How To Vacuum Seal Bags?

Are you facing food preservation issues? Does your material get bacterial contact when kept for a duration of time? Vacuum seal is a method that can ease you in this situation and lower your stress. Vacuum seal extracts the oxygen and contaminants out of the bag and helps the product to remain secure with extended shelf life. But the question remains how vacuum seals can be applied to bags? What types of sealing can be applied to different types of bags?

To answer queries and provide you a complete guidance regarding vacuum seal bags, this blog contains all the necessary information. If you are interested and enthusiastic!Then let’s start learning this blog to take the most out of it.

1.What Is Vacuum Seal?

Best Vacuum Sealer - Picture Courtesy: Food & Wine

Vacuum seal is an advanced method used commonly for the preservation of products from bacterial and microbial attacks. Vacuum seal is a customized serried of method that involves the extraction of oxygen and air out of the bag and helps create a vacuum space within the bag. Evacuation of air out of the bag makes the internal environment free from microbes and does not support any bacterial growth.

Finally, the sealing is applied to the vacuum bags to make an airtight environment. This keeps the product alive and fresh for a longer duration and also supports their safe traveling. Vacuum seal is commonly used in electronics, food, chemicals, cosmetics, and other industries.

2.What Are The Advantages Of A Vacuum Seal?

Vacuum seal has wide applications and are beneficial in many ways like

Preservation

Preserve Your Food - Picture Courtesy: Westron Brands

The primary advantage of vacuum sealing is to preserve the product that is sealed in different sizes of bags. The seal applied to these bags keeps the natural content of the product alive for a longer period. Vacuum reduces the flow of air inside the bags and maintains high-quality measures for preservation.

Product Life

Advantage Of Vacuum Seal Bags - Picture Courtesy: Bunzl Express

The most important benefit that can be taken from a vacuum seal is that it significantly supports extending product life by removing all the environmental influences within the bag. Vacuum seal helps in slowing the oxygen reaction inside the bags and directly contributes to avoiding food and other product wastages.

Safe Freezer Burn

Vacuum Packing - Picture Courtesy: Wikipedia

Vacuum seals are vulnerable to freezer burn as the vacuum created within the bageliminates the chances of moisture in it. Most of the products with a vacuum seal are safe from freezer burn due to this reason that normal sealing cannot provide generally.

Safe Travelling

Vacuum Sealed Bags For Travelling - Picture Courtesy: The Travel Hack

Products that are vacuum sealed ensure that no products get out of the bag. It prevents any type of material leakage even if the product is in liquid force. Products are traveled around the globe without any chance of spillage making the storage secure and safe.

Space Saving

During the extraction of air and the creationof a vacuum, most of the space gets contacted and creates compact packaging. This helps in packing of large number of products in a single carton or box due to their less space consumption. Also, vacuum seal bags are easy to store in refrigerators due to this advantage.

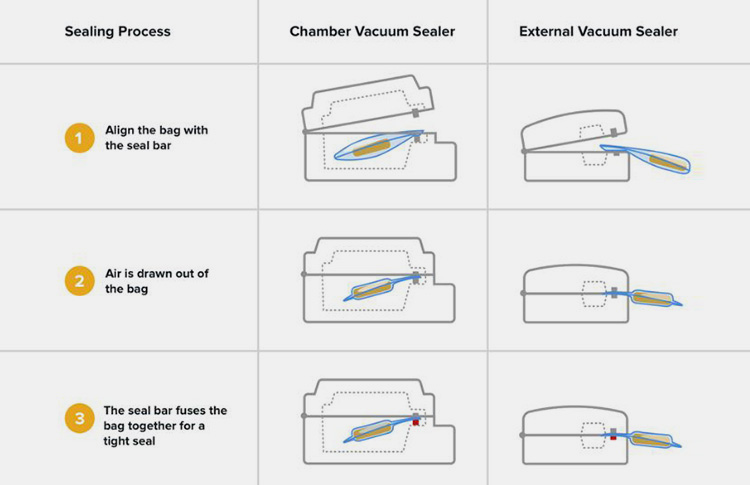

3.How To Vacuum Seal Bags?

How To Vacuum Seal Bags - Picture Courtesy: Webstaurant Store

Vacuum sealing is a simpler process that only involves the extraction of air and oxygen from the bag and then creating an airtight seal on it. The process of how to vacuum seal bags is as follows

Initially a vacuum machine is preheated to its defined range of temperature and likewise the material is inserted into their specific type of bags. Both food and non-food products can undergo a vacuum seal process.

Selection of bags is also an important thing to do. Only bags that support vacuum seal and can handle the material in it are to be selected initially.

Once the material is filled inside the bag, the open side of the bag is positioned towards the vacuum sealer. It is important to leave some space at the top of the bag for the removal of air and also for sealing purposes.

The open side is perfectly placed in the center of the liquid catch so that any excess of the material can be left toward the catch side.

The nozzle inserted inside the bags starts its operation to createa vacuum. All the sides of the bag are to be pressed uniformly so that complete removal of air can be made sure.

Once the vacuum is created the sealing bar is activated and applies seal on it. Overfilling of a vacuum sealer is to be avoided at this stage.

The bags are then sealed according to their prescribed duration and then cooled for some time.

Finally, airtight vacuum seal bags are taken out of the vacuum sealer and are then transported in packaging.

4.What Type Of Foods And Eatables Can Be Vacuum Sealed In Bag?

Some of the food and eatables that can be vacuum-sealed in bags are

Dairy Products

Packaging Of Dairy Products - Picture Courtesy: Barrier Vacuum Bags

Most dairy products like cheese, yogurt, butter, powdered milk, cream, etc. can be vacuum sealed easily using a vacuum sealer. Dairy products are the ones that can directly be influenced by environmental conditions and can also multiply the growth of bacteria in a few seconds. This is why vacuum sealers can help preservation of these products and extend their shelf life.

Dry Products

Some of the dry products like grains, seeds, rice, and oats that cannot remain fresh for a longer period during their environmental conditions are vacuum sealed in bags so that they can be kept in their natural health until they are used.

Fruits And Vegetables

In the modern world, countries that do not have any agricultural facilities or produce less than their requirements import fruits and vegetables from other parts of the world. These products like bananas, apples, carrots, broccoli, etc are vacuum sealed in bags so that they can be transported worldwide with their natural and fresh essence.

Meat

Meat Vacuum Sealer - Picture Courtesy: Bob Villa

Mostly meat products either beef, fish, chicken, mutton, or any kind of raw meat can easily be vacuum sealed in bags so that the meat does not get rotten and can be consumed for a longer period.

Ready To Eat Meal

Meals that are ready to eat or already cooked are one of the most commonly consumed food products these days.These meals can somehow be used after months as it only requires heating them at a certain temperature. To keep the freshness of food alive, the outer bag of these products isvacuum-sealed in bags and then transported globally.

Electronic Products

Vacuum Sealing For The Electronics Industry - Picture Courtesy: Boss Vacuum

Few countries in the world are responsible for supplying their chips and boards around the world. These products travel either by sea or by air this is why there is a greater chance of getting moisture in them. The vacuum seal on these products reduces the chances of moisture and lets the precise component reach its destination.

Other than these materials;bread, pickles, grains, spices, jams, ketchup, etc. are also vacuum sealed so that they can be used over a period of time.

5.What Are The Methods To Check The Quality Of Vacuum Seal Bag?

You Need To Know About Vacuum Sealing - Picture Courtesy: TOUFOOD

Most of the machines that are involved in the process of vacuum seal give completely precise and accurate results. But still, there is some measure that should be taken to check the quality of the vacuum seal bag. The methods in this respect are

Visual Inspection

The most reliable source for checking the quality of a vacuum seal bag is visual inspection. This not only leads to visual inspection with the naked eye but also allows the operator or inspector to be completely satisfied with the process.

Dry Run Test

Some industries perform a dry run test by sealing an empty bag and checking its edges. This test helps in checking if any type of change in operating parameters is required or not.

Quality Control Check

Quality control check guidelines involve proper inspection with touch and hearing. Any type of folding or wrinkles can easily be detected by touching the surface of the vacuum seal bag. Alsopressing the bag can identify if there is any type of leakage or spillage.

Seal Strength

Another method for checking the quality of a vacuum seal bag is to check its strength. The inspector needs to tug on the applied sealing witha vacuum sealer in this method. If the edge of the seal remains the same and firmly remains tight enough, this indicates that a strong vacuum seal bag is produced.

Water Check

Some of the products can undergo a water check to identify if there is any leakage. The appearance of a bubble on its surface can be identified easily.

6.What Is The Difference Between A Vacuum Seal Bag And A Normal Seal Bag?

Both of the types of bag sealing are entirely apart from each other. Some of the differences between both types of sealedbags are

Operation

The operational procedure of a vacuum seal bag starts with filling of material in the bag and then insertinga nozzle in it. The nozzle extracts all the air and oxygen from it and creates a vacuum. Finally, sealing is done on the open surface of the bag to make it airtight.

For a normal seal bag, once the material is filled the edges of the open side are entered into the sealer jaws, and the sealer process is carried out directly.The sealing creates an air-tight atmosphere but leaves oxygen in it that can cause contamination.

Removal Of Oxygen

Secondly, a vacuum seal completely removes oxygen and air contents from the bag and creates a vacuum in it. The seal in the end keeps the bags airtight and blocks the entrance of any particle.

A normal sealing process seals the bag without any removal of air. The air or oxygen content remaining inside the bag can directly affect the freshness of the product.

Preservation

Vacuum seal bag's primary concern to blocking the entrance of any microorganism and this directly preserves the product for a longer period.

Products that have normal seal bags on them can live only for a shorter period of time and cannot have a long freshness period.

Storage Capability

A large number of bags can easily be traveled if they are vacuum sealed as it occupies less space as comparedto normal sealed bag. Their transportation and storage are reliable and much easier.

7.What Are The Factors That Affects The Shelf Life Of Products That Are Vacuum Seal Bag?

For any manufacturer, the basic goal to perform vacuum seal bags remains to increase the shelf life of their products. But some of the factors that can affect the shelf life of products are

Product Quality

The most important factor remains the quality of the product under gone vacuum seal. If the product has already faced bacterial growth in it or is not fresh,this can directly reduce its shelf life even if it is vacuum sealed.

Quality Of Bag

The specifictype of bag is required for the vacuum seal. Other than these bags the product cannot remain free from environmental influence for a longer period. Poor quality of bags can also affect the shelf life of products.

Handling

As the products are to be traveled for longer distances, the handling of it can also be a factor that can affect their shelf life. Proper handling at any station is necessary to reduce this matter of concern.

Moisture Content

In some of the products moisture content is a greater concern to think of. While performing vacuum seal bags this factor is also always kept under consideration so that the product does not lose its identity at any cost.

8.How Can A Vacuum Seal Bag Used To Extend The Shelf Life Of A Product?

Some of the important aspects by which a vacuum seal bag offers extension in the shelf life of products are

Blocking Oxidation Reaction

The most important aspect of a vacuum seal bag is that it blocks the internal oxidation reaction in any bag. The vacuum that is created and the airtight seal are so capable that they do not allow any of the environmental factors to enter into it. As the oxidation chain reaction supports in growth of bacteria, this gets completely cut at any conditions.

Material Wastage

The other factor that helps in shelf life extension is that a vacuum seal bag reduces material wastage at a greater level. No spillage or leakage occurs in the vacuum seal bag and the product remains of the same size and weight for longer periods.

Flavor Preservation

Vacuum Sealed Meat - Picture Courtesy: Meat Sumo

A vacuum seal bag also keeps that flavor preserved of any type of food or non-food product.This also helps in keeping the same product alive even if it is transported to any of the continents.

9.Can Vacuum Seal Bag Be Useful For Liquid Products?

Vacuum Seal Liquids - Picture Courtesy: A Life Well Planted

Some vacuum sealers support vacuum seal bags for liquid products. However, these vacuum sealers use specific types of bags to handle any type of liquid material. Also, careful handling of these vacuum seal bags is to be done to avoid any type of spillage or leakage. Material like sauces, soups, frozen meals, ready-to-eat meals, and other liquid materials mostly prefer vacuum seal bags to protect their consistency.

10.What Are The Precautionary Measures Taken While Doing Vacuum Seal Bag?

Vacuum Seal Bags Do’s & Don’ts - Picture Courtesy: Style Degree

Some of the precautionary measures while vacuum seal bags are

Dryness In Products

The most important measure to take before going for a vacuum seal bag is that the product that is to be sealed should be dry. Dry products mostly support good-quality sealing and vacuum options. Products with moisture or water content can face material spoilage at any level.

Seal Bag Properties

Secondly, the quality of the sealed bag is also important to be considered before doing a vacuum seal. If the bag that has poor quality is kept under a vacuum seal can cause fire and potential hazards at a certain temperature. Also, the seal of these types of bags can get open during handling or transportation.

Vacuum Sealer Bars

Cleaning of vacuum sealer bars is always necessary before starting the process. The cleaning process should be repeated after every batch so that no wrinkles or holes can occur in these bags.

Equipment Maintenance

A proper equipment and machine maintenance schedule should be carried out for a vacuum seal bag. It is important to check all the components before the start of operation so that any type of hazard can be prevented.

Cooling Time

Proper cooling time is required while vacuum sealingthe bag so that the seal can properly settle down and result in strong sealing.

Conclusion

Vacuum seal bag is a simple process, only the right bag for the vacuum seal bag process is the only important thing to consider. We hope you have complete information regarding “How To Vacuum Seal Bags” and gathered related facts about it. If you are still looking for more information on how to vacuum seal bags or are interested in buying the specific machine, Allpack is always there for your guidance and assistance. You can easily send us your queries and contact our representatives 24/7.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide