Shrink Labeller: The Complete FAQ Guide In 2025

Do you feel strange about shrink labeller? This is a practical packaging machine, you can regard it as the combination of labeling machine and shrink tunnel, why? This machine is to add the labels on the bottles, and then adopts heat shrinking method to let the labels fit the bottles perfectly. In other words, shrink labeller can provide beautiful and fit labeling to all kinds of products.

Therefore, adding a shrink labeller to your business is a good choice for you, do you know how to choose a good shrink labeller? And do you understand this machine? If you don’t, don’t worry, you can read this FAQ guide which will introduce shrink labeller in detail.

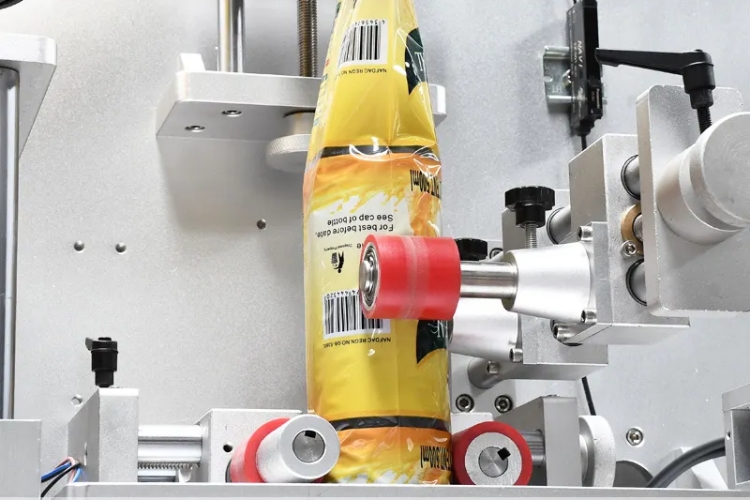

1.What is a shrink labeller?

Shrink Labeller-Photo Credit: APACKS

Shrink labeller is an efficient automatic packaging machine which is to apply sleeve labels to different shaped containers and heat shrink them so that they can fit the containers tightly, to provide beautiful package and strong branding effect to your products. Shrink labeller is widely used in food, beverage, personal care products, pharmaceutical, household products industries, etc.

2.How can a shrink labeller benefit you?

A shrink labeller has many advantages and it can benefit you a lot, some of its advantages are as follows:

High Flexibility

As is mentioned that shrink labeller can heat shrink the sleeve labels to make them fit different containers, whether the shapes of these containers are regular or irregular, they can be easily labeled by shrink labeller. Moreover, shrink labeller is suitable for all kinds of label demands, such as full body, half body and so on.

Tamper-evident

Shrink labeller provides product a tamper-evident package, the sleeve label covers the whole container, if the sleeve label is broken, it is obvious that the product is tampered. This advantage of shrink labeller can protect your rights, help you purchase reliable products.

360-degree Branding

By using a shrink labeller, you can add a beautiful and designed label to your product, such a large area of package can make your product attractive and promote your brand. Why? It is because of the information and brand logo which are printed on the label, which can strengthen the impression of products of customers and enhance brand awareness.

Save Cost

To be honest, using a shrink labeller in your production process can save your cost. On the one hand, this machine combines the operation of labeling and sealing, which simplify the packaging process; On the other hand, the shrink labeller can provide high speed production and fast changeover, as a result, it can label more products in limited time.

3.Which industries have demand for shrink labeller?

As you know, shrink labeller can label a variety of containers, therefore, it can be used in different industries, which will be listed next.

Food Industry

Food Industry-Photo Credit: PDC International

In fact, shrink labeller is commonly applied in food industry to package food products, including but not limited to dressings, jams, salads, all kinds of jarred and bottled snacks and so on. These food products are labeled by shrink labeller so that they have tamper-evident packages, which are beneficial for their sale.

Beverage Industry

Beverage Industry-Photo Credit: CCL Label

There is no doubt that shrink labeller plays a important role in beverage industry because nearly 90% of beverages are packed by sleeve labels. Various bottled and jarred fruit juices, carbonated drinks, electrolyte drinks, are labeled by the shrink labeller. This machine provide attractive and beautiful packaged to beverages, to increase their market competition.

Personal Care Products Industry

Personal Care Products Industry-Photo Credit: Packaging Strategies

The personal care products, such as shampoo, conditioner, body milk, shower gel, face cleanser and so on, are packaged by sleeve labels, what equipment can do this operation? Obviously, it is shrink labeller. The personal care products which are packed by shrink labeller have beautiful appearances, are popular on the market.

Pharmaceutical Industry

Pharmaceutical Industry-Photo Credit: Dion Label Printing

In pharmaceutical industry, there are many medicine bottles packed by shrink labeller, no matter there are capsules, tablets, syrup or other medicines in them, the machine can provide perfect packaging and labeling to these bottles. By applying shrink labeller, the medicines are sealed in the bottles, not affect by air.

Household Products Industry

Household Products Industry-Photo Credit: Eastgate Group

You’ll never be unfamiliar with household products, including dish washing liquid, toilet cleaner, laundry detergent, disinfectant, hand sanitizer and so on. It is not difficult to find that they are packed by sleeve labels if you usually observe them, these products are shrink labeled by shrink labeller and get their fitting packages.

4.What is the classification of shrink labeller?

Is there only one type of shrink labeller on the market? Of course that the answer is “No”. So, how many types of shrink labellers there are? Let’s discuss together.

- According to Degree of Automation

(1).Manual Shrink Labeller

Manual shrink labeller has a compact design, it is small in size and can be operated on any tabletop. This machine has low degree of automation, all operations need to be done manually, you should put the bottle and label the bottle by your hands. Therefore, the labeling speed and accuracy of manual shrink labeller are low, this machine is suitable for family use or small scale production.

(2).Semi-automatic Shrink Labeller

Compared with manual shrink labeller, semi-automatic shrink labeller has higher degree of automation, you only need to put and remove bottles, the machine will label the bottles automatically. Also, semi-automatic shrink labeller is more accurate than manual shrink labeller, therefore, it is more suitable for small to medium scale production.

(3).Fully-automatic Shrink Labeller

Fully-automatic shrink labeller has the highest degree of automation, it can do all operations, which include bottle feeding, shrink label forming, labeling, heat shrinkage automatically. Fully-automatic shrink labeller has fast speed and high accuracy, can package a large amount of products in a short time, therefore, it is an ideal equipment for industries which require high production capacity.

- According to Labeling Direction

(1). Vertical Shrink Labeller

Vertical Shrink Labeller-Photo Credit: Allma

In the vertical shrink labeller, the bottles are conveyed and labeled in a standing position, therefore, this type of shrink labeller is suitable for bottles and other containers with various width range and label position application. In addition, the vertical shrink labeller is easy to integrated with other equipment.

(2). Horizontal Shrink Labeller

Horizontal Shrink Labeller-Photo Credit: GIENICOS

Compare with vertical shrink labeller, the horizontal shrink labeller is more suitable for labeling small, light and long products, because the products are horizontally placed on the conveyor and labeled. Horizontal shrink labeller can be applied in a variety of industries such as cosmetic, stationery, medical, confectionery and so on.

5.How does shrink labller differ from regular labller?

Both the shrink labeller and regular labeller are designed to label containers, however, are there any differences between the two machines? Let’s make a comparison between them.

Shrink Labeller VS Regular Labeller-Photo Credit: Siddhivinayak Engineering

- Labeling Method: Basically speaking, the labeling methods of shrink labeller and regular labeller are different. Shrink labeller is to apply sleeve labels to containers and adopts heat shrink method to label them, while regular labeller directly sticks the labels on the containers.

- Label Material: As a matter of fact, shrink labeller and regular labeller adopt different labels. Shrink labeller use sleeve labels which are made of all kinds of plastic materials such as PE, PVC, PETG, etc, while regular labeller uses paper labels in general.

- Label Durability: As is mentioned that shrink labeller uses plastic labels while regular labeller uses paper label, therefore, the labeling which provided by shrink labeller is more durable because paper label get wet and break easily.

- Suitable Container: Shrink labeller is suitable for almost any container, regardless of shape, size and material, this machine can provide the most fit labeling for different containers. Regular labeller can apply labels to the side, top and bottom of round bottles, cans, jars and so on, however, it can not label on irregular surfaces.

6.How does a shrink labeller work?

The working process of shrink labeller isn’t complex, you can simply understand it, only need to remember the following steps:

- Bottle Loading: At the beginning, the bottles are put on the conveyor and delivered to the working station.

- Sleeve Label Forming: Next, the plastic film which is on the film holder are fed into the working station, pulled and shaped by film pulling mechanism.

- Bottle Positioning: When the bottle is delivered to the working station, there will be a pause, at this moment, the bottle is stopped and positioned so that the label can be applied on it accurately.

- Labeling: When the bottle is stopped on the correct position, the film cutting mechanism will cut off the shaped sleeve label so that it can fall on the bottle and cover it exactly.

- Heat Shrinkage: The next step is heat shrinkage, when the bottle is covered by sleeve label, it is heated and the sleeve label will shrink until it fits the bottle tightly.

- Cooling: After the heat shrinkage process, the bottle will pass by a cooling section to cool down, during this period, the temperature drops gradually, the sleeve label is stable and finalized.

- Inspection: Some shrink labeller is equipped with photoelectric sensors which can inspect unqualified products, then these products are rejected.

- Discharging: And next is the final step, the labeled bottles are conveyed to the output and discharged.

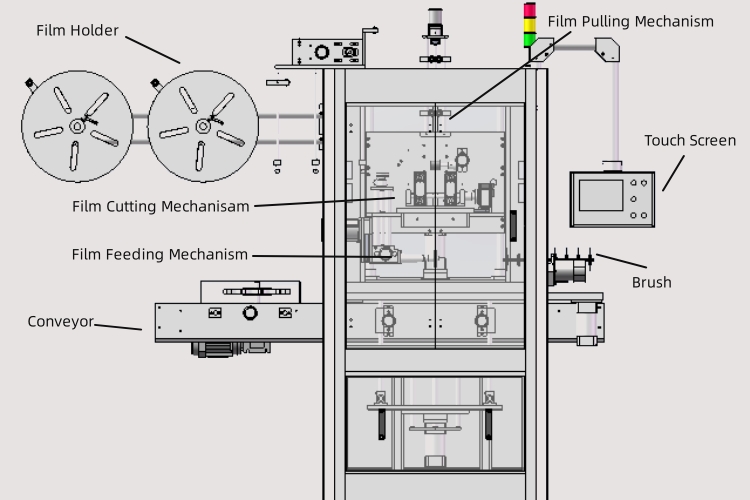

7.What is the structure of shrink labeller?

- Film Holder: The function of this part is to hold the plastic film which is used to label the containers.

- Conveyor: Conveyor plays a role in delivering bottles, conveys them to the correct position, this is an important component of shrink labeller.

- Film Feeding Mechanism: This part is to feed the film on the film holder to film pulling mechanism.

- Film Pulling Mechanism: This part consists of several rollers, it is to pull and tension up the film and shape it.

- Film Cutting Mechanism: After the film is shaped by film pulling mechanism, the film cutting mechanism cut off it so that a sleeve label is produced.

- Touch Screen: You can regard the touch screen as the brain of the shrink labeller, it communicates instructions to other parts of the machine so that the whole machine can work smoothly.

- Brush: The function of brush is to let remove the wrinkles on the labels, when the bottles pass by it, the brush will sweep up and down the label on the bottle, make the surface flattened, as a result, the labeling effect w+ill be perfect.

- Shrink Tunnel: Shrink tunnel plays a role in heat shrinkage, when the bottle passes by this part, the label is shrunk under high temperature.

8.Which kinds of shrink labeling styles can be provided by shrink labeller?

Do you know that? Shrink labeller can provide different shrink labeling style, to meet different labeling demands, such as the following styles:

Full-body Shrink Labeling

Full-body Shrink Labeling-Photo Credit: Impact Sleeves

As the picture shows, full-body shrink labeling is to cover the whole body of the bottles, including the caps. Full-body shrink labeling is generally applied in food and beverage packaging, make the products attractive and obvious.

Standard Shrink Labeling

Standard shrink labeling is also called partial shrink labeling, which means that the label covers a large area of the bottle body, but doesn’t cover the cap. Standard shrink labeling doesn’t has the tamper-evident function, it is more suitable for packaging juices and drink water.

Collar Shrink Labeling

Collar Shrink Labeling-Photo Credit: Traco Packaging

This is a kind of tamper-evident labeling method, you can see that the bottle mouths are tightly sealed by the label. The collar shrink labeling is always used for packaging wine, beverage, cleaning products and so on, ensure a safe packaging.

Multi-pack Shrink Labeling

Multi-pack Shrink Labeling- Photo Credit: Traco Packaging

This shrink labeling style is not as common as others, it is not label a singe product, but used to pack a group of products together, which is convenient for combination sales. This method is always applied in beverage and cleaning products packaging.

9.Which types of containers are compatible with shrink labeller?

It is mentioned that shrink labeller can package different containers, including bottles, cans, cups, jars, etc.

Bottles

Bottles-Photo Credit: Packaging Gateway

Shrink labeller can deal with all kinds of bottles such as water bottles, wine bottles, juice bottles, drop bottles, irregular bottles and so on, and the labels can fit the bottle body perfectly. Generally speaking, industries such as beverage, pharmaceutical, chemical, personal care products, household products, need to add labels on bottles.

Cans

The application of shrink labeller for cans is common in beer and carbonated beverage packaging. Originally, the products are packed in pure colored aluminum cans, which look a little ordinary. However, if you use shrink labeller to add colorful and designed labels on the cans, they will be totally different.

Cups

Under what circumstances does the cups need to be shrink labeled? In general, there are many food products such as yogurt, ice cream, cheese and so on, are packed in cups. To make these products attractive and hot-selling, it is necessary to use shrink labeller to add labels on them.

Jars

Of course, shrink labeller can be applied to package jars, no matter glass jars or plastic jars. No matter what kinds of shrink labeling styles you need to achieve on the jars, the shrink labeller can meet your needs. It is a good choice to use shrink labeller to package jars, because the machine can provide a tamper-evident and airtight labeling.

10.What are the common issues of shrink labeller? How to solve them?

As a commonly used equipment, there will also be some small issues during the work process of shrink labeller. When this situation happens, calm down, and try to solve them by yourself. And here are some common issues of shrink labeller, let’s learn them together.

- There are wrinkles and fish eyes on the shrink label.

Wrinkles & Fish Eyes-Photo Credit: Label & Labeling

When there are wrinkles and fish eyes on the shrink label, the problem may be in the temperature, during the heat shrinkage process, if the temperature is uneven or not high enough, there will be this situation. What should you do to solve this problem? Just need to increase the tunnel temperature or airflow so that the degree of shrink is also increased.

- The position of shrink label is up

If the shrink label is positioned higher than originally planned, there might be two reasons, the first one, maybe the bottle is a a tapered design, and the other reason is that there are too much heat on the top of the bottle. The solution of this problem is simple, you should fix the label on the correct position before the heat shrinkage process.

- Tearing or Over-Shrinking

Tearing or Over-shrinking-Photo Credit: PDC International

If there is a tearing or over-shrinking problem of the shrink label, it may be that the temperature is too high or the heating time is too long during heat shrinkage. According to different causes, there are two solutions, the first one is to lower the temperature, and the other one is to shorten the heat time in the shrink tunnel.

11.Are there any tips to maintain a shrink labeller?

If you want to extend the service time of your shrink labeller, it is important to make good maintenance, the maintaining tips are as follows:

The most vital thing is the cleaning, if there are too much dirt on your shrink labeller, it can not work smoothly. Every time when you finish using the shrink labeller, you need to use a wet cloth to swipe the machine body, and remove the dirt and dust on its surface, this operation is not only for cleaning, but also to prevent scratches on the machine.

Notice that besides the surface of the whole machine, you also need to clean the rollers of shrink labeller, you should use soap water to swipe them so that they can work smoothly in the next time.

Except cleaning, checking is also important, there are many things to check, you need to check whether there is a oil leakage of the machine, whether the screws are loosen, and whether the moving parts are worn. If these situations happen, remember to solve them in time, so as not to affect the normal operation of the shrink labeller.

12.How to choose a shrink labeller for your business?

Before purchasing a shrink labeller, you need to figure out what kind of machine is suitable for your business, therefore, there are some factors for you to consider.

Production Speed

The most important thing is the production speed of a shrink labeller, you need to ask the manufacturer how many bottles can be labeled by the machine, and judge whether the speed of this shrink labeller can meet your demands. Don’t choose a shrink labeller whose speed is too slow, it will affect the whole production output.

Machine Quality

Also, you need to judge the quality of a shrink labeller, if the machine has a poor quality and often breaks down during production process, this is not allowed. Therefore, you’d better to test and try out the machine before purchasing, only if you confirm that the quality of the machine, you can consider to buy it.

Space of Workshop

By the way, the size of the machine you buy depends on the area of your workshop, there are large and small sized shrink labellers on the market, if you have enough space to accommodate this machine, you can buy a large one, otherwise, buy a smaller one.

Conclusion

There is no doubt that shrink labeller is a high grade packaging equipment which can benefit you a lot, it has high efficiency and accuracy, is the best choice for industries. Anyway, after reading this blog, do you understand the shrink labeller? How do you think of this machine? Welcome to contact us if you have questions about shrink labeller.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide