Cracker Packaging: The Complete FAQ Guide In August 2025

You know the fresh cracker is always love, but the real credit goes to effective cracker packaging. Especially, the producer, who has carefully executed them.

You can also be the one. With the right approach and the right investment, you’ll be able to make your business quite stronger.

Let’s roll up your sleeves and read the blog if you’re looking to achieve success in offering fresh crackers to customers.

1.What Is Cracker Packaging?

The Cracker Packaging- Picture courtesy: Simporter

Cracker packaging can be denoted by the carefully packed snack products such as biscuits, crackers and chips etc in such a packaging that preserves the food’s freshness, it’s flavor and odor along with ensuring a better shelf life. The packaging is designed in such a way to accommodate the crackers in an airtight safety and promoting the brand through effective and intriguing graphics, calling for consumers attraction.

Good quality material and unique formats of packaging is a drive force in delivering the scrumptious and tasty crackers to you. Crackers packaging enables the crackers to be safe from crumbling into chunks and gives durability and protection against environmental moisture and oxygen preventing them from turning soggy or stale.

2.What Is a Cracker Product?

The Cracker Packaging- Picture courtesy: Good Housekeeping

Crackers are scrumptious, crunchy and flavorful snack products manufactured by food confectionery industries, that can be defined as baked biscuits that are light in texture and weight made from flour. Crackers can be seasoned with spices and herbs, salt and sugar or made into healthier variety by incorporating nutritional value ingredients.

The Cracker Packaging- Picture courtesy: Times Food

This food product can also be consumed as chips having spicy, cheesy, onion and garlic, or chicken flavoring added to it. They are available in many shapes and sizes and their characteristic texture represent holes on the surface of it. Crackers can be consumed by their own or accompanied by other food items such as along with meat slices, jellies and jams, soups or even added to desserts for complimentary taste.

3.Why Do You Need Cracker Packaging?

You might know that crispy and crunchy snacks need extreme delicacy in their storage and therefore the need arises for protective and safe crackers packaging. Additionally, a good packaging is an effective marketing strategy for any brand’s success.

Now, reading some of the benefits of crackers packaging will make you realize it’s need.

Preserving Freshness

The fresh it is delivered to you, the better it will taste. For this it is necessary to maintain airtight condition inside the packaging of crackers, so that they are crunchier the same way it was first produced. Different packaging materials are thoughtfully designed to prevent these crackers from getting in contact with moisture or air and turning stale and flavorless.

Effective Branding

Picture courtesy: The Saturday Evening Post

A high quality visualized and labeled packaging will bring more customers attraction to buy your cracker product. Choosing and styling such packaging formats that not only lock the crackers taste but also deliver effective labeling, giving eye catching details about your cracker products nutritional value promotes the brand.

Marketing and Transportation

Ease of Marketing and Transportation- Picture courtesy: Law.com

Until the crackers packaging reaches your market shelves or your kitchen’s cabinet , it is required that they stay crispy and fresh. Use of sturdy packaging material will ensure mechanical protection and safe transportation of your cracker product by the time it reaches the hands of consumers.

Longer Shelf Life

The cracker packaging- Picture Courtesy: food and wine

The cracker packaging is meant to keep the crackers crispy, fresh, and flavorful. The estimated shelf life of unopened cracker is mostly varying from six to nine months in a very good quality. After this period, we won’t say crackers can go bad; though its quality starts affecting such as you won’t find them as crispy, light, and flavorful as before.

In some cases, cracker packaging with preservative tend to give longer shelf life such as nearly to 12 months; the best way to look and assess the cracker if it creates an odor then it is suggested to consume but an airtight and appropriate cracker packaging seldom gives such issues.

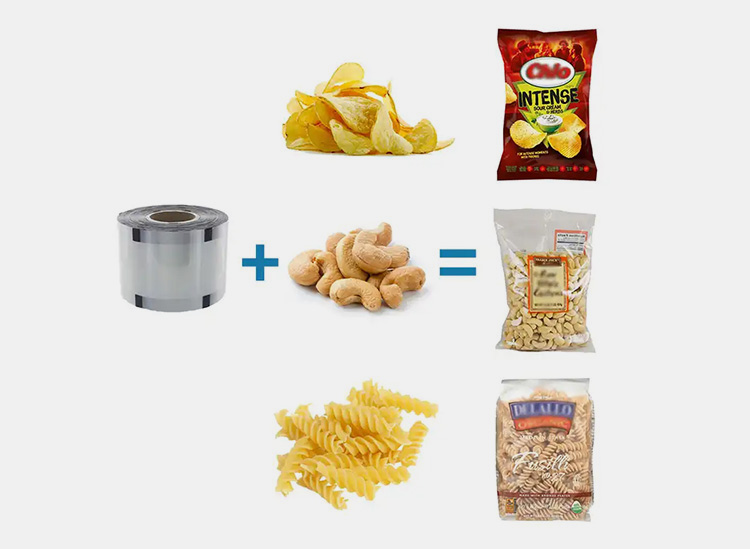

4.What are Longer Shelf Life? How does cracker packaging take place?

The crackers itself a versatile product that features a broad classification; likewise, the packaging machines for it also offering you with a large classification. Discussed below are the lists of machines that can help you in the packaging crackers.

VFFS Machine

VFFS Cracker Packaging Machine

This is commonly used machine that everyone of you is aware of. The role of Vertical Film Form Seal machine is undoubtedly very simple and effective. This is named as VFFS as it carries the packaging task in a vertical fashion. Considering from small to large batches a VFFS machine can perfectly dispenses accurate and measurable quantity of crackers into each formed bag. The amazing factor about VFFS machine is its cost-economical budget. Whether a large, medium, or small company; this is an affordable choice of packaging cracker.

Working Principle

A VFFS machine is best known for its versatile applications, it works by unwinding the film roll which is fixed on the dancer arm holder. An estimated portion of the film gets narrow down in the film forming tube where an acquired shape to the bag is given. The presence of vertical and horizontal heat sealers helps in the sealing of the film edges around the three sides. The crackers are positioned inside the bag followed by the final sealing at the top side of the packaging material. Once the cracker packaging is achieved the cutters separate the formed bag and allow it to the discharge unit.

HFFS Cracker Packaging Machine

An HFFS Cracker Packaging Machine

This is another category of cracker packaging where from film forming till sealing of crackers takes place following horizontal manner. You might be thinking why it is significant as vertical film forming sealing machine. Though, it is mostly preferred in case of retaining the uniformity, shape, and integrity of the goods. This machine can cater delicate crackers efficiently and prevent them against breaking so ultimately ensures the end user to get highly professional goods.

Working Principle

The working of HFFS machine is very simple as VFFS machine. Once you load the film on the rolling arms; the machine picks them and produce the fine bag by the help of forming tube and allow the content to feed inside the pouch and carried it to the next section where sealing of the film takes place and discharges the crackers product respectively.

Premade Pouch Cracker Packaging Machine

Premade Pouch Cracker Packaging Machine

A premade pouch cracker packaging machine is an important equipment that offer unlimited benefits to its users as in a very short time it can streamline the cracker packaging process. The premade pouch is encountered directly so bag formation and sealing step is skipped so a fast packaging is achieved.

Working Principle

The working procedure of this machine is very simple can cater large packaging capacity. You can simply load the bunch of premade pouches in the loading unit where gripers pick each bag and subjects them to air-inflators for opening them so measured quantity crackers are fed into the pouch and top sealed by heat sealers to form an airtight tamper proof packaging. Your product is ready to sale.

Cartoning Cracker Packaging Machine

Cartoning Cracker Packaging Machine

Crackers are mostly comes in the form of carton or box packaging presenting an appealing way of marketing and consumer’s acceptability. The cartoning cracker packaging machine is efficiently utilized in the packaging industry for the securing products and ensuring ease of transportation.

Working Principle

This is another amazing cracker packaging device that allow you an easy operability. The crackers are loaded manually into the machine or can be fed using a conveyor. On the other side, flat carton boxes stack is loaded which is picked one by one by grippers and mechanical gluing and sealing tuck its corner to form a carton. The crackers are positioned inside the carton by a gentle push followed by the wrapping and closing of the top flip to finish the packaging process. This is an advanced machine that follows robotic arms for mechanical supports and high quality sensors for detecting errors or damage cracker so it can automatically move away from the packaging line which ensuring safe product with no defects.

Flow wrapping Cracker Packaging Machine

Flow wrapping Cracker Packaging Machine

A flow wrapping machine is an advanced technology that inserts and secures the crackers and other food items in a separate and individual packaging. The packaging procedure in the flow wrapping machine takes place in a horizontal fashion which ensuring the cracker packaging process is carried out in an efficient and continuous manner.

Working Principle

The working principle of flow wrapping machine begins with unwinding of the film roll which is mounted on the dancer arms of the unit. The presence of guided arms helps in the proper and secure expansion of the film. The next section is forming unit where a film creates a shape of a required design. The already loaded crackers are fed into the packet respectively. Once they’re loaded, an opened end of the pouch is sealed and cut and discharged from the unit for other packaging steps.

Jar Cracker Packaging Machine

Jar Cracker Packaging Machine

This is the most conventional method of packaging that is commonly used in various other food industries as well. The jars or container cracker packaging is mostly preferred by consumers due to it excellent presentation and reusing the packaging container can double their happiness. The jar cracker packaging machine is therefore a significant solution that promises improving your market value with economical budget.

Working Principle

The crackers are fed into the system in the bulk quantity via conveyor unit. Similarly, the set of packaging materials such as empty jars or containers are introduced into the system in an oriented manner. Once jars reach to filling unit, an optimized quantity of crackers are poured into each jar followed by the next packaging material. The jars move to the next unit for cap positioning. Depending upon the requirement of the manufacturer, cap is placed either twisting, screwing, flip inversion, or by pre-cut lids method. The finished packaging product is discharged from the system for further packaging tasks.

Vacuum Sealing Cracker Packaging Machine

Vacuum Sealing Cracker Packaging Machine

Vacuum sealing cracker packaging is essential equipment that offers promising throughput by displacing oxygen in order to preserve the cracker for the longer time. The machine itself is an advanced solution used in small and large production set-ups. If you’re planning to opt this handy machine then you must be opening a horizon of success and building customer’s satisfaction in the competitive market.

Working Principle

The crackers to be packed are introduced into the machine. Whether vacuum packaging bags, pouches or boxes are fed into the unit. The system is capable of removing air inside the packaging material during placement of the crackers and sealed them securely to remain air-free till you cut or open the bag. A vacuum sealed cracker packaging is ready to transport.

Tray Sealing Cracker Packaging Machine

Tray Sealing Cracker Packaging Machine

Crackers are also distributed and marketed in trays adding good consumer’s impression. This packaging is new and unique marketing trend that uses plastic or paper made packaging materials such as PET, PP, and other. This packaging is commonly used for ready to eat food items. The tray sealing machine is absolutely excellent machine if you are looking to dispense crackers in trays.

Working Principle

The cracker inside the machine are subjected toward filling nozzles where specific quantities crackers comes in the contact with trays which are already loaded into the unit manually or by an integrated unit such as conveyor. After filling, tray is secured by a film sealing around the edges and fused tightly to prevent the incorporation of the air inside. The excessive film roll is finely cut by cutters to give a nice and finished presentation. The machine is also featured with cooling unit that helps in the maintaining the temperature once the sealing has been done.

5.What are the materials and formats of cracker packaging?

Cracker packaging is encompassed with two broad categories, such as packaging material and packaging formats.

The Packaging Materials Used in Cracker Packaging

As you saw above different formats of packaging used for packing of crackers, now you’ll be looking into their respective materials that are usually employed by each format for processing the crackers into packets and boxes.

Paper Cracker Packaging

Paper Cracker Packaging- Picture courtesy: PKN Packaging News

Boxes and packets made up of kraft paper or cardboard paper constitute as secondary packaging material for any food products like those used in snacks and confectionery industry. Such boxes enclose bag packaging or a tray inside as a primary packaging material for containing crackers. Paper is an easily recyclable and transport feasible option and protects the crackers from moisture and light degradation. Base cards or corrugated folds are also designed in the form of paper as a primary packaging material that enables mechanical protection to the crackers by spoilage from crumbling.

Plastic Cracker Packaging

Plastic cracker packaging

One of the most commonly used material for packaging formats of crackers is plastic such as polypropylene, polyethylene terephthalate etc. Plastic bags , plastic pouches , plastic containers and boxes are some of the designed materials for packaging of crackers. Plastic packaging enables airtight and tear proof safety to the food product that is placed inside. Available in multilayer, shiny and metallized film, plastic packaging can ensure good shelf life of crackers too.

Metal Cracker Packaging

Metal cracker packaging- Picture courtesy: Milk Bar

Boxes made up of tin or any other metal are used to package biscuits and crackers as a premium packaging style. Metallic packaging serves to protect the crackers from environmental degradation like moisture, oxygen and light thereby preserving it’s freshness and quality.

The Packaging Formats of Crackers Packaging

In order to adhere to the trending packaging formats of various types of crackers, marketers have brought forward multiple styles of crackers packaging for consumers. You’ll see some of them below.

Pillow Pouch cracker Packaging

Pillow pouches are one of the usual preformed formats, centrally sealed which are utilized for packaging of confectionery products such as these crackers, as they serve easy to go and convenient option for consumers. Various sizes of pouches are available which can protect your crackers from environmental degradation.

Stand-up Pouch Cracker Packaging

The cracker packaging- Picture courtesy: Packaging -360.com

Stand up pouches are prominently displayed on market shelves and enable customers to look at the product’s description and are convenient for storage. Crackers in such packaging comes in resealable bag option which can allow consumers to eat whenever they want , locking freshness of the crackers as well to enable quality.

Gusseted Bags Cracker Packaging

The gusseted cracker packaging-Picture courtesy: Varna Packaging

Gusseted bags crackers allow for easy opening feature having tear notch and resealable zipper option for consumers convenience. These pouches usually have a bottom seal and two or three sided gusset which allows for extra space inside the packet. They have the ability to safeguard the crackers crispiness and taste, same as freshly packed.

Doypack Cracker Packaging

The doypack cracker packaging- Picture courtesy: Good Eggs

Similar to stand-up pouch , doypack packaging preserves the flavor and odor of crackers along with protecting their crispiness. These doypack are made of double layer film providing barrier against moisture and oxygen. They also have resealable feature and tear notch for easy opening and provides to give easy to go snack serving for consumers.

Box Cracker Packaging

The box cracker packaging- Picture courtesy: Baking Business

One of the most widely used forms of packaging for crackers is the box style packaging. The boxes are of various shapes and sizes enclosing crackers packed in another packaging case of any material such as plastic bags or paper bags . Boxes enable extra layer of crispiness and taste preserving as they’ve double layer of packaging material.

Containers & Tray Cracker Packaging

The container and tray cracker packaging- Picture courtesy: Tin Box

Crackers are also packed in preformed containers and trays which locks the freshness, taste and aroma of the product inside. They give quality serving in sharable size packaging and can be enjoyed by consumers wherever they go.

Fin Seal Cracker Packaging

The Fin seal cracker packaging- Picture courtesy: QLM Label Makers

Fin seal packets contain back seal as a tamper evident packaging of small quantity snacks such as crackers. They are made of plastic film laminate ensuring good quality protection of crackers.

Slug Cracker Packaging

The Slug cracker packaging- Picture courtesy: Industrial Meeting

Slug packaging for crackers is a flexible type of packaging format allowing crackers to be packed horizontally or vertically stacked up in line arranged in a row. In such packaging, crackers can be packed in as little as 2 to as many as 12 pieces held in a plastic trays or even without tray. Slug packs offer single time use and serves as a snack size packaging for consumers.

6.How is nitrogen flushed to keep cracker packaging fresh?

The role of nitrogen flushing- Picture Courtesy: Fluid-Aire Dynamics

Primarily, you must know what is the role of nitrogen flushing for keeping any food product fresh? Unlike oxygen which deteriorates the food product, nitrogen doesn’t react with the food product instead it preserves it’s freshness and helps to prolong the shelf life for storage and shipping. Nitrogen flushing means adding nitrogen gas to your snacks packaging which due to being inert does not react with food and helps to remove out oxygen from the packet.

First the crackers are filled inside the pouch or box or whatever the packaging format is, and then the nitrogen flushing machine forcefully takes out oxygen and immediately replaces it with nitrogen inside the packet and then crackers packaging is sealed. Nitrogen gas serves to keep crackers packaging from getting stale or crumbled, as this gas acts like a cushion due to being heavy it moves down and prevents the crackers from spoilage. The sides of the packet are also protected from crushing or crumbling the crackers.

7.What are basic cracker packaging mistakes? How to overcome them?

Basic Cracker Packaging Mistakes

There are several ways that can affect better cracker packaging. Discussed below are some key checks you must keep in mind to prevent cracker packaging mistakes.

Ignoring Nitrogen Flush

Importance of Nitrogen Flush in Cracker Packaging-Picture Courtesy: On Site Gas System

Remember, crackers loss their crispiness when exposed to air or oxygen cause stale texture. The presence of oxygen inside the packaging is the culprit. User must look for the innovative cracker packaging machines that efficiently displaces oxygen with nitrogen to offer controlled environment inside.

Overloaded Cracker Packaging

An overloaded cracker packaging must be avoided

An overloaded cracker packaging is another biggest mistake that directly leads to break the delicate crackers during transport or handling. You must optimize the quantity of cracker assembling in each pack before planning to carry the whole process.

Using Expensive Cracker Packaging Material

The Cracker Packaging- Picture Courtesy-ScienceDirect

Be simple when planning to cracker packaging as it is perfectly acceptable among consumers and market to pick effective and good packaging. Therefore, selecting expensive material and making unwanted designs can affect your target goals and budget.

Using Unsuitable Cracker Packaging Machine

The cracker packaging machine- Picture Courtesy: Samful

There are several cracker packaging machines performing specific jobs such as VFFS, HFFS, Premade pouch, Tray sealing etc., You cannot attain crackers packaging in trays from VFFS and vice versa. You must understand the type of cracker packaging and select the right packaging machine.

A wasteful Cracker Packaging

Eco-friendly cracker packaging is a significant element for successful branding- Picture courtesy: Refinery

If you haven’t thought of recycling, then we would suggest not be too over cracker packaging. Being a seller, you must ensure the packaging product is remained protected from unwanted elements. So, select packaging material as eco-friendly and business booster.

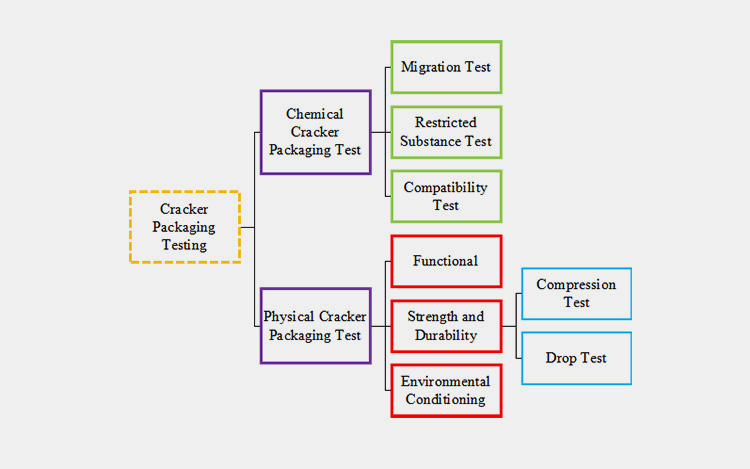

8.What is Cracker Packaging Testing?

Cracker pack in your hand comes after passing through various production and packaging assessments. The cracker packaging testing is the procedure that ensures that crackers you consume is safe and quality product which is away from contamination and received to you in an undamaged form. The list of cracker packaging testings are discussed below:

The Chemical Cracker Packaging Test

Cracker packaging test- Picture Courtesy: BBM

The chemical cracker packaging testing which focusing on the chemical composition of the cracker packaging material that comes in the contact with crackers. The following list of tests must be considered when planning for cracker packaging.

| Migration Test | The migration test is performed to assess the transfer of chemicals to crackers to protect the consumer from unwanted chemicals and helps in ensuring compliance with quality standards. |

| Restricted Substance Test | This is the test which is performed to ensure cracker packaging is safe from restricted items such as BPA, lead, or heavy metals,etc. |

| Compatibility Test | This is another safety test that ensure cracker inside the packaging doesn’t interact with packaging material or with compromised quality. |

Physical Cracker Packaging Test

Physical Cracker Packaging Test- Picture Courtesy: ZwickRoell

| Functional Test | This test is performed to ensure the intended purpose of the cracker packaging is to be carried out safely and securely to maintain consumer’s trust. | |

| Strength and Durability Test | Compression Test

The cracker pack is squeezed to assess how much compression and force it can tolerate and withstand against wear and tear. |

Drop Test

The cracker packaging is dropped over the flat surface to assess the durability and stability to tolerate vibration and shocks during transportation and distribution. |

| Environmental Test | This is tested to be performed to assess the cracker packaging is stable and withstand several environmental parameters such as humidity, temperature, cold and harsh atmosphere, heat etc., | |

9.What Things Should Be Considered While Crackers Packaging?

There are certain things which must be considered while crackers packaging. Let’s see them below.

Labeling and Designing

Cracker Packaging

Giving your consumers customized and variable designing and labeling options, allows for significant crackers packaging because of brand recognition . Adding specific details like nutrition information and allergens warning make it a reliable choice for better consumers understanding of crackers product.

Selection Of Packaging Material

Cracker Packaging- Picture courtesy: Packaging Strategies

Choosing of appropriate packaging material that would give your crackers ultimate originality and also provide food grade safety by assuring that the packaging material is unreactive to your crackers is must. Kraft paper or cardboard material ensures temperature resistance is given to the crackers so they may not get moist and spoil. Making a sturdy, eco-friendly and durable crackers packaging is also important to assure environmental consciousness and quality.

Customized Options in Cracker Packaging

Cracker packaging options- Picture courtesy: Gram

Customized options in packaging involving seal end, tuck end or resealable zipper features in different shapes and sizes of crackers packaging allow for convenient filling, easy opening , secure shipping and quality product delivery to the consumers. Introducing new designs of crackers packaging attract customers, especially if it is sustainable and claiming to be safe for product.

Sizes Of Cracker Packaging

Cracker Packaging

According to shapes and packaging material, different sizes of crackers packaging are available and can be tailor made too as per consumer preference. However, there is no specific size, but it can be categorized as small and single serving pouches and boxes to bulk and sharable size bags and containers.

Conclusion

Planning for new cracker packaging business can keep you overwhelmed and busy in creating and making ideas to bring an enticing packaging formats and ideas. Therefore, knowing the above-mentioned knowledge is fruitful to start an outstanding set up. We hope the discussed knowledge would be helpful in firing you in beginning the new exciting journey. Allpack always care for their customers side by side in understanding their hurdles, so hit us back if you want to start your journey with us! Our experience and qualified staff are right here to guide you from the very scratch. Happy Shopping!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours