Small Scale Gummy Making Equipment Complete Buying Guide in 2025

If you’re a gummy bear manufacturer, then small scale gummy making equipment won’t be surprising to add into a production facility for small scale gummy candies formation. This is successful equipment for making health enriched gummies under a high level of hygiene as possible, meaning a conventional way of forming gummies was more prone to encounter cross-contamination but this specialized equipment is highly regulated equipment allowing you to produce sweet treat exactly the way you want.

Today, we are going to talk about important guidance points of small scale gummy making equipment like significance, working, installation points, etc., So Readers, without further ado, let's jump into the main topic.

1.What is a small scale gummy making equipment?

A small scale gummy making equipment is a one stop solution used to make a number of professional gummies in various sizes, shapes, and colors in the simplest manner.

The compact machine with stainless steel build is a modern version to attain perfect outcomes than using a conventional method.

This machine is the newest opportunity for those who run a small business with astringent pockets, that’s why this is a popular machine as it gives you an appealing and versatile variety of gummy bears.

The most important reason for using a small scale gummy making machine as it particularly gives you a small quantity of results ensuring you satisfactory profitability.

2.What raw materials do you use in a small scale gummy making equipment?

Tantalizing gummies are everyone’s favorite but do you what are its ingredients. Different raw materials give gummies their characteristic texture and flavor.

Some basic raw materials used for formulating gummies in small scale gummy making equipment are:

Gelatin

Gelatin- Picture Courtesy: Amstel Products

This is the main ingredient in traditional gummies and has been used in gummy making since the oldest times. It is acquired from the collagen protein present in different tissue parts of animals, such as cows and pigs. It is a clear and translucent gelling and thickening powder that imparts gummies their chewy and melt-in-mouth texture.

Pectin

Pectin- Picture Courtesy: Ketogenic.com

It is a vegan or vegetarian alternative to Gelatin and is obtained from fruit peel like apple and citrus. It is a type of carbohydrate (polysaccharide) as opposed to gelatin which is a protein. It is a white or brown powder with a slight bitter taste. It serves as a thickening agent in gummy recipes.

Sucrose or Table Sugar

Table Sugar

It is the most widely used agent for adding sweetness to gummies because gelatin does not have any taste. Sometimes, fructose or glucose (reducing sugars) are also incorporated to boost the sweet flavor of gummies.

Sweeteners

Sweeteners

Sometimes, gummies are manufactured as sugar-free for diabetic and diet-conscious people. So, different sweeteners are added instead of sugar like maltitol, stevia, sorbitol, and, xylitol. These agents imitate the flavor of sugar without affecting health.

Corn Syrup

Corn Syrup

As the name suggests, it is derived from corn and its main function is to preserve water content in gummies, consequently, keeping them fresh. Moreover, it also serves as a sweetening and thickening agent.

Flavoring Agents (Natural and Artificial)

Flavoring Agents

Gummies have fruity, sour, and bubbly tastes due to the addition of flavoring agents during gummy manufacturing. They are both natural and synthetic. Natural flavors are obtained from fruit juice extracts while artificial flavors include methyl anthranilate and ethyl caproate.

Food Colors

Food color- Picture Courtesy: Bigger Bolder Baking

Food colors are routinely used in small scale gummy making equipment for giving gummies vibrant and bright colors such as red, yellow, orange, etc.

3.How small scale gummy making equipment benefits you?

Although small scale gummy making equipment is small by its name, however, it packs a power punch of benefits. Small and medium-sized manufacturers integrate this machine in their productions because it has tons of advantages such as accuracy, and less labor intensive over manual gummy making.

Some of the exceptional benefits of this handy machine include:

Production of Large Batch in Less Time

Production of Large Gummy Batch

Gone are the old days, when pots, stirrers, and heating stoves were used for gummy making. Today, even small-scale businesses use small scale gummy making equipment because of its high speed and production rate. With the help of automatic systems offered with this equipment, manufacturers can produce large batches of gummies in no time.

Precision and Consistency in Every Piece

Precision in Gummies

One of the biggest reasons for using small scale gummy making equipment is precision. With the aid of intelligent controls modern molding systems, and critical temperature monitoring sensors, precision in every gummy piece is achieved. Manual labor is prone to human mistakes causing non-uniformity in gummies and batch-to-batch variation, but this machine is successful in producing consistently shaped and sized gummies in every batch.

Hygiene and Safety Guaranteed

Hygiene in Small Scale Gummy Making Equipment- Picture Courtesy: ABM Equipment

This machine is designed with keeping in consideration GMP guidelines and critically selecting food-grade components and materials, resulting in hygienic construction with easily cleaned parts. This ensures that gummies are safe for consumption.

Say Yes to Customization

Small scale gummy making equipment can be equipped with two hoppers that aid in the production of gummy with two colors. In this way, you can increase the shelf appeal of gummies, ultimately creating more buying impulse in customers.

Financially Benefiting

Saves Money With Small Gummy Making Equipment

Yes, small scale gummy making equipment can bring financial benefits. For one, it is less labor-demanding that saves your labor wages. Second, with this machine, there is a small chance of error in gummy manufacturing which in turn lowers material wastage and saves your money.

4.What industries can use small scale gummy making equipment?

Small scale gummy making equipment has found its use in multiple industries, where material heating and molding are involved. A list of industrial applications of small scale gummy making equipment is penned below:

Confectionery Industry

Small Scale Gummy Making Equipment In Confectionery Industry

Small scale gummy making equipment is a big part of the confectionery industry. Chocolates, candies, gummies, jellies, jerkies, and any kind of confectionery products are made using small scale gummy making equipment. Enticing shaped and colored gummies are possible due to innovative moldings in small scale gummy making equipment.

Pharmaceutical Industry

Small Scale Gummy Making Equipment In Pharmaceutical Industry

Nowadays, the pharmaceutical industry is one of the popular applications of small scale gummy making equipment. This machine is used for making cannabis gummies to treat chronic pain, inflammation, stress, and depression, and also to boost appetite. These cannabis gummies are gaining traction because of their ease of use.

Nutraceutical Industry

Small Scale Gummy Making Equipment In Nutraceutical Industry

In the nutraceutical industry, small scale gummy making equipment formulates soft, elastic nutraceutical gummies that are well-liked by adults and children. These nutraceutical gummies increase vitamin and mineral compliance.

Cosmetic Industry

Gummy Soaps- Picture Courtesy: Moms and Tots Group

Small scale gummy making equipment is also responsible for creating colorful and visually appealing jelly-like soaps and shampoos. It is also used for making gel-like masks and hair serums in the cosmetic industry.

Veterinary Industry

Pet Gummies-Picture Courtesy: crossinghost.com.ar

Nowadays, pet treats are also fabricated using a small scale gummy making equipment. These gummies in the shape of bones, claws, dogs, squares, etc. are not only used as snacks but are also used for treating nutrient deficiencies and anxiety in pets.

5.What are the components of small scale gummy making equipment?

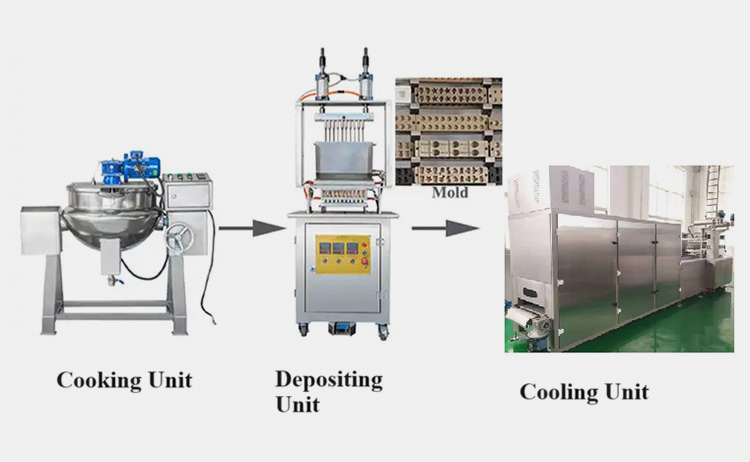

Do you know what exactly the components of small scale gummy making equipment would be? For your clear understanding, we have demonstrated below a figure that illustrates three basic parts of the machines that includes in the gummy making process.

The process is composed of three basic units, each of which plays a significant role. The main parts of each units are discussed below.

COOKING UNIT

A cooking unit is also known as a dissolving unit. This is indeed a simple machine used for dissolving and mixing the raw ingredients. The basic parts of this machine are discussed below.

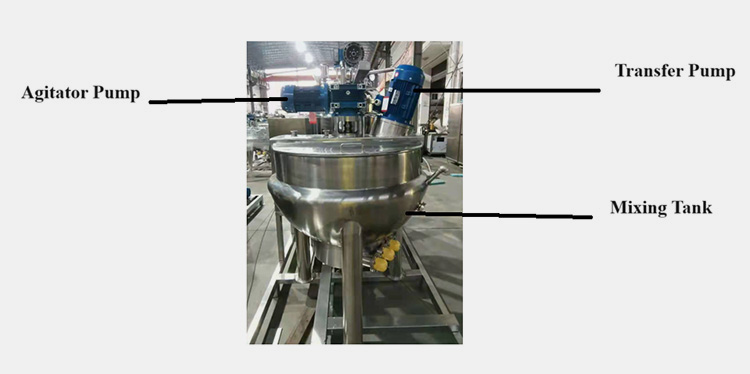

Agitator Pump

The cooking and dissolving of gummy bears is incomplete without agitator pump that assists in the formation of gummy syrup with evenly distribution of the raw ingredients particles such as gelatin, reducing sugars, flavor and other ingredients. The most important thing is to be noted that this agitator pump is simply driven by motor pump which induce the movement of impeller inside the mixing tank to make the mixing and dissolving procedure easy.

Transfer Pump

You must be wondering about transferring slurries from cooking unit to depositor, this is mainly achieved by transfer pump that converts electrical force to mechanical force where an already prepared solution from the mixing tank is evacuated directly into the next machine to process the production seamlessly. So, when it comes to maintain a consistent flow of material, the transfer pump is the device to offer this task.

Mixing Tank

In the cooking and dissolving unit, a mixing tank is a leader that is capable to accumulate the ingredients and allow mixing, cooking, storing processes in it. The mixing tank is featured with a temperature regulator that detects the required cooking temperature while it keeps maintain the inside temperature by gentle agitation of the unit to carry a homogenize syrup ready for the depositing unit.

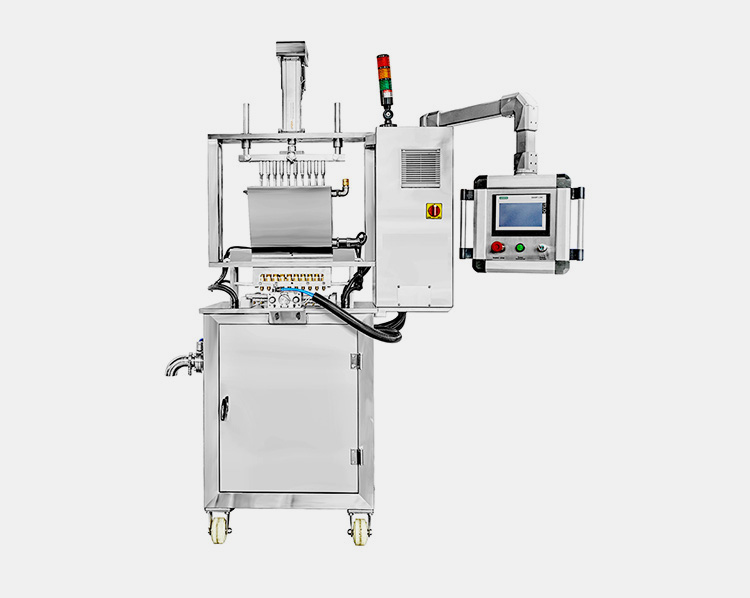

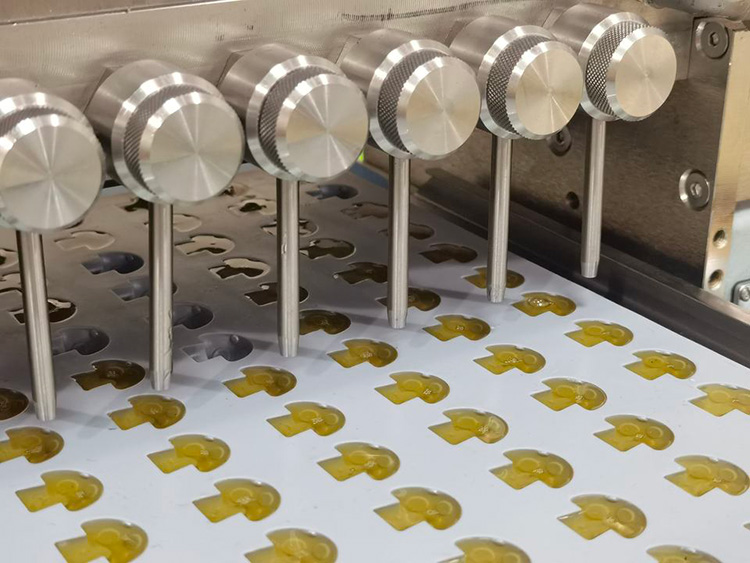

DEPOSITING UNIT

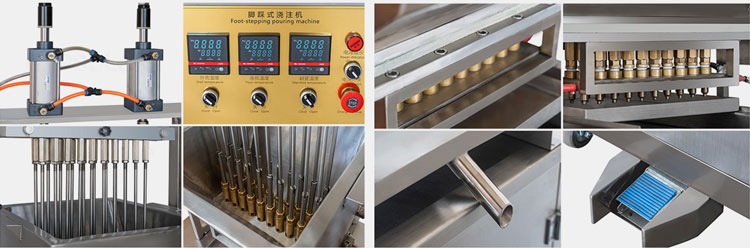

Depositing Hopper

This unit is known as a reservoir of the small scale gummy making equipment which is a hollow and deep tub for holding or storing the prepared gummy syrup effectively. The depositing hopper is connected to depositing nozzle that allows the controlled flow of syrup during process for precisely filling of solution into each depositing cavity of particular shape.

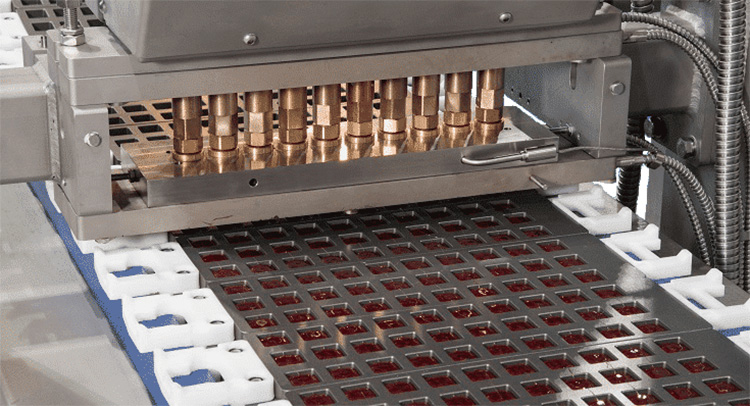

Depositing Nozzle

A fine and narrow set of nozzles which is designed to draw the gummy syrup into designated molds allowing efficient processing. The small scale gummy making equipment is configured to operate in a way that can dispense the solution as withdrawn in automatic or large scale gummy making equipment.

Temperature Sensor

The gummy depositing machine is featured with a temperature sensor which plays a significant role in regulating and notifying the temperature variation throughout the production procedure. This is highly recommended as over-heating or under-heating can disturbs the whole process quality.

Air Pressure Switch

This is a safety switch that has a practical approach relies on air-pressure to manage the process of an electrical compressor used to prevent the system from damaging and ensure quick emergency shut down of the unit via reflex alarm.

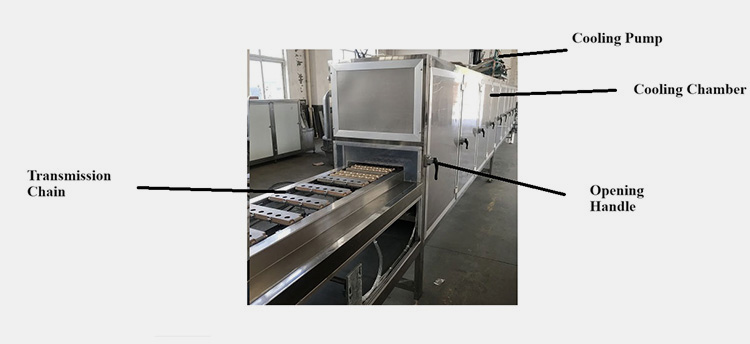

COOLING UNIT

This is the largest unit if the small scale gummy making equipment that works based on a simple process. A cooling unit is meant to offer a maintained cooling temperature for gummies to acquire the shape perfectly.

Cooling Pump

This component of a cooling tunnel is responsible for compressing air into cooling medium to maintain required cooling temperature inside the cabinet.

Cooling Chamber

This is the primary and main part of the machine which allow dynamic and continuous flow of chilled air inside the compartment or tiers to facilitate cool temperature needed for solidification of the gummy bears.

Opening Handle

As it names shows, you can easily open and close the cooling chamber by simply holding the opening handle and twisting it. This component is responsible for facilitating fast access to reach inside the machine for observation, cleaning as well as rectifying or troubleshooting the problem.

Transmission Chain

This is a momentary unit helps in the continuous transportation of gummy mold from depositing unit to cooling unit and cooling unit to de-moulding unit. The transmission chain ensures that operation is taken place with flexible and smooth workflow without haphazard movement of operators.

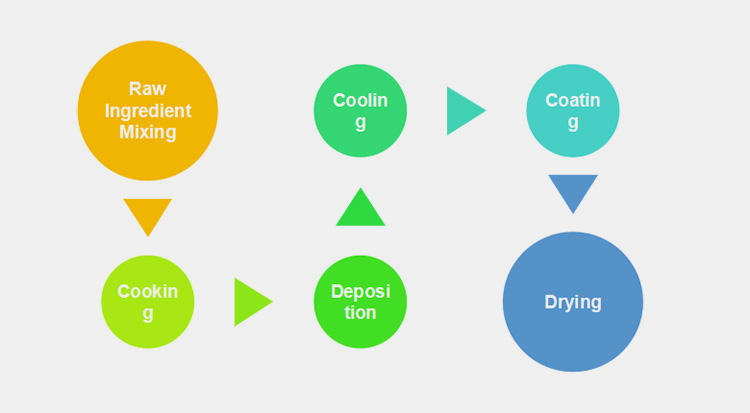

6.How Gummy Bears Are Made Step By Step Using A Small Scale Gummy Making Equipment?

The working of small-scale gummy making equipment consists of synchronized and inter-connected steps. These steps are carefully regulated to achieve perfection in the final gummies as deviation in a single step disrupts the whole process. The order of working steps in small scale gummy making equipment is detailed below:

| Step 1: Raw Ingredients Preparation | At the beginning of gummy making operation, first gather all the ingredients such as Gelatin, sugar, corn syrup, and additives. Next, weigh and measure their quantity. Then mix these ingredients in the ratio as required by the formulation. |

| Step 2: Cooking | Afterward, these ingredients are added to the double-jacketed cooker. This double-jacketed insulation ensures constant temperature throughout the cooking step. The mixture is gently stirred with an agitator, After 15-20 minutes, the mixed ingredients resemble a thick slurry. The bubbles can be seen on the surface of gummy slurry. The cooking phase takes place at around 108-110°C. After the formation of the slurry, it is then cooled down to a temperature of about 60-70°C. |

| Step 3: Deposition | This hot gummy mixture is then loaded inside the depositing hopper. This loading can be performed by the operators themselves or by using transfer pumps. After loading, due to the movement of pistons, a precise amount of gummy syrup is deposited onto gummy molds via depositing nozzles. The molding tray is placed on a conveyor and by the constant movement of the conveyor, every mould cavity is filled with syrup. |

| Step 4: Cooling | After filling, the moulding tray is removed from the depositor machine and placed inside the cooling tunnel. For setting and acquiring the ideal gummy shape, the cooling process is essential. Chilled air in the cooling unit aids in the solidification of gummies. After setting, these gummies are then removed from the moulding tray. |

| Step 5: Coating | It is the optional step that is carried out to increase the shelf-appeal of gummies. After de-moulding, gummies are transferred to coating equipment. This machine applies a thin coat of oils and dust gummies with sugars while they are rotating inside the pan. This gives gummies a glossy and smooth appearance. |

| Step 6: Drying | In the final step, coated gummies are moved to drying trays. The air is blown on the surface of the gummies which assists in removing water vapours from the gummies and drying them. This step takes about 18-24 hours. Now gummies are ready for packaging and shipment. |

7.What are types of small scale gummy making equipment?

Small scale gummy making equipment has come a long way since the old gummy making process in homes and apothecaries. In recent times, there exists a diverse range of makes and models of small scale gummy making equipment. Detailed classification of this instrument is penned below:

Classification Based on Automation

There are two kinds of small scale gummy making equipment when classified on automation.

Manual Small Scale Gummy Making Equipment

Manual Small Scale Gummy Making Equipment

In this machine, cooked gummy syrup is directly deposited in the product hopper. From where a precise amount of this liquid solution is poured on the molding tray with the action of pistons. It is a portable unit and is fairly priced. However, its productivity is low and gummy-making takes a lot of time with this equipment.

Semi-Automatic Small Scale Gummy Making Equipment

Semi-automatic Small Scale Gummy Making Equipment

Although its production capacity is slow, it is all in one unit with a cooker, mixer, depositor, and molding unit. It produces more gummies than its manual counterpart. It is way more efficient and precise in gummy making due to its advanced controls such as PLC systems and HMI.

Classification Based on Size

Desktop Small Scale Gummy Making Equipment

It is a small desktop unit, lightweight, with compact size, and can be fitted into small spaces. This system is equipped with a PLC unit, molding tray, 10 depositor nozzles, servo motors, and guide systems that aid in machine operation control. Also, if no molding tray is detected in this machine, then the depositing of gummy syrup is automatically stopped.

Industrial Small Scale Gummy Making Equipment

Industrial Small Scale Gummy Making Equipment

This system is part of a small-scale gummy processing size with a large size and weight. It has a bulk-capacity hopper in which a larger amount of gummy syrup is placed for high production of gummies. Moreover, it is offered with advanced electronic controls and stainless steel that are easily adjusted to control the flow of syrup and depositing speed.

8.What auxiliary units of small scale gummy making equipment?

The small scale gummy making equipment is associated with several other auxiliary working machines to facilitate a smooth production process. The list of those helping equipment is discussed below:

| Auxiliary Unit | Description |

| Gummy Drying Trays

A drying tray |

A silicon made up gummy drying trays are composed of perforated tray by which an air can easily pass through and assure optimum drying. These drying trays can allow positioning of the gummy bears without risk of cross-contamination of wastage. |

| Tray Dollies

A tray dolly |

The tray dollies are essential components of small scale gummy bear production. The tray dollies are used to transport gummy bear trays from operating facility to drying section easily and safely. |

| Sand/Sugar/Oil Coating & Polishing Machine

A sugar coater for gummy bears- Picture courtesy: Gummy tech |

A rotational coater which sprays sugary, oily, or sandy material over the gummy bear bed to ensure the application of the material is properly applied on the entire surface of the gummy material. This unit is significantly important as it enhance the appearance of the gummies. |

| Elevating Conveyor

Elevating Conveyor- Picture Courtesy: Gummy tech |

The elevated conveyor is an important unit used for transportation of gummies from coating or polishing to drying unit by a narrow and continuous passage. |

9.How small scale gummy making equipment is different from commercial scale gummy production?

Small scale gummy equipment is quite different from commercial scale gummy production as components and production rates vastly differ from each other. These differences are discussed in detail below:

| Small Scale Gummy Making Equipment | Commercial Scale Gummy Production |

Small Scale Gummy Making Equipment |

Commercial Scale Gummy Production |

| In small scale gummy making equipment every component whether mixers, depositor, molding, or demolding unit are present in a single machine | In commercial-scale gummy production, there are different machines such as cookers, mixers, depositors, and cooling tunnels for each of the separate gummy-making processes. |

| Small scale gummy making equipment is a small-sized compact machine with smaller floor space. | In commercial scale gummy production, the machine sizes have a larger footprint, consequently requiring large space in the production plant. |

| As the name suggests, small scale gummy making equipment is typically a part of small-sized businesses due to its lower production output | It is employed in large production plants where higher processing volume is needed. |

| Due to its simplicity, a small scale gummy making equipment requires little expense. | It is more costly due to its sophistication and advanced technology. |

10.What are desirable laboratory conditions of small scale gummy making equipment?

Sticky Gummies- Picture Courtesy: Indo Expo

Gummy making is a scrupulous process following an accurate set of conditions to achieve optimal quality gummies. Deviation from standard conditions could result in weeping or sticky gummies. Sometimes, harsh conditions should cause gummies of hard texture. Moreover, small scale gummy making equipment has desirable laboratory conditions at which it has ideal processing.

The laboratory temperature of using small scale gummy making equipment is about 20-25°C while humidity should be around 55%. The working temperature of cooking and dissolving is around 150°C. Also, make sure to properly ventilate the laboratory or other room housing small scale gummy making equipment to eliminate harsh or unpleasant odors from the room.

11.What different shapes can be made using small scale gummy making equipment?

Various stylish gummy shapes are available in the market that are possible due to specially designed molding in the small scale gummy making equipment.

Some attractive gummy shapes include:

Gummy Bear

Gummy Bears

It is the most common gummy shape with a cute little mouth, ears, and tummy resembling just like a teddy bear.

Gummy Worms

Gummy Worms

Wiggly, multicolored, and enticing flavored gummy worms are fun to eat. These are often dusted with sugar or cornstarch to enhance their appeal.

Gummy Ring

Gummy Rings

These are circular rings that are fun to spin in fingers. These candies are sweet and sour, perfect for an afternoon snack.

Gummy Alphabets and Numbers

Gummy Alphabets- Picture Courtesy: Oh! Nuts

Different alphabet and number-shaped gummies are an entertaining and creative way to boost learning and build memory in young kids while they are munching on chewy goodness.

Gummy Bottle

Gummy Bottles

If you are a fan of soda drinks, then these are just the right gummies for you. These two-colored candies are popular snacks on little get-togethers and for movie-watching.

Gummy Hearts

Gummy Hearts

This heart-shaped candy is the best way to celebrate special occasions like anniversaries or Valentine’s Day. Moreover, it can be given as a gift to loved ones. Gummy hearts are tiny bite-sized candies often coming in red, pink, or purple color.

Gummy Teeth

Gummy Teeth- Picture Courtesy: L‘Orenta Nuts

These silly teeth-shaped gummies are ideal for adults who are young at heart. They can be used for trick or treating and also for pranking people.

Gummy Belts

Gummy Belts

Vibrant, long, attractive, colorful thin strips of gummy candies are beloved among small children. These are often called sour belts due to their slightly sour taste due to coating or the addition of critic acid. To appeal to young children, they are coated with sugars.

Gummy Fruits

Gummy Fruits

Yes, your favorite gummy snack is also shaped into different fruits like apple, mango, lemon, strawberry, orange, and many more. Each fruit gummy has its characteristic flavor.

Gummy Bones

Gummy Bones- Picture Courtesy: Roch Sweets

To tempt pets, their gummy candies often are manufactured in bone shape. These candies are well-liked by grownups as they provide an exciting touch to scary theme parties.

12.How to avoid cross-contamination using small scale gummy making equipment?

Different procedures are developed to avoid cross-contamination in manufacturing gummies using small scale gummy making equipment. It is very important to prevent cross-contamination especially if you are making medicated gummies.

Sanitary Design

Small scale Gummy Making Equipment- Picture Courtesy: TG Machine

Small scale gummy making equipment has a sanitary construction made from stainless steel. This material is quite easy to clean and is resistant to rusting, which prevents contamination of gummies. Moreover, small scale gummy making equipment is manufactured following GMP and FDA guidelines. This aids in decreasing contamination risk.

Regular Cleaning

Cleaning of Gummy Molds

Besides this, regular cleaning and sanitation of food-contact parts also avert the risk of contamination. This involves disassembling parts and properly cleaning with food-grade cleaning agents them after every product switchover.

13.What are the basic problems and solutions when using small scale gummy making equipment?

Small scale gummy making equipment is a robust unit with exceptional results in terms of gummy consistency and uniformity, but sometimes it faces unexpected failure, causing low productivity and downtime. But with proper training, these problems can be resolved without going for lengthy repairs.

Some common problems and their solutions are:

Differences in Gummies

Variations in Gummies

Sometimes gummies produced by small scale gummy making equipment have disparities in terms of their texture, geometries, and sizes.

Cause

It is due to faulty molding of the gummies and is also because of the incorrect setting of the depositing process.

Solution

If the molding unit is facing wear and tear then change it. Moreover, check the program parameters of the depositing process and adjust them if they are incorrect.

Poor Working Order of Connecting Pumps

These pumps fail to transport materials.

Cause

Sometimes, debris or residues accumulate in these pumps which leads to their clogging. Moreover, due to gummy adhesivity and poor cleaning schedule sticky content buildup on the pump sides. Loose wirings of the pump also cause pumps to break down.

Solution

Use detergent water and clean cloth to fully clean the interior and exterior of connecting pumps. Examine thoroughly pump connections and fix loose wirings.

Non-uniform Mixing of Ingredients

Non-uniform Mixing

Sometimes there are clumps in the gummy liquid.

Cause

Poor mixing speed of the agitator could lead to clumping of ingredients. Also, due to the agglomeration of gelatin, ingredients do not flow properly.

Solution

Increase agitator speed and check agitator for damage. Take out large gelatin mass to increase the flow of other raw materials.

Poor Blooming of Gummies

Poor Blooming of Gummies- Picture Courtesy: Miette Patisserie

The resultant gummies produced by the small scale gummy making equipment do not have the correct blooming ratio.

Cause

Incorrect temperature during cooking may cause blooming.

Solution

Reset the cooking temperature. It is recommended that the blooming temperature should be around 150°F.

Gummy Residue on the Depositor

Gummy Residue on Depositor

It is the main part of a small scale gummy making equipment and because of flawed demolding sticky residue remains on the depositor.

Cause

The spray system may be damaged so is not working properly. Moreover, the formulation of gummies may be causing stickiness.

Solution

Access the working condition of the spray system and properly oil the molding system. Moreover, reformulate gummy recipes to avoid stickiness. Before molding, layering the molding pan with cornstarch may decrease the stickiness of gummies.

14.What are buying considerations when purchasing small scale gummy making equipment?

There are different variables involved when purchasing small scale gummy making equipment. It takes substantial research when buying the best machine for your production. The purchase of small scale gummy making machine is no small feat and should be taken after deliberating different factors.

Here is a list of important buying considerations that helps in purchasing a high-end machine for your business.

Cost

Cost Of Small Scale Gummy Making Machine

It is the first and foremost important factor when purchasing small scale gummy making machine. Cost is determined by several factors, out of which technology and automation play a big role in price value. But remember to purchase a machine that fits your wallet without compromising on quality.

Type of Gummies

Types of Gummies

Currently, there are diverse varieties of gummies such as Gelatin-based gummies, pectin-based gummies, and carrageenan-based gummies. These gummies are suitable for all walks of people based on their ingredients like vegan, Halal, or Koscher. Therefore, it is important to determine what kind of gummy you will process, so that you can select the right equipment for that gummy type.

Versatility

Verstility in Gummies

As you know gummies are available in all kinds of shapes and sizes. Hence, select small scale gummy making machine that can manufacture gummies with diverse ranges of shapes and sizes. It is essential to choose small scale gummy making equipment that comes with numerous molding trays. This will increase your chances of sales as unique style gummies appeal to customers.

Design Quality

Design Quality Of Small Scale Gummy Making Equipment

Since small scale gummy making equipment is a costly purchase, select a machine with high-quality materials that are durable and last long. Before selection, ensure that all the components of the machine are well-built according to GMP quality standards.

Ease of Use

Ease to Use Gummy Molds- Picture Courtesy: My Silly Squirts

Hard-to-use machines are labor-intensive, requiring much training and skilled operators. This often results in a huge number of errors in gummy making process, resulting in inconsistency and poor quality of gummies. Therefore, it is imperative to select small scale gummy making machine with easy-to-use controls and touchscreen options that require little-to-no training and in turn, increase your productivity.

Conclusion

A small scale gummy making equipment is perfect for small and medium-scaled productions due to its affordability, smaller footprint, and easy maintenance. It packages a variety of benefits in its small size such as hygiene and quality in gummy manufacturing, versatility in gummy shapes and sizes, and customized gummy designs. If you are the owner of a startup gummy business then visit our Allpack machine portfolio for the best deals. We are a renowned company exporting high-grade machines and parts all across the globe.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide