What Is The Difference Between Rigid And Flexible Packaging?

Are you anxious about the packaging of your products? Do you want to opt for the packaging which can better protect the quality, integrity, and image of your company? That's admirable! It is something every manufacturer should be concerned about. After all, it is the packaging that can make or break a product's sales. However, instead of worrying, the best and ultimate solution is to explore eclectic packaging options out there. For this, we have come with the most relevant blog post, what is the difference between rigid and flexible packaging, which will indeed answer all your queries.

In the realm of packaging, you will always find the basic categorization of packaging into rigid and flexible packaging. But what actually they are? Can they be employed for same products? Or their application is restricted? On which parameters they can be differentiated? And most importantly, how to choose between them the best compatible one for your goods? Knowing these questions is paramount for determining the fate of your business. So, let's unveil them one by one!

1.Define Rigid And Flexible Packaging?

Rigid Packaging

Multiple rigid glass bottles-Picture Courtesy: packagingoftheworld.com

By rigid packaging we mean all types of packaging which are hard in their nature, having durable structure, and ensuring greater strength to your products. These include cans, bottles, buckets, and cartons which are derived from rigid materials such as glass, plastic, metal, and card boards etc. Hence, you can employ them for maintaining the integrity, quality, and susceptibility of your vary goods from production till end users.

Flexible Packaging

Various flexible pouches-Picture Courtesy: packagingoftheworld.com

Flexible packaging encompasses multiple packaging options comprising bags, pouches, and sachets etc. They are created from most flexible, light weighted, and affordable substances including plastic films, aluminum foils, and paper. Therefore, they are resilient enough to be moulded in any desired and customized shape. Moreover, flexible packaging can better allow manufacturers to market their products by providing the edge to bring about innovative designing and labeling for engrossing consumers.

2.Explain The Pros And Cons Of Rigid And Flexible Packaging?

Everything in this globe has substantial benefits to discover, and at the same time few associated downsides to acknowledge. So, let's uncover the pros and cons of rigid and flexible packaging:

Pros of Rigid and Flexible Packaging

Rigid Packaging

Durable

Durable plastic juice bottle in hand-Picture Courtesy: rawpixel.com

Rigid packaging is more durable due to the sturdy structure and excellent support which containers provide for the protection of delicate products against damage and breakge, especially during carriage.

High Barrier Properties

Corrosion resistant can-Picture Courtesy: packagingoftheworld.com

All types of rigid packages including tin cans, glass bottles, and hard plastic have stout strength to resist heat, light, corrosion, and moisture. Consequently, your goods remain distant from environmental elements and stay fresh for a longer period.

Superior Quality

Glass wine bottle display-Picture Courtesy: cocktailcourier.com

Another sparking attribute of rigid packages is their fancy and expensive look which indeed reflect the superior quality of products. Hence, reputable brands can utilize rigid packaging for enhancing the perceived value of their items.

Flexible Packaging

Market Appeal

Various food stick packs-Picture Courtesy: www.behance.net

Flexible packaging is better suitable for merchandising purposes, as they are favorable for printing multifarious graphics and logos on. Together with tittle bags and sachets, they have greater proclivity to fascinate buyers.

Customizable

Tea bag sachet-Picture Courtesy: etsy.com

Customization is the key for uplifting your business growth. In essence, you can make your customers enjoy the same products in unique and different flexible packages like spouted pouches, tear notch doypacks, toys shaped bags, and beyond.

Cost-effective

Flexible packaging is cost efficient in terms of packaging material used, shipping charges as well as in case of mishandling.

Light Weighted

Girl holding multiple flexible pouches-Picture Courtesy: whisps.com

Flexible packages are light weighted which promote customer convenience and place saving, as they can be easily stacked without any fear of breakage.

Cons of Rigid and Flexible Packaging

Rigid Packaging

Expensive

No doubt, rigid packaging is paramount for depicting quality, however, it is comparably expensive in its cost. Also, you will have to pay high transportation charges due to their bulky and heavy weight.

Restricted Customization

Multiple tomato sauce bottles-Picture Courtesy: packagingoftheworld.com

Rigid packaging has limited room for customization, so, it cannot be modified to meet the exponential market trends.

Fragility

Broken glass bottle-Picture Courtesy: pond5.com

Rigid packages are more sensitive and have low bearing to mishandling. As a result, a minor fall can cause dents in cans and break the glass bottles.

Flexible Packaging

Low Barrier Properties

You will always find goods packed in flexible packaging with shelf life of few months. What's the reason? The reason is their low barrier properties particularly against temperature and light which degrade the content inside with the passage of time.

Narrow Size Range

Narrow size flexible packages-Picture Courtesy: Pinterest

Flexible packaging has a downside in terms of size range. Pouches, bags, and sachets can only be used for storing small to medium amount of goods. For excessive and bulk volume, you will need to switch towards rigid packaging.

3.What Is The Difference Between Rigid And Flexible Packaging?

Rigid and flexible packaging are distinct from one another in the core aspects. These differences can be better acknowledged by thoroughly understanding the points highlighted below:

| No | Points | Rigid Packaging | Flexible Packaging |

| 1 | Nature | Hard and robust construction. | Soft and malleable. |

| 2 | Material Used | Material used for rigid packaging include metal, glass, and durable plastic. | While as, flexible packaging revolves around using plastic film, aluminum foil, and paper etc. |

| 3 | Strength | High sturdiness against environmental factors and product damage. | Flexible packaging is bouncier and tamper resistant to accidental fall. However, comparably, it may not withstand heat and light. |

| 4 | Weight | Rigid packaging is heavy weighted due to being made from denser materials. | In contrast, flexible packaging is quite light weighted, covers less space, and can be easily stacked for shipping. |

| 5 | Cost | Generally high in cost. | Cost-effective and affordable. |

| 6 | Reusability | Yes, rigid packaging can be reused multiple times. | No, flexible packaging are only for single use. |

| 7 | Customization | Rigid packaging has low customization available. | Flexible packaging is desirable for extensive customization. |

| 8 | Picture |

Coffee bottle-Picture Courtesy: www.behance.net |

Flexible pillow bags-Picture Courtesy: packagingoftheworld |

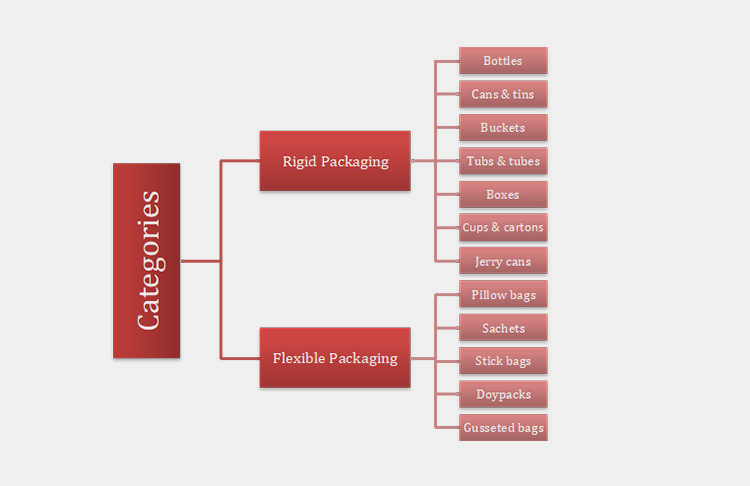

4.Enumerate The Categories Of Rigid And Flexible Packaging?

You may be curious to know about the wide range of packaging options offered in both rigid and flexible packaging. So, let's break it:

Rigid Packaging

Bottles

Various juice bottles-Picture Courtesy: redeleitundjunker.de

Bottle is something you will always confess to be familiar with. Generally, bottles are having narrow neck with caps over them. However, their shape and size may vary according to product as well as content. Most of the bottles are made from either plastic, glass, or rarely metal. They are always suitable to be used for storing pickles, jams, drinks, and other non-food goods like cosmetics and chemicals.

Cans & Tins

Paint can-Picture Courtesy: farbenloewe.com

Cans and tins have their origin from metal. They are incredibly versatile with exceptional barrier against corrosion, bacteria, and light. Hence, you can use cans and tins for multitude of goods, ranging from edible oils and beverages to paint and lubricants etc.

Buckets

Food buckets-Picture Courtesy: packagingoftheworld.com

Usually, buckets are cylindrical shape containers with broad opening, a lid, and attached handle to carry. They are made from plastic and available in small to large sizes. Hence, for storing large amount of food and non-food items, buckets are always the best suitable.

Tubs & Tubes

You may have an experience of enjoying potato chips from a tub or sucking chocolate from tube. These both are cylindrical containers often made from plastic or occasionally of paper with laminated foil inside. But, the distinction arises when tube is sealed from bottom in linear form. The former is perfect for solid items, while as, later for liquids such as toothpaste, lotion, and cream etc.

Boxes

Chocolate box-Picture Courtesy: rogerschocolate.com

Boxes can be simply described as flat containers, typically available in square, rectangular, and other shapes. They are most environmentally friendly because of their 100% biodegradable material which is card boards. Boxes are cost-effective too, so, you can use them for both primary, as well as secondary packaging.

Cups & Cartons

Cups & cartons -Picture Courtesy: Pinterest

Cups and cartons are semi-rigid disposable packages. Cups are made from plastic and sometimes paper. Similarly, they are used for snacks, yogurt, and cream etc. While as, cartons are derived from multiple layer of plastic, aluminum, and card board. Mostly, cartons are used for milk and juices.

Jerry Cans

Edible oil jerrycan-Picture Courtesy: abasana.in

Jerry can is another type of rigid package with capacity to hold up to 25 liter of liquids. Jerry cans are too obtained from sturdy plastic. They are easy to handle and good for all types of fluids including liquid detergent, petrol, diesel, edible oils, and pesticides etc.

Flexible Packaging

Pillow Bags

Pillow bags-Picture Courtesy: packagingoftheworld.com

Did you feel cozy after reading the title? Surely, that must have happened! This type of flexible packaging, known as pillow bag, gives the same safety to your products to that of pillow by maintaining their integrity through a bouncy structure. So, you can deliver all your delicate snacks and dried fruits in these bags.

Sachets

Biscuit sachets-Picture Courtesy: www.behance.com

Sachets are small flexible bags with usually 3 to 4 side sealing. They are most convenient to use, easy to carry, and are used for single serving. Hence, either it is cooking recipe condiments, tea time biscuits, a medicine dosage, or a hair color formula, sachets are all time favorite.

Stick Packs

Various tea stick bags-Picture Courtesy: matchabloom.com

Among other types of flexible packages, stick packs are smallest in size with long but narrow structure. Powders and to some extent liquids can be packed in stick packs. They are travel friendly and mostly used for offering instant individual serving of tea, coffee, and protein boost.

Doypacks

Doypack presentation idea-Picture Courtesy: dossiercreative.com

Doypacks are also popularly known as stand-up pouches due to their ability to erect. They are highly resistant to UV light, moisture, and heat due to the durable aluminum foil layer. Apart from that, you can use doypacks for liquids as well as solid items with range of customization including zipper sealing, spouts and heat sealing etc.

Gusseted Bags

Cat food gusseted bag-Picture Courtesy: Pinterest

Gusseted Bags are well known for their capacity of holding large volume of products like pet food, laundry powder, and tea etc. They have additional piece of a film attached to either bottom or both horizontal sides of the bag, which extend their storage size.

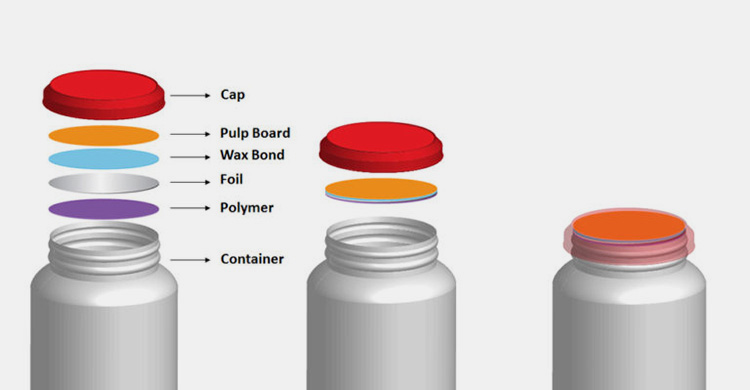

5.Does The Sealing Method Of Rigid And Flexible Packaging Similar?

No, the sealing of rigid and flexible packaging is entirely different. Both are sealed by using totally change methods. These methods are described below:

Rigid Packaging:

Induction cap sealing process-Picture Courtesy: inductioncapsealing.com

The sealing of rigid packaging is stringent because it is done via induction or conduction method. Here, all types of bottles and jerry cans are tightly sealed through non-contact sealing of induction sealing and contact based sealing of conduction sealing. Besides this, can sealing is used for the air proof sealing of cans and ring sealing for liquid bucket packaging.

Flexible Packaging

Vacuum bag sealing

Flexible packaging use heat sealing and cold sealing for most packages. However, the upper sealing of flexible packages may include a zipper, band sealing, and spout etc. Heat sealing can be further categorized into vacuum sealing and nitrogen flush sealing. Vacuum sealing is good for perishable and unprocessed goods like meat, vegetables, and fruits etc., to suck out the air. In contrast, nitrogen flush sealing can be employed for delicate products like potato chips and snacks, where oxygen is replaced with nitrogen.

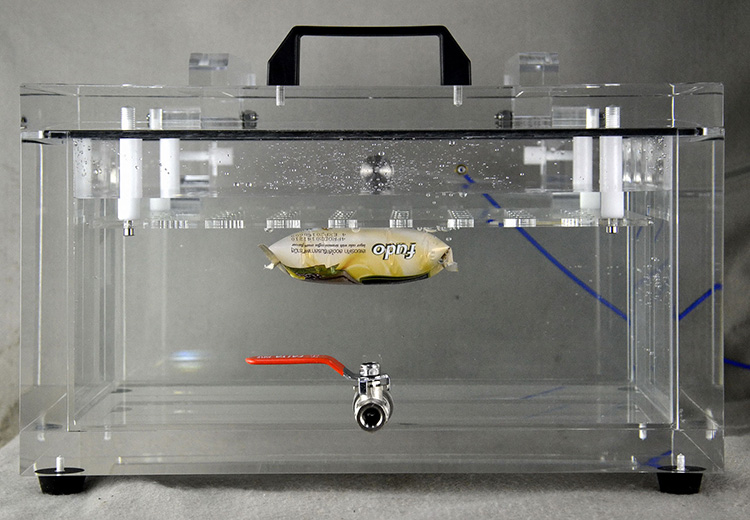

6.How Can You Test Rigid And Flexible Packaging?

It is significant to undergo both the rigid and flexible packaging through multiple tests, so, their defects could be easily tracked before its too late. These tests are explained below:

Vacuum Leak Test

Vacuum leak test-Picture Courtesy: at2e.com

Vacuum leak test is the lastest test employed for assessing all types of rigid and flexible packages including bottles, tubes, cans, and pouches etc. Under this test, the tester is filled with water and a finished package it kept inside the tester. Hence, during the operation of machine, if any leakage is present in the package, it will appear in the form of bubble.

Visual Inspection System

This sophisticated method of testing flexible and rigid packaging has been introduced to facilitate the convenient testing. By using multiple automatic cameras and sensors, printing errors and packaging faults are identified by the machine.

Pressure Decay Test

Pressure decay test-Picture Courtesy: zaxisinc.com

Pressure decay test is another popular testing technique to find the pakaging leakage through applying excessive pressure. Here, pressure is allowed into an enclosed product chamber. If the loss of pressure is found under fixed time period, it will indicates the presence of leakage, otherwise, packaging is tightly sealed.

7.Which Packaging Mode Between Rigid And Flexible Packaging Is More Environmental Friendly?

Eco-friendly icon-Picture Courtesy: environmentblog.net

When it comes to discuss the environmental impact of rigid and flexible packaging, every manufacturer is keen to know the ultimate answer. So, we are making is easier by looking into the facts and figures associated with them:

Rigid packaging including cans, plastic, and even glass are recyclable and also reusable making is favorable for producers to save money. However, it is not always the case! Improper handling of rigid packaging after consumption can result in excessive landfills for hundred years. Also, rigid packaging has more carbon footprint and require additional energy during production compared to flexible packaging.

Flexible packaging, on the other hand has low carbon footprint, having low ratio of landfills, and consume less energy for production. However, their mismanagement also deteriorate the environmental sustainability.

Hence, both rigid and flexible packaging are eco-friendly in their extent if managed properly. But, flexible packaging is more sustainable, energy efficient, and having less pollution.

8.What Quality Standards Should Rigid And Flexible Packaging Comply With?

Quality standards for both rigid and flexible packaging matters the most. It plays pivotal role in determining the shelf life of your goods, their quality maintenance, and safety etc. Hence, to ensure these factors, certain quality standards have been established for the regulation of protected and superior quality packaging.

ISO quality standard icon-Picture Courtesy: reciprocity.com

Among them, the most prominent one is International Organization for Standardization (ISO). ISO works on national level across the globe to provide manufacturers with certificates which validate their processing of hygienic packaging.

Food and Drugs Administration is US based agency with the same agenda of supervising the circulation of reliable packaging. Apart from that, Good Manufacturing Practices enforce the safety SOPs regarding all types of food and non-food production as well as packaging. Moreover, CE is the quality standard fixed by European Union to make sure that goods exported their are of prime quality.

9.How To Choose Between Rigid And Flexible Packaging Style The Best Suitable For Your Business ?

When dealing with the complications of selecting right type of packages option, you will always be required to consider few questions and also find the right answers.

Business Level

What is the level of your business? Indeed, the is an instrumental question to ask for. If you are new in the realms of production and want to have low packaging charges. Then, it is always better to advertise your products with the help of flexible packaging and designing beautiful mesmerizing labeling over them.

Customer Proclivity

Consumers having snacks pouch during traveling-Picture Courtesy: jakobwandel.com

Now, people want more handy products to buy and use. Similarly, if you deliver your goods in user-friendly flexible pouches, sachets, and stick packs. It will surely make a room in the heart of every consumer to pick them from market shelves and take wherever they want.

Strength

Candy can-Picture Courtesy: os-design.ru

Another question arises from your concern regarding product safety. If the packaging strength, durability, and content safety seem more important to you than the cost. So, rigid packaging would be the right choice.

Superior Packaging

If you want your goods to be displayed as fascinating, valuable, and robust, expressing the elegancy of your brand, then you should go for rigid packaging.

Conclusion

To end up the discussion, we are sure, that this blog has enabled you to better answer what is the difference between rigid and flexible packaging. Not only this, but understanding in depth the categories of rigid and flexible packaging, their pros and cons, environmental sustainability, and most essentially the customer proclivity, are all key figures which every successful manufacturer must explore. So, what's your next step after exploring them? Take time to plan your budget, packaging requirements and go on the right track. In case you find any difficulty, feel free to ask for help!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours