Tablet Counter: The Complete Buying Guide In 2025

Are you an infant in the realm of pharmaceutical industry and looking forward for completing your production line by introducing an ultimate solution for precise counting? Or do you have a well established business of similar kind but your plan to thrive it is becoming a compelling factor to trace an advance equipment for enhancing efficiency and precision? If yes! You have finally found the answer which in form of tablet counter.

Tablet counter is a lucrative device known for the decisive role it plays in very sectors in form of counting tablets, pills and capsules. As the competition in market is gaining momentum for producing same things, industries are more concerned about using advance technology and revoking reliance on traditional methods. Therefore, if you are curious to explore in deep the tablet counter, this guide is providing you a good opportunity to acquire more knowledge of the machine's features, working mechanism, applications and more. Let's get started and fetch all you are looking for!

1.What Is A Tablet Counter?

Tablet counter refers to the advance machine designed to effectively undertake the function of counting huge number of tablets, pills and capsules without any calibration. The machine is equipped with unique features of automatic tablet detection, intuitive operating interface and fast counting cycle which collectively contributes to its efficiency, precision and convenient handling.

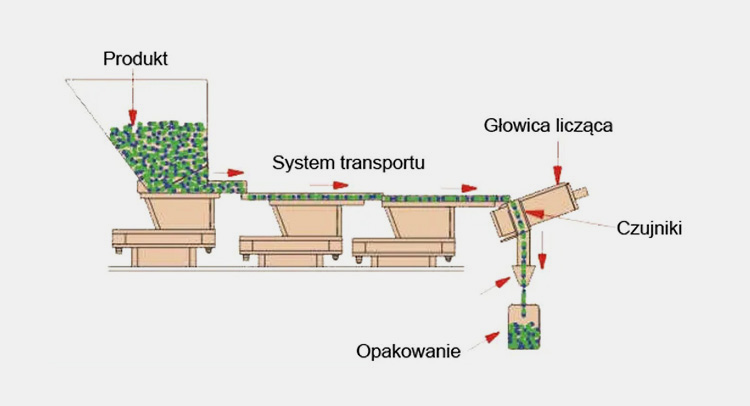

This standalone device requires minimal or no interference of user during operation, and thus, carries out the assigned task by processing tablets from hopper through detection phase and ultimately tracking them to be loaded in bottles awaiting. At the same time, the machine aims at reducing tablet breakage, counting error and providing desired outcome. Therefore, every industry is keen to incorporate this effective tool into their manufacturing line to get targeted objectives.

2.How Does A Tablet Counter Functions?

Picture Courtesy: K D Machine

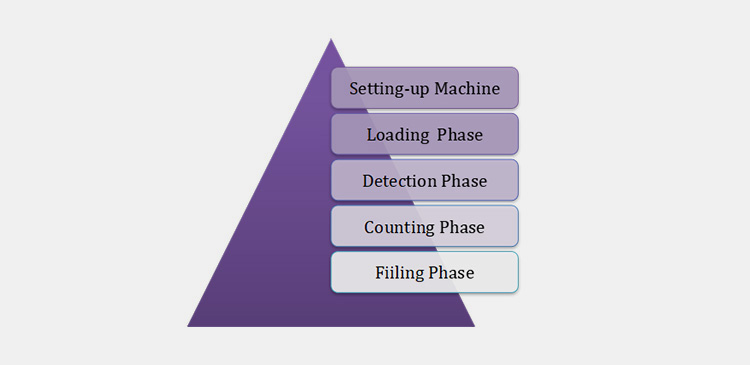

A standard tablet counter follows smooth and straightforward way for execution, however, there may be slight difference in the working principles of different types of tablet counter. Following points will clearly demonstrate the basic working steps followed by a tablet counter.

Setting-up Machine

Before starting operation, the operator must go for setting the basic parameters of machine on the basis of which machine will process tablets. It may include the amount of tablets to be counted and filled in each bottle.

Loading Phase

After setting parameters, the operator is required to feed the hopper with bulk of tablets. Once, the loading is done, machine is ready to start for further processing.

Detection Phase

Picture Courtesy: IDE

Moving forward, tablets will be gradually released from hopper onto the vibratory trays. These channels help in aligning tablets and removing defective tablets from the rest ones.

Counting Phase

Picture Courtesy: Cremer

The tablets will be moved from vibratory channels towards counting head where intellectualized system of sensors will count and pass the tablets to sleeve hopper.

Filling Phase

At last, with the help of filling nozzle, counted tablets will be released from sleeve hopper into the bottles laying over conveyor belt.

3.Which Benefits You Can Get By Using A Tablet Counter?

Tablet counter brings with it plethora of benefits which can change the fate of your business in the best possible manner. Let's have a look towards these attributes one by one:

Convenience of Handling

Undoubtedly, this machine brings greater degree of convenience due to its compact structure and simple processing features. Together, they contribute to easy handling of machine in terms of mobilization as well as execution.

Counting Precision

The foremost characteristic of tablet counter for which it has always been admired, is its excellence in counting the exact number of tablets and consequently, filling them into bottles. Similarly, it helps the manufacturers to bolster their aim of satisfying customers and avoid instances which can lead to grievances.

Hygienic Processing

Picture Courtney: iPharmachine

Tablet counter is made with GMP complaint corrosion resistant stainless steel and integrated with dust-proof system to fully assure that tablets are processed free of contamination.

Time-Saving

Indeed, tablet counter is the most suitable alternative to manual counting as it can fill up to 150 bottles in a minute. In this way, it saves the precious time which can be dedicated to increase production and also reduces humanly possible counting errors.

Clear Observation

The entire mechanism of tablet counting can be clearly seen via transparent window. It thus, enables user to keep an eye on the process of machine in order to keep it running smoothly.

Reliable

Tablet counter is reliable for being cost-effective and adaptable that it can be used for variety of tablets and pills irrespective of their nature, size and shape.

4.Can Tablet Counter Process Things Other Than Tablets?

A tablet counter is most compatible and resilient machine which not confined to the processing of particular kind of tablets, rather it has broad spectrum of application over numerous things including:

Tablets

All types of coated, uncoated, sterile and compressed tablets are eligible to be counted by tablet counter.

Sweets

Sweets such as chocolate balls, candies, chewable, jelly and bubble etc., can be counted while using this machine.

Capsules

Capsules of both categories including soft gels and hard gel capsules filled with powder, granules or essential oil are often processed by tablet counter.

Laundry pods

Laundry pods are water-soluble pouches filled with liquid detergent used for washing clothes. Among other things, these small pouches are also counted and filled by tablet counter into bottles.

Gel Blasters

Gel blasters are small jelly like balls filled with liquid gel which are used in toy guns for shooting. They are delivered in fixed quantity, hence, tablet counter is mostly found usable for counting and filling bulk gel blasters into different bottles and containers.

5.Describe The Key Components Of A Tablet Counter?

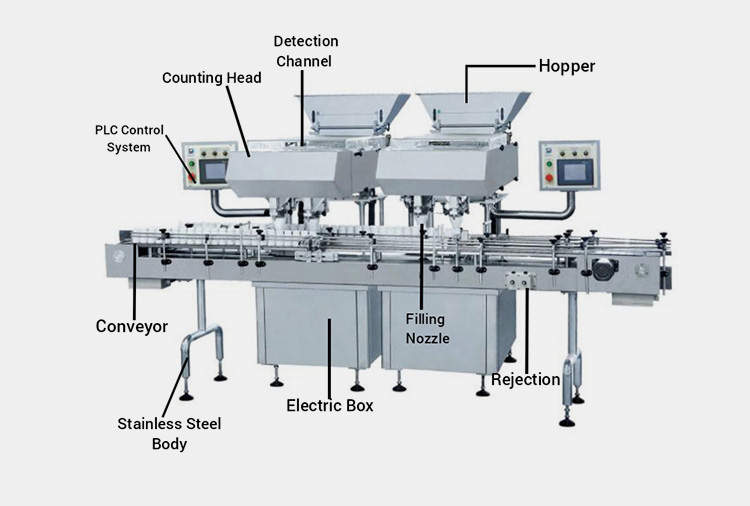

Tablet counter consists of several small to large components which together make a multidimensional ergonomic machine. These key parts are described below:

Hopper

Hopper is the feeding unit of machine where bulk of tablets or other stuff is loaded which are to be processed. It has a narrow opening at the end from where these tablets are gradually released via vibratory trough.

Detection Channel

Detection channel is a crucial component consists of vibratory trays. These trays are made up of stainless steel and constantly vibrate during process to serialize and detect tablets for counting.

Counting Head

It is the core part of tablet counter, where actual task of counting tablets takes places with the help of electric sensor.

Filling Nozzle

Filling nozzle is small tablet discharging hole attached with sleeve type hopper. It dispenses the counted tablets into bottles.

PLC Control System

It is the control system of machine with a touch screen display through which user delivers the commands to machine.

Conveyor

This key component of machine play vital role in the transportation of bottles from one place to another.

Stainless Steel Body

The entire body of machine is made up of 304 stainless steel, making the tablet counter more durable and stable during performance.

Electric Box

It is the control cabinet of machine with a web of servo drives and electromechanical components. It protects the internal machinery of tablet counter.

Rejection

Among other components, rejection system is one of the most crucial as it assures the bottles are accurately filled with desired amount of tablets, otherwise, it rejects them.

6.Explain The Various Types Of A Tablet Counter?

As a matter of fact, there are different levels of businesses which are directly or indirectly involved in manufacturing tablets such as large scale industries, medium scale production facilities or home based businesses. Therefore, keeping in view the divergent demand for tablet counter, it has been categorized into several types which can be better understood by looking in deep the below description:

Fully Automatic Tablet Counter

Fully automatic tablet counter is the most advanced and top quality machine made with cutting-edge technology to aid large scale industries. It is self-sufficient in its working once the desired parameters are fixed into it, the machine independently regulates tablet detection, dust suction, tablet counting and eventually filling them into bottles or containers. Its structure and cost are relatively larger than that of other types of machines, however, its fast performance help manufacturers in expanding their production and gaining more profit.

Semi-Automatic Tablet Counter

Semi-Automatic tablet counter another type of tablet counter which is more compact, precise and handy in nature. It follows simple procedure for working where the initial step such as feeding hopper and bottle require manual interference while the rest of counting and filling is carried out automatically. Since, it is low in its production in contrast to fully automatic machine, manufacturers who are running medium-sized food factories or pharmacies prefer using this type of machine.

Manual Tablet Counter

The most simplified form of tablet counter you will find is the manual one. It has extremely simple design comprising a mold tray, plain stainless steel base and a handle for easy holding. The user put tablets into molds and turns it after counting the tablets, where these tablets get collected at the end and thus discharged into container or bottle etc. Although, manual tablet counter is cheap and requires no techniques, it is a very slow process and only preferable to areas with low level of daily production such as home based businesses.

Digital Tablet Counter

Digital tablet counter is small size machine which do not use any hopper or vibratory trays for the counting of tablets and pills; rather it takes the help of sample plate to count tablets. It consists of sample plate, tight button, adjustable screw, speed controller, host and splash cover. It is suitable for variety of products including medicines, beans and sweet etc.

7.How Would You Distinguish A Fully Automatic Tablet Counter from Semi-Automatic Tablet Counter?

To better know the distinctions between fully automatic tablet counter and semi-automatic tablet counter consider the table below:

| No | Factors | Fully Automatic Tablet Counter | Semi-Automatic Tablet Counter |

| 1 | Nature | Fully automatic and self reliant | Depends upon manual handling |

| 2 | Structure | Complex with multiple components | Simple with precise construction |

| 3 | Productivity | High productivity by filling up 150 bottles per minute | Relatively low productivity by filling 10-30 bottles per minute |

| 4 | Cost | Expensive due to automation | Cost-effective with low level of automation |

| 5 | Application | Large scale industries | Moderate or small factories |

| 6 | Example |  |

|

8.In Which Areas A Tablet Counter Can Be Brought Into Use?

Table counter serves as a primary tool for counting in range of areas which are highlighted below:

Pharmaceutical Industry

It is one of the largest industries which discovers and produces millions of tablets, pills and capsules every day. Counting such gigantic volume is humanly impossible, therefore, a tablet counter has been introduced to resolve this issue.

Nutraceutical Industry

Unlike pharmaceutical industry, nutraceutical industry aims at strengthening the natural immunity of humans to cure diseases. These medicines are obtained from sources such as fruits, vegetables and herbs etc. Hence, the growing demand for supplements has made the industry dependent on using tablet counter.

Veterinary Industry

Veterinary industry encompasses the dental, medical and surgical treatment of animals where most of the time help of medicines are taken. In this way, the presence of tablet counter has also been found there.

Cosmetic Industry

Nowadays, the focus of cosmetic industry is shifted towards providing natural solutions, for strengthening hairs, reducing dark circles and aging skin, in form of gummies and capsules containing vitamins, proteins and essential oil. Therefore, processing of these ingredients require the assistance of tablet counter.

Food Industry

As there is no age restriction to enjoy the colorful flavors of sweet and juicy gummies, candies and chocolates. Similarly, there is no way out for manufacturers to make these goods process for you with machine other than tablet counter.

Chemical Industry

Like other industries, chemical industry has also been influenced by the efficient performance of tablet counter in a way that most of the chlorine tablets, laundry pods and confidor tablets are processed by this machine.

9.How To MaintainA Tablet Counter?

It is worthy to mention here that a tablet counter needs regular maintenance and cleaning to keep it on right track. Therefore, to familiarize you with the maintenance of tablet counter, explanation is given below:

Machine Setting: Accurate machine setting is the core step for successful operation. Therefore, you need to set the parameters of machine in accordance with your desired requirements. In addition, checking the machine setting each time before starting an operation can reduce the chances of possible errors.

Cleaning: It is necessary to clean your tablet counter on daily basis in order to remove the debris and tablets residues. The cleaning procedure of machine is quite easy. You can use potable water to wash the different parts of machine like hopper, vibratory trays and sleeve hopper etc. For parts like control panel and conveyor belt, you can use isopropyl alcohol sprayed cloth for dirt wiping.

Lubrication: A tablet counter uses several components at the same time to carry out the counting task such as conveyor belt, counting channels, and tablets outlet. These parts are driven by internal mechanical system which needs proper lubrication to run smoothly. Therefore, lubrication is inevitable for successful operation.

Examining External structure: Another aspect of tablet counter maintenance requires you to examine the external structure of machine before and during operation. It will help you in timely correction of these parts. For instance, if any screw is loose or missing and the wire is worn out you may be able to go for troubleshooting.

10.What Are The Auxiliary Devices For A Tablet Counter?

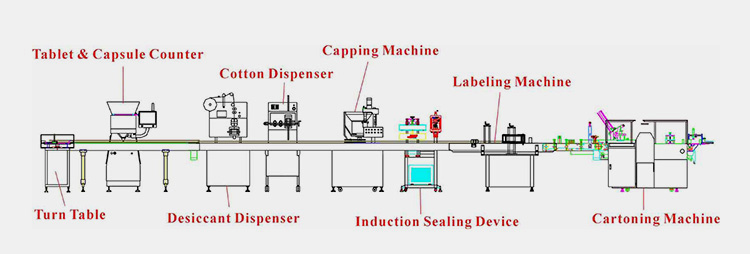

A tablet counter may be integrated with other machines to make a full-fledged production line and bring ease in whole processing. These auxiliary devices are mentioned below:

Turntable

Turntable is a machine with rotary table and supporting stand. It is used for serializing bottles before they go to filling machine.

Desiccant Dispenser

As the name justifies, desiccant dispenser is a machine used in the production line of tablet packaging. This machine dispenses desiccant pouches, containing silica gel into tablets filled bottles which helps in reducing the risk of condensation.

Cotton Dispenser

This machine is employed to cover the neck of tablet filled bottles by releasing hard cotton over it.

Capping Machine

Capping machine is designed to cap the filled bottles with neck. The necks of bottles are loaded in hopper of the machine from which it is delivered one by one and screwed over the bottles.

Induction Sealing Device

It is an electromagnetic device which uses heat radiation to get the hard cotton or aluminum foil stick to the neck of the bottle for protecting against moisture, temperature and harmful ultraviolet light.

Labeling Machine

Labeling machine plays a major role in tablets packaging. It is used to label the bottles with adhesive stickers or paper labels containing useful information about product usage, expiry date and prescription etc.

Cartoning Machine

Cartoning machine is the ultimate equipment which finally pack the processed tablet bottles into separate cartons.

11.How To Diagnose The Common Pitfalls Of A Tablet Counter?

To counter the possible problems caused when operating a tablet counter, the table below is containing useful description:

| No | Pitfalls | Causes | Diagnosis | Picture |

| 1 | Erroneous Counting | It happens when the counting time is fixed incorrectly | Accurately set the tablet counting time by using HMI |  |

| 2 | Abrupt alarm without malfunction | The sensors may be overloaded by tablets' residues | Clear the sensors with cloth and empty dust collection box |  |

| 3 | Loud noise during process | Either screws are loose or vibratory trays are not well linked to outlet | Tight the screws and align the trays in accordance with outlet |  |

| 3 | Tablets dispersion or leakage | The distance between nozzle and bottle is wide | Decrease the distance by adjusting nozzle |  |

12.What Are The Quality Standards For A Tablet Counter?

Tablet counter is a machine designed to fulfill the responsible task of processing tablets, pills and capsules which requires highly hygienic and safe environment. Therefore, it becomes inevitable to check whether the machine you are going to purchase is complying standard quality certifications? For this below information can be useful:

GMP

Good Manufacturing Practice or current manufacturing good practices is an international aspect of quality standards which has established principles regarding safety of all those equipment which are to be used for pharmaceutical and biotechnology manufacturing purposes.

ISO

International Organization for Standardization is an independent organization formed for the purpose of generating such quality standards whose compliance will produce safe and quality products.

FDA

Food and Drug Administration is an American regulatory agency established to ensure safety of the processing and manufacturing of drugs and associated products such as medicines, vaccines and medical devices.

CE Standards

CE standards are formulated for the purpose of promoting manufacturing and supplying of safe goods and products for countries wishing to trade in European Union countries.

The above discussed standards provide an opportunity for you to check the quality of machine you are going to purchase. If your tablet machine is complying the above standards, it is safe to use.

13.How To Choose An Excellent Tablet Counter For Your Business?

Sometimes, choosing the right tablet counter for your business becomes tricky. To help you solve this issue, we have provided few points for your ease:

Capacity

One of the essential factors to consider is the machine's capacity for potential production. It is because you are going to purchase the machine in order to fulfill your production requirements. Therefore, the capacity of tablet counter complement your need than it is the suitable one

Customization

Another aspect to look for is the degree of customization machine possess. For instance, there must be enough room available for customization in case you have diverse products to process.

Budget

Considering your budget is a significant factor to look for. It will help you choose the best possible tablet counter within your range.

Customer Service

Last but not the least; make sure to check the customer support on part of your supplier. It can be really helpful for you in future, whenever, you face difficulty in machine setting or feel need for change of parts.

14.What Is The Aipak Collection Of Tablet Counter And How It Differs From Other Machines Available In Market?

Aipak has a huge collection of tablet counter which can suit your small to extra large industrial production. Below details will better display you the versatility of machine Aipak is offering:

| Machine | Automation | Speed/ Bottles per min | Filling Nozzle | Application |

| Desktop electronic tablet counting machine | Semi-Automatic | 10-30 BPM | Single | Medium Scale |

| APC-8 Automatic Tablet Counting Machine | Fully Automatic | 10-30 BPM | Single | Medium Scale |

| APC-24 Automatic Counting Production Line/capsule /tablet counting machine | Fully Automatic | 20-80 BPM | Double | Large Scale |

| APC-48 Brand New Simple Operation Tablet Counting Machine | Fully Automatic | 40-150 BPM | Four | Extra Large Scale |

| APC-202 automatic tablet counting machine | Fully Automatic | 20-40 BPM | Double | Large Scale |

Aipak Pharmaceutical Equipment is a proficient company specialized in manufacturing all kinds of pharmaceutical equipment from processing till last step of packaging. The company offers extensive range of tablet counter with immeasurable incentives. Some of them are highlighted below:

Quality Certified

All of their equipment are certified by all the international quality standards including CE, FDA, GMP and ISO. It affirms that all of their equipment are no exception to quality.

Warranty

The company's unique policy of 12 months warranty distinguishes it from all other companies who are not willing to give any type of assurance.

Huge Variety

While going through Aipak collection of tablet counter, you will find huge varieties of machines with diverse features and applications making them resilient to process products beyond tablets and pills.

Full Installation and Training Support

The company is providing full Installation and training support to the customers followed by 24/7 sales and technical support.

Conclusion

In a nutshell, tablet counter is the most desirable device for every manufacturer who is engaged in pharmaceutical, food, cosmetic and other relevant industries. Its efficiency, precision and safety are the qualities every business wants to be well known for. Hence, its significance cannot be overlooked. If you also want to get benefits from this magnificent machine Aipak Pharma is complying all the needs. So, don't make any delay and approach us via given link!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide