Honey Bottling Machine: The Complete Buying Guide In 2025

Honey is one of the naturally produce viscous substance that is made by a group of bees. This honey is filled and stored into certain bottles by a highly efficient honey bottling machine. Around the globe honey is being consumed as a food product and also for various other reasons. But with the increase in its global demand, manufacturers are now using highly versatile honey bottling machine to provide hygienic and pure product to their customers.

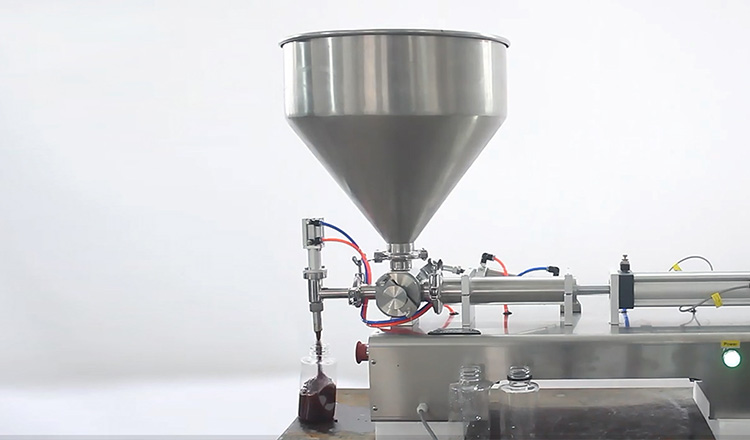

Semi-Automatic Honey Filling And Bottling Machine - Picture Courtesy: Filling Machinery

If you are also interested in buying a Honey Bottling Machine, this buying guide will provide you complete assistance regarding it. Read the complete blog to get the most of it.

1.What Is A Honey Bottling Machine?

Honey Bottling Machine- Picture Courtesy: MAKWELL MACHINERY

Honey is naturally produced with high viscosity and inner bond strength. To deliver honey products in a highly customized manner and with greater productivity, honey bottling machines are used in many industries these days. Honey bottling machine is designed to allow accurate, hygienic and efficient filling and bottling of honey.

2.What Are The Applications Of A Honey Bottling Machine?

Keeping in view the current requirement of a honey bottling machine, there are numerous applications of it according to its usage. Some of the applications of a honey bottling machine are

Artisanal Honey Producers

Artisan Honey Industry- Picture Courtesy: Wares of Knutsford

The most basic application of a honey bottling machine is done by the artisanal honey producers. The producers are mostly focused on the quality of honey and its packaging that is to be delivered to the customers. The artisanal producers carry highly accurate semi-automatic and fully automatic honey bottling machines to meet their quality requirements and having no compromise in the end product.

Food Industry

Honey Food Industry- Picture Courtesy: News Medical

These days honey from natural farms and gardens are collected and then delivered to specific food industries. The industry is fully equipped that they gather the honey and process it according to different standards so that the customer receives the best product. After complete refining, filtering and hygiene processes, various types of products including highly viscous honey is bottled accurately by using a honey bottling machine. Labeling is applied on the final product and is then packed to give it a more pleasant look.

Pharmaceutical Industry

Honey Filling Machine - Picture Courtesy: VKPAK

Naturally honey contains antioxidants like polyphenols, glucose, oxidase, osmotic effects, vitamins, minerals and other important ingredients that are used in several medicines to cure human life. Pharmaceutical industry uses these chemicals from honey and packs them using a unique type of honey bottling machine.

Also, different types of syrups, gels, ointments, suspensions and fillers that have high viscous properties are filled in a pharmaceutical industry using a honey bottling machine.

Cosmetic Industry

Viscosity Liquids - Picture Courtesy: Filamatic

Honey bottling machines are also applied in chemical and cosmetic industries for filling and packaging of different products. Mostly skincare products like lotions, creams, hair gels, serums, liquid foundations, peel off masks and dermal fillers are filling in different types of packaging using a honey bottling machine.

Bakeries

Honey Cake - Picture Courtesy: Lals Chocolate

On a very small scale, honey bottling machines are also used in bakeries and apiaries where they fill small jars of glass with honey and directly offer to their customers. The packaging and filling processes are usually carried out in front of the customers that attracts them and also proves the hygienic of the facility.

3.What Benefits Can We Get From A Honey Bottling Machine?

Honey bottling machine is an amazing invention of science and an outstanding technology. The machine is of greater usage and with several advantages. Some of the benefits that can be get using a honey bottling machine are

Consistency

Honey Filling Solution - Picture Courtesy: CUBII

The most important benefit that can be taken from a honey bottling machine is its consistency regarding product quality and composition. Special types of hoppers and filling lines are installed in a honey bottling machine that allows the travel of honey efficiently. This honey is then filled into the jars and cans with a consistent flow that is always important to maintain the standards of quality in each spoon.

Efficiency

Automatic Honey Filling Machine - Picture Courtesy: Pratik Enterprises

Honey bottling machine can cope up with both small- and large-scale industries due to its efficient working and automated processes. The operations are done both manually and automatically depending upon the productivity and are designed according to it. The liquid is filled in an efficient manner so that now jars gets broken while the process continuation.

Hygienic Packaging

Maintaining Hygiene - Picture Courtesy: Plant And Food Research

The whole world these days is concerned in having hygienic products in their consumption. As honey and other liquid are directly consumed by humans, it important to have products that contain no bacterial or microbial symptoms. Honey bottling machine assures that now such particle gets into and provides a sealed pack packaging to it. The packaging also remains safe and secure even if transported to large distances.

Accurate Filling

Automatic Honey Filling Advantage - Picture Courtesy: MAKWELL MACHINERY

Each bottle or jar filled by a honey bottling machine has an accurate weight according to the requirement and no product differs from the other. Even if various types of jars or bottles are handled in the machine, the filling remains accurate in each.

Shelf Life

Storing Honey

Tight and air packed seal packaging offered by the honey bottling machine ensures that no environmental influence may occur within the packaging. This directly leads to an extended shelf life of products and allows the consumer to use it for a longer period.

Product Branding

Modern Beekeeping Honey Cake - Picture Courtesy: Kilimo News

Honey can be consumed directly from combs located in different farms and gardens. But filling of honey in special types of bottles using honey bottling machine makes the manufacturer to brand its product globally. The products are with brand name, location, product ingredients and other information that helps the consumer to get easily familiar of it and also the manufacturer to trace their products.

4.What Is The Working Principle Of A Honey Bottling Machine?

Honey Bottling Machine - Picture Courtesy: Universal Filling Machine Co.

Like other bottling machines, honey bottling machine also has a common working principle to filling and pack different types of bottles and jars. The only difference remains in the type of hopper and filling lines due to the viscosity of honey and other products. The machine operates in following steps.

In the initial step the hopper of container present at the top of a honey bottling machine is cleaned and filled with the desire product that is to be filled. Mostly these containers are made up of stainless steel to avoid contamination.

In the next step the containers, jars or bottles are placed on the conveyor to feed into the system. First cleaning of their inner surface is performed and then they are moved to filling station.

A honey bottling machine has an internal pumping system that allows the dispense the of viscous liquid. Once the container reaches the filling nozzles, these pumps get activated and release the liquid into the containers. The special thing is that accurate volume of dispensed is carried out in this step as predefined.

Once the containers are filled the anti-drip mechanism clear the leftover viscous liquid from the face of nozzle to avoid any wastage and maintainingspotlessness in the system.

After filling of containers, sealed pack capping is provided onto the top of these containers by capping machines so that the liquid remains active for greater duration.

Some of the honey bottling machine also apply labels and do induction sealing on containers to provide water proof and contamination free packaging solutions.

5.What Are The Main Components Of A Honey Bottling Machine?

Honey Bottling And Filling Machine

A honey bottling machine is equipped with highly advanced and modern technology components. Each of the components have their own specific job to performing the bottling procedure. These components are

Liquid Level Control

Liquid level control is the part the is responsible to manage the level of honey in both hopper and containers. It helps in preventing the overflow of honey and also eliminates the chances to underfilling. Makes accurate filling possible to make a sync production setup.

Up And Down Step Motor

In a honey bottling machine, the step motor is used to control the systems in and outflow both. It supports in efficient movement of honey while they are being filled in hopper or in containers. The step motor is highly automated and fills the container in an accurate manner.

Hopper

The most unique thing in a honey bottling machine which differs it from other bottling machine is its hopper or filling containers. Various types of mixing and filling hoppers are available there according to their usage and material composition. A mixing hopper ensure that the composition of product remains consistent throughout the filling processes and no any effect in material thickness occurs.

Material Barrels

Material barrels are designed according to the viscosity of product. The motor and pump allow the honey move from the hopper towards the filling nozzle through these material barrels. The valves at the open and close side of material barrels continuously work according to the situation.

Conveyor

The conveying system in a honey bottling machine is responsible to feed the containers into the washing and filling system and also to carry them back out of the system after complete processes are performed. It is actual responsible for the movement of container within the system. The speed of a conveyor depends on the requirement of production.

Electrical Box

The main control of a honey bottling machine is present in the main electrical box. It allows the system to start its operation and monitor all the situations in current scenario. It contains PLC, emergency stop, conveyor speed control and powers switches and has a direct human access for controlling and monitoring.

Bottle Gate And Hold Device

When the container or bottles enters the filling station of a honey bottling machine, both the gate and hold device gets activated. The gate allows the entrance of these bottles whereas the hold device stops it tight beneath the nozzle so that no wastage or spillage occur.

Anti-drop Pneumatic Nozzle

Some of the honey bottling machine have an advance feature of anti-drop mechanism. This mechanism ensures that the viscous liquid that is left on the filling nozzle after filling process is properly cleaned and returned back to the filling line. This mechanism prevents any type of material wastage that makes the system cost effective.

6.What Are The Types Of Honey Bottling Machine?

There are different types of honey bottling machine according to their automation and working procedures. Some of the types of a honey bottling machine are

According To Automation

Manual Honey Bottling Machine

Manual Honey Bottling Machine

A manual honey bottling machine is significantly used in small and household industries that have low productivity requirement. It can be single handedly handled in all filling, capping and sealing procedures.

Working Principle

Initially the bottles are placed under the filling nozzle by the operator.

It manually operates the main panel and allows the filling of container. Once the filling is performed the operator removes it and performs the capping procedure.

Lastly, the labelling or customizations are done once airtight sealing is performed.

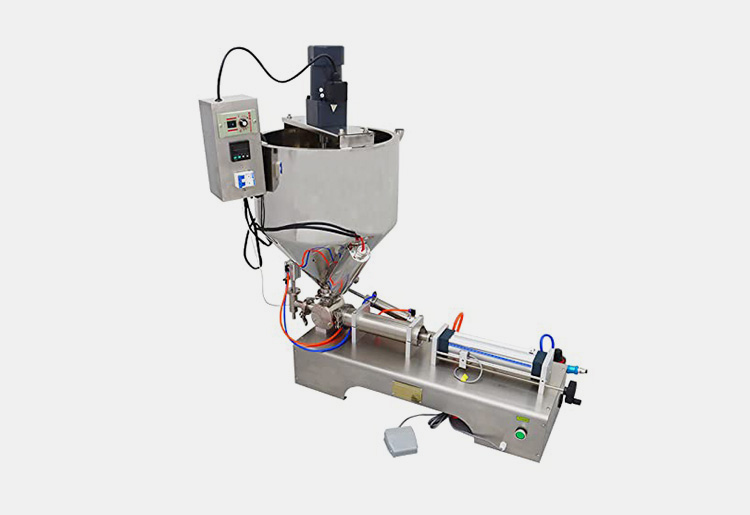

Semi-Automatic Honey Bottling Machine

Semi-automatic Liquid And Paste Filling Machine

A semi-automatic bottling machine involves both manual and automated operations. Most of the machines are used in medium and large-scale industries. Machine have hopper placed above the machine and a conveying system for traveling of containers.

Working Principle

Initially the bottles are placed on the conveying system by the operator. Usually cleaning is also done by the operator.

The bottles travel through the filling, capping system on the conveying system.

Once the filling and capping is completed the operator removes it from the system.

Fully Automatic Honey Bottling machine

Automatic Paste Filling Machine - Picture Courtesy: Taizy Packaging Machinery

Industries with large scale production requirements usually prefer fully automatic honey bottling machines to meet their productivity with effective quality. These machines have an ability to fill numbers of containers in no time.

Working Principle

The machine is designed in a way that the manual intervention is reduced to nearly zero. The containers are automatically fed to the system and move by highly precise conveying system.

Complete washing, filling and capping procedures are carried out automatically and then come out of the system by the same system.

The quality remained controlled in each process and also the production is achieved without any damage to the containers.

Once any abnormality occurs the system shuts off automatically.

According To Processes

Vacuum Honey Bottling Machine

Stainless Steel Honey Vacuum Processing Machine

A vacuum honey bottling machine is an advanced type of bottling machine that has a hopper on its top and drains the honey by creating vacuum in the filling lines. It is mostly used due to its precision and accurate filling mechanism.

Working Principle

Initially the hoppers are filled with viscous liquid and as the name suggest, it creates vacuum with the assistance of atmospheric pressure and uses it for drawing the liquid.

Once the bottle reached under the filling nozzle, the valves operate and releases the liquid into it.

Complete filling of containers is then checked by highly advanced sensors and then airtight sealing is applied on it.

Finally, the finished container is received at the output side and packed for transportation.

Piston Honey Bottling Machine

Honey Piston Filling Machine

Piston honey bottling machines work on the to and fro movement of pistons present in the cylinders of system. The movement supports the dispensing of both thick and thin liquids for medium and large-scale industries.

Working Principle

The hoppers are firstly filled with the filling material and then allowed to travel in the filling lines.

Once the piston starts its movement, the material is dispensed from the nozzle to the container.

As it reaches its maximum defined limit, the piston stops the operation and controlled filling is performed.

Completely filled containers are then checked by highly advanced sensors and then airtight sealing is applied on it.

Finally, the finished container is received at the output side and packed for transportation.

Pressure Honey Bottling Machine

Pneumatic Honey Bottling - Picture Courtesy: ApiHex

Pressure honey bottling machine also a similar principle like vacuum bottling machines. The filling of containers is done by creating an internal pressure that allows the flow of material.

Working Principle

After filling of hoppers, the containers are fed into the system and moved by a conveying system.

The internal pressure created in a pressure honey bottling machine allows the material to flow in the filling lines and reach the filling nozzles.

Here the dispensing is firmly controlled and also the excess material is allowed to travel back to the hopper.

Once the containers are filled and checked properly, they are advanced towards the application of airtight sealing which prevents the entrance of microbes.

Finally, the finished container is received at the output side and packed for transportation.

Gravity Honey Bottling Machine

Gravity Filling Machine - Picture Courtesy: World Star Engg.

The filling lines of a gravity honey bottles are filled with the help of earths gravitational pull. The machine completely relies on natural phenomenon and are very economical due to this

Working Principle

The viscous liquid present in the hopper tank of a gravity honey bottling machine is travelled towards the filling nozzle by gravitational pull.

As the containers are received in the filling station, the nozzle automatically releases the liquid into it and shut the valves when they reach to their maximum limit.

The containers are completely filled and checked properly so that they can be advanced towards the sealing application.

Finally, the finished container is received at the output side and packed for transportation.

Rotary Honey Bottling Machine

Rotary Type Honey Filling And Sealing Machine - Picture Courtesy: INTELTEK

Unlike other honey bottling machines, a rotary honey bottling machine has rotating platform where multiple of containers are filled at a single time. The centrifugal force allows the movement smoothly and prevents any collision. These types of honey bottling machines are usually used in high scale industries.

Working Principle

The containers with the help of a conveying system are moved towards the filling system where multiple containers attach to a rotating platform.

The filling material is then released into these containers at the same time. The jaws that attach the containers then release them once the filling is completed.

The filled containers then advanced towards the sealing application and then received at the end for packaging purpose.

Overflow Honey Bottling Machine

Overflow Filler - Picture Courtesy: Liquid Packaging Solutions, Inc.

An overflow honey bottling machine has a unique property that is collects the liquid that has been overflowed or dispensed in access and taken back to the hopper tank. Irrespective of the viscosity, the liquid is travelled back into the hopper to avoid any type of wastages.

Working Principle

The viscous liquid present in the hopper tank travels from the hopper towards the filling nozzle initially.

Once the filling of these containers is completed, the conveying system moves the container towards the sealing application.

The leftover and remaining liquid then travels back to the hopper by a proper overflow mechanism.

The containers are then automatically fed to the offloading side and then offered for packaging.

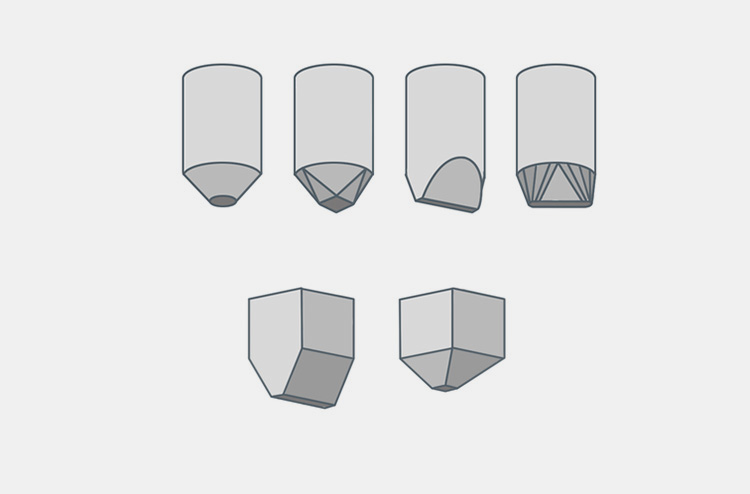

7.What Are The Different Types Of Hoppers Used In A Honey Bottling Machine And How Are These Hoppers Filled?

A honey bottling machine depends a lot on the properties, size and shape of a hopper tank due to the viscosities of different materials. Some of the common types of hoppers present in a honey bottling machine are

Pressurized Hopper

Pressurized Hopper – Picture Courtesy: GST Automation

Pressurized hoppers are ideally used in a honey bottling machine as they create pressure for material that have poor fluidity rate. Honey also being a less dense material is travelled efficiently using this type of hopper.

Stirring Hopper

Vertical Stirring Hopper

Materials with sediments like honey, oil or paste can ideally be filled in a stirring hopper. Here the material is stirred continuously in a way that the material remains uniform without any lump or impurity.

8.What Are The Auxiliary Machines Associated With A Honey Bottling Machine?

There are many auxiliary devices that support the operation of a honey bottling machine and make a product look pleasant to the customer. Some of the most commonly used auxiliary devices are

Honey Bottle Unscrambler

Automatic Turntable Unscrambler - Picture Courtesy: Lyson Beekeeping

Surprisingly a honey bottle unscrambler is a machine that is used in many of the automated processes where it simply classifies the containers into their groups. It lets them to be transmitted to the system in a proper way so that no collision or breaking appears.

Hot Air Circulation And Sterilization Oven

Hot Air Circulation Sterilization Oven - Picture Courtesy: SUNTER MACHINERY

The jars, bottles or containers are sterilized at a certain temperature in a hot air oven where they are treated in three different temperature zones. This removes the impurities and make them sterilized.

Bottle Washing Machine

Honey Bottle Washing Machine

The bottles before sterilization are washed at a high temperature by rinse and pure water in a bottle washing machine.

Capping Machine

Pneumatic Capper

A capping machine is almost found along with each type of honey bottling machine and sometimes an integral part of it. Here the filled bottles, jars, containers or pouches are capped using force, screw and induction sealing principles. The machine also creates vacuum inside it so that no environmental particle can enter in it.

Labeling Machine

Labeling Machine - Picture Courtesy: HD Process NZ

The capped bottles and containers are labeled with manufacturers logo, name, details, ingredients, composition and other information on their outer surface with the help of a labeling machine. It is mostly controlled by an automation system that controls its display and design.

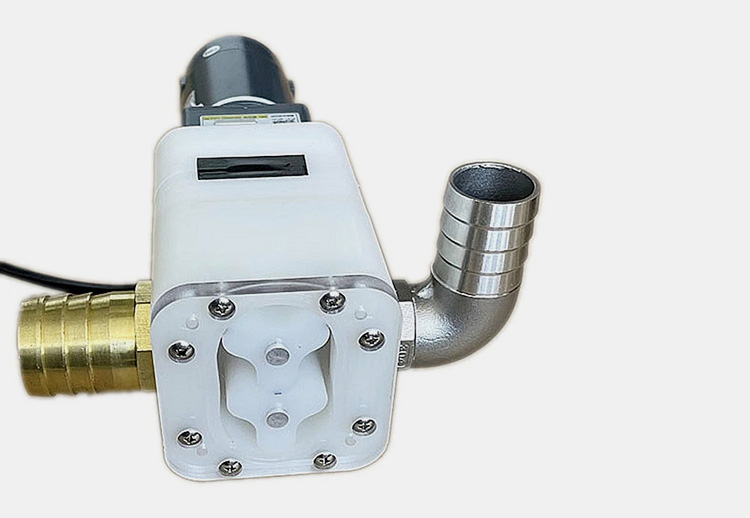

9.How Honey Bottling Machine Cope Up With Different Viscosity Of Honey?

Honey bottling machines are highly advanced that they can cope up with number of different measures of viscosity. As there are different types material composition and specifications, a honey bottling machine has an ability to perform accurate filling on all these scenarios due to

Pump Systems

Honey Filling Machine Gear Pump

Pump systems are the ones that makes a honey bottling machine stand out among others. It allows the system to maintain a pumping pressure in the hopper to make the liquid remain with original properties for a longer period. This can be set according to the material and differs for each.

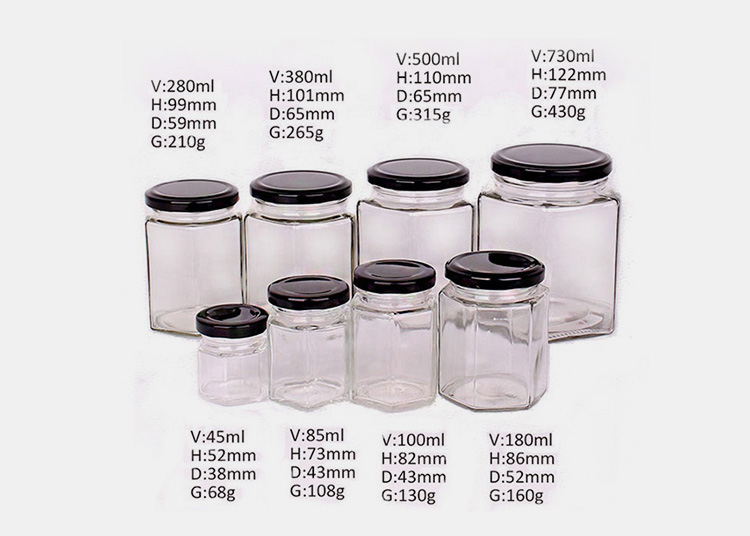

Adjustable Filling

Different Size Glass Jars- Picture Courtesy: OLYCO

Other than pump system, the adjustable filling mechanism for different size of containers and viscosities is also one of the features of a honey bottling machine. This not even disturbs the composition and keeps consistency in the system.

Heating System

Heated Honey Bottling Tank - Picture Courtesy: Betterbee

In some of the honey bottling machine there is a heating system that helps in reducing the viscosities of liquid material that become thick due to any external impact. Crystallized honey can be tackled in better way using this unique heating system.

Different Types Of Hoppers

Hoppers - Picture Courtesy: Labster

No any bottling machine can cope up with different types of bottling machine other than a honey bottling machine. This allows to fix any types hopper according to its usage and material viscosity.

Conclusion

Consumption of honey has increase in all sectors these days. To achieve the global requirement and standards, honey bottling machines are widely used in various industries. This is why manufacturers should gather complete information before going for a honey bottling machine. If you are interested in a honey bottling machine we Allpack are here for your assistance and to provide you more information 24/7. Feel free to contact our representative if you stuck at any situation.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide