-lane stick packaging machine that uses straight cutting method, in which longitudinal straight cuts are placed across the packaging film to develop individual stick pouches. It is a very common cutting method that is used. |

Zigzag Cutting

Zigzag cutting involves placing irregular waves like cuts that are put across the sides of packaging film in a zigzag fashion. This creates an aesthetically appealing design and texture of the stick pouch. |

Irregular/Special Cutting

Irregular cutting which is almost similar to the pattern created by zigzag cutting, involves a variable style of cutting pattern which could be a combination of rounded, curvy and straight cuts placed across the packaging material. This gives a more customized and unique design to your stick packets. |

11.What are different Sealing Type a Multi lane stick packaging offer?

Different sealing types of multi lane stick packaging are:

Fin Seal (Longitudinal Seal) Or Back Seal

Fin seal

Fin Seal which is also known as back seal is applied on the backside of your stick pouch packaging. The seal runs centrally behind the packaging film in a persistent manner , making a secure bond between the edges of the packaging.

Cross Seal (Transverse Seal)

Transverse seal

Cross seal is carried out transversally to the fin seal , creating a strong seal at both ends of the stick pouch. Fin seal and cross sealing combines to give a safety closure to the overall packaging.

Three-Side Seal

3 sides seal

Three side sealing involves one cross seal and two fin seals, closing the packaged product from all these sides.

Four-Side Seal (Quad Seal)

4 sides seal

Four side sealing is also known as quad sealing, which gives additional layer of protection to the products as all four sides are giving your product a more secured and enclosed packaging.

Gusset Seal

Gusset Seal

Gusseted sealing involves creation of an extra sealing material from the inside of the stick packets, giving the packet some extra space. It creates a pleated look and gives a gusseted appearance.

Zipper Seal

Zipper seal

However uncommon, zipper seals are nevertheless used in stick packs too. Zipper seals in a stick packaging enables the consumer to reuse the product again if required.

Tear Notch

Tear Notch

Tear notch as well like zipper seals are not that commonly used. It is a small cut like opening line, that allows the consumer for convenient tearing of packaging material. It is used alongside other sealing types.

Perforated Seal

Perforated seal

Seals are created that have small perforated holes along the edges of the packaging film. It allows consumer feasibility as it can be easily teared open for use as per requirement.

12.What different Multi-lane Stick Packaging Machine are there?

4 lane, 5 lane, 6 lane, 8 lane, & 10 lane multi-lane stick packaging machine

There are various models and machine types available that vary according to the features they offer such as some having four lanes and some having six or more lanes of a stick packaging machine. Some of the types are as follows:

| 4 Lane Stick Packaging Machine | This machine type has four lanes that allows stick packaging simultaneously. It is appropriate for industries which does not have high scale of production output. |

| 5 Lane Stick Packaging Machine | This machine is composed of 5 lanes for formation and packaging of stick packaging. The machine is ideal to run production belonging to small to medium capacity. |

| 6 Lane Stick Packaging Machine | As compared to a five lane stick packaging machine, it offers six lanes which allows side by side production of stick packs enabling to generate a higher output than the former one. |

| 8 Lane Stick Packaging Machine | 8 Lane Stick Packaging Machine has different rows of 8 lanes that enables furthermore higher capacity generation of stick pouches. This fits industrial applications where high throughput is given. |

| 10 Lane Stick Packaging Machine | A 10 lane stick packaging machine simultaneously packages and produces ten stick packs, suiting the application for industries that run at a higher scale. |

13.What Different Material Types a Multi Lane Stick Packaging Machine Fills?

The different multi lane stick packaging machines for different materials are stated below:

Powder

A multi lane stick packaging machine for solid

One of the famous used product that a multi-lane stick pack machines can handle are powders. These powderous products oftentimes belong to food and beverages industry and also some are from pharmaceutical industry. Examples include coffee powder, salt, sugar and spices, drink mixes, medicated dusting powders, antacid powders etc.

Liquid

A multi lane stick packaging machine for liquids

Another of the usual product handled by this machine is liquids. Liquids can be filled by the help of volumetric fillers into stick packs that generally belongs to food and beverages industry. Examples are sauces like ketchup, chilli sauce, mayonnaise, peanut butter, chocolate spread, liquid sweetener, milk samples etc

Granular

Allpack multi lane stick packaging machine for granules

Multi-lane stick pack machines are also applicable for dispensing of granular products that mostly belong to food companies. Free flowing granules like salt, sugar, black pepper, coffee grains and some chemical products like fertilizers, and household chemicals.

14.What are technical problems and solutions of Multi-lane Stick Packaging Machine?

As a Multi-lane stick packaging machines has complex industrial equipment design, it may encounter some difficult to handle technical problems during regular functionality. We’ve jotted down some of the common technical issues that may arise with multi-lane stick packaging machines and their potential troubleshooting.

| Problem | Solution | |

| Film Crumpling and Disorienting

|

The packaging material may be crumpled or disoriented during the forming and sealing process. | Analyse and correct the film constriction, guide rollers, and orientation processes. Make sure that the film material is loaded precisely, and any crumples or disorientation are checked promptly. |

| Gaps in sealing

|

There might be inadequate seals on the stick packets which affects the quality of your product, thus leading to leakage or compromised product hygiene. | Check if the temperature and pressure configuration is properly set of the sealing units. Test and modify or replace the sealing parts, such as heating jaws, if they show signs of any damage. Recheck if the chosen film material is appropriate according to the chosen sealing method. |

| Inadequacy in filling

|

Filling of the product in your stick packets may be insufficient or imprecise, resulting in less filling or over filling of stick pouches. | Perform the calibration and recheck the filling system, such as augers or volumetric fillers, to assure exact quantity measurements. Inspect if any hindrances are present in the product feeding system. |

| Packaging material getting jammed or breaks

|

The packaging film may jam or break during the feeding or sealing process. | Check the material track for any presence of obstructions or any disorientation. Test for accuracy in tension control and correct it if needed. Make sure that the film material is within the specified width range. |

| Temperature Control Issues

|

If the temperature settings are inappropriate according to the film’s requirement, it may affect the sealing to be ineffective. | Inspect and check temperature control parameters oftenly. Change the error causing temperature sensors or controllers. Assure that the heating components are working perfectly. |

Conclusion

After reading the blog, you would be able to understand the entire presentation of an innovative multi lane stick packaging machine and its pivotal role in the manufacturing and packaging industry worldwide. The machine is not only versatile but meets the high production demands with high speed output. This machine is capable of enhancing the market considering long term cost adhering to astringent regulatory demands. If you have any questions relevant to multi lane stick packaging machine; Allpack team welcomes to give answer your queries. Contact us for machine’s inquiries or purchase now!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide