Condiment Packaging: The Complete FAQ Guide In 2025

Nevertheless, you can judge a book by its good cover! With hard market competition, there’s absolutely no room for shortcuts. A significant condiment packaging is key to grabbing the attention of customers and compelling them to pick the one from the shelf.

When it comes to condiment packaging, your passion, commitment, and market goal lead to successful development in creating a unique profile and success story.

Today's blog has the leverage to talk about condiment packaging and its designs, materials, and types utilized in the bringing of strategic approach in the market to obtain the right business goals. So, let’s begin with our topic!

1.What Is Condiment? What Comes into This Category?

The Perk Of Condiment Packaging

This word is not new for anyone but exactly what condiment is uncleared to everyone. A condiment is defined as an agent that is sprinkled or added to your dishes in order to increase the flavor. They are commonly used in a little concentration to improve the taste, tantalizing smell, and color as well. Also, this is available in a wide variety such as spices, sauces, spreads, and much more. For your clear understanding, we have made a table that includes the different categories of condiments.

SPICES

| Herbs | Oregano, thyme leaves, Basil leaves, mint, coriander, etc |

| Dry Spices and Seasoning | Red chili, turmeric, white and black pepper, coriander powder, etc |

| Salts and Pepper | The basic taste enhancers such as Ajinomoto, salts, etc |

| Various Spices Blend | Various spice blends include, mixed spices, garam masala, Thai spices, Chinese spices, fish powder, curry powders, etc., |

SAUCES & DIPS

| Ketchup | The widely used sauce that is made up of tomatoes gives sweet and sour taste. |

| Mustard | This is made up of mustard seeds widely accepted sauce to improve spicy taste and flavors in foods. |

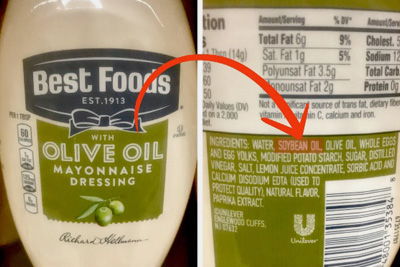

| Mayonnaise | This is used in the dressing of salad, sandwiches, burgers made up of thick creams, egg sauces and salt with unique and addicted taste. |

| Hot Sauce, BBQ Sauce, Soya Sauce etc | These sauces are prepared from various spices, vinegar, and salts inducing flavor of Asian and continental cuisines. |

| Pickles | Olives, chilies, cucumber, carrots pickle in vinegar. |

2.What Is Condiment Packaging?

Condiment Packaging

The condiment packaging is a state of the art to preserve and maximize the freshness as well as the taste of condiments and make you feel consuming the real taste. The condiment packaging is incorporated into a broad definition including packaging using filament, paper, and other materials with the help of innovative equipment to protect your condiment from unwanted intrinsic and extrinsic factors in an economical way. Plus, this is the robust way to achieve an aseptic method of preservation to make them long lasting under a reduced environmental impact with limited or no packaging waste.

3.Why Condiment Packaging is Important?

Condiment itself is short lived but has long lasting impact and quality when packaging is done carefully and correctly. We have enlisted the most important reasons why condiment packaging is significantly important to you.

Offering Primary Protection

Maximum Protection with Condiment Packaging- Picture Courtesy: Dieline

This is the major point that comes to everyone's mind, the condiment packaging prevents your product from harm during various distribution stages. This includes transportation, general handling, physical and chemical factors, etc.,

Tamper Evident Condiment Packaging

The original Condiment You Get with Condiment Packaging- Picture Courtesy: Dieline

A condiment packaging is very important to you as it gives you evidence of originality. It satisfies the consumer that the marketed product is a virgin material as they claim.

Boosting The Attractiveness

Expanding your Business with Condiment Packaging- picture Courtesy: Food Business News

This is also the major reason many manufacturers focus on it. The good packaging grabs the attention and lets the consumer pick the product from market shelves with a high willingness to buy them. Overall, the condiment packaging enhances the sales.

Communication with Consumers

Condiment Packaging- Picture Courtesy: Philadelphia Inquirer

Condiment packaging is the gateway to convey the message to consumers, including the benefits of particular ingredients, manufacturing, expiry date, and much more.

Usability

The usability of Condiment Packaging- Picture Courtesy: The Manual

The condiment packaging is fit for repurposed packaging. This is also good and perfect as a functional demand by users. This allows simple opening and closing of the jars, bottles, or whatever the material is and enhances the usability.

4.What Is the Classification Of Condiment Packaging?

Condiment Packaging- Picture Courtesy: Delkor System

You’ve to ascertain that the way you pack your condiments will guarantee quality and customer satisfaction. For this, you’d need to be carefully looking into the type and formats of packaging according to different condiments.

PACKAGING FORMATS

Pouches

Reliable and one of the most flexible form of condiments packaging are stand-up or spout pouches. They’re multilaminated film composed of different materials in order to preserve your product against microbial growth, prevent moisture, odor leakage etc thus safeguarding it’s taste and quality. Pouches allow their consumers to easily take out some amount of condiment have the feature to be prominently displayed on market shelves and serve customer compliance.

Depending on the style of pouches they offer various options such as stand-up pouch, gusseted pouch, side sealed pouch, pillow pouch etc. These all can be used to pack condiments and each of them have their own benefits according to their design.

Sachets

Sachets are single time use packaging format of condiments that can be conveniently taken by consumers wherever they go. These are composed of highly resistant barrier that protects the ingredients inside from any type of deterioration . They’re commonly used at restaurants, takeaways and deliveries and elsewhere for easy-going feasibility.

Jars & Bottles

You might’ve definitely seen an entirely separate section in supermarkets that displays jars and bottles of spices and condiments, which are either constructed of plastic or glass. These bottles and jars offer an aesthetic experience of adding condiments to your recipes along with providing them inertness to outside environmental conditions.

Containers

Containers are made of different shapes and materials and are popular amongst consumers who prefer shopping for their bulk monthly grocery and even for restaurant owners who stock up their pantry for adding delight to their recipes. Containers having nozzle pump delivery ,screw caps or those that comes with spoon or sifter caps allow controllable delivery of the condiment by their consumers .They provide tamper proof packaging to the product so that it may not leak while storage or transport and also protect the condiment from any contamination or spoilage.

Cups

This type of packaging is used to contain condiments that comes in serving sizes for single use, minimum from 2oz till 5oz. Cups are also called as souffle cups or portion cups which can used to hold sauces, dips, dressings and other side dishes served at restaurants and for food samples. Cups for holding condiments are designed to be mechanically strong and usually contain lids.

PACKAGING TYPES

Plastic

This is the most versatile forms of packaging type used by food and confectionery industry to package their products into plastic made containers and bags. Condiments have been widely packaged into plastic pouches, bags, containers, cups and bottles as it is lightweight , flexible and durable in its features.

Plastic packaging material are known to be unbreakable and conveniently transported. Plastic packaging uses PET, HDPE, PE and other types, out of which most commonly used being PET. PET plastic containers or bags are heat resistant and enable a good barrier against moisture and is unreactive to the condiment stored inside, however, it poses some safety concerns for consumers.

Glass

Glass being the expensive and most fragile form of packaging material, is still been used by food companies such as for condiments packaging. The reason behind is that FDA approval as GRAS- Generally Recognized As Safe material for packaging in terms of consumers health and safety as well as being completely recyclable. Glass bottles and containers have the inertness quality which makes it unreactive to the condiment filled inside it. It is impermeable to moisture, water and oxygen therefore serves as an excellent barrier and prevents the loss of taste and contamination, along with blocking any odor invading the glass packaging.

Metal

Metallic cups ,bottles or containers holding condiments packaging are constructed of stainless steel, tin, aluminum or chromium oxide coated steel. These metallic packaging material have many benefits such as they have good stacking strength, are impermeable to light and gases, and are also thermally well stable. It also provides a good level of protection in terms of shelf life and is also recyclable.

Paper

Paper packaging for condiments has recently surfaced in the markets to promote sustainable and more eco-friendly options. Paper material like Kraft paper, paper made out of pure wood pulp, sugarcane, and eco-friendly paper can be designed to make paper souffle cups and even bottles and bags have been made for trial purposes. It provides an aseptic environment to keep the condiment safe and healthy.

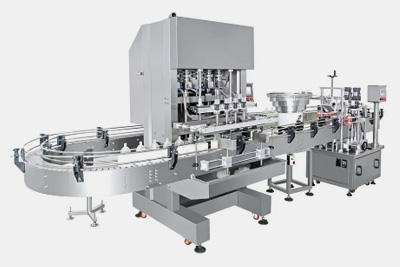

5.What Is the Condiment Packaging Equipment?

There are several equipment which come under the category of condiment packaging. Each machine offers unique features which will help you in condiment packaging. Let us discuss each of them below.

| Machine | Working | Picture |

| VFFS Condiment Packaging Machine

This easy to use and budget friendly vertical film form seal machine is great for packaging condiments. It does this by packaging them in vertical manner. Whether you’re dealing with high volume production or low volume production, VFFS machine can easily package the condiments into bags or pouches with high precision and accurate measurements. It does not matter how big your company is, it is the go-to choose for small, medium and large scale companies. |

Known for its versatility, the VFFS machine works by unwinding the film roll which is situated on the film arm holder. A specific length of the film is cut in the film forming tube after which the bag is given an appropriate shape. After this, the horizontal and vertical sealers are used to seal the three edges of the film. The required condiment is put inside the bag which is then sealed finally from the top. Lastly, the cutters remove the filled bag and send it to the discharge unit for shipping. |  |

| HFFS Condiment Packaging Machine

HFFS condiment packaging machine, unlike the VFFS machine is used to package the condiments in a horizontal manner. This type is very important for use in industry because it has the ability to package delicate condiments without destroying them or damaging them. It can easily maintain the original shape and size of any condiment and seal them in bags with great efficiency and ease. Thus, the consumer would get high quality product due to its use. |

The working principle of this machine is very similar to the VFFS machine. It uses the film which is situated on the arm rollers and gives proper shape to the bag with the help of forming a tube. The desired condiment is then poured into the bag and finally sealed from its edges. They are discharged to the next section accordingly. |  |

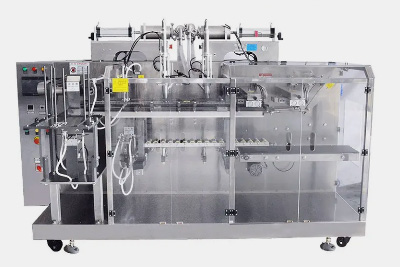

| Premade Pouch Condiment Packaging Machine

Premade pouch condiment packaging machine is an excellent machine which offers huge benefits to its users since it has the amazing ability to feed the condiments directly into the pre made pouches. Thus, it carries out the process faster without doing the bag making and sealing process. |

The working principle of this machine is very simple. It has a large capacity so it can package many pouches in short period of time. The premade pouches are first placed on the loading unit. The gripers then pick each pouch and make them go through air inflaters which open them appropriately. The desired condiment is then put into the pouch and sealed by the sealers, giving it an air tight seal. The packaged condiment is finally sent for shipping. |  |

| Carton Condiment Packaging Machine

All around the world, carton boxes are used to package condiments since they offer safe and easy transportation. Moreover, they are great for marketing. Thus carton condiment packaging machine are excellent option for your company. |

This machine is quite easy to use and you won’t have a problem handling it. The condiments are made to go through conveyor belt into the machine. Meanwhile, the flat carton boxes are loaded onto the machine and picked up by grippers after which they are glued and sealed to give it carton shape. The condiments are then fed into the carton and are finally wrapped and sealed by closing the carton lid. This process is done by highly advanced robotic arms which have powerful detecting sensors to check for any defective condiment and reject it. Thus, ensuring that only high quality products make it to the finish line. |  |

| Flow Wrapping Condiment Packaging Machine

Flow wrapping condiment packaging machine highly efficient equipment which pours the condiment into separate bags or pouches in a secure manner. The process of packaging takes place horizontally. Thus, making sure that perfect quality product leave the factory for shipping. |

The process of packaging begins when the film roll is unwind with the help of dancer arms. After this, the film is expanded by guided arms. In the next step the film is rolled into a specific shape bag according to your requirements by forming unit. The condiments are then put into these bags, sealed and are finally sent to the next step of production line for final shipping. |  |

| Jar Condiment Packaging Machine

If you are looking for an opportunity to market your brand and provide a tough and resistant package to your consumer, then using jar condiment packaging machine would cater to your demands. It is one of the most popular ways used in various industries to package your condiment since they are excellent in appearance and can be re used. |

First, large amount of condiments are introduced into the machine through conveyor belt. The empty jars are placed in specific position and are made to move inside the machine. As soon as the jar or container reach the filling unit, they are fed with specific number of condiments with high accuracy. The filled jars are moved to the capping unit. This unit is different for different customers since they can choose to seal the jars with different methods of capping such as flip inversion, screwing, twisting or pre-cut lid method. Finally, the capped jar is moved on the next section to begin the further processes. |  |

| Vacuum Sealing Condiment Packaging Machine

If you’re looking for ultimate customer satisfaction and optimum packaging for your product, then vacuum sealing condiment packaging machine would be a great choice. As the name suggest, it uses vacuum to package your product by removing oxygen from it. This ensures that your product does not spoil and remain fresh for as long as possible. It can be used in both small and large companies. |

The condiments which need to be packed are introduced into the machine. At the same time, the bags or pouches which need to be filled are inserted inside. After that, the machine sucks out all the air inside the bag, creating a vacuum like environment inside and the condiment is filled inside. The filled bag is ready to reach its final destination. |  |

| Tray Sealing Condiment Packaging Machine

Nowadays, companies are using trays to package their condiments for value added benefits since it gives attractive look and appeal, thus increasing the marketing potential of the product. These packaging materials are made of paper, PET and PP. it is great for use in food industries for packaging edible items. So using this machine will reap huge benefits for your company. |

The attractive trays are loaded onto the machine in the loading unit. The condiments are taken up the machine inside the filling nozzles. The nozzles pour them inside the trays with precision. The filled trays are sealed as tightly as possible all around the edges to prevent air from coming inside. After that, the cutters cut the film to give it an enhanced appearance. Finally, the cooling unit lower the temperature of the sealed film and the final product is now ready to be shipped to its destination. |  |

| Sauce Filling Condiment Packaging Machine

If you belong fast food industry, then this machine is the right one for you. The sauce filling condiment packaging machine is great for packaging sauces like ketchup, mayonnaise, marinara sauce and peri peri sauce. By using volumetric filling method, it will give you high end product and ensure excellent customer satisfaction. |

Sauce filling condiment packaging machine works on the concept of volumetric filling. The machine is provided with the number of filling nozzles. The sauce or ketchup is fed into the tank and the filling nozzles then fill the bottles or containers with equal quantity in every batch. In this way, the bottles are always filled equally. After this, they are sealed with caps and discharged to the final unit for shipping. |  |

| Auger filling condiment packaging machine

Do you deal with herbs, spices, flour and salts and need an effective machinery to package them? Then this one is the best for you. It will not only provide high quality product to you but also give you the opportunity to market your brand and earn huge profits. |

The dry powders like herbs and spices are introduced to the machine by sending them to the hopper. The auger rotates constantly so that the powder goes down into the funnel. The auger blade rotates in the opposite direction of the auger in order to remove any air in the powder and provide consistency. Finally, the powder is fed into the bag or pouch, sealed and then transferred to the next unit for shipping. |  |

6.How Long Does A Condiment Packaging Last?

Consumers are increasingly conscious about the environmental impacts of their actions. They evaluate the carbon footprint of the packaging before buying a product. The labeling on the packaging which gives clear information on the products and packaging’s environmental impacts and recyclability, will definitely catch consumer’s eye positively.

Depending upon the mentioned date of expiry, type of condiment and the temperature you provide to store it’s packaging determines how long will be the shelf life. Generally, a condiment packaging has a shelf life of 12-18 months however this cannot be decided to be specific for all your sauces ,dips and flavorants.

Some condiments like honey, salt and sugar do not expire at all. Others like hummus have a shorter expiry date. Ketchup and other sauces like barbeque sauce , mustard sauce, red sauce, oyster sauce, soy sauce, tartar sauce, chutneys, pickles and salad dressing etc can last for one year. Mayonnaise can last for 3-6 months. Jams and jellies will last for 3 years.

7.What Are the Top Avoidable Mistakes By Condiment Packaging?

The condiment packaging- Picture Courtesy: The Good Wine Club

Condiment packaging can make and break your business. Exceptional-quality condiment packaging rapidly gains the trust of the customers and hence increases the chances of buying. To produce condiment packaging without faults, here is a list of mistakes that should be avoided while packing condiments.

| Misleading Labelling of the Condiments

|

Labeling has a significant role in informing users about the expiry date, ingredient list, serving size, calorie count, etc. Poor, incorrect, wrinkled, torn, and poorly printed labels miscommunicate users. Moreover, poor use of topography leads to unreadable labels that drastically reduce the quality of condiment packaging. |

| Wrong Packaging Size Selection

|

It is one of the most common mistakes while condiment packaging. Brands chose large-sized packaging for packaging small quantities of condiment and sometimes small containers for packing large volumes of the condiments. |

| Going with the Cheapest Option

|

Businesses are always trying to cut down their costs. Nevertheless, it is vital to not select the packaging material and design based only on price because it can result in defects in condiment packaging, such as leakage or bursting during shipment and handling which could jeopardise your business. |

| Wrong Selection of Condiment Packaging Machine

|

As already discussed, there is a wide range of condiment packaging styles and different machines catering to specific condiment packaging styles are available in the market. Before machine purchase, you must determine your desired condiment packaging format and then select the machine accordingly. |

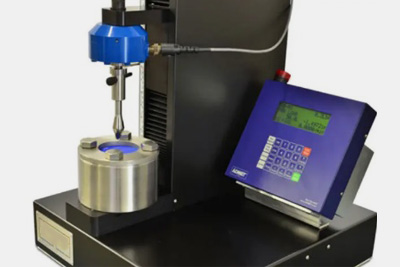

8.What Are the Integrity Tests of Condiment Packaging?

Integrity Tests of Condiment Packaging- Picture Courtesy: Sealtick

Safety concerning parameters analyzing the whole packaging process is to check that no external factors affect the condiment inside the packaging such as microorganism invasion, unwanted gas permeation, humidity, and moisture ingress. To prevent diminishing the quality is the purpose of integrity testing.

Some of the methodologies of these tests are named seal performance test, dry chamber test, leak test, bubble test, and puncture resistance test. You will read about them below.

| Seal Performance Test

|

This test assesses for any punctures, cracks, holes, or sealing inefficiency in the condiment packaging by visually inspecting or performing additional tests that might destroy the packaging. The seal performance test ensures that neither oxygen nor any air bubbles or microbial contamination penetrates the packaging due to the inappropriate sealing of the package. |

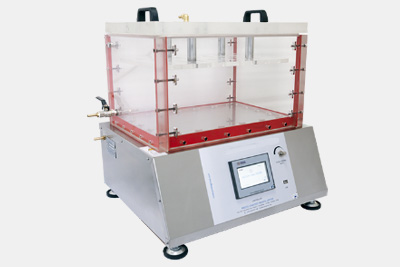

| Dry Chamber Test

|

A dry chamber is set up and the condiment package to be tested for any signs of leakage is placed inside. An absorbent material is present which will absorb any liquid that might seep out from the packaging. The condiment packaging faces mechanical pressure and the resulting leakage tells that the packaging is unacceptable |

| Leak Test

|

Leak tests carried out are particularly the destructive and non-destructive types of test carried out for inspection of whether any tear on the surface of packaging might leak the odor, and freshness and compromise the quality of condiments packaging. Usually, vacuum chamber test and bubble tests are done in this. |

| Bubble emission Test

|

The condiment packaging whether rigid or flexible is submerged in a water bath which is at control applicable pressure. If the bubbles escape from the packaging material, it shows that there is a defect at that place of your packing. |

| Puncture Resistance Test

|

This test is carried out on flexible packaging material used for condiments to check the physical and mechanical strength properties of the packing. The puncture needle hits the packaging several times until the packaging is ruptured, and the maximum strength required to do so is noted. |

| Pressure Decay Leak Test

|

In this test, the condiment packaging is placed under a provided pressure and then the air supply is blocked to check the pressure decaying time. In this way, the degree of leakage is detected. |

| X-ray Inspection

|

An X-ray machine along with visual camera software detects any contaminants in stacked condiments packaging in boxes as well helps to count and verify the actual weight of the packaging. |

9.What Is the Market Size Of Condiment Packaging?

The High Market Size of Condiment Packaging- Picture Courtesy: Daily Updates

The global market size of condiment packaging is progressing by leaps and bounds as day by day more consumption and demands of food products.

Not just quality but condiment packaging enhances the life and freshness of the condiments for a longer time. That’s why the forecast for condiment packaging is expected to grow enormously in the future.

Competitive companies like Kroger Co, Allpack, General Mills, etc are reported to be among the key players in condiment packaging. The condiment market size is assessed as 9.3 billion USD in 2021 while it is expected to grow 13.8 billion by 2030.

Conclusion

Good condiment packaging is fit for purpose and offers preservation of the materials as freshly prepared for you. Now you can enjoy the tantalizing taste and appetizing aroma when use the condiments. To achieve good packaging, ALLPACK cannot forget you! We’re here to work jointly to offer you the effective result that you dreamt of for your condiment business. ALLPACK offers you excellent state-of-the-art machinery on an astringent budget at your doorstep. Now what are you waiting for? Please message us now to Open the Horizon of New Innovative Condiment Packaging Machineries.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide