Modified Atmosphere Packaging: The Complete FAQ Guide In 2025

Are you worried about the freshness of your food products? Well, with the industrial revolution, a new technique has been introduced for food packaging called Modified Atmosphere Packaging or MAP.

This technique is just a modification of the packaging atmosphere and is essential in maintaining the freshness, taste, texture, and nutritional quality of foods. With only alteration in gas composition, you have affordable and reliable solutions for keeping food and other products safe from physical, biological, and chemical agents.

This informative guide is for newcomers and veterans in the packaging business, as we will discuss in detail about benefits, challenges, and equipment of modified atmosphere packaging.

1.What is Modified Atmosphere Packaging?

Modified Atmosphere Packaging- Picture Courtesy: Edinburgh Sensors

As the name suggests, this technique is a change of atmosphere in the packaging. It is also called MAP for short and is an innovative technique for keeping products fresh throughout their shelf life.

In modified atmosphere packaging, an inert gas mainly nitrogen is imposed on packaging with a combination of microbial inhibitory gas- carbon dioxide to replace oxygen in the packaging. This controlled mixture of nitrogen, carbon dioxide and other gases is pivotal in extending the serviceable life of sensitive food products.

The first commercial trial for modified atmosphere packaging was done in the 1950s and this technique for commercial preserving of food was increasingly used around the 1970s and 80s.

2.What are the Useful Benefits of Modified Atmosphere Packaging?

With the advent of modified atmosphere packaging, the problem of food wastage is resolved which lowers land pollution. In addition to this, some handy benefits of modified atmosphere packaging are discussed below:

Upholding Freshness

Freshness with Modified Atmosphere Packaging

Since oxygen is eliminated or used in very low quantities, food products mainly fresh fruits, vegetables, meat and dairy products remain fresh for a longer time with modified atmosphere packaging.

Their respiration or fermentation is reduced with this technique, so consumers can get maximum nutritional benefits by consuming food packaged in modified atmosphere packaging.

Say No To Preservatives

Say No To Preservatives with Modified Atmosphere Packaging- Picture Courtesy: Dieline

With health awareness, several customers demand organic and fresh food without added preservatives. By using modified atmosphere packaging, there is no need to add preservatives or stabilizers, this increases natural or organic foods in the market.

This method acts as an alternative to preservatives, UV light, infrared radiation, etc in improving shelf-life.

Improved Logistics and Transportation

Improved Logistics and Transportation- Picture Courtesy: Packaging Strategies

Modified atmosphere packaging acts as a barrier against different food deteriorating agents, consequently, increasing the protection of food products during a long supply chain. With simplified logistics with modified atmosphere packaging, it has become easier to transport food and other products.

No Contamination

No Contamination with Modified Atmosphere Packaging- Picture Courtesy: Body Nutrition

Modified atmosphere packaging has an inhibitory effect on the growth and colonization of harmful pathogens like bacteria and moulds. These pathogens pose a substantial risk to human health. Due to the bactericidal and fungicidal effects of carbon dioxide in modified atmosphere packaging, there is no chance of microbial contamination.

Attractive Appearance

Attractive Appearance with Modified Atmosphere Packaging- Picture Courtesy: Dieline

The product becomes inflated with the use of modified atmosphere packaging due to the introduction of gases inside the packaging. Due to this inflation, the product boosts an attractive product appeal. Furthermore, with this technique, there is no chance of product squeezing during transportation that may occur with vacuum packaging.

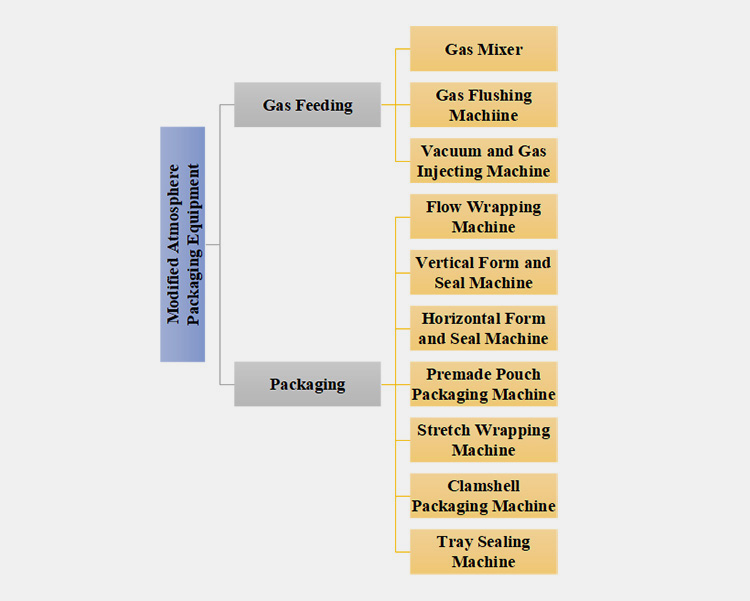

3.What Equipment is Used for Modified Atmosphere Packaging?

Since there are far and wide packaging styles with which modified atmosphere packaging is used. So, there is quite a different equipment for modified atmosphere packaging, for instance:

According to Gas Feeding

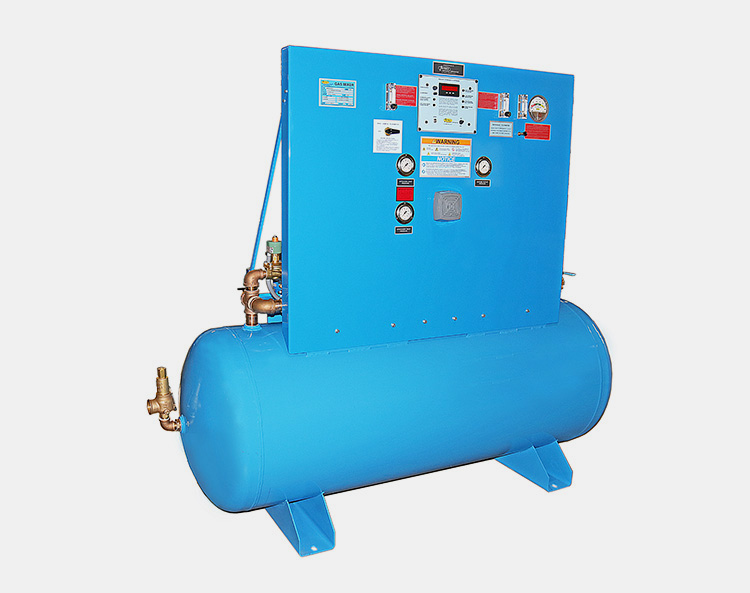

Gas Mixer

Gas Mixer- Picture Courtesy: Thermco

For creating the right proportion of gas mix, gas mixers are employed in industrial settings. This machine mixes, nitrogen, oxygen, and carbon dioxide as per the operator's instruction. Both custom-made mixes and pre-saved recipes are used for gas blends in this machine.

Gas Flushing Machine

Gas Flushing Machine

This machine is mostly used in combo with other flexible pouch packaging machines. The gas flushing machine feeds the gas mixture inside the packaging before its sealing. Due to this gas mixture, oxygen diffuses out from the packaging, thereby creating a required modified atmosphere in the packaging.

Vacuum and Gas Injector

Vacuum and Gas Injector

This machine creates a vacuum and introduces gas in one cycle. It is a highly effective machine that is used to quickly attain low levels of oxygen. It maintains a vacuum and feeds gas blend inside the packaging. It has smooth processing since it lowers the risk of errors with its built-in leakage test station.

According to Packaging

Flow Wrapping Machine

Flow Wrapping Machine

It is used for wrapping fresh products and other individual products like candies and chocolates, due to its extreme flexibility. It creates a gift-like packaging with products enclosed in barrier materials. It fabricates strong seals by using perfect conditions of time, pressure, and temperature. Integrated modified atmosphere packaging units in this system lengthen shelf life.

Vertical Form and Seal Machine

Vertical Form and Seal Machine

A vast majority of products are packaged by vertical form, fill, and seal machines, because of their cost-effectivity and smaller footprint. After pouch formation, product filling takes place by the filling devices. Upon filling the desired quantity of products, air composition is changed inside the packaging by gas injectors. Immediately, after gas feeding, the pouch is sealed.

Horizontal Form and Seal Machine

Horizontal Form and Seal Machine

It is an all-in-one machine for food packaging and it creates endless flexible pouches. It offers clean and hygienic processing and thus, is the preferred choice of manufacturer for food safety. In HFFS, the film after unwinding travels to the forming station, where it is changed into a pouch. Afterwards, this pouch is loaded with products. Gas injectors inject gases inside the packaging before its sealing.

Premade Pouch Packaging Machine

Premade Pouch Packaging Machine

It is a versatile machine with rotary turn tables and carousels to increase productivity. Unlike VFFS, it uses already-made pouches to pack food like snacks, nuts, precut vegetables, etc. Premade pouches are opened, inflated, and filled with products and before pouch sealing, different gas-feeding machines alter the inner atmosphere of the packaging to minimize the proportion of oxygen in the packaging.

Stretch Wrapping Machine

Stretch Wrapping Machine

It uses different kinds of plastics like PVC or PE to seal various food products. It is employed in conjunction with a tray-sealing machine. By controlling the length of packaging film, it decreases film wastage and in turn, increases sustainability. The tray containing food travels to a gas flushing machine, where gas blends are fed into the tray and immediately after that, the tray is covered by stretch wrap for protection.

Clamshell Packaging Machine

Clamshell Packaging Machine

This machine is increasingly utilized for packing fresh produce and eggs in the food industry. It stores products in plastic and thermoform clamshells. The fresh produce is placed inside the clamshell, after which an in-built gas flusher introduces the gas mixture. Finally, the top part of the clamshell is joined by the lower part with heat.

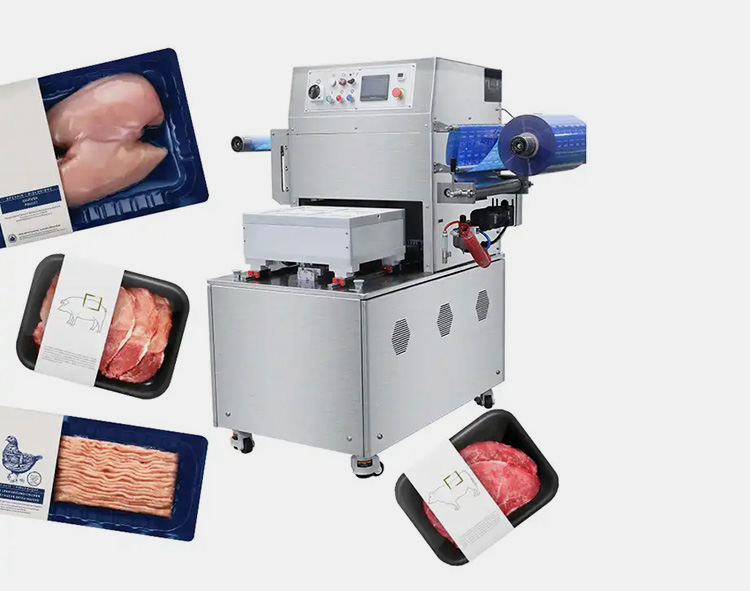

Tray Sealing Machine

Tray Sealing Machine

It packs both frozen treats and fresh produce. It is an adaptable and robust equipment that handles trays of far and wide geometries, depth, and dimension. After loading foods on trays, they are conveyed to gas-flushing units to alter their packaging environment. Then, food-containing trays are sealed with plastic film in the sealing unit.

4.What is the Role of Different Gases in Modified Atmosphere Packaging?

Role of Gases in Modified Atmosphere Packaging- Picture Courtesy: Dress the Home

In modified atmosphere packaging, three types of gases are used that are nitrogen, oxygen, and carbon dioxide. They have a particular role in modified atmosphere packaging like:

| Nitrogen | It is a non-reactive and flavorless gas. It is mainly introduced in packaging to replace oxygen and to avert the collapse of packaging. It is also used for balancing gas pressure inside the packaging. |

| Oxygen | It is used in modified atmosphere packaging because it inhibits the reproduction of anaerobic microbes. But it also has different undesirable effects, it boosts the multiplication of aerobic bacteria, causes fresh produce ripening, promotes fat rancidity, and stales baked items. Therefore, oxygen use is often circumvented in modified atmosphere packaging. |

| Carbon dioxide

|

It prevents the growth of microbes and lowers the respiration rate of numerous fresh produce products. |

| Carbon monoxide

|

It is introduced in minute amounts in modified atmosphere packaging. It plays a role in preventing microbial growth. It is harmful to human health, hence its usage is limited in modified atmosphere packaging. |

| Sulfur Dioxide | It is used for stopping food browning by oxidation and for inhibiting molding. |

| Argon | Argon is rarely used in modified atmosphere packaging. It decreases bacterial and fungal growth. |

5.Is Modified Atmosphere Packaging Used With Other Products Besides Food Stuff?

Yes, in addition to foodstuff, modified atmosphere packaging is also utilized for the protection of the following products:

Pharmaceutical Products

Pharmaceutical Product and Modified Atmosphere Packaging

Modified atmosphere packaging is used in cannabis packaging in the pharmaceutical industry to extend its shelf-life.

Nutraceutical Products

Nutraceutical Product and Modified Atmosphere Packaging- Picture Courtesy: Brook

+ Whittle

Yes, nutraceutical supplements and dietary products are also protected by modified atmosphere packaging. this lowers moisture levels and prevents oxidation of drug ingredients.

Cosmetic Products

Cosmetic Product and Modified Atmosphere Packaging- Picture Courtesy: Laminate Tube

Perfumes, lotions, and certain creams are also packaged under modified atmosphere packaging to maintain their aroma and freshness.

Agriculture Products

Agriculture Product and Modified Atmosphere Packaging

Certain seeds and seedlings in the agriculture industry are packed under modified atmosphere packaging to control their sprouting and lower their chemical treatment.

6.What Packaging Materials are Well-suited with Modified Atmosphere Packaging?

Modified atmosphere packaging is used in flexible, rigid, and, semi-rigid containers like pouches, bags, trays, cups, and tubs. These materials are made with plastic laminates. The detail of these materials well-suited with modified atmosphere packaging is penned below:

Polyethylene (PE)

PE Pouch- Picture Courtesy: PlasticPortal.eu

It is an important material used for making flexible and rigid packaging. LDPE and HDPE are two forms of PE. PE makes a good barrier and offers transparency. It is also used for creating overwraps and trays in addition to pouches.

Polypropylene (PP)

PP Trays- Picture Courtesy: The National Provisioner

It is a more rigid material than other plastic forms. PE trays are used in modified atmosphere packaging. It is a resistant material and is impermeable to chemicals and grease.

Nylon

Nylon Bags- Picture Courtesy: ULINE

It is a stretchable and synthetic fiber, known for its sturdiness and extreme puncture resistance. It prevents the permeability of gases in modified atmosphere packaging. Tough pouches made with nylon are ideal for packaging red meat, butter, and cheese.

Polyethylene Terephthalate (PET)

PET Clamshell- Picture Courtesy: Ubuy Ghana

It is a rigid and strong material used for fabricating trays, tubs, and packaging lids. It is a clear material, offering a robust barrier against oxygen.

Compostable Films

Compostable Film and Modified Atmosphere Packaging- Picture Courtesy: Renewable Carbon

It is an innovation in the modified atmosphere packaging. It is formed by PLA and cellulose, which offer excellent printability. They are coated with other chemicals to improve their barrier properties.

7.What Are the Gas Ratio For Different Food Products Used In Modified Atmosphere Packaging?

Different food products have different nutritional compositions so the gas ratio in modified atmosphere packaging also varies from product to product. The gas ratio in the main food groups is given below:

Red Meat

Red Meat- Picture Courtesy: Airgas Thinks

This food group has red pigment and thus, requires a high amount of oxygen to preserve its red color while carbon dioxide is employed for inhibiting microbial development. The gas ratio is 2:1 oxygen to carbon dioxide. It has about 20-30% carbon dioxide and 70–80% oxygen.

Raw Poultry Product

Raw Poultry Product- Picture Courtesy: Food Navigator

For raw poultry packaging, oxygen is not used in modified atmosphere packaging and rather than oxygen more percentage of carbon dioxide is used and nitrogen is used as filler gas. About 25-35% carbon dioxide is used in retail modified atmosphere packaging of raw poultry, whereas 100% carbon dioxide is used in bulk packaging.

Fish

Fish -Picture Courtesy: The Fish Site

Oxygen is used as an inhibiting agent when packaging non-processed white fish by modified atmosphere packaging. A gas mixture of 30% oxygen, 40% carbon dioxide, and 30% nitrogen is used for non-fatty fish.

For packaging, smoky and fatty fish with modified atmosphere packaging, 40% carbon dioxide and 60% nitrogen as the inclusion of oxygen does not affect their shelf-life.

Fruits and Vegetables

Fruits and Vegetables- Picture Courtesy: Food Navigator

Fresh produce mainly fruits and vegetables respire and produce ethanol while ripening that discolors them. So, a perfect modified atmosphere packaging gas balance is essential for this food group.

It is observed that a low percentage of oxygen and a high concentration of carbon dioxide reduce the ripening and aging of fresh fruits and vegetables. Thus, for this food group, 2-10% oxygen and 15-20% carbon dioxide are employed in modified atmosphere packaging.

Dairy Products

Dairy Products- Picture Courtesy: The Irish Times

They include milk powders, butter, sliced cheese and, fat spreads. Modified atmosphere packaging containing 40% carbon dioxide and 60% nitrogen significantly boosts the shelf life of dairy products.

8.Is Modified Atmosphere Packaging Sustainable?

Modified Atmosphere Packaging and Sustainability- Picture Courtesy: Dieline

With global warming and the increasing deterioration of the planet, there is growing concern about the sustainability of products. Therefore, the sustainability of modified atmosphere packaging is a question on the mind of an average person.

Here is good news for environment-friendly consumers and brands, modified atmosphere packaging is extremely sustainable. Now are you asking how?

First, by using modified atmosphere packaging, there is minimal food waste, resulting in less landfill. With a boost in the shelf life of foods, they are less likely to spoil and, hence are easily transported to far-off places. This reduces food wastage across the supply chain and in turn, improves sustainability.

Moreover, there is less use of protective films by incorporating modified atmosphere packaging, which also contributes to reducing land pollution.

The benefits of modified atmosphere packaging go beyond reducing food wastage because, with this technique, there is lower use of pesticides and chemicals to protect fresh produce against different elements

This in turn decreases postharvest chemicals in the environment and reduces air pollution. This proves to be another sustainable advantage of modified atmosphere packaging.

9.Is Modified Atmosphere Packaging Safe?

Safety of Modified Atmosphere Packaging- Picture Courtesy: Dieline

Yes, one of the biggest reasons for the popularity of modified atmosphere packaging, is its safety. As already mentioned, there is no need to add health-damaging chemicals, stabilizers, preservatives, and agents in packets when using modified atmosphere packaging.

This approach of atmosphere alteration only utilized gases like nitrogen, carbon dioxide and oxygen to keep food crisp and wholesome. These gases are naturally present in the surroundings and pose no risk to human health.

10.How Long the Shelf Life of Food Products is Extended with Modified Atmosphere Packaging?

Shelf-life of foods with Modified Atmosphere Packaging- Picture Courtesy: Adria Développement

The shelf life of food products is prolonged by using modified atmosphere packaging. This time extension in shelf life is different for different products.

However, it is observed by conducting various tests, that the shelf life of foods is increased by up to 12 months with modified atmosphere packaging. By removing or minimizing the amount of oxygen in food packaging, manufacturers can not only decrease microbial growth but also prevent food oxidation.

The reactivity of oxygen with food contents causes oxidation. This oxidation leads to rancidity of fats that give off a bad taste and smell to dairy products. It will also cause discoloration of pigments in meat products and yellowing of leafy vegetables.

However, low oxygen amount in modified atmosphere packaging reduces and delays rancidity, discoloration, and spoilage of food, consequently increasing the consumable life of foodstuff.

11.What Quality Control Tests are Necessary for Modified Atmosphere Packaging?

Quality Control Tests for Modified Atmosphere Packaging- Picture Courtesy: Packaging Strategies

Quality control is necessary for modified atmosphere packaging because it determines the seal integrity and consistency of the packaging. The easiest way to implement a quality control test is by taking a few samples from the batch and then running non-destructive tests to observe leakage in the packaging.

Here is a list of non-destructive quality control tests for modified atmosphere packaging:

| Headspace Gas Analyzer | It is specialized equipment for identifying the proportion of gas inside the packaging. This is a nondestructive instrument that extracts a minute quantity of gas from the upper part of the packaging. Afterward, the ratio of nitrogen/ oxygen/ carbon dioxide is analyzed using approaches similar to techniques like gas chromatography and mass spectrometry. |

| Vacuum Leakage Test | It is another nondestructive test for determining the leakage in packaging. In this test, the package is put inside the chamber and pressure difference is observed via a pressure gauge in case of leakage. |

| Visual Inspection Test | In this method, the packaging quality is visually inspected to see the micro-perforation or hole inside the modified atmosphere packaging. |

| Dye Penetration Test | This test is essential in assessing the seal integrity. In this test, dye is applied to one end of the modified atmosphere packaging and if a dye is seen on the other side of the seal, this means the seal is incomplete or weak. |

| Bubble Leakage Test | In this test, the packaging is placed under the water, and air is eliminated from the water surface. If water bubbles are observed rising above the water, it means that there is leakage in the packaging. |

| Seal Strength Test | In this test, a high force is applied on the packaging to move the seal 1 inch apart. If it moves easily, it means that the seal is loose. |

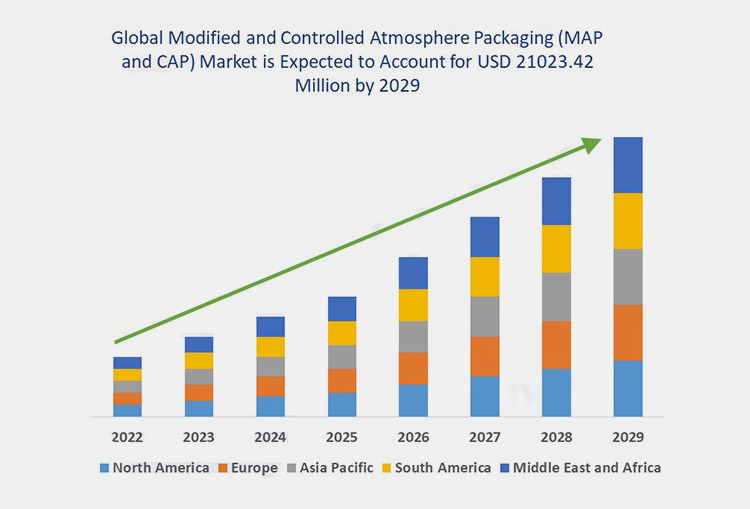

12.What are the Future Trends of Modified Atmosphere Packaging?

Market of Modified Atmosphere Packaging- Picture Courtesy: Data Bridge Market Research

The high demand for fresh food and other products has led to a surge in the market for modified atmosphere packaging. This market of modified atmosphere packaging was estimated to be about US $15,600, in 2021 and it is anticipated to grow about US $21023.42 million in 2029, with a growth CAGR of 3.80%.

The growth of the food industry has propelled the increased use of modified atmosphere packaging, It is a profitable business and is an absolute must in food packaging to reduce food wastage.

More and more brands are using modified atmosphere packaging, because of its convenience and sustainability. It is a perfect solution to keep ready-made meals and snacks fresh for an on-the-go busier lifestyle.

Manufacturers are striving best to achieve the perfect packaging recipe by combining various packaging elements. So, the protection of futuristic modified atmosphere packaging will be enhanced with the use of smart labels, intelligent sensors, and active packaging. Furthermore, the use of biodegradable materials with modified atmosphere packaging is predicted to increase in the future.

Conclusion

Modified atmosphere packaging is simply the modification of the internal food packaging atmosphere by flushing a combination of gases to improve its shelf life, simplify the supply chain, reduce food waste, and enhance product appeal. Modified atmosphere packaging is beneficial both for sellers and the environment. By simple investment in equipment related to modified atmosphere packaging, manufacturers can get huge profits. So, are you intend to add modified atmosphere packaging in your plant and want to learn about prices and deals, then visit our main Allpack website to get the best offers. Happy Shopping!!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide