How To Make Softgels?

"He who has health, has hope; and he who has hope, has everything". Indeed, good health is the most valuable asset an individual can have. That's why, people around the globe are becoming more concerned about their health especially after the disastrous pandemic of COVID-19. The growing awareness regarding possible side effects of high dosage tablets, vaccines, and other drugs have alarmed people to look for safe alternative which is off course Softgels!

Softgels supplements holds magnificent benefits for all age humans. Thus, their demand has exceeded the desire for most of nutraceucal manufacturers to make Softgels. Are you among one of them? But confused How To Make Softgels? Then welcome to this blog post which is brought for enabling you How To Make Softgels!

1.What Are Softgels?

Softgels dispersed from bottle- Picture Courtesy: 100percentpure.com

Softgels are liquid based supplementary capsules characterized by an external soft gel shell encasing liquid or semi-solid formulation. The purpose of softgels is to promote convenient swallowing of unpalatable liquids such as fish oil, vitamins, and vegetable oils by masking them with digestible cover.

Today, softgels are known for their enhancement of nutrients bioavailability, preventing vitamin deficiency, and curing certain illness. Therefore, they may be used by different methods according to the requirement of each type of softgel. For instance, some softgels are consumed orally by swallowing, some are opened in mouth, while others are mixed with formula.

While, the uses and types of softgels are multiple, their making process is similar which you will know below.

2.How To Make Softgels- Ingredients Required?

Softgels are basically composed of two types of materials; the outer shell and inside liquid solution. Therefore, for making softgels, you will need certain ingredients or components which can be divided into two categories. These are as follows:

Outer Shell Material

Red softgels- Picture Courtesy: stylecraze.com

The shell of softgels constitutes the external body to protect inside content. Hence, it is made from the mixture of few ingredients such as:

Gelatin

Yellow gelatin powder- Picture Courtesy: indiamart.com

Gelatin is a primary ingredient used in the formation of softgels' outer shell. It is mainly derived from animal sources by boiling their skin, connective tissues, and bones. Therefore, gelatin also holds various benefits for human health such as proteins and amino acids.

Pectin

Fruit liquid & powder pectin- Picture Courtesy: foodsguy.com

Pectin is a fiber found in vegetables and fruits. It helps in thickening the external layer of softgels. Therefore, pectin is widely used as an alternative to animal-based gelatin due to multiple reasons such as people abstention or allergy from it.

Plasticizers

Sorbitol powder with explained specifications- Picture Courtesy: stylecraze.com

Plasticizer is a substance added into softgels to reduce their brittleness and enhance their structural integrity. It is one of the key constituents of softgels' shell due to its elasticity and pliability. The common plasticizers used in softgels include Polyalcohol, glycerol, and sorbitol etc.

Preservatives

Examining parabens bottle- Picture Courtesy: reequil.com

Preservatives are also added into softgels to prevent the formation of bacteria and molds. Thus, they help in the extension of softgels' shelf life. More than 20 preservatives are internationally recognized as safe to be used in softgel capsules. These include Potassium sorbate, Methyl, ethyl, & propyl hydroxybenzoate, paraben and others.

Colorants

Multiple types of colored softgels- Picture Courtesy: soft-gel.com

Various colors may be used to give the softgels eye-poping appearance. Mostly, colors are added to retain the inside content getting away from contacting light.

Opacifiers

Sea oil opaque softgels- Picture Courtesy: Pinterest

Opacifiers are additives mixed in softgels mixture to give them opacity in order to improve softgels appearance and brightness against ultraviolet light. Titanium dioxide is the common opacifier used in softgels.

Solvent

Water filling in glass- Picture Courtesy: Life With Heidi

Water works as a primary solvent to mix all the ingredients of softgels' shell.

Flavors

Various fruits flavorings- Picture Courtesy: spiresart.com

Although, flavors are optional and infrequently needed, yet, their addition make the taste of soft gels patient-compliant. Ethyl vanillin, essential oils, and sucrose can be used as flavorings to softgels.

Inside Filling Material

The inside material of softgels vary from one type of softgels to another. Therefore, the ingredients can be divided under following three categories:

Oily Mixtures

Omega-3 fish oil softgels bottle- Picture Courtesy: ubuy.com.pk

Softgels which are purely made up of oils are termed as oily mixtures. They only require oils which are filled inside the shell cover. These include fish oil, vitamin D, E, steroids, and vegetable oils etc.

Solution Fills

Calcium food with softgels- Picture Courtesy: AglaeCal

Softgels solution fills are composed of active ingredients of drugs which are dissolved in liquids or solvents such as water, glycerin, dimethyl isosorbide, and diethylene glycol monoethyl ether etc. Thus, you will need active ingredients of drugs and solvents for making solution fills.

Suspension Fills

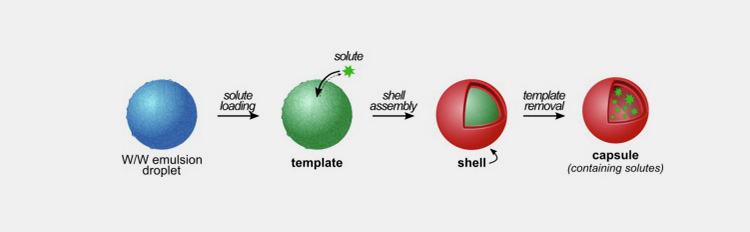

Emulsion based capsule filling solution idea- Picture Courtesy: sciencedirect.com

Suspension fills are those fills which do not completely solve in liquids. Therefore, solid active ingredients of drugs are uniformly dispersed in carrier solution. So, you will require solids as suspension ingredients and solvents for their even lubrication and dispersion.

Post Preparation Ingredients

Although, post preparation processing of softgels is optional, but it can have great implications on your capsules’ stability and quality. Hence, most of the manufacturing industries adopt this practice as compulsory step. It simply includes the following ingredients:

Aldehyde Post-treatment

Plant based polished capsules- Picture Courtesy: Vitalfoods Insights

Aldehyde post-treatment involves the cleaning of capsules to remove out the excess aldehyde residues from softgels. Hence, it reduces the dissolution of softgels in stomach and help them reach desired point. It also removes the toxicity of softgels.

3.How To Make Softgels- Equipment Needed?

Similar to the multiple ingredients used for making softgels, you will also require several equipment to process these ingredients and form softgels. What are these equipment? We have discussed them below in detail:

Gelatin Melting Tank

Gelatin Melting Tank- Picture Courtesy: Aipak Pharmaceutical Equipment

Gelatin melting tank is a machine used to melt down the gelatin for making the shell of softgels. It is mainly composed of a melting tank, water-filled jacket around the melting tank, electric heaters, a motor, and attached control system. Hence, gelatin can be melted in this tank by putting all the essential ingredients in this gelatin melting tank. These ingredients then melt down and give you finished gelatin shell or ribbon.

Prepare Tank

Prepare tank- Picture Courtesy: Aipak Pharmaceutical Equipment

Prepare tank also known as cooking tank is another device you will need to process your filling solution. It consists of a stainless steel body with heating system, an inside stirrer, motor, an outlet valve, and control board etc. The machine uses heat to cook your liquid mixture at desired temperature. You can use this machine to make solution fills for your softgels.

Main Machine

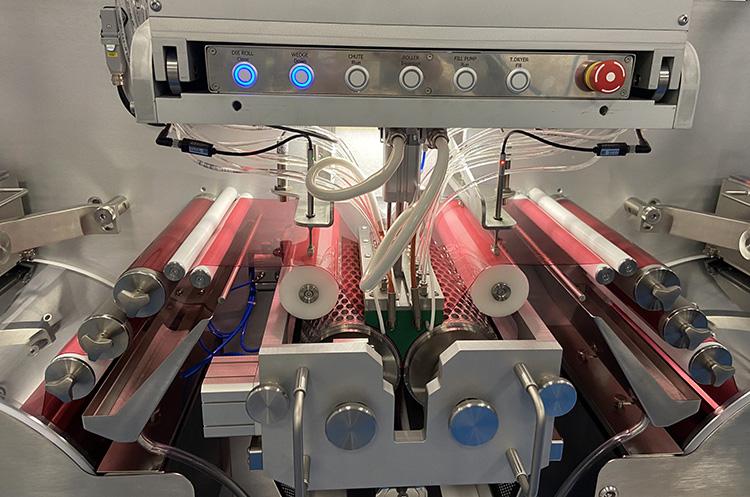

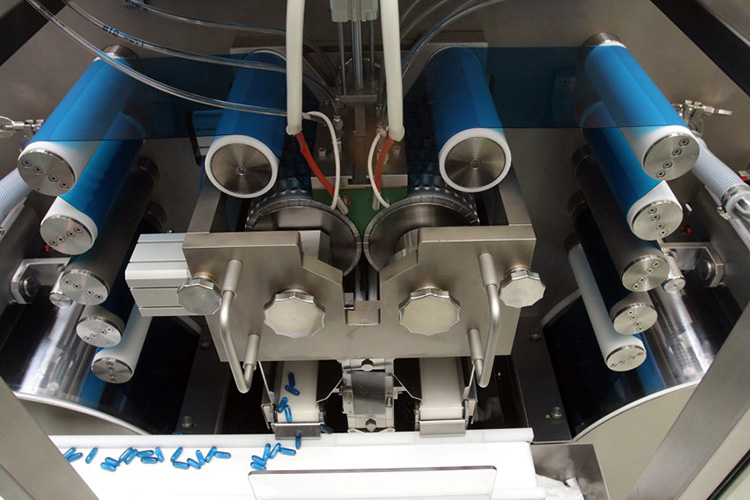

ZTHT-100 Softgel Encapsulation Machine- Allpack

Softgel encapsulation machine is the main machine for softgels manufacturing process. It is made up of small to large parts which at the same time perform dual functions of gelatin ribbon forming as well as filling material infusing. Material hopper, gelatin tank, cooling drum, injection wedge, and die roller are the major components of this machine. These when operated, resulted in the formation of beautiful and quality softgels.

Colloid Mill

Colloid mill- Picture Courtesy: Aipak Pharmaceutical Equipment

Colloid mill is another significant equipment used to reduce the size of solid particles or droplet present in liquid emulsion and suspension. It consists of an input funnel, output control valve, a motor, colloid adjustment knob, adapter plate, lifting cover, base support, and other components. The machine works on the principle of rotar and stater where high shear hydraulic pressure is applied over liquids after their loading in hopper. This leads to the formation of small droplets .

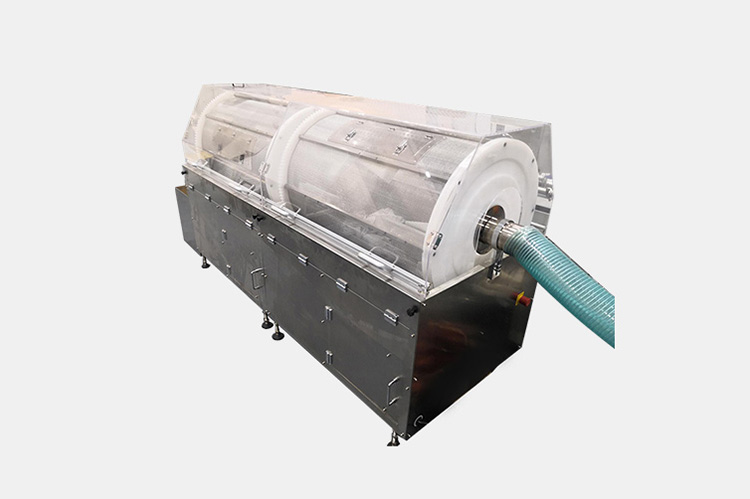

Tumbler Dryer

Tumble dryer- Picture Courtesy: Aipak Pharmaceutical Equipment

Tumbler dryer is a drying system employed for drying bulk softgels. This equipment adopts advance technology of blowing to dry the softgels without degrading their quality. It has a rotary perforated deck where softgels are poured. When machine is powdered on, the deck starts rotary movement under which multiple blowers start generating air to get the softgels dry.

Vacuum Pump

Vacuum pump- Picture Courtesy: Aipak Pharmaceutical Equipment

Vacuum pump is of paramount importance for making softgels as it helps in normalizing the air pressure from higher to lower. It is used to reduce the air and gas present in softgel encapsulation machine so, the internal environment will be suitable for processing. Its structure is made up of drive shaft, diffuser plate, diffuser, casing, suction port, impeller, and discharge hose.

PVC Trays

Stacked PVC drying trays- Picture Courtesy: Aipak Pharmaceutical Equipment

PVC trays are the tools you can use for the purpose of drying softgels. They are stackable and perforated, thus, occupying less space and consuming less energy as compared to machine. These trays can be used as it is open to air or placed on a drying car for drying in machine.

Light Inspection Table

Light Inspection Table- Picture Courtesy: Aipak Pharmaceutical Equipment

Light inspection table is designed to facilitate the observation of softgels after they are get manufacture. It is made up of a stainless steel body, table, illumination system, detection system, and control system etc. By using optical illumination and visual technology the table inspect the damage, breakage, size inconsistencies, and weight of softgels. Thus, it helps in the quality checking of softgels.

Drying Car

Drying car- Picture Courtesy: Aipak Pharmaceutical Equipment

Drying car can be simply described as a PVC perforated tray attached with movable trolley. It is helpful for drying your produced softgels by stacking softgels filled trays over it and mobilizing them towards drying machine.

4.How To Make Softgels- Steps Involved?

This question is designed to enable you with the actual method of making softgels. So, let's know the fundamental steps it follows:

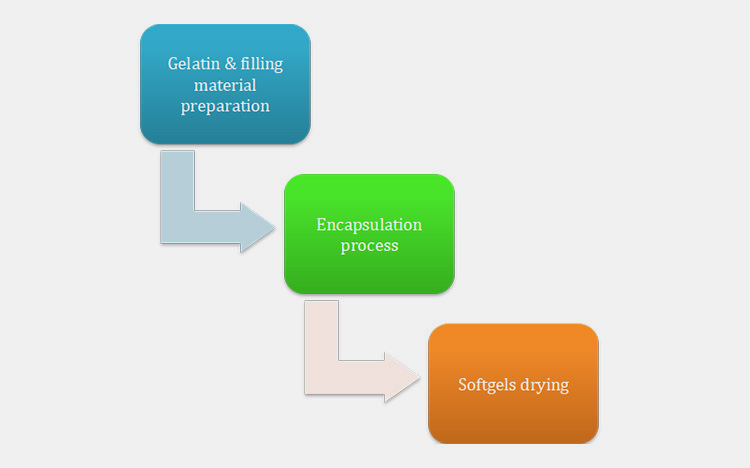

Preparation of Gelatin And Filling Material

Softgels gelatin preparation- Picture Courtesy: ACIC Machinery

The first step involves making gelatin and filling material for softgels. Here, you can put the ingredients required for shell making and that of filling in separate cooking tanks. After both get prepared take them out of their respective melting and cooking tanks and load into softgels encapsulation machine.

Encapsulation Process

Encapsulation process of softgels- Picture Courtesy: Aipak Pharmaceutical Equipment

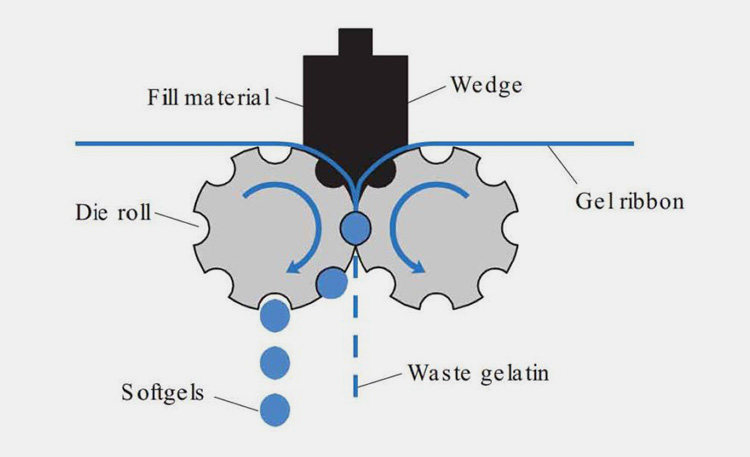

Once, you have poured the prepared gelatin into gelatin tank and filling solution into material tank of softgels encapsulation machine, turn on the power button. Now, the machine will form softgels through underlying principles:

Forming Ribbon

Softgels ribbon formation- Picture Courtesy: ACIC Machinery

The ribbon formation takes place when the machine cools down gelatin through cooling drum and turn it into flat ribbon by rolling around rollers on other sides. Here, double flat layers of gelatin are pulled from rollers towards die rolls which move in opposite rotary direction.

Filling Solution

The injection wedge dispenses filling solution into ribbons which are between die rolls.

Sealing Softgels

Softgels sealing through heat- Picture Courtesy: Pharmachine

Similarly, the die rolls adopt circular movement opposite to each other and softgels are tightly sealed through heat.

Discharging Softgels

Softgels discharging- Picture Courtesy: ACIC Machinery

After sealing, these softgels are discharged by the machine through chute.

Softgels Drying

Softgels drying in trays- Picture Courtesy: ACIC Machinery

Drying of softgels is an important step which occurs after encapsulation process. Here, softgels are placed in tumbler dryer whose constant air blowing result in the effective drying of softgels.

Apart from above mentioned steps, printing, polishing, and packaging are the other steps which are carried out for maintaining the quality of softgels for a longer period.

5.How To Make Softgels- Quality Control?

Laboratory testing of softgel capsule- Picture Courtesy: soft-gel.com

While making softgels, it is important to keep in mind their quality control in order to ensure safe delivery of drugs and other therapeutic agents. You can examine the softgels quality through following angles:

Raw Material Testing: You must have to check the raw materials you are going to use for making outer shell and filling solution.

Weight Consistency: After softgels get form, test if their weight is uniform.

Structural Integrity: Structural integrity will include the softgels stability under different conditions like cold and heated temperature.

Disintegration Testing: Assess the speed of softgels dissolution into body for ensuring the suitable drug delivery in body.

6.How To Make Softgels- The Benefits?

The benefits of softgels are acknowledged around the globe and you will wonder how extensive they are. Let's explore few of them:

Increase Shelf Life

Blister packed softgels- Picture Courtesy: depositphotos.com

Softgels play a key role in enhancing the shelf life of filled solutions like fish oil, vitamins, and other suspension by creating durable layer over them. Hence, its hermetic sealing prevent the possible oxidation and degradation which adds into the potency of inside content for years.

Convenient Swallowing

Woman swallowing softgel- Picture Courtesy: beyondhealth.com

Most of the people face difficulty in swallowing large tablets and hard capsules. However, softgels are odorless, mask the unpleasant taste of inside content and are slippery, therefore, their swallowing is easier for the people of all ages.

Improved Bioavailability

Active hair biotin softgels- Picture Courtesy: ebay.co.uk

Softgels promote bioavailability of such liquids which are otherwise poorly soluble. In this way, they make all the active ingredients of filling solution available to the body.

Diverse Usability

Twist off cosmetic softgels- Picture Courtesy: Freepik

Softgels are now available in multiple sizes, shapes, and forms which can be used for diverse ends. For instance, you can use softgels for enhancing your beauty, strengthening immunity, curing diseases, and adding into your daily diet a healthy dose.

7.How To Make Softgels- Considering Shapes, Sizes And Types?

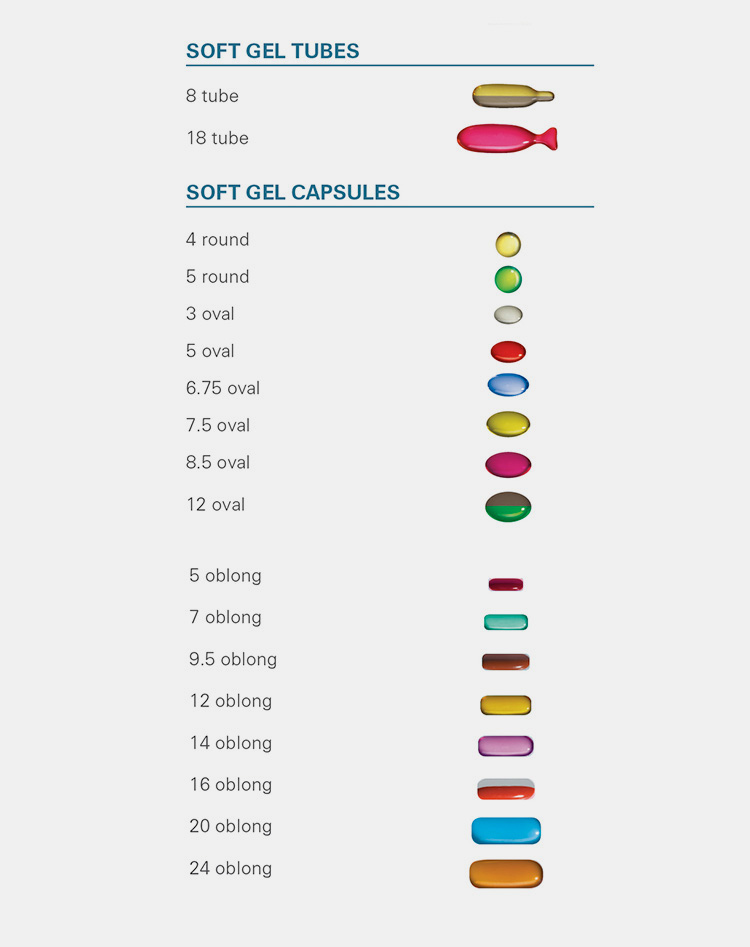

There are enormous shapes and sizes of softgels which you can adopt for making Softgels. Apart from that, knowing various types of softgels will better help you understand the versatility of these capsules. Let's begin reading these all:

Softgels shapes & size chart- Picture Courtesy: spherehealthcare.com

Shapes

Softgels can be formed in different shapes with attractive and appealing looks. These shapes are commonly used with respect to dosage of medication like small dosage volume is often delivered in oval and round shapes, while as large dosage rmust be encased in oblong or tube shape. Similarly, softgels which are meant for opening instead of swallowing must be formed in twist off shape. Some common shapes of softgels include:

- Round

- Oval

- Oblong

- Tube

- Even

- Suppository

- Twist off

- Special shapes

Sizes

When it comes to talk about softgels size, many people get confused as they think that there may be a standard size of softgels. However, it's not the case! Infact, softgels can be molded into any size keeping in view the dosage requirement of capsules.

Types

The softgels can be divided into four types depending upon their usage or delivery method. These are described below:

Swallowing Softgels

Fish oil softgels- Picture Courtesy: Natural Products Insider

There are softgels which are designed with highly degradable and digestible gelatin and ingredients to get easily absorb in body. Similarly, they are made to be swallowed and eliminate the need for swallowing tablets and medication of harsh forms.

Chewing Softgels

Woman holding softgel between teeth- Picture Courtesy: Huda Beauty

Another type of softgels include chewing softgels which, like candy and gummy, are meant to be well chewed in mouth for releasing the inside content instead of swallowing. Therefore, such softgels are strongly flavored to avoid discomfort of patients regarding taste.

Sucking Softgels

Liquid softgel presentation idea- Picture Courtesy: Aspire Pharma

Another type of softgels are used to suck in mouth so, that the inside formulation will release in mouth and support quick dissolution in stomach. However, they are comparably more resistant to dissolution thus, having pleasure flavors.

Twisting Open Softgels

Twisting off softgel- Picture Courtesy: Catalent Consumer Health

Last but not least, twist open softgels are not as common like other types of softgels, but they are twisted, opened, and used either orally or mixed in a formula like cosmetic creams. It is important to note, that shell of twist open capsules is not meant to be consumed.

Conclusion

How to make Softgels? This question is of great importance for all the manufacturers of softgels and we hope you have also found the answer! Softgel is a superior dosage form that accurately deliver precise liquid solution to your body with much ease and convenience. It is eminent to follow the mentioned steps required for making uniform softgels and keep their quality up to the mark. Are you ready to make softgels? If yes! Don't make delay to have all the core equipment required for making softgels by Allpack, who is leading the world in providing sophisticated machines for manufacturing softgels. Stay tuned and be in contact with us!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide