Pet Food Packaging: The Complete FAQ Guide in 2025

Do you know that increased pet adoption has positively influenced the Pet food packaging market?

As with other packaging, pet food packaging has experienced transformation and innovation in the last few decades. Nowadays, there are diverse types of pet food packaging, packing gravies, curries, nibbles, treats, and other pet food. It is multifaceted consisting of special materials that are safe for both pets and the environment.

Let’s delve into the unique world of pet food packaging to learn more about its function, design, and importance in the lives of our dear furry friends.

1.What Do You Know About Pet food packaging?

Picture Courtesy: allthingsmama

Pet food packaging is a way of enclosing pet food like biscuits, meat cuts, wet feed, dry food, and other snacks or medicines in a container. This container can be a bottle, jar, pouch, bag, tray, stick pack, etc.

Due to busier lifestyle pet owners want readymade pet food because of convenience and variety. Thus, they prefer to buy pet food from the market. It is where pet food packaging has significance because it is a safe way to contain pet food to prevent its deterioration from biological and chemical agents and aids in preserving the shelf-life of pet food.

Pet food packaging comes with resealable options and handles that provide ease of use.

2.What are the pros of using pet food packaging?

Quality nutrition is extremely important for pets, as healthy pets mean happy pet owners. Pet food packaging has proved to be successful in maintaining the value of pet food.

Some handy pros of pet food packaging are listed below that you might find useful.

Resealable

Picture Courtesy: Roaster

The latest styles of pet food packaging feature zippers, sliders, Velcro tapes, and other closures for a resealing container after feeding four-legged friends. Without resealing, the packaging would remain open and is prone to pet and microbial contamination. But these re-closing options provides a mean for keeping pet food fresh for a longer period.

Product Information

Pet owners are concerned about the nature and ingredients of pet products therefore, they always check the content of pet food by meticulously studying its labeling. The latter is an essential component of packaging as it informs customers about details regarding the product. Labeled pet food packaging helps pet owners in selecting the right pet food for their pets based on their growth requirements and taste.

Brand Representative

It is analyzed that pet food packaging is the first thing that attracts customers. The design, color, font, and graphics of pet food packaging aid in creating exceptional brand identity and also help in memory building. Moreover, its distinctive patterns and color combinations assist pet food products to stand out among the crowd.

Convenience

Pet food packaging provides convenience and portability on travel. It has handles and other holders that present ease of carrying during pet walks. Furthermore, it comes in onetime-serve and multi-pack formats containing a fixed amount of pet food. This offers users the luxury of feeding pets without measuring the amount of food.

Storage and Shipment

Pet food packaging encloses bulk quantities of pet food for ease of storing pet food in warehouses and also in shipping it over a large distance. These containers are often stackable and occupy less space in storage and transportation while keeping the product safe from damage.

Claw and Teeth Proof Packaging

Picture Courtesy: YAYUSA

Often our four-legged friends puncture and tear pet food packaging with their claws and teeth. Now brand owners are introducing innovative materials that can withstand sharp punctures of claws and teeth and are tear-resistant.

Hidden Openings

Picture Courtesy: Biopak

Pet food packaging may have secret or covered openings that are not easily visible to pets. These openings are hidden by Velcro tapes or other add-ons. Pets are put off by said feature, therefore, losing their interest in packaging.

Dispensing Sprouts

Picture Courtesy: Logos Packaging

Pet food packaging also incorporates sprouts and caps. This feature assists pet owners in dispensing pet food and resealing pouches. Besides these benefits, caps also hinders pet from opening the packaging.

Locking Mechanisms

Picture Courtesy: Popular Science

For making pet food packaging pet-proof, it is designed with locking mechanisms. These built-in safety features are opened using certain twisting actions by the pet owner consequently making it difficult for the pet to manipulate the inner contents of packaging.

3.What are different types of pet food packaging?

There are a variety of pet food packaging for each different type of pet food. These food packaging containers have their unique design style and manufacturing materials. Their details are listed below which you might find helpful.

Types of Pet Food Packaging- According to Format

Pouch

They are made with plastics and laminate materials. There are diverse styles of pouches available for pet food packaging holding different quantities of pet food.

| Stand-up Pouch

Picture Courtesy: Printing Blog |

It has a flat base design with tapered at the top. The base offers stability to the pouches allowing them to stand tall on the retail shelves for display purposes. It is widely employed nowadays for packing wet feed and dry snacks. It has the additional benefit of a large printing area that offers maximum brand promotion. |

| Quad Seal Pouch

Picture Courtesy: Sante |

It is also referred to as a four-corner pouch and it has four sides that expand to give a box-like appearance when filled with pet food. It has a compact yet sturdy appearance that takes little space on the shelf. Moreover, due to its flat bottom, it holds a large volume of pet food. |

| Flat Bottom Pouch

Picture Courtesy: Packaging News |

This is an excellent choice for holding large volumes of pet food as it has more space at the base. Moreover, it has five sides that allow for more display of brand information consequently appealing to more pet owners. |

| Side Gusset Pouches

Picture Courtesy: Longdapac |

As the name indicates, this pet packaging pouch style has two folded sides. On filling these side gussets swell giving a cylindrical shape. However, it does not have a flat base and therefore, cannot stand on the retail shelves. Due to its limited space, it encloses less quantities of pet food. |

| Sprout Pouches

Picture Courtesy: allthingsmama |

This pouch has a sprout-like opening for ease in pouring pet food. It comes with a cap, so, has the option of resealing after use. It is used for packaging wet pet food and semi-moist like curries and gravies. |

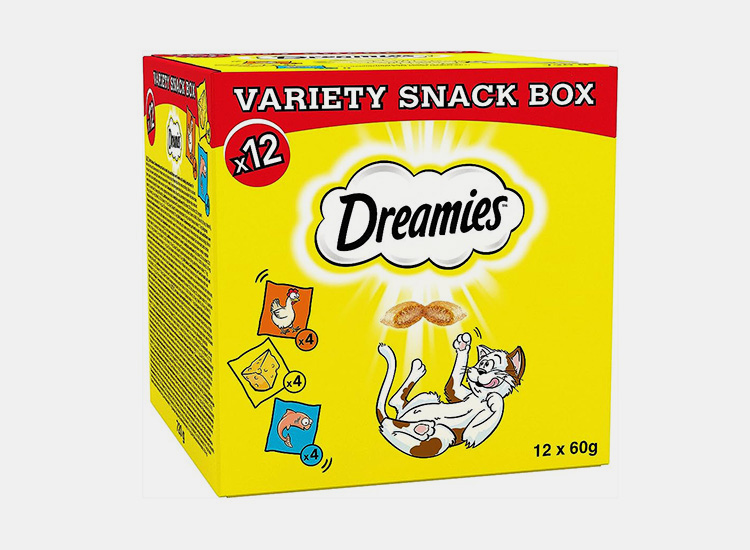

Carton Boxes

They are rectangular or square in shape and are formed using cardboard or paperboard. Biscuits, treats, and small snacks are usually packaged inside carton boxes. They are used for bulk packing and also holding other pet food containers for storage and shipment.

Cans

These containers are derived from metals like aluminum and tin which make them robust and tough. They are used for storing wet pastes and curries for pets.

Jars

Jars is a cylindrical container usually created from rigid plastic and glass. Sometimes, for premium packaging, brands use glass jars for packing semi-wet or dry pet food. Due to their transparency, they offer better product display.

Trays

These are the shallow containers usually made with aluminum foil. They come with a re-closable lid so that these containers can be securely closed after use They are ideal for single-serve packaging or portion-control packaging.

Different Types of Pet Food Packaging- According to Material

With innovations in material fabrication, diverse kinds of materials are employed for manufacturing pet food packaging. These materials have their texture, finish, color, and look and feel. A list of these materials is discussed below:

Aluminum

It is a strong, tough, and ductile metal, commonly employed for creating cans and foil pouches. This metal can hold semi-moist as well as pasty pet food like gravies. Aluminum provides a stringent barrier against environmental agents.

Plastic

Wide-ranging types of plastics like PET, HDPE, LDPE, and PP are employed for making pet food packaging. HDPE and LDPE plastic is often utilized for forming bottles and jars. Clear bags and flexible pouches are mainly formed by PET and LDPE. Different plastics have different characteristics but they typically fabricate airtight and moisture-proof packaging.

Glass

Picture Courtesy: Cheeseburger

For classy and luxurious pet food packaging, glass is used for producing clear jars. It is a non-reactive and airtight material that improves the shelf-life of inside products

Paperboard or Cardboard

Folded cartons are derived from paperboard or cardboard. These materials are fairly robust and durable and their finish aids in printing high-definition vibrant graphics.

Laminates

It is made with multi-layer plastics and paper. The laminate material is an essential component of flexible pet food packaging. It has a smooth and glossy finish, high tensile strength, and is a resistant impermeable barrier.

Compostable Materials

Picture Courtesy: Noissue

They are manufactured using paper. The latter is created using a compost heap. This paper is readily converted into organic manure within a short period. It has a significant value in sustainable packaging.

Biodegradable Plastics

Picture Courtesy: Bioplastic News

It is composed of layers of paper and bioplastics, which are in turn made from corn starch, seaweed, and potato. Its composition aids in its decomposition naturally by microbes over a longer time. In recent times, bioplastics have gained popularity for their use in flexible pet food pouch packaging.

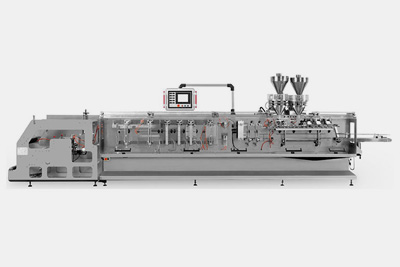

4.What kinds of machines produce pet food packaging?

Principal machines used in pet food packaging businesses have two important features. One they automate the pet food packaging and second these machines package pet food with high accuracy. These machines ascertain fast high-quality packaging.

Some important kinds of machines in pet food packaging are detailed below for your information.

| Details | Working Principle | Image |

| Premade Pouch Packaging Machine | ||

| This machine is an excellent choice for packaging custom-designed premade pouches, varying in shape, style, and size. Pet food whether wet or dry, solid or semi-solid is packaged efficiently by this equipment. It is ideal for processing pouches with resealable options. | Typically, premade empty pouches are loaded on the bag magazine while bag grippers pick these pouches from the bag magazine and take them to the filling station. For filling, this machine has auger, volumetric, or net weigh fillers that precisely load pet food inside the pouches. Afterward, sealing bars are used for sealing fill pouches. |

Picture Courtesy: Allpack China |

| Flow-wrapping Machines | ||

| It wraps pet food bars or other snacks using clear or ornate plastic film. Sometimes, this machine wraps and seals pet food inside a glossy metallic film. | The pet food product is placed on the conveyor for transportation to the forming station. Here grippers place products on film and after that sides of the film are folded. Next, the wrapped product goes to a sealing area where folded sides are glued using heat and pressure. |

Picture Courtesy: Allpack China |

| Horizontal Form Fill and Seal Machine | ||

| It offers high flexibility in pouch processing and it uses film roll for making pouches. This machine features horizontal direction packaging. It is best for packaging heavier pet foods that can get damaged if travel vertically. | First, the packaging film is put on the film holders, unwound, and folded. After traveling across rollers, this film is moved to the forming station where it is shaped into a bag. The pet food is placed onto conveyors and by the movement of conveyors, it travels to the filling station. Then it is inserted inside bags and finally at the sealing station, the sides of the bags are permanently fused to create airtight pet food packaging. |

Picture Courtesy: Allpack China |

| Vertical Form Fill and Seal Machine | ||

| This machine is one of the most common equipment for pet food packaging. It can accommodate almost every type of pet food such as dry treats, cat curries, and seeds for pet birds. It is widely employed for both liquid and solid pet food using gravity because it has vertical processivity. | The film roll gradually unwound and proceeds to form a tube after crossing the rollers and the dancer's arms. Bulk pet food is loaded inside the hopper of the machine. A conical forming tube folds and fashions a pocket-like pouch. Pet food after passing through a hopper, flows to fillers from where it is forced inside a pouch. Then sealing bars fuse the top edges of the pouch. |

Picture Courtesy: Allpack China |

| Can Filling and Sealing Machine | ||

| This machine is usually employed for filling wet feed inside the can packaging. It is equipped with a nozzle and filling units that measure the precise dose of pet food and load it inside the cans. These cans are filled either by volumetric or weight filling. | Bulk quantities of pet food are stored in a hopper and cans are put on the conveyor. Once cans reach under the filling nozzle, sensors signal the start of filling. Using different fillers like auger, pressure, or gravity, the cans are packaged with pet food. After complete filling, they are relocated to a sealing unit that places lids over the cans. |

Picture Courtesy: IC Filling System |

5.What are the different sizes of pet food packaging pouches?

There is no fixed size for pet food packaging as various brands opt for varying pet food packaging sizes depending upon the required quantity of product as well as their customer penchant.

Below discussed are some popular pet food packaging sizes:

Small Pouch

These pouches could hold about 10 grams (0.022 pounds) to 1 kilogram (2.2 pounds) of pet food. Small-sized pet food packaging pouches are ideal for single-serve. Also, they are employed for trial purposes.

Medium Pouch

It has a larger size than small-sized pouches and has more quantity which exceeds 2.2 pounds (1 kilogram). It holds up to 12 pounds (5.4 kilograms) of pet food. This bag is good for storing food for medium-sized pets. The pet food in this pack lasts longer than small-sized pouches.

Large Pouch

It is a cost-effective size for pet owners who have larger-sized pets and usually like to buy pet food in bulk. This larger-sized pouch starts from 15 pounds (6.8 kilograms) and can retain about 30 pounds (13.6 kilograms) of pet food. However, there is a large variation in the sizes of large pouches.

Extra-Large Pouch

It is also a bonus-sized pouch having more amount of pet food that is greater than 30 pounds (13.6 kilograms). Sometimes it can package about 50 pounds of pet feed. This pouch size is ideal for customers having multiple pets. These customers choose to buy a substantial portion of pet food in one go.

6.Can you recycle pet food packaging?

Picture Courtesy: Steve Food Real

Well, the answer to that question is yes. With the rising awareness about the earth's deterioration, people are opting for sustainable pet food packaging. Sustainability is key to protect earth deteriorating eco-systems as environmental effect of pet food packaging is difficult to overlook.

So, they prefer to buy pet food comes in sustainable and recyclable packaging that is manufactured using eco-friendly and green materials. For this pet food packaging machines are innovated to handle recyclable amaterials.

Manufacturers are making conscious efforts to develop pet food packaging that have positive impact on planet without conceding on pet food quality.

Some examples of sustainable pet food packaging materials are:

Aluminum cans for pet food packaging have low environment footprint and are infinitely recycled and reused. These containers are collected and melted at high temperatures for reuse.

PET and HDPE plastic bottles and pouches for storing pet food are shredded and then used as raw material for plastic manufacture, thus making them more sustainable.

Carton boxes used for holding dry treats are shredded and broken down into paper fibers in the recycling step.

Some flexible pouch packaging is also recycled by going through special recycling steps.

7.Is Pet Food Packaging Safe?

If you are concerned about the safety of pet food packaging, then do not worry! Pet food packaging is extremely safe. Environmental agents could affect the nutritional quality of pet food resulting in loss of pliability and freshness. Also, microbes and pests may grow on pet food rendering it unfit for consumption.

However, pet food packaging is made with impermeable materials that offer superior protection against moisture, UV light, air, and temperature. Moreover, it is designed with inert materials and thus, does not react with chemicals.

It is packed and sealed under the vacuum that removes the air. Sometimes, nitrogen is also flushed inside the pet food packaging to eliminate atmospheric oxygen. Oxygen is the main culprit in the oxidation of nutrients and promotes microbe growth. However, by eliminating this problem, pet food remains fresh ensuring better taste and nutrition in every bite,

8.What is the Difference Between Wet Pet Food and Dry Pet Food Packaging?

There are different formats of wet pet food and dry pet food packaging. Each has its pros and cons. The choice between both these packaging is influenced by the palatability and diet of pets as well as the convenience of pet owners.

Some of the differences between these packaging kinds are detailed for your information.

| Feature | Wet Pet Food Packaging | Dry Pet Food Packaging |

| Format | Wet or semi-wet pet food is usually available in cans. | Dry pet food like kibbles is packed inside the flexible pouch. |

| Convenience | Cans are closed with lids requiring a can opener to open them. | Dry food packaging has tear-away seals that are easier to open. Moreover, it has re-closable tapes for closing it after use. |

| Space on Retail Shelves | Wet food packaging has more volume and weight and thus takes more space on retail shelves. | Flexible pouches are lighter requiring minimal space in the display area of the shopping market. |

| Price | It is a more expensive option. | It is less price. |

| Shelf-Life | The quality of pet food decreases rapidly after opening wet food containers. | Pet food remains fresher for a longer period in dry pet food packaging after opening them. |

| Recyclability | This packaging is easily recycled. | Special steps are taken for recycling dry pet food packaging. |

9.What Is the Shelf-Life of Pet Food Packaging?

This shelf-life or operational file of pet packaging is the time during which packaging keeps the pet food from getting spoiled and contaminated by environmental agents, chemicals, pests, and microbes and ensures that the product is fit to eat.

The shelf-life of pet food packaging depends upon several factors including the type of packaging material, environmental changes, type of pet food packaged, closure options, storage, expiry date of pet food, etc.

Usually, the shelf-life of pet food packaging is the same as that of the expiry date of pet feed mentioned on the packaging container. This is around 1-2 years. However, if the pet food packaging is opened then pet food should be consumed within 1 and a half months, otherwise, pet food would its quality.

Conclusion

Since pets are dear to pet parents, they always want the best for their pets, and pet food packaging is no exception to the rule. Today, in the market, a wide assortment of pet food packaging is available differing in their styles, materials, and sizes. But one thing is common in all these varieties- protection. These different pet food packaging offer exceptional barriers to agents that damage the taste, aroma, and nutritional value of pet food. For the safest, superior-quality, creatively-styled pet food packaging you can visit our “Allpack” website. Here you can get the best price deals on your packaging and machine.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide