Dried Herbs Packaging: The Complete FAQ Guide In 2025

Dried herbs spice up various cuisines and are a staple source of bringing taste to various cultures. Besides the food industry, dried herbs are also added in different herbal formulations in the pharmaceutical and nutraceutical industry. All their extensive use is attainable due to dried herb packaging. This packaging has prime importance in transporting herbs safely and damage-free to commercial industries as well as to end-users. Moreover, it also serves as a brand model for the promotion of dried herbs. The dried herb business is booming across the globe.

Do you want to start a dried herb business? Do to want to know about different packaging types for dried herbs?

Then this informative guide is solely compiled for novices and veterans in dried herb ventures.

1.What Is Meant by Dried Herbs Packaging?

Dried Herbs Packaging- Picture Courtesy: World Brand Design Society

Some herbs are rare and thus of high value. So, it is important to preserve such herbs for their lasting use. This is achieved by storing the dried herbs in the packaging. Dried herbs packaging is an enclosed system that fully wraps the dried herbs for their protection and containment.

The main purpose is to preserve the taste and aroma of dried herbs throughout the supply chain.

It aids in distributing, retailing, and transporting dried herbs. It is integral in maintaining the consistency and quality of dried herbs and keeping them in edible form till their expiry date. Different packaging formats like tins, jars, pouches, and boxes are used for packaging dried herbs.

2.Why Dried Herbs Packaging is Important?

Opened dried herbs are difficult to handle and transport. Moreover, they are prone to deterioration by various culprits present in the surroundings. Therefore, brands always use dried herbs packaging to keep their products safe.

A few benefits of dried herbs packaging are mentioned below:

Containment

Containment in Dried Herbs Packaging- Picture Courtesy: Noted UK Ltd

Dried herbs packaging's foremost purpose is to contain dried herbs. It holds dried herbs in a container to lower their loss by spilling. Also, it increases the expiration date of the dried herbs, consequently leading to their less wastage.

Chemical Protection

Chemical Protection by Dried Herbs Packaging- Picture Courtesy: Designer People

With dried herbs packaging, compositional alterations in dried herbs initiated by the environmental impact like exposure to air (mainly oxygen), water vapors, and light are prevented. The packaging offers a barrier against these environmental factors.

Dried herbs packaging is a closure system that allows minimal to no permeability of these agents, resulting in the preservation of freshness, nutritional quality, taste, aroma, and color of dried herbs.

Biological Protection

Biological Protection by Dried Herbs Packaging- Picture Courtesy: Dieline

Biological culprits usually rot the dried herbs by feeding on them. Different pathogens, like bacteria, molds, insects, vermin, and rodents degrade the quality of dried herbs and can be the source of disease and damage. However, due to dried herbs packaging, the colonizing of such agents can be avoided. Moreover, the dried herbs packaging regulates the aging of dried herbs.

Brand Promotion

Brand Promotion by Dried Herbs Packaging- Picture Courtesy: Visican

Dried herbs packaging is like a bulletin board of the product advertisement. Uniquely designed packaging with innovative labels and colors can augment the selling of dried herbs by being conspicuous on the display shelves. Besides, serving as a brand ad, the labels on dried herbs packaging communicate vital information regarding products, such as ingredient list, expiry date, and, nutritional count to the food lovers.

Trackability

Trackability by Dried Herbs Packaging- Picture Courtesy: Dieline

Different barcode, electronic identification, or radio labels aids in trackability and tracing of the dried herbs products. These tracible labels ensure the correct supply of the dried herbs, aid in food safety, and also facilitate in differentiating dried herbs products from other low-quality and fake products.

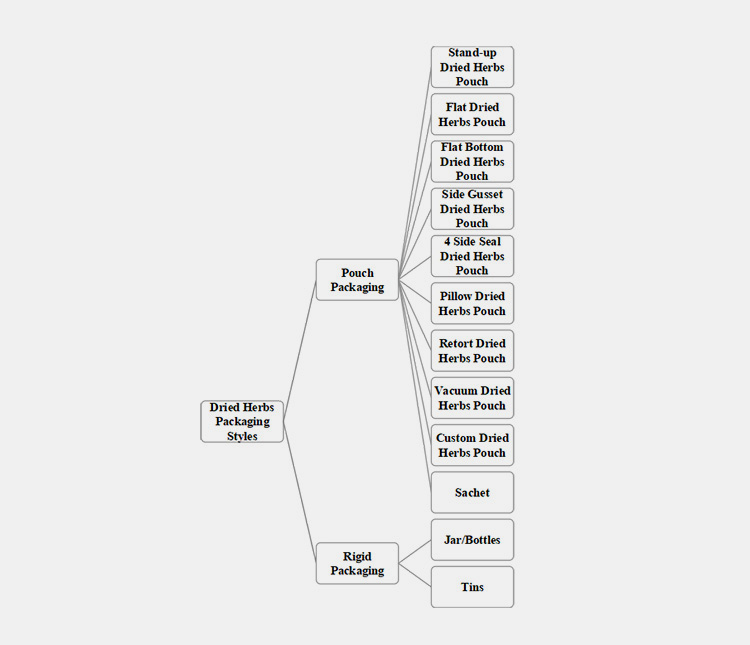

3.What are Some Widely Used Formats for Dried Herbs Packaging?

As there is huge market interest in dried herbs because they boost the eating experience, Hence, brands are creating distinctive dried herbs packaging to improve their brand appeal. So, there is a wide range of formats for dried herb packaging, such as:

Pouch Packaging

Huge kinds of pouch packaging styles exist for dried herbs packaging.

Stand-up Dried Herbs Pouch

Standup Dried Herbs Packaging- Picture Courtesy: Packaging of the World

It is also called a doypack and has a bottom gusset due to which it can stand firm on the display area. It is the most common kind of packaging for dried herbs because of its convenience and cost-effectiveness.

Flat Dried Herbs Pouch

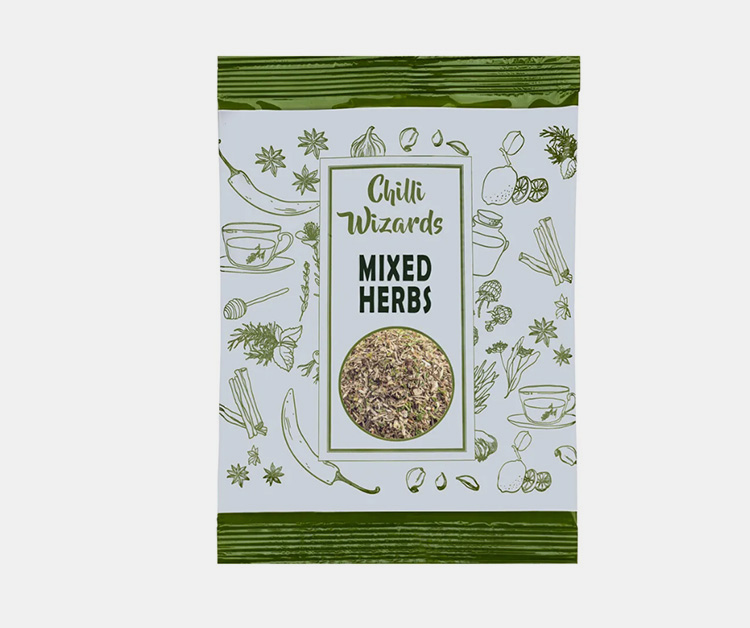

Flat Dried Herbs Packaging

It is square or rectangular and is usually sealed on 3 sides. It is light in weight and can occupy little space. However, flat dried herbs pouches usually lay on their sides and cannot stand on retail shelves.

Flat Bottom Dried Herbs Pouch

Flat Bottom Dried Herbs Pouch

It is also referred to as a block box pouch because of its box-like look. It has a rectangular base due to which it can easily retain its standing ability. It has side gussets and, therefore, can hold more quantity of dried herbs.

Side Gusset Dried Herbs Pouch

Side Gusset Dried Herbs Packaging- Picture Courtesy: standuppackagaging.com

As the name indicates, it is designed with two-side folding and can offer more storage area. The pouch is typically sealed at the top and bottom parts. Nevertheless, it does not feature a flat bottom, consequently, it is supported by other pouches for display purposes.

4 Side Seal Dried Herbs Pouch

Pillow Dried Herbs Packaging- Picture Courtesy: ento.com.br

This type of dried herbs pouch is sealed at 4 sides and it has little space for packing dried herbs. It is typically employed for filling single-serving of dried herbs.

Pillow Dried Herbs Pouch

Pillow Dried Herbs Packaging- Picture Courtesy: ento.com.br

The top and bottom sealings of this type of pouch usually form a pillow-like shape. Its back seal runs along the whole backside. It is a cost-saving dried herbs pouch type, often used for retailing.

Retort Dried Herbs Pouch

Retort Dried Herbs Packaging- Picture Courtesy: Designer People

It is designed with plastic and aluminum foil material and offers higher protection to dried herbs because of its sterility. Its biggest benefit is its temperature resistance which extends the perishable life of dried herbs.

Vacuum Dried Herbs Pouch

Vacuum Dried Herbs Packaging- Picture Courtesy: World Brand Design Society

It is created with multi-layered plastics and is highly moisture and puncture-resistant. Before sealing its final side, the air is drawn out of the formed pouch to uphold the freshness of dried herbs.

Custom Dried Herb Pouch

Custom Dried Herbs Packaging- Picture Courtesy: Retail Design Blog

It is designed in any shape like triangular, prism, etc to offer uniqueness to the brand and present a distinct marketing style. It can be customized in any size and form depending on the type of dried herbs.

Sachet

Dried Herbs Sachet

Single-serving dried herbs usually come in sachet pouch packaging that has 3 or 4 side sealings. Its portability and convenience make this packaging a favorite of various customers.

Rigid Packaging

There are generally two kinds of rigid packaging for dried herbs.

Jar/Bottles

Jar Dried Herbs Packaging- Picture Courtesy: Bon Appetit

These are wide-mouth containers with small necks and usually are made with clear glass and plastics. Screw-on caps on these containers offer airtight seals that prevent degradation of inside dried herbs.

Tins

Tin Dried Herbs Packaging- Picture Courtesy: Herbal Revolution

These are the cylindrical containers sealed using reinforced lids. Tins are generally manufactured using tinplate and aluminum. These metals are the ideal protective materials that extend the consumable life of dried herbs.

4.What are the Machines Used for Dried Herbs Packaging?

To accommodate a huge range of dried herbs packaging styles, there are diverse kinds of dried herbs packaging machines. The detail of these machines is discussed below:

Premade Pouch Packaging Machine

Premade Pouch Packaging Machine

A high-speed unit with a rotary configuration that offers versatile types of pouches for dried herbs. This machine processes already-made pouches that are customized with different sealing ties, zippers, hang-holes, etc. It can create doypack and zipper pouches with its automatic feeding and pickup system.

Working Principle

First, a large bunch of empty pouches are placed on the bag magazine, from where a set of grippers pick and carry the empty pouches to the opening station. The gripper opens the pouch and then it is flattened by the compressed air. Afterwards, the auger devices are used for filling dried herbs in the inflated bag. Ultimately, the sealing bars seal the top edge of the filled pouch.

Sachet Packaging Machine

Sachet Packaging Machine

For creating three and four-side sachets, this machine is utilized. It has heavy-duty construction and features a film holder that holds a large film reel. With automatic feeding and sachet forming stations, it has a high production capacity. PLC controls and sensors provide precision in dried herbs filling.

Working Principle

After loading of film roll on the holder, this film is uncoiled with the revolution of the unwinder. Then it travels to the forming station where it is folded, wrapped, and sealed.

In the next step, the preprogrammed amount of dried herbs is added to the formed sachet via auger or net weigh fillers. Sealing jaws heat seal the upper side of the sachet after filling.

Vertical Form Fill and Seal Machine

VFFS Machine

One of the most frequently employed machines in the flexible dried herbs packaging line is the VFFS machine. It carries out bag formation, filling, and sealing itself. It is popular because of its flexibility and can designed a variety of pouch styles like standup, flat bottom, side gusset, and many more. In addition to versatile processing, it also has a minimal footprint.

Working Principle

As with the sachet packaging machine, the operation is initiated by placing the film roll on the holder. After unwinding, the film moves to forming tube located at the top of the equipment. This film is then transformed into a pouch. The filling of dried herbs in the pouch occurs due to the movement of auger devices. After dried herbs feeding, the pouch is hermetically closed with sealing jaws.

Pillow Packaging Machine

Pillow Packaging Machine- Picture Courtesy: Penglai Machine

It is used for filling dried herbs in pillow-like pouches. Servo built-in systems are often employed in this machine for fast processing. Moreover, with the use of a smart HMI system, programmed parameters are easily input. Registration sensors keep track of the film and provide precise cutting and sealing.

Working Principle

In the beginning, the film is placed on a holder and at the forming area, this film is fashioned into a pillow-like bag. The products for packaging are placed on the conveyors. At the filling unit, they get picked up by the grippers and fed into the pillow pouch. Lastly, sealing elements seal the pouches using heat or pressure.

Jar and Tin Packaging Machine

Jar and Tin Packaging Machine

It is generally employed for filling bulk amounts of dried herbs in jars and tins. This machine has sanitary construction that assists in fast cleaning. Smart controls and servo-driven motors control the movement of conveyors and filling devices. It has a robust design that offers a long operational life.

Working Principle

The dried herbs are stored in the machine hopper at the start of packaging. Then either manually or automatically, the containers are placed on the conveyor.

They travel to the filling station, where the filling nozzle doses the correct quantity of dried herbs in the jars and tins. After the required filling, the filled containers are transported to the sealing area.

Rotary Vacuum Packaging Machine

Rotary Vacuum Packaging Machine

It is made of food-grade materials and has different stations like bag opening, sealing, and vacuuming. The double vacuum system in this machine can create 95-100% vacuum for dried herbs packaging. The barometer and temperature control device monitor the exact pressure and temperature, respectively.

Working Principle

First, the empty bags from the bag holder, travel to the inflating area. In the next step, these empty inflated bags are loaded with dried herbs. Before sealing, the vacuum is created inside the filled pouches using a vacuum tube. After the removal of air, the pouch is immediately heat-sealed using sealing bars.

5.What is the Difference Between Flexible and Rigid Packaging for Dried Herbs?

Rigid Packaging for Dried Herbs- Picture Courtesy: Dieline

Traditionally, rigid packaging, like tins and jars is used for packaging dried herbs. However, with the invention of plastics, flexible packaging is becoming mainstream for packaging dried herbs. Some consumers love to buy a premium tin of dried herbs. Let’s find out the differences between flexible and rigid packaging.

| Features | Flexible Packaging For Dried Herbs | Rigid Packaging For Dried Herbs |

| Weight | Flexible packaging for dried herbs is lightweight and takes up less space during storage and shipment. It is bundled up easily. | Rigid packaging for dried herbs is heavier and takes up more space in the cargo area. It is not bundled up easily. |

| Materials | It includes polymers such as plastics, laminates, and paper. Mostly, these are used for making pouches. | It includes materials such as glass and metals and is typically utilized in manufacturing tins and jars for filling dried herbs. |

| Barrier Properties | It does not make an effective barrier material as compared to rigid packaging. However, the use of retort pouches for dried herbs has solved this issue. | It protects packaged dried herbs better because it is made with tough and resistant materials. |

| Cost | It is less pricey to manufacture. | It has more manufacturing costs. |

| Customization | It can be customized and printed easily. Different styles of flexible packaging are designed to increase product influence. | It is difficult to customize and print. |

| Cosmetic Aberrations | It does not get scratched, dented, and deformed easily. | It is more prone to denting and scratching. |

6.How are Dried Herbs and Fresh Herbs Packaging Different?

Dried and Fresh Herbs Packaging- Picture Courtesy: Pixartprinting

Although dried herbs are essentially herbs that are dried to eliminate all water content, their packaging is way more different than fresh herbs packaging. Some of the differences in their packaging are detailed below:

| Features | Dried Herbs Packaging | Fresh Herbs Packaging |

| Materials | Dried herbs usually are packaged in sturdy and durable containers like jars. | Fresh herbs generally are packaged in breathable containers like paper and mesh bags. |

| Transparency | Packaging for dried herbs should be opaque as light degrades the quality of dried herbs. | The packaging for fresh herbs is mostly transparent because consumers can view the freshness of fresh herbs through the clear packaging. |

| Packaging Styles | Jars, bottles, tins, and pouches are used for packing dried herbs. | There are a variety of packaging styles for fresh herbs like bundles, ties, trays, clamshells, pouches, and jars. |

| Shelf-Life | This packaging has a longer best-before-life. | Fresh herbs in packaging usually have a shorter shelf life. |

| Air Vents | There are no perforations in the dried herbs packaging. | There are small air vents in the fresh herbs packaging to allow ripening and breathing. |

| Smart Sensors | There is no need for smart sensors in dried herbs packaging. | Fresh herbs packaging has smart sensors to indicate the quality, freshness, and status of microbial growth in the fresh herbs. |

7.What are Different Finishes for Dried Herbs Packaging?

Finishes of dried herbs packaging is a means to boost product visual appeal. These finishes make the graphics and colour of the packaging look better and more vibrant. There are a variety of food-grade finishes for dried herb packaging, for instance:

| Matte Finish

Matte Finish Packaging- Picture Courtesy: BIANCO China |

It is the most widely popular packaging finish for dried herbs. It has an elegant look and feel that attracts high-end users. It is very easily discerned on the retail shelves as it does not reflect light. It has a more natural look and, therefore, is best for packaging dried herbs as they are considered organic and assumed to be flavorful. |

| Gloss Finish

Gloss Finish Packaging- Picture Courtesy: QLM Label Makers |

It offers dried herbs packaging a lustrous sheen and luxurious look. This finish glimmers on light reflection. This increases shelf appeal as customers are attracted towards flashy packaging. It can withstand physical damage like scratching and smearing. It also keeps dust and debris away from dried herbs packaging and can accommodate clear windows. |

| Soft Touch Finish

Soft Touch Finish Packaging- Picture Courtesy: CarePac |

This finish imparts a silky-smooth touch to dried herbs packaging, unlike a matte finish. It has the lowest sheen consequently, it gives an all-natural look and feel. However, it is quite expensive but it usually resonates well with luxurious customers. |

| Spot UV Finish

Spot UV Finish Packaging- Picture Courtesy: MT Pak Coffee |

In this finish, some elements are given a glossy look while others remain matte to pop certain design elements of dried herbs packaging. UV light is used for curing inks in it. It highlights logos and labels to communicate with upscale consumers. It is also moisture-resistant. |

| Uncoated Finish

Uncoated Finish Packaging

|

In this finishing type, no coat is applied to dried herbs packaging which presents an earthy and natural vibe to the packaging. An uncoated finish allows the product to be more prominent among glitzy and loud dried herbs packaging. |

8.Why Vacuum Drying is Important in Dried Herbs Packaging?

Vacuum Drying and Dried Herbs Packaging- Picture Courtesy: Dieline

Vacuum drying is essential in dried herbs packaging as it removes the water vapors due to evaporation. This occurs at low pressure in the vacuum conditions.

Because there is no oxygen during vacuum drying in dried herbs packaging, it will inhibit the oxidation of herbs which could degrade their texture and nutrient quality.

Moreover, due to the absence of air, the herbs will retain their tangy and umami flavour and aroma.

It is a delicate process that also sustains the color of the dried herbs. Furthermore, it also prevents the growth of microbes in the dried herbs without compromising their quality. Due to low-temperature vacuuming, the volatile oils in dried herbs do not vaporize, subsequently will maintain their original intense essence.

9.How Dried Herbs Packaging is Sustainable?

Sustainable Dried Herbs Packaging- Picture Courtesy: Three Creative

With the issues of global warming and waste in landfills and water, environmental regulatory authorities have issued guidelines to make packaging sustainable which in turn has a positive impact on the environment and causes minimal formation of greenhouse gases.

To fulfil the requirements of environmental regulatory authorities, brands have made their dried herbs packaging sustainable by incorporating lightweight materials and using thin layered materials.

Recently, brands have started using mono-layered plastic materials for dried herbs. Furthermore, efforts have been made to use biodegradable and compostable materials, such as Kraft paper, seaweed, cornstarch, cellophane etc.

Edible films are used for packaging dried herbs, these are either applied as a coat on the dried herbs or are wrapping layers covering them.

These films are acquired from plant and animal sources and are ingestible, consequently producing less landfill.

Lastly, there have been drives to refill and reuse dried herbs containers which is another step for making packaging sustainable.

10.How Long Do Dried Herbs Last in Packaging?

Shelf-life of Died Herbs Packaging- Picture Courtesy: Packaging of the World

Dried herbs are composed of volatile oils that evaporate with the passing years, thus, these herbs lose their tanginess, aroma, and color with time.

Nevertheless, dried herbs have a longer expiration date. In an unopened airtightly sealed, dried herbs are good for 4 years.

However, if the dried herb packaging is open then they get exposed to air, and their texture will degrade before the best-before date. It is reported that dried herbs in the opened containers will retain their potency and aroma for around 6 months.

It is recommended to store dried herbs in a cool and dark place in the packaging that is not transparent and subject dried herbs to light as it may adversely impact dried herbs.

Use glass jars or zip-lock pouches to store dried herbs for a longer time. It is best to keep them in drawers and cabinets away from moisture. For best quality, make sure to lightly close the lids of dried herbs jars and bottles.

Conclusion

Dried herbs packaging keeps dried herbs good for both culinary and medicinal use. The packaging offers them environmental, biological, and physical barriers. It contains, stores, and, transports dried herbs far from their place of origin. Furthermore, dried herbs packaging can be customized in any design, shape, and, size to increase aesthetics that spellbind customers and increase the chance of selling. Contact us Today via email or leaving a message on our Allpack website, if you want to inquire more about our dried herbs packaging.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide