Freeze Dried Packaging: The Complete FAQ Guide In 2025

You may be well familiar with the vary techniques employed for preservation of food products. However, the traditional method of drying foods which brother you to wait for weeks and even months to get your food dry is fading away. Its place has been taken over by innovative means gifted by the modern technology. Among them, the quicker, convenient, and effective technique is freeze drying. Do you also agree? If yes, you must be associated with freeze drying and probably, scrolling down to discover the trends for your freeze-dried packaging!

So, let us introduce you with this informative FAQ guide by Allpack which is designed to help you out in attaining awesome freeze-dried packaging. Not only that, but we will also disclose the changing requirements for freeze dried packaging, how you can uplift your freeze-dried packaging, and get admiration from customers across the globe. Let's, begin reading it!

1.What Is Freeze Dried Packaging?

Fruits & vegetables freeze drying-Picture Courtesy: survival-mastery.com

Freeze drying refers to the drying of multiple types of food items including fruits, vegetables, and even drugs through the method of dehydration. It involves freezing products into a freeze dryer after which the water present in these products is removed out via sublimation and absorption respectively. Now, these goods can be used for a longer period as the dehydration process inhibit spoilage and extend their storage life.

To keep them in their original condition and restrict moisture, air, and temperature, it is necessary to securely pack these freeze-dried items in safe packages such as jars, containers, bags, and boxes etc. Similarly, this process of packaging will be termed as freeze-dried packaging.

2.Which Products Are Eligible For Freeze Dried Packaging?

Drying is one of the oldest means employed for preservation of foods. However, with advancement in technology, freeze drying has made it more convenient. Now, you can horde multifarious products by using freeze dried packaging. Some of these are described below:

Vegetables & Fruits

Multiple freeze-dried fruits-Picture Courtesy: mashed.com

Fruits and vegetables are the most wanted products which are necessary for our survival. However, due to their perishable nature, they get spoil quickly. To tackle this issue, dried freeze packaging technique is now popularly applied to prepare adequate products for emergency condition, tourism, or camping etc.

Ready to eat Meal

Readymade freeze-dried packaging-Picture Courtesy: dogsmeal.com

Ready to eat meals are always best for saving your time, getting rid of hunger, and healthier to consume. This is the reason, why prepared meals are commonly freeze dried and packed in beautiful and sturdy pouches, boxes, and bottles etc.

Seafood

Freeze dried seafood Picture Courtesy: hk.pinkoi.com

Seafoods such as fish, shrimp, octopus, and salmon etc., are rich in proteins, vitamins, and minerals. Most of the landlocked countries with no fishing spots also want to have access to seafood. That's where freeze dried packaging come into use to fulfill these desires.

Ice Cream

Freeze dried orange bar-Picture Courtesy etsy.com

It may be weird to think ice cream as dried, but yes! It's a fact. Multiple types of ice cream like fruits bar, chocolate bar, and cookies ice cream are freeze dried after which they are packed in various packages including doypacks, and pouches.

Pet food

Freeze dried duck chest dog pet treats-Picture Courtesy: petbesty.com.au

Pet food processing industries use diverse means to provide pet owners with treats and food for cats, and dogs etc. Therefore, they use freeze dried packaging for preserving the freshness of pet food.

Drugs

Freeze dried drugs in vials-Picture Courtesy: drugtargetreview.com

Due to the excessive demand for drugs, especially, since COVID-19, freeze drying method is commonly applied for storing vaccines, injections, and other drugs. Therefore, drugs also come under the umbrella of freeze-dried packaging application.

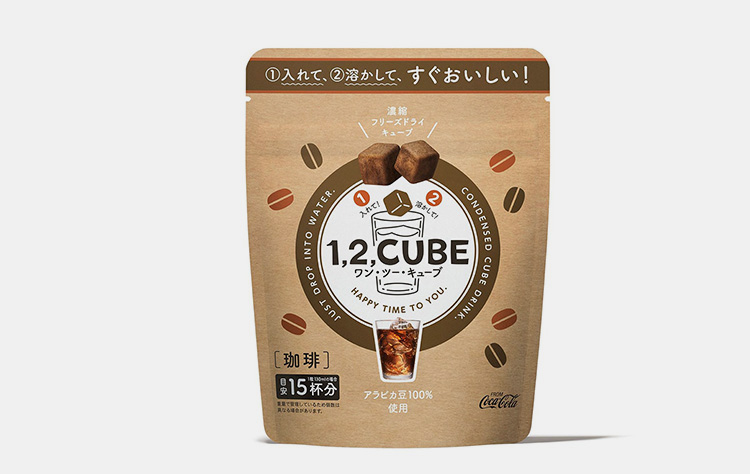

Drinks

Freeze dried coffee cubes-Picture Courtesy: hypebeast.com

Although, freeze drying is prioritized for solid food products in one way or another, it may also be used for different types of drinks such as beverages, alcoholic drinks, milk, and coffee etc. Hence, you can enjoy your favorite drink anywhere you want just by taking a small, freeze-dried cubes pouch with you.

Apart from above-mentioned products, other goods including grains, legumes, eggs, and meat are also delivered in the form of freeze-dried packaging.

3.How Does Freeze Dried Packaging Influence The Quality Of Your ProductsAnd Benefits You?

It must be clear to you, that mere freeze drying is not going to keep your products intact, but you must have to go for packaging which will ultimately take you to meet your ends. So, let's know how freeze-dried packaging influence the quality of your items:

Strong Barrier

Moisture & light proof Standup pouch display-Picture Courtesy: bowepack.com

Freeze dried packaging create a strong barrier against moisture, light, and air which restrict the entrance of air, oxygen, and discoloration of products. In turn, water content and light cannot decrease the crisp of your freeze dried products, and there will be zero chance for bacterial growth.

Shelf Life

Dried freeze fruits shelf life in jars-Picture Courtesy: commonsensehome.com

Another most dominant influence of dried freeze packaging is the extension of product safety and edibility for longer period.

Tangible protection

Durable freeze-dried packaging bag-Picture Courtesy: dhgate.com

Last but not least, freeze dried packaging protect your goods from all types of physical damages including distortion, compression, and tampering by establishing durable and flexible safely wall around them.

Marketing

Freeze dried strawberries pouches presentation idea-Picture Courtesy: packagingoftheworld.com

To acquire customer trust and recognition in market, manufacturers have to spend their good share of earnings, which is, however, not feasible for new and medium to small businesses. Thus, freeze dried packaging is providing the most affordable and quick alternative to brand your goods across the globe.

Coffee bottle display-Picture Courtesy: Pinterest

"People buy with their eyes first", a common idiom almost everyone is familiar with. What about you? Obviously, you will also be its believer, and want to apply it for your business success. And this becomes possible when you use appetite freeze dried packaging with mouth watering designs to catch the consumers' attention towards your products.

Consumer Convenience

Easy to open chips bag-Picture Courtesy: wonderkindco.co

It is a matter of fact, that all producers want to keep their customers happy by delivering their materials in convenient packages. This aim can be perfectly achieved by using versatile freeze-dried packaging such as zipper pouches, tear notch doypacks, and resealable containers etc.

4.Enumerate The Eclectic Packaging Formats For Freeze Dried Packaging?

Below is the comprehensive description for various freeze-dried packaging formats:

Bottles

Freeze dried strawberry yogurt bottle-Picture Courtesy: rockyandmaggies.com

Bottles are characterized by their narrow neck and a lid over them. They are either made from glass, bottles, and in some cases paper as well. Manufacturers who want to deliver their freeze-dried products in beautiful packages and at the same time cutting packaging costs, so, bottles are the most suitable to use.

Cans

Freeze dried banana can-Picture Courtesy: amazon.com

Cans are metallic containers made from any of three core materials including aluminum, tin, or coated steel. They are highly compact and support hermetic sealing which adds to the greater protection of freeze-dried foods both in solid and powder form. This is the reason; reputable brands prefer advertising their goods through assorted cans.

Jars

Freeze dried vegetables dispersing from jar-Picture Courtesy: homesteadinginohio.com

Jars are smooth containers with glass as a core structural component. They give appealing sensation by displaying all sorts of freeze-dried food from fruits to drinks, snacks, and nuts etc., while laying on the shelves.

Standup Pouches

Freeze dried standup pouches-Picture Courtesy: ilasacademy.com

Standup pouches are also called doypacks which are famous for their ability to stand erect on their bottom. Several layers of plastic and aluminum constitute their body which ultimately give them higher barrier protection against environmental elements. Freeze dried fruits laying in standup pouches look attractive and are easy to carry due to their flexibility.

Pillow Pouches

Freeze dried beet pillow pouch display-Picture Courtesy: packagingoftheworld.com

Pillow pouches are most economical and flexible packaging bags with high resemblance to pillow. They have top, bottom, and a back sealing which greatly protects your freeze-dried products against all types of damages. Sterile freeze-dried products such as fruits, vegetables, and pet treats are often packed in pillow pouches, so that, their structural integrity could be well retrained.

Gusseted Pouches

Gusseted pouch display-Picture Courtesy: made-in-china.com

These pouches are well known for the added gussets to pouch sides and bottom which extend their storage capacity. Hence, whether its bulk freeze-dried fruits, vegetables, or milk powder, all can be delivered in these convenient bags.

Sachets

Freeze dried milk powder sachets- Picture Courtesy: CBC International

Sachets are precise size plastic pouches with 3 or 4 side sealing. They can hold little amount of freeze-dried food and medicine powders which can be consumed within a single sitting.

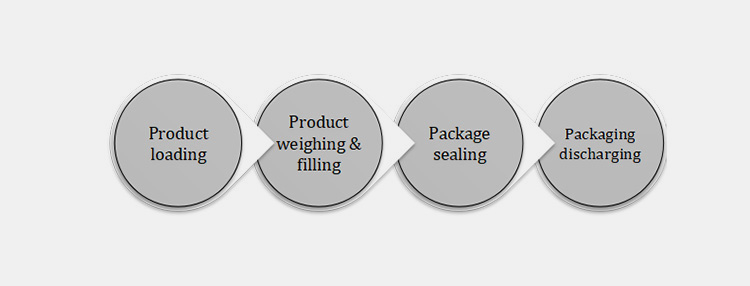

5.Describe The Process Of Freeze Dried Packaging?

The procedure of freeze-dried packaging is as follows:

Product Loading

Freeze dried coffee beans loading into hopper-Picture Courtesy: duropackpackaging.com

This step involves supplying the hopper of machine with abundant freeze-dried goods, so that, machine will process it further.

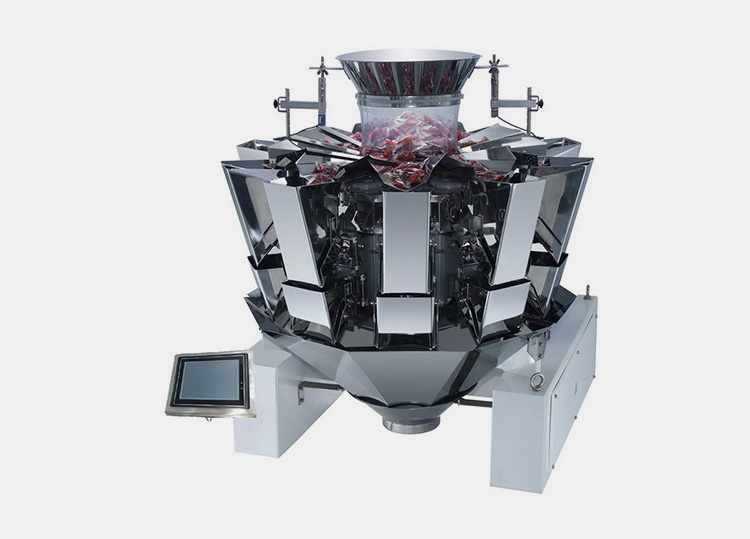

Product weighing & Filling

Freeze dried coffee weighing process-Picture Courtesy: all-fill.com

Now, the freeze-dried products are subjected to strict weighing phase, where exact amount of goods are measured as per the fix parameters. After that, the measured products are filled into bags and containers.

Package Sealing

Freeze dried coffee bag sealing process-Picture Courtesy: jdaprogress.com

Once, the packages get loaded, they are ready to undergo sealing phase. Here, multiple sealing methods such as heat sealing and pressure sealing are done in accordance with type of packaging.

Package Discharging

Finally, the finished freeze-dried packages are discharged out of the machine safely.

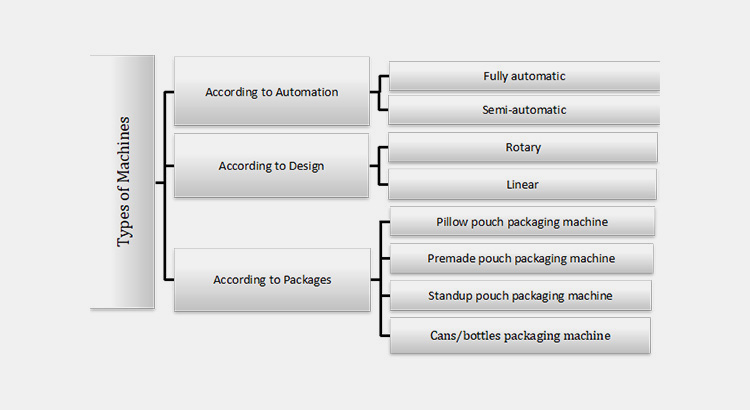

6.How To Begin Freeze Dried Packaging? Which Machines Are Required For Freeze Dried Packaging?

If you are new to the realm of freeze-dried packaging, and keen to embark on the successful business, then you must think on several crucial factors. Among them, the mostly confusing factor found is the selection of right machinery. Therefore, this question is particularly drafted to facilitate you in selecting the type of machine which suits you more:

According to Automation

Fully Automatic Freeze-Dried Packaging Machine

Fully Automatic Freeze-Dried Packaging Machine-Allpack

This machine is fully automatic in technology with exceptional performance in terms of speedy packaging of all types of freeze-dried products including fruits, vegetables, snacks, legumes, and powders. The machine has automatic processing with no human interference. Its complex structure with advance features makes it perfectly suitable for large scale industries.

Semi-Automatic Freeze-Dried Packaging Machine

Semi-Automatic Freeze-Dried Packaging Machine-Allpack

This semi-automatic machine by Allpack has integrated semi-automatic features which can precisely measure the very freeze-dried products and fill them into bags and containers. It requires operator intervention to load the machine with bulk freeze-dried products and perform placing and discharging of packages manually. Medium scale industries can better take advantage of this machine.

According to Design

Rotary Freeze Dried Packaging Machine

Rotary Freeze-Dried Packaging Machine-Allpack

This is a specialized machine with exceptional efficiency for freeze dried packaging in a rotary manner. The machine is automatic in nature and can pack all the products from grains to powders and snacks. It loads the machine hopper with bulk products and deliver to the main weigher. Similarly, fill, seal, and discharge freeze dried packages simultaneously in a rotary direction.

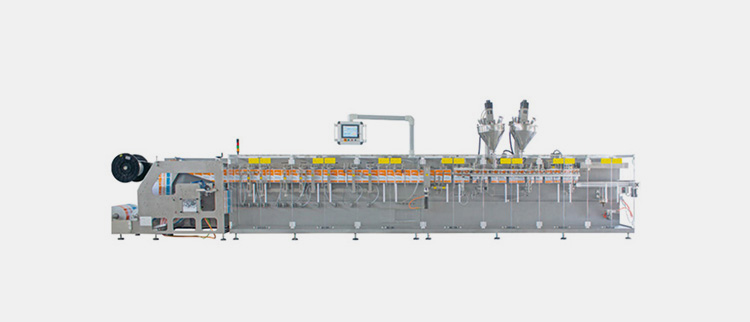

Linear Freeze-Dried Packaging Machine

Linear Freeze-Dried Packaging Machine-Picture Courtesy: gloex.net

Linear freeze-dried packaging machine is an inline, compact equipment that simply process your goods in a straightforward way. Such machines have been part of the production facilities for decades. All your containers and bags are here processed in a straight sequential order where observation becomes easy, and the machine is quite user-friendly to handle number of containers.

According to Packages

Freeze Dried Pillow Pouch Packaging Machine

Freeze Dried Pillow Pouch Packaging Machine-Allpack

The machine has been introduced in the market to flourish your freeze-dried packaging by safely pouring your goods into attractive pillow pouches. With vertical or horizontal structure, the machine consists of various components such as a conveyor, bag forming mechanism, film roller, sealer, and cutter etc. After turning on, it will automatically initiate pouch forming, product weighing, filling into pouch, pouch sealing, and ultimate discharging after cutting.

Freeze Dried Premade Pouch Packaging Machine

Freeze Dried Pre-made Pouch Packaging Machine-Allpack

This cutting-edge machine mainly consists of a z-shaped elevator, multi head weigher, filling head, conveyor belt, and control system. It works by moving bulk freeze-dried goods from tank towards weigher, after which goods are measured, filled into pre-made pouches, sealed tightly, and discharged by the conveyor. Producers who want to cut down the time spend on pouch forming, are the beneficiaries of this machine.

Freeze Dried Stand-up Pouch Packaging Machine

Freeze Dried Stand-up Pouch Packaging Machine-Allpack

This machine is resilient and multi-tasking in its processing. You can use it to form any type, size, and format of pouch and simultaneously use it for the filling and sealing of these pouches. Hence, you will not be bothered to accommodate the expenses of buying premade pouches.

Freeze Dried Cans/ Bottles/ Jars Packaging Machine

Freeze Dried Cans/ Bottles/ Jars Packaging Machine-Picture Courtesy: isywen.com

Ultimately, you are reading about the most desirable freeze-dried packaging machine which suits almost all packaging options including cans, bottles, jars, and pouches in some cases. Here, the process will be carried out via conveyor belt in fully automatic machine, otherwise, operator will place containers on stand which will be filled by the machine. Consequently, the ultimate step of discharging occurs after filling get completed.

7.Freeze Dried Vacuum Packaging Vs Freeze Dried Nitrogen Packaging? Which Is More Suitable?

Vacuum packaging and nitrogen packaging are different methods which are used for freeze-dried packaging. Most of the manufacturers get confused in deciding which packaging method is more appropriate for their products. Therefore, below table will be helpful in this respect:

| No | Factors | Freeze Dried Vacuum Packaging | Freeze Dried Nitrogen Packaging |

| 1 | Definition | Freeze dried vacuum packaging refers to the removing of air present inside the products filled bags and containers. | On the other hand, freeze dried nitrogen packaging can be defined as the process of replacing oxygen with nitrogen to restrict bacterial growth. |

| 2 | Process | It can be achieved by placing freeze dried goods in bottles or pouches, sucking out the air, and swiftly sealing packages. | The process involves filling freeze dried products in bags and containers, introducing nitrogen gas into packages, exerting out oxygen, left nitrogen gas inside, and sealing the bags. |

| 3 | Cost | Freeze dried vacuum packaging has low cost. | While as, freeze dried nitrogen packaging is a bit expensive as you have to use additional nitrogen gas for packaging. |

| 4 | Place covered | It covers less space and can be easily stacked together. | It requires more packaging space. |

| 5 | Suitable for | Freeze dried meat, chicken, and readymade meal. | Freeze dried vegetables, fruits, snacks, and pet treats etc. |

| 6 | Product Integrity | Although, this method is safe, but it may harm the structure of products. | On the other hand, it provides greater safety to maintain products integrity till end user. |

| 7 | Examples |

Dried-freeze vacuum packed meat-Picture Courtesy: Pinterest |

Freeze dried apple nitrogen packaging-Picture Courtesy: packagingoftheworld |

8.What Are The Container Integrity Tests For Freeze Dried Packaging?

In order to ensure that the freeze-dried products which you have packed in different containers are fully impermeable and protected, there are several tests which can be employed. These are described below:

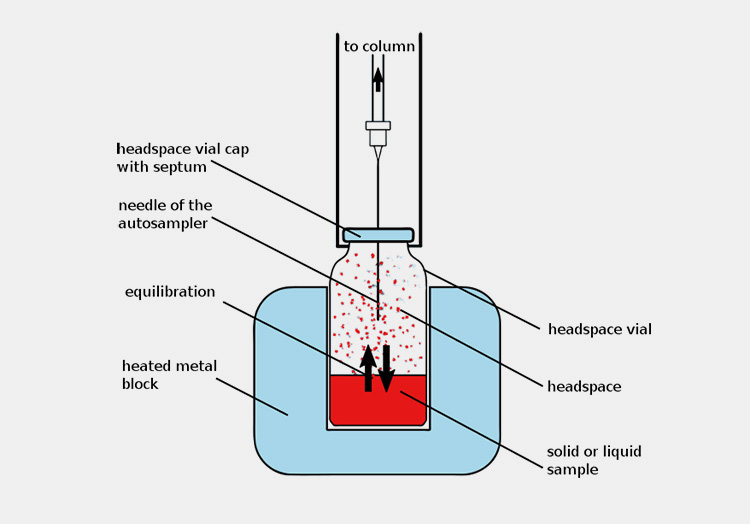

Headspace Gas Analysis

Headspace gas analysis-Picture Courtesy: blog.biomall.in

Headspace gas analysis let you know about the completion of nitrogen cleaning process for your containers by verifying, that no harmful gases such as carbon dioxide or oxygen are present in the head of freeze-dried packed containers.

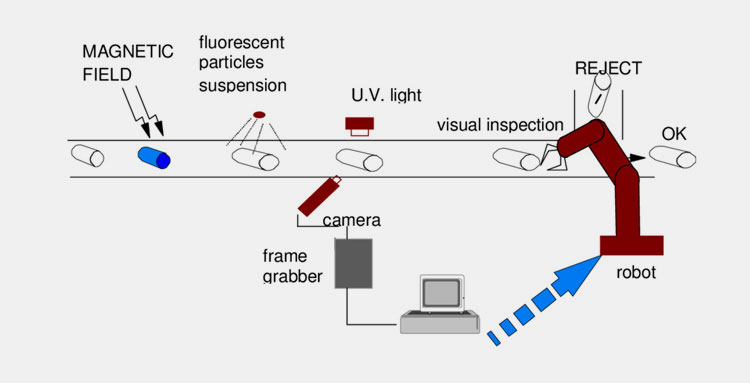

Automatic Visual Inspection

Automatic visual inspection-Picture Courtesy: researchgate.in

This method ensures that container containing freeze dried products is free from any sort of crack, leak, contamination, and dent etc. For this, multiple pictures of the container are taken and detected by the machine to examine container's integrity as well as check the presence of non-compliant constituents.

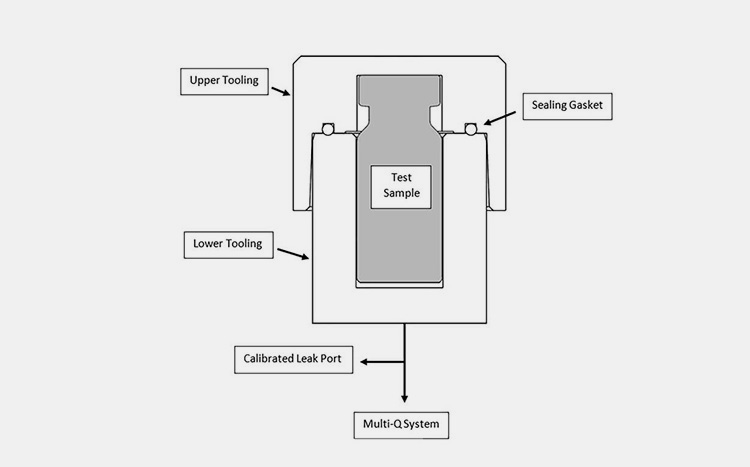

Vacuum Decay Method

Vacuum decay method-Picture Courtesy: sepha.com

Another test for assessing container integrity is vacuum decay method. Under this, a vacuum is used to suck all the air from containers which resultantly display if there is any hole or leak present in package.

9.Why Choose Allpack For Your Freeze Dried Packaging?

If you are haphazard in deciding which company is best, then you must consider Allpack, which offers you range of machines with cost-effective price, greater customization, and much more. Let's know them one by one:

Broad Spectrum

Here, you will be able to pick any type of freeze-dried packaging machine whether it is based on automation, orientation, filling heads, and most importantly the type of packaging containers and pouches you want. You can also align auxiliary devices with your main machine for getting extraordinary performance.

Customization

Freeze dried packaging multi head weigher-Allpack

Not only you can choose a machine, but you can also ask for desired customization. For instance, if you want to purchase a pillow pouch freeze dried packaging machine, but instead of simple elevator you want a multifunctional weigher, then you are always welcomed.

Warranty

One year warranty icon-Picture Courtesy: vecteezy.com

Allpack gives you a valuable opportunity to get your freeze-dried packaging machine with one year of warranty, which is sufficient to acknowledge that the machine is a product of high-quality tools.

Conclusion

We are concluding this discussion with a positive gesture, that you have finally got a general idea regarding every aspect of freeze-dried packaging. Freeze dried packaging is the most desirable packaging technique which have a good prospect in future as well. So, embarking on a freeze-dried packaging business will indeed open the doors of prosperity for you. Are you ready for that? If yes! Then let us know which machine is your choice. We will be glad to help you in this way!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide