Fruit Juice Filling Machine: The Complete Buying Guide In 2025

Fruits have been a type of beverage consumed around the globe for a long period. With the advancement in technology the filling of these juices is now done using unique types of Fruit Juice Filling Machines. To cope up with the global demand, fruit juice manufacturers are now transforming their filling procedures on both semi and fully automatic machines. But this is also confusing them in selecting the best type of machine.

Are you are interested in buying a fruit juice filling machine? This buying guide will completely help you in understanding what is a fruit juice filling machine and how can you get benefit from it.

1.What Is A Fruit Juice Filling Machine?

Small Scale Fruit Juice Filling Machine- Picture Courtesy: Fruit Juice Filling

It is an advanced type of filling machine that is used to fill both organic and carbonated fruit juices in proper packaging materials like cans, bottles, sachets and etc. Filled juice is then easy to handle and also transported efficiently around the globe. A fruit juice filling machine retains the quality and pureness of juice for a long period and helps the manufacturer to maintain its brand reputation.

2.What Are The Applications Of A Fruit Juice Filling Machine?

In a generalized manner, fruit juice filling machines are widely used in beverages, pharmaceutical, dairy and cosmetics industries. The application of these filling machines in these industries can be describes as

Beverage Industry

Fruit Juice - Picture Courtesy: King Beverages

With a very vital role, fruit juice filling machines are essential in beverage industry for filling of various types of fruit juices and their mixtures. The hygienic filling process and compact designs of these machines support beverages industry to perform high speed and accurate filling of fruit juices into variety of packaging. The machine consistently follows precision in filling of juice to maintain the quality and product standards.

Pharmaceutical Industry

Adult Syrup - Picture Courtesy: Pharmaceutical Packaging

Other than the basic role of a fruit juice filling machine, it also adheres production requirements in pharmaceutical industry. Different types of syrups and liquids for both babies and elder ones is filled using a fruit juice filling machine. The rigorous requirement of these pharmaceutical medicines is fulfilled with complete precision and hygiene according to the standards of regulatory authority.

Dairy Industry

Filling Lines For Milk - Picture Courtesy: GEA

Another distinct application of a fruit juice filling machine can be observed in dairy industry. Different types of dairy products including milk, flavored and infused milks are hygienically filled in a flexible manner using a fruit juice filling machine. Aseptic filling of dairy products is carried out that helps in long time product life and also keeps the product safe from being contaminated.

3.What Benefits Can We Get From A Fruit Juice Filling Machine?

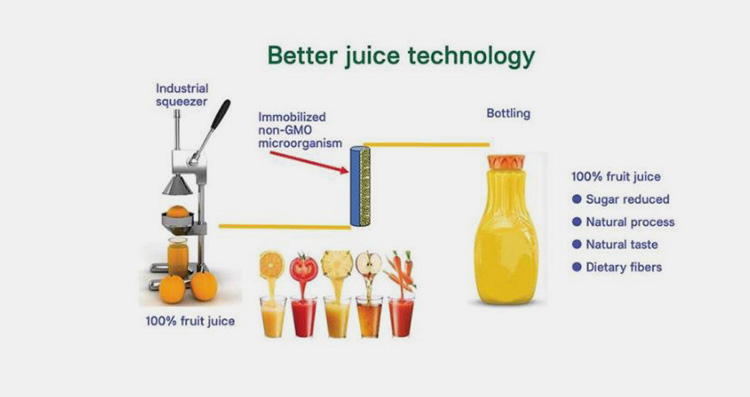

Better Juice Technology - Picture Courtesy: Food Engineering

In the modern era where automation has remarked the whole world, fruit juice filling machine has also stood to be one of the greatest inventions in terms of filling of liquid juices. Out of numerous advantages, some of them are

Accurate Filling

Mango Pulp Filling - Picture Courtesy: Bottle Filling Machines

The primary advantage of a fruit juice filling machine is that it gives accurate and precise filling of fruit juice at a large scale. The throughput of the system remains high and the overall efficiency of the system also gets greater by adding a fruit juice filling machine in the system.

High Productivity

Juice Production Line - Picture Courtesy: Bottle Beverage Factory

Fruit juice filling machines are highly versatile that they can manage large number of production targets in a small interval of time. The machine has ability that even in high production setups the quality and efficiency of the system remains the same so that each of the products is similar to other.

Product Hygiene

Machines are mostly made up or stainless-steel material that it supports the system to resist contamination and also provide a clean environment while filling of juice. One of the unique advantages of a fruit juice filling machine is that is also incorporates aseptic filling scenarios where temperature helps to decompose microbial organism. The bottles, cans and jars are treated at a very high temperature and pressure. This aseptic process of filling directly sterilizes the system and completely blocks the entrance of bacteria.

Product Shelf Life

Juice Manufacturer Process - Picture Courtesy: InterTech Processes

As most of the packaging is done under aseptic environment in a fruit juice filling machine, the chances of microbial entrance become 0% at real time. This increases the shelf life of a fruit juice and gives the customer a fresh impact even if used after a long time. Also, the cost of filling machine gives early return on investments so that the manufacturer can get greater profits for a longer period.

International Standards

Purpose of Standards - Picture Courtesy: Benefits of ISO

Fruit juices are directly associated with human life and requires greater concerns according to international standards and norms. The regulatory authorities of world can completely rely on the filling of fruit juices done by a fruit juice filling machine.

4.What Is The Working Principle Of A Fruit Juice Filling Machine?

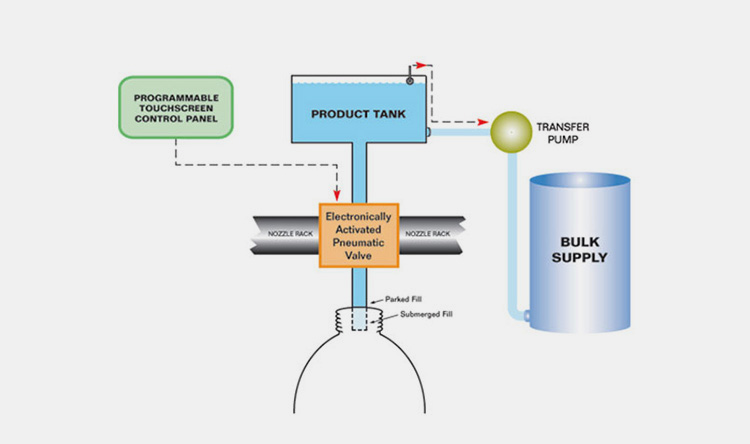

How Does A Gravity Filler Work- Picture Courtesy: KPAK

A fruit juice filling machine works in a highly precise and sophisticated manner. The machine is designed in a way that all the steps are performed systematically one after another and also with less human influence. Some of the basic steps involved in the working of a fruit juice filling machine are

- Empty bottles, cans or prepared pouches are initially introduced into the system where they are properly handles according to the moving mechanism.

- Bottles and cans are further washed so that the contamination can be removed and to ensure sterilization.

- While the washing process is carried out, the filling of hopper of tanks is done with the desired juice.

- The juice travels through different mechanisms and then reaches the filling nozzle where the process of filling is carried out.

- As the filling material reaches the filling nozzle, the juice product is dispensed out of it according to the machine mechanism. The flow stops efficiently as it reaches to its maximum level.

- Further these packaging materials are moved to capping, labeling and sealing steps.

5.What Are The Main Components Of A Fruit Juice Filling Machine?

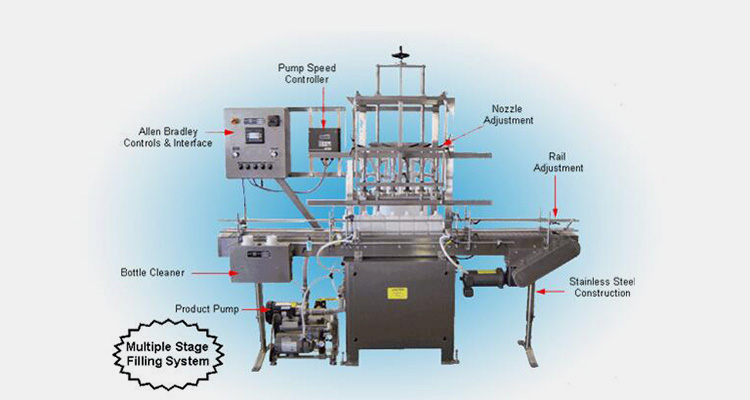

Components of A Filling Machine - Picture Courtesy: Aipak Liquid Filling Machine

Some of the main components of a fruit juice filling machine are

Conveying System

A conveying system of a fruit juice filling machine is responsible to carry the bottles from loading side and transporting it to the finish line after facing all the procedures. The continuous flow of system can only be ensured when the conveying system of the machine is working properly.

Bottle Cleaner

In some of the fruit juice filing machine, bottle cleaning is carried out at the initial stages by a proper bottle cleaner device. Here water at high pressure is inserted into the bottles so that any type of dust or contamination can be removed. The cleaned bottle is then proceeded to the next step for filling purpose.

Filling Nozzle

The most important part in a fruit juice filling machine is its filling nozzle. This is responsible to dispense accurate amount of fruit juice into bottles, cans or pouches. These nozzles are of high importance and needs to be checked after every production shift.

Hopper Tank

This is mainly present at the top of a fruit juice filling machine that holds all the fruit juice in it. This juice travels from the hopper tank to the filling nozzle by maintaining its quality and nature.

Quality Control Sensors

Some of the fruit juice filling machine also has quality control sensors that ensure accurate and complete filling of packaging material. Also, these sensors are used to detect object when kept under the filling nozzle.

Auto Cleaning System

In some of the situation, the fruit comes out of the bottle or s left in terms of spillage or dropping. This juice is then directly cleaned by an automatic cleaning system.

Human Machine Interface

A human machine interface is equipment that helps the operator to check and verify the real time conditions of production setups. It is mostly present at the front side of a machine so that the operator can check it freely. Speed controllers are also present in this HMI from where the conveying speed is set according to the production.

6.What Are The Types Of Fruit Juice Filling Machine?

There are number of fruit juice filling machines depending upon their working principle, construction style and productivity measures. Depending upon their requirements, different industries use different types of machines. Some of them are

Vacuum and Pressure Fruit Juice Filling Machine

Automatic Juice Filling Machine

The concept of a vacuum and pressure fruit juice filling machine is same as both the machine rely on the factors like vacuum and pressure respectively. The machine holds the filling mechanism in it and is suitable for highly precise filling production lines.

Working Principle

- Initially the tank is washed with pure fresh water and then filled with the filling juice.

- Once the packaging material is placed beneath the filling nozzle, the fresh fruit juice is releases by either comparing two relative pressures or is drawn out by proper vacuum pressure.

- Once the filling level reaches out to its maximum, the flow of juice shuts off and the system results in accurate filling.

- The packaging material is then further sealed and capped so that it can be used for a longer period of time.

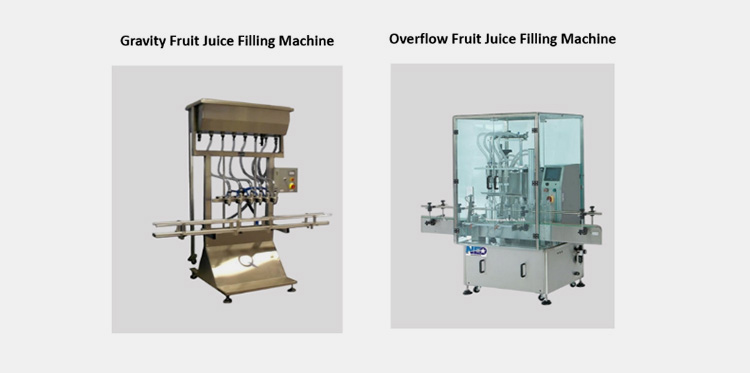

Gravity Fruit Juice Filling Machine

Gravity Automatic Filling Machine

A gravity fruit juice filling machine directly depends upon the force of gravity directly. The machine has a filling nozzle and an overhead hopper tank that holds the fruit juice that has to be filled. It is mostly suitable to the juices that have low viscosity and are suitable for small production setups.

Working Principle

- Initially the tank is washed with pure fresh water and then filled with the filling juice.

- The machine relies on the force of gravity and the juice travels from the tank towards the filling nozzle according to the same principle.

- The filling nozzle disposes off the juice into the placed bottles or cans and fills them up to the filling level.

- The packaging material is then further sealed and capped to preserve the juice from any microbial attack.

Isobaric Fruit Juice Filling Machine

Isobaric Filling Machine - Picture Courtesy: Equitek Filling Machines

As the name suggests, isobaric fruit juice filling machine also depends on the relative pressure comparison to fill fruit juice at a high accuracy. This type of machine is highly reliable in terms of quality and productivity measures as its construction stands odd in compare to other fruit juice filling machines.

Working Principle

- In an isobaric fruit juice filling machine, initially the hopper tank is washed with high pressure fresh water and is then allowed to be filled with the juice.

- Once the bottle reaches the filling nozzle, the juice is released and a relative pressure is inserted into the packaging material.

- This pressure is constantly monitored as it creates a pressure inside it to maintain the level of carbonation.

- The packaging material is then further sealed and capped so that the carbonated juice remains in same condition for a longer period and can be delivered throughout the globe.

Overflow Fruit Juice Filling Machine

Overflow Liquid Filling Machine - Picture Courtesy: Liquid Packaging Solutions

An overflow fruit juice filling machine is designed in a way that the filling of fruit juice is controlled a unique overflow mechanism. The filling of juice is done in a precise manner that no spillage or overflow is carried out in this type of filling machine.

Working Principle

- Initially the placement and washing of packaging material is done in an overflow fruit juice filling machine.

- In an overflow fruit juice filling machine when the packaging material reaches the filling nozzle precise volume of juice is dispensed into it without any overflow.

- In case any of the fruit juice comes out of the system, a return or overflow system is there which takes the juice back to the overflow chamber.

- The filled bottles are then moved to the further processes of capping and sealing.

Piston Fruit Juice Filling Machine

Piston Juice Filling Machine - Picture Courtesy: Piston Liquid Filling Machine

Piston fruit juice filling machines are well known for their accurate filling and volume control features. These machines work on the mechanism of piston movement and create internal pressure due to it.

Working Principle

- Same like other fruit juice filling machines, the hopper tank is washed initially and then filled with carbonated or non-carbonated fruit juice.

- As the packaging material is placed under the filling nozzle the piston mechanism gets started and moves to and forth at a constant speed.

- This movement of pistons creates an internal pressure and draws the fruit juice out of the filling nozzle.

- Accurate amount of juice is filled in these packaging materials and are then further sealed and capped to block entrance of external microbes.

Rotary Fruit Juice Filling Machine

Rotary Filling Machine - Picture Courtesy: Pharmaceutical Machinery

A highly versatile fruit juice filling machine with an ability of high-speed productivity in an accurate and efficient manner. Rotary fruit juice filling machine helps manufacturer to produce high volume of products in no time.

Working Principle

- In a rotary fruit juice filling machine, the bottles or cans move in a circular motion and are filled in the same manner.

- The fruit juice present in the hopper tank flows from the tank to the filling nozzle and is allowed only when the packaging material is senses.

- Once the packaging material is sensed the fruit juice is released from the filling nozzle and constantly fills it.

- These are then moved in the same rotary manner towards next steps and efficiently results in greater production outcomes.

7.What Are The Auxiliary Machines Associated With A Fruit Juice Filling Machine?

In large manufacturing companies, a fruit juice filling machine is usually present with auxiliary machines that support the process of filling. These machines perform their working procedures and generate a complete packaging solution. Some of them are

Fruit Juice Capping Machine

Once the filling process gets completed, the packaging bottles or cans are moved toward the capping machine where highly accurate air tight capping process is carried out. The sealing of caps is done in a way that it prevents leakages and also ensures that no bacterial or environmental influence in done into it.

Labeling Machine

Fruit Juice Bottle Labelling Machine - Picture Courtesy: Pharmaceutical Machinery

These bottles are then labeled with the manufacturers and packaging details using a labeling machine. The labeling of products makes their traceability easier and also helps in proper product identification. Manufacturer can also mention the product composition and its production batch on the label of a juice bottle or can.

Inspection Machine

In some of the fruit juice filling machine, an inspection machine is also present that helps in identifying the quality of finished products. It helps in determining any of the defects that the product carries.

Shrink Packaging Machine

As the bottles, cans or pouches are to be travelled around the globe, some of the manufacturers uses highly volatile shrink-packaging machines to pack the products in a uniform manner. These cartons are sealed in a way that the filled juice does not gets leakage during its travelling.

8.What Is The Difference Between A Gravity And Overflow Fruit Juice Filling Machine?

Both the machines are types of fruit juice filling machines but do you have any idea that is there any difference between both of these or not? The statement always gives positive words that there are differences in both of the fruit juice filling machines according to the design, usage and application. Some of the differences are

Operating Principle

A gravity fruit juice filling machine allows free movement of juice from holding tank to filling nozzle depending upon the gravitational force. The level is controlled by the filling process itself.

In an overflow fruit juice filling machine proper dispensing of liquid is carried out and the excess returns to the overflow chamber in an accurate manner.

Application

A gravity fruit juice filling machine is suitable for low production and low viscous setups.

An overflow fruit juice filling machine can cope up with both medium and high scale industries and also with the products of any viscosity.

Conclusion

Fruit juice filling machine is an advanced method to perform reliable, efficient, secure and accurate filling of fruit juices into variety of packaging materials. In this regard, the manufacturer should be completely aware of all types of fruit juice filling machine and invest in the one that can enhance its productivity and quality. If you are interested in investing in fruit juice filling machine, we Allpack are here to completely guide and help you in solving your queries. We are 24/7 available for your guidance and feel free to contact us.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide