Square Bottle Labeling Machine: The Complete Buying Guide In 2025

Do you want your products to mesmerize consumers while laying on the shelves of market or selling stores? Obviously! Every manufacturer has the desire to be admired by customers for supplying quality products and in turn have a good demand for them. However, it is not going to happen, mere by dreaming instead you have to adopt the means to make it happen. Therefore, Allpack has brought for you an amazing solution of Square Bottle Labeling Machine which is ready to take your dreams ahead.

This Square Bottle Labeling Machine is in itself a comprehensive whole by possessing the advance features of performing efficiently and precisely while showing high degree of resilience to objects' diversification. You can get much more by using this machine in a way explained in this useful review. So, don't waste time in thinking and start solving your conundrums by delving in this article!

1.What Is A Square Bottle Labeling Machine?

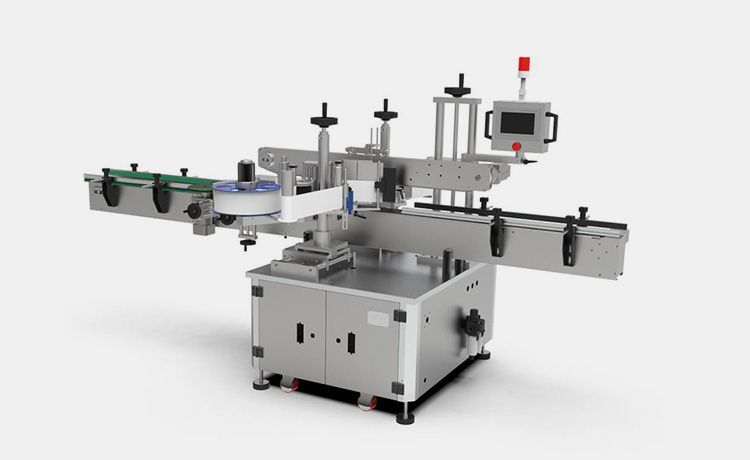

A square bottle labeling machine is cutting edge ergonomic labeling device made with innovative technology of automation to undertake intricate square bottle labeling. It is featured with intelligent inspection system, electrical energy transformation and flexible dimensions range to facilitate the bottle labeling. By using these attributes, it effectively takes the labels from roller and applies them over bottles through mechanical system.

This self-centered operation by full proof hygienic machine is resultantly expanding its appeal in different industries, who are looking forward for an ultimate solution to cope up with their numerous square bottles including pharma industry, food industry, beverage industry and others.

2.How Does A Square Bottle Labeling Machine Perk UP Your Business?

Bringing a square bottle labeling machine to your business can definitely enhance the pace of production and give you so many other incentives. Let's have a look towards them:

Ensuring Clarity

The foremost concern of every producer is indeed to attain high level of precision in labeling bottles. Here, the machine is accomplishing this aim by utilizing its stunning feature of focused design on targeted area.

Less Demanding

This machine is requiring minimal labor as well as operation demand. This is because the system of machine is designed in such a way where bottles are moved automatically during labeling once commands are fixed into it.

Versatility

As the manufacturing goods vary from one type of industry to another, similarly, the bottles used for storage also have different sizes. Ergo, the machine is resilient enough to complement the vast needs of diverse industries in terms of labeling.

Multiple Labeling

Another crucial advantage of square bottle labeling machine is the variety it offers for labeling bottles. For instance, you may use it for multiple labeling at once such as front, back, neck or full labeling of bottles.

Structural Integrity

The machine is made up of stainless steel and heavy-duty mechanical tools which are collectively making it more robust and live longer life.

High Throughput

Efficient tooling system, high speed and consistent operation together contribute to improve the rate of production to next level.

3.What Are The Working Principles Of A Square Bottle Labeling Machine?

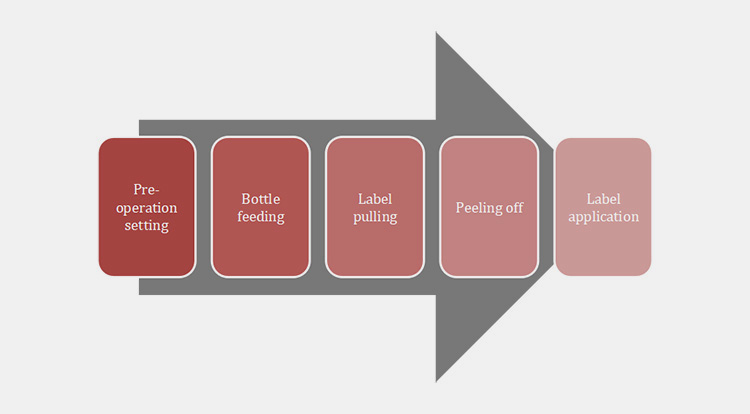

Operating a square bottle labeling machine is now becoming a piece of cake due to the high degree of automation as well as innovative structure and features of machine. The underlying steps would better enlighten your understanding about the machine's working procedure:

Pre-Operation Setting

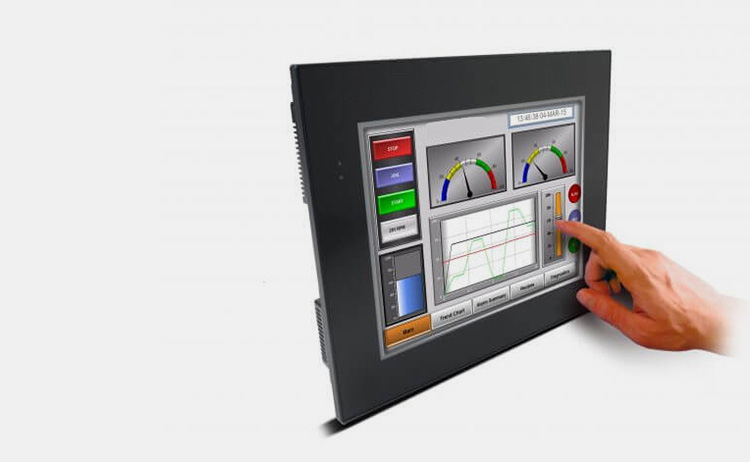

Before starting operation, it is required to set the machine for operation. For this, basic parameters of machine can be fixed by using HMI unit such as speed of conveyor belt, the gap between each label and the time of moving shafts. In this step, machine is supplied with required number of label rollers.

Bottle Feeding

The operation of machine begins with feeding of bottles which are carried out be the conveyor on their ways towards labeling.

Label Pulling

In this phase, electric eye detect the gap between each label on one hand, while as, the drive wheels start pulling labels from label holder on the other hand.

Peeling Off

Now, the peel off device comes into action and removes the back side of label by separating their ways.

Label Application

Finally, when the bottles reach to the labeling station, the label applicator applies single, double or multiple labels to the bottles. These bottles are then passed by the fur brush for sticking labels accurately over them.

Bottle Discharge Phase

The labeled bottles are intermittently discharged by the conveyor belt to other machines for processing. In case of semi-automatic machine, operator is required to take the bottles out of discharge unit.

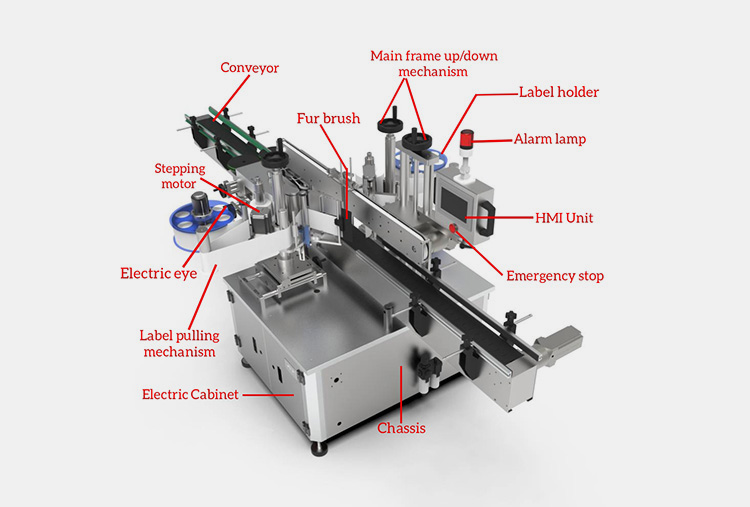

4.What Components Make A Square Bottle Labeling Machine Composite?

A square bottle labeling machine is a robust unit of several small to large components which together maintain the integrity of machine. These are described below in detail:

Chassis

Chassis refers to the base of machine which works as a supporting device for all other components which are attached over it. This framework of machine is made up of durable stainless steel to better ensure the smooth flow of labeling.

Electric Cabinet

This part of machine works as an electric box which houses the overall electrical wires and power circuits of machine to help in seamless operation.

HMI Unit

This unit holds in it the essential feature of machine in form of touch screen display which allows for easy monitoring and controlling of machine through setting parameters.

Main Frame Up/Down Mechanism

As shown in the picture above, this part of machine is located on the top side of machine. It is responsible for adjusting the height of upper mainframe.

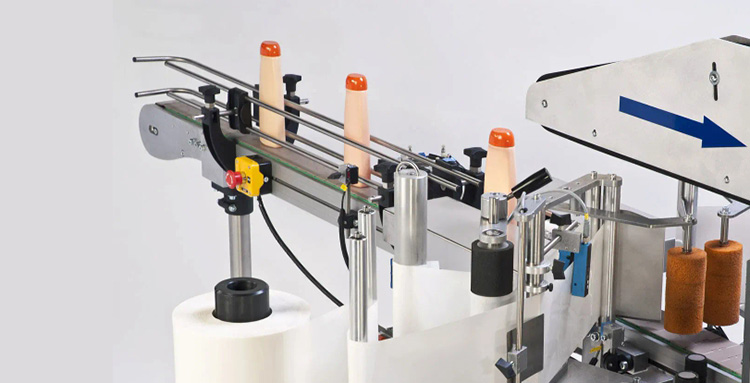

Label Holder

Label holder is a round device with labels rolled over it. This component plays a crucial role in providing machine with sufficient volume of labels.

Label Pulling Mechanism

It refers to the group of circular steel stands which are located in specific areas for the purpose of pulling labels from label holder and supplying it to the label applicator.

Electric Eye

Electric eye is a label sensor device that is responsible to detect the space between each label, thus, sends the message to machine for controlling the label stop sequence.

Stepping Motor

Stepping motor is a device that converts the electrical power into mechanical energy and thereby initiates the rotational movement of label pulling shafts.

Fur Brush

Fur brush is located alongside label applicator. When labeled bottle passes through it, the device brushes labeled sides of bottle to get the label stuck to it.

Conveyor

Conveyor is an inevitable part of every packaging machine which profoundly undertake the function of transporting bottles for labeling.

Alarm Lamp

Alarm lamp can be found on the top side of HMI unit which makes the user aware about sudden uncertainty through red light and high volume.

Emergency Stop

Similar to alarm lamp, emergency stop assist in the safe operation of labeling. Its large size and red color makes it easier for operator to stop the process swiftly.

5.Which Type Of Bottles Can Be Labeled By A Square Bottle Labeling Machine?

A square bottle labeling machine is well-equipped to match the flexible needs of bottles with ranging material and size. They are discussed below:

Plastic Bottles

Plastic bottles are commonly used for juices, medicines and sauces etc., for their flexibility and cheap price. Therefore, a square bottle labeling machine can conveniently process these bottles for beautiful labeling.

Glass Bottles

Most of the temperature sensitive products are not suitable to be stored in plastic bottles, therefore, glass bottles are used as an alternative. Hence, non-porous glass bottles containing tablets, honey, jams and vegetable pastes can be precisely labeled by this machine.

Metal Bottles

Unlike glass, metal bottles are durable and have higher protection against breakage. This fact leads many enterprises to make use of metal cans, jars or bottles etc. Ergo, the machine is eligible to label metal bottles.

It is worthy to mention here, that a square bottle labeling machine can be used not only for square bottles, but for range of other shapes of bottles such as:

- Square Bottles

- Rectangular Bottles

- Round Bottles

- Triangular Bottles

- Special Shape Bottles

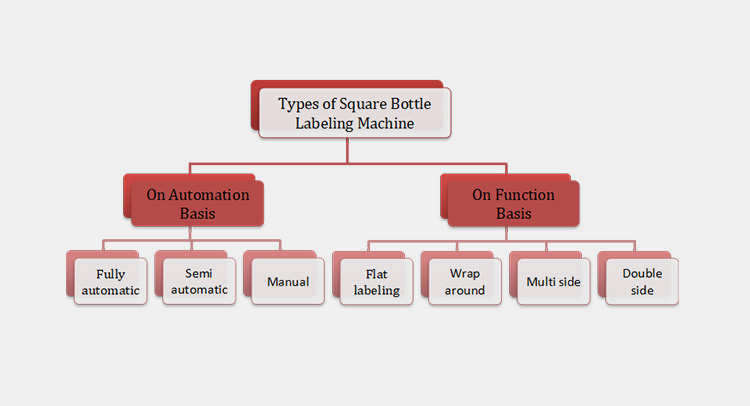

6.Are There Any Types Of Square Bottle Labeling Machine?

There are different types of square bottle labeling machine available in market. This question will particularly emphasize on showing you the range of square bottle labeling machine which can be used for making your business more lucrative. They are as follows:

On Automation Basis

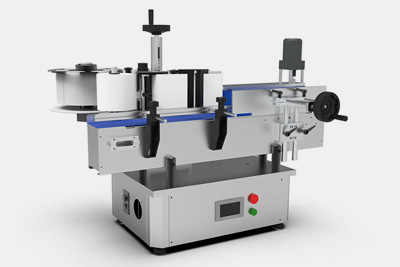

Fully Automatic Square Bottle Labeling Machine

Fully automatic square bottle labeling machine is excellent quality intelligent machine with PLC controlled operation. The machine is highly productive to meat the desired demand of labeling by range of industries encompasses food, pharmaceutical, beverage and cosmetic etc. Driven by self operated system, the machine requires no parts' changeover thereby reducing labor, time spent and energy used.

Semi-Automatic Square Bottle Labeling Machine

Semi-automatic square bottle labeling machine on the other hand, is based on the principles of partial human labor. The machine is precise in its structure and therefore occupying less space. Moreover, the cost-effectiveness and satisfactory speed of machine are making it more appealing for industries with medium level of businesses.

Manual Square Bottle Labeling Machine

Manual square bottle labeling machine is the handiest device which is entirely dependent upon user for its function. With small footprint, this machine is extremely portable, thus, meeting the demand of user to carry it wherever one wants. It can be used by putting the labeling roller into lever and then start applying labels over bottle by pressing the handle. In this way, the machine can play its positive role in small level business labeling.

On Function Basis

Square Bottle Shrink Sleeve Labeling Machine

This type of machine is brought into the field to precisely label the bottles via air and moisture proof labeling. The machine works by putting the loose sleeve labels over square bottles and passing them through a heat tunnel which resulted in the contraction of sleeve labels around the bottles. Similarly, the bottles get dual benefits of having information over them, and along with that, any type of moisture and heat is restricted to approach the inside content. Most of the mineral water, cooking oil, and medicine bottles are processed by this machine for shrink sleeve labeling.

Big Square Bottle Flat Surface Labeling Machine

This type of machine is designed for big square bottles like jerrycans. The machine has automatic processing regulated by computerized system. With heavy-duty structure, it is able to withstand large number of loaded bottles and label them by applying flat labels on dual sides of each bottle. It is widely applicable to food industry, chemical industry, and lubricants industry.

Square Bottle Wrap Around Labeling Machine

This machine is employed to label the square bottles with one label on four sides. With simple operation and maintenance requirements the machine is user-friendly, and even a primitive man can use it. During labeling, the bottles automatically rotate with the help of rolling shafts thereby allowing the labeling device to apply labels with exerting force. Eventually, all the four sides of bottles are wrapped with one label. This machine is suitable for bottles which require multiple information over them, thus, has demand in food, chemical and medical industries.

Square Bottle Multi Side Labeling Machine

Another type of square bottle labeling machine is the one with application of labeling on multi sides. It is proficient in applying single adhesive label over three sides of each bottle. The structure of machine is composed of host, labeling station, bottle transmission system and label feeding mechanism etc. The machine simply applies labels to bottles by pressing them in movable shafts where label applicator performs the actual task of label application. It is ideally perfect for wide range of industries including cosmetic, condiments and snacks etc.

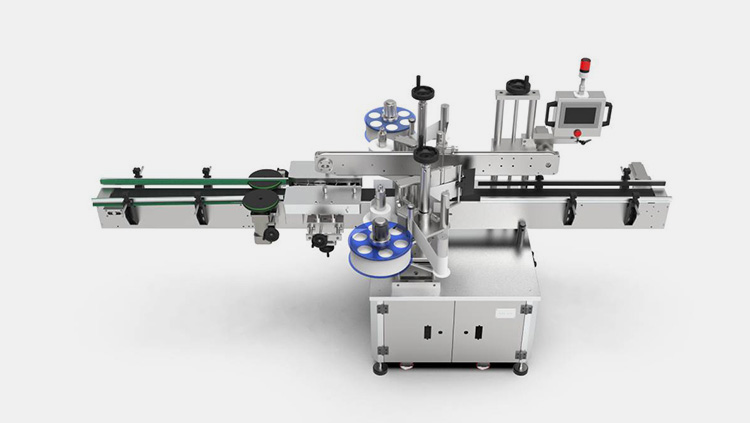

Square Bottle Double Side Labeling Machine

This machine is integrated with dual system of labeling feeding. It thus fulfills the task of labeling by taking two separate labels from opposite sides of the middle conveyor belt. When bottles pass through the labeling station, labels applicators from both sides swiftly release the labels over double sides of bottle. Hence, two labels on a single bottle are attached. This machine is useful for manufacturers who to give their bottles different look by displaying information about company and product separately on front and back respectively.

7.Pin Down The Key Differences Between Automatic Square Bottle Labeling Machine And Manual Square Bottle Labeling Machine?

To know differences between fully automatic and manual square bottle labeling machine consider the facts given below:

| No | Factors | Fully Automatic Square Bottle Labeling Machine | Manual Square Bottle Labeling Machine |

| 1 | Automation | Fully automated | Zero automation |

| 2 | Structure | Complex and large | Small and precise |

| 3 | Process | Self operated | Entirely depends upon user |

| 4 | Speed | High speed by labeling 4000 bottles per hour | Low speed as rely on user |

| 5 | Cost | Expensive | Cheap |

| 6 | Application | Medium to large scale industries | Small scale business or wholesale markets etc. |

| 7 | Pictures |  |

|

8.Describe The Eclectic Labels Supported By A Square Bottle Labeling Machine?

This machine can support wide range of labeling material such as:

PET Sticker Labels

PET labels are most commonly used labels made from flexible plastic. With self-adhesive material behind them, polyethylene terephthalate sticker labels are effectively processed by this machine.

Paper Sticker Labels

Like PET labels, paper labels are also popularly used in wide range of industries due to its cheap price. These paper labels have external layer of plastic to avoid decomposition in case of contacting water or moisture.

Aluminum Sticker Labels

These stickers are made from the aluminum foil which makes the labels more strong against ultraviolet light. Square bottle labeling machine is thus right equipment to apply these labels with.

Transparent Sticker Labels

This machine is also able to apply transparent sticker labels in a pretty precise way by cutting the labels on the basis of distance rather than marking present over colored labels.

Foam Adhesive Labels

Foam adhesive labels are made up of soft bouncy foam. These labels are useful for bottles which are placed in uneven surface, so, the risk of damage can be reduced by the protection given by flexible adhesive labels. Here, it is notable that these labels can be processed by square bottle labeling machine

Shrink Sleeve Labels

Shrink sleeve labels can be processed by this machine which made from stretchable PET plastic which easily get shrunk when exposed to heat.

9.What Information Is Provided On Labels Dispensed By A Square Bottle Labeling Machine?

A label used for labeling square bottles contains several types of information which is necessary to educate the shoppers about product. Below description will clearly display the useful information:

Product Name

On of the prominent thing which can be found on the front of square bottle labels is the product name. Since, the shoppers are always in search of finding desired item, product name help them to get it easily.

Brand Name

The next important information is brand name which is printed on the front part of bottle. It can assist customers to identify the brand they trust. Similarly, brand name can change the fate of business for giving them identity.

Ingredients

Mentioning ingredients on your bottles is necessary whether it is food item, cosmetic or medical, because, most of the people do not believe in the originality of products if the labels lack ingredients information.

Fact Chart

Fact chart shows the power and effects of products. For instance, labels over food bottles contain ingredient chart which display information about calories, fats and proteins etc.

Company Information

Giving information about company on labels helps in regulating trust among consumers about company's validity and authorization. It may include certifications, location and contact number etc.

Barcode

Barcode consists of bars and spaces which are printed on labels to enable the employees of supermarkets to distinguish the products of one company from rest one.

Expiration Date

Expiration date tells us about the time period until which product is safe to consume. Therefore, product can be used before its quality gets expired.

10.How To Provide A Square Bottle Labeling Machine With More Catchy Labels?

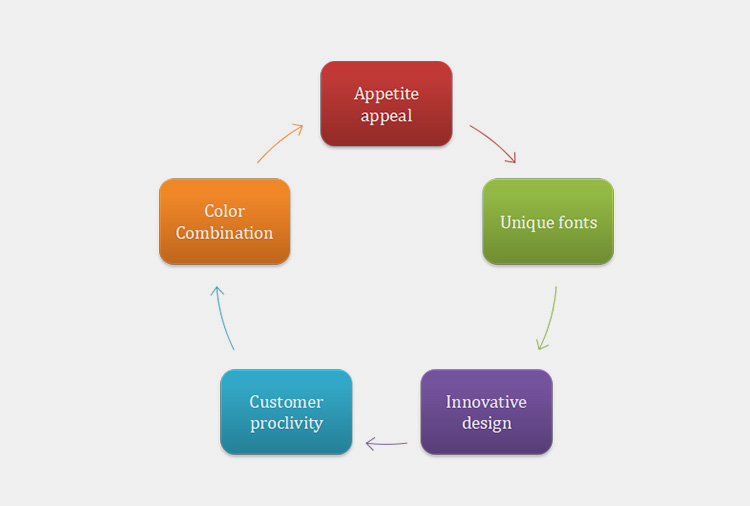

It is one of the most desirable questions frequently asked by manufacturers who are really concerned about the quality and packaging of their goods. Hence, we are going to provide you with the best ever techniques whose adoption will surely lead you to be known for astonishing packaging. These include:

Appetite Appeal

Food labels can be made tantalizing by employing the most desirable technique of appetite appeal. By printing quality food picture over labels will definitely entice the consumers to add your product into their cart.

Unique Fonts

Fonts carry great significance to make your packaging look more professional than others. In addition, using unique fonts for brand name and product name helps the customers to distinguish your products in huge sea of similar items.

Color Combination

Colors are the lights which influences soul, thereby using colors in your labels to make eye-popping combination can also pave the way to make them more attractive.

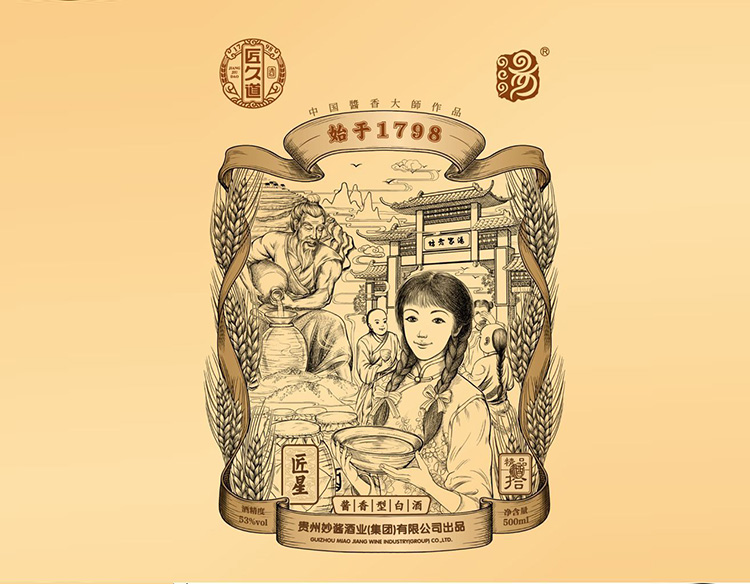

Customer Proclivity

Keeping in mind the customer proclivity while designing labels can help you target them easily. For instance, labels' resembling traditional blend can increase the charm of product for people having great love for their heritage.

Innovative Design

Sticking to the primitive way of using flat square labels for your square bottles will include your packaging among ordinary ones. Therefore, try to adopt new and creative labeling methods by using different shapes like triangle, round, half shape or labels joining cap and bottle etc.

11.Highlight The Significance Of A Square Bottle Labeling Machine In Various Sectors?

After having established the mind mapping about square bottle labeling machine, now, it is the time to show its significant role of labeling in diverse sectors through below description:

Medical Industry

Medical industry which encompasses pharmaceutical industry, nutraceutical industry, veterinary industry, herbal industry and dental industry is the first ever beneficiary of square bottle labeling machine.

Food Industry

Food industry is another area which has an unending demand for this machine which can be practically seen via square labeled bottles of sauces, chocolate, candies, jam, and dairy products etc.

Beverage Industry

Among other manufacturing fields, beverage industry has greatly advantaged by the versatility of this machine, for labeling square bottles of mineral water, juices, wine and soft drinks etc.

Cosmetic Industry

The unprecedented growth of cosmetic industry has directly increased the need for effective packaging tools among which square bottle labeling machine is the crucial one. With the help of this machine, square bottles of perfumes, shampoo, lotion and soaps etc., can be magnificently labeled.

Oil and Lubricants Industry

As we have mentioned above, the square bottle labeling machine has an individual machine for big square bottles which is used to label them. Hence, oil and lubricants market can be found using it.

12.How To Maintain A Square Bottle Labeling Machine?

Indeed, success of your business depends upon the consistency of keeping good work which is itself relying upon the smooth functioning of your machines. Therefore, to enhance the working life of your square bottle labeling machine, following maintenance points can be helpful:

Fixing Configurations: This machine is flexible enough to perform multiple types of labeling alone. However, these features can be brought into operation only if the operator is ready to fix the parameters of machine according to changing demand of labeling. Ergo, it is important to modify the machine's configuration.

Proper Cleaning: As the machine is constantly engaged in separating and applying adhesive labels, it is inevitable to properly clean it on daily basis. For this purpose, neat fabric soaked in non-aggressive detergent can be applied over sticky areas to keep the machine flow smooth.

Lubrication: Parts such as conveyor belt, labeling feeder and rolling shafts require lubrication to follow smooth pace of running. Therefore, lubricating these parts can reduce causing friction and process stagnation.

Parts Changeover: Installation of machine does not mean it will remain same forever, instead parts damage or wornout will demand for parts changeover. This implies responsibility on part of user to take timely step for resolving these issues.

13.What Other Machines Can Be Integrated With A Square Bottle Labeling Machine?

A square bottle labeling machine is able to work along with other machines in a production line. These machines are as follows:

Bottle Unscrambler

Bottle unscrambler is an advance machine used for feeding the bottles to manufacturing lines in a serialized manner. This machine is robust in its construction with the help of which it takes randomly positioned bottles from hopper and turn them into accurate position for accelerating the production speed.

Liquid Filling Machine

Picture Courtesy: Lodha

Liquid filling machine is topnotch equipment designed to undertake the filling of numerous liquids into bottles and containers including free flowing and thick liquids. It is part of the packaging line where square bottle labeling machine can further process these filled bottles via labeling.

Tablet Filling Machine

This excellent machine is made in such a way that all types of tablets, capsules, candies, chocolate balls and gummies etc., can be perfectly counted as well as filled into bottles. Similarly, these bottles are then labeled through square bottle labeling machine.

Bottle Capping Machine

Picture Courtesy: Tecno

To cap the filled square bottles, a machine namely bottle capping machine is thus introduced to perform this job effectively and adds to the overall production efficiency.

Induction Sealing Machine

Another machine which can be directly attached to the square bottle labeling machine is an induction sealing machine. This device is expert in sealing the aluminum foil under the caps of closed bottles through an ultraviolet radiation, so that the inside content can be fully secured from leak and moisture.

14.Elicit The Troubleshooting For A Square Bottle Labeling Machine?

There are some possible challenges which you might face during operating this machine. Therefore, below table can help you resolve them quickly:

| No | Issues | Reasons | Troubleshooting | Illustration |

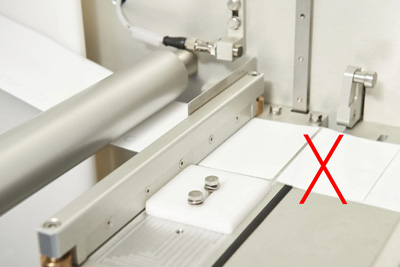

| 1 | Label pulling mechanism do not function properly | Either substrate motor is not moving or drive belt is loose | Check the motor and lubricate it or tight the drive belt. Take the help of an expert if problem remains unsolved |  |

| 2 | Incorrect cutting of labels | The electric eye is unable to detect the space between each label due to incorrect positioning | Correct the position of electric eye right in front of labeling feeder |  |

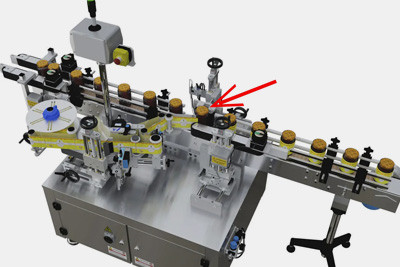

| 3 | Bottles do not rotate swiftly during wrap around labeling | The rolling shafts are not parallel to label applicator | Align the rolling shafts to that of label applicator in order to balance the pressure over bottles from both sides |  |

| 4 | Label feeding error | Incorrect setting of sensor after keeping new label roller | Make sure to set the sensors each time when loading machine with new set of labels roller |  |

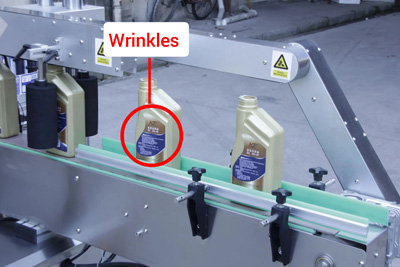

| 5 | Wrinkles appear on labels | The delivery speed of labeling wheel is too fast | Adjust the speed of label application wheel to ensure wrinkle free labeling |  |

15.What Are The Keys For Getting A Magnificent Square Bottle Labeling Machine?

If you want to get the best square bottle labeling machine you must have to follow the essential requirements needed for it. The underlying keys are holding some of these requirements to make you understand them without any effort:

Required Volume

The first key towards journey of getting perfect compatible machine is to determine your production volume you want to label by this machine. It will simply allow you to know whether semi-automatic, fully automatic or manual square bottle labeling machine is your need.

Compliance

Another key is to check the compliance of machine with international quality standards such as ISO, FDA and GMP. By doing so, you can get quality equipment and include your business in safe zone when undergoing quarterly scrutiny by food packaging authorities.

Flexibility

As above-mentioned types of square bottle labeling machines include one which can process multiple shapes of bottles. Therefore, if you are running large scale business with eclectic bottles choose the machine which is more flexible.

Capital Investment

Investing on the capital for your industry is essential; however, keeping in view the amount of money required is flip side of the coin. Hence, choosing a machine under your budget can save your money from being wasted.

Conclusion

To put in a nutshell, square bottle labeling machine is ergonomic equipment which is showing its excellence in almost every sector that has been associated with bottle packaging. Its use can enhance your packaging charm, efficiency as well as accuracy. Apart from that, you can get other advantages in case of considering Allpack which is offering one year of warranty, full installation and training support and much more. So, don't waste time and get your order booked by using the given link.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide