Plastic Bottle Washing Machine: The Complete Buying Guide in 2025

Did you know your product is at High Risk of Contamination if not cleaned Properly? We know the solution! A plastic bottle washing machine is a perfect answer for general and sterile preparations. You can defy its importance as it ensures the filling container is free from foreign particles.

Before purchasing a plastic bottle washing machine, we would suggest reading this guideline. Here, our experts have collectively answered the major questions that everyone looks for. Have a look!

1.What Is Plastic Bottle Washing Machine?

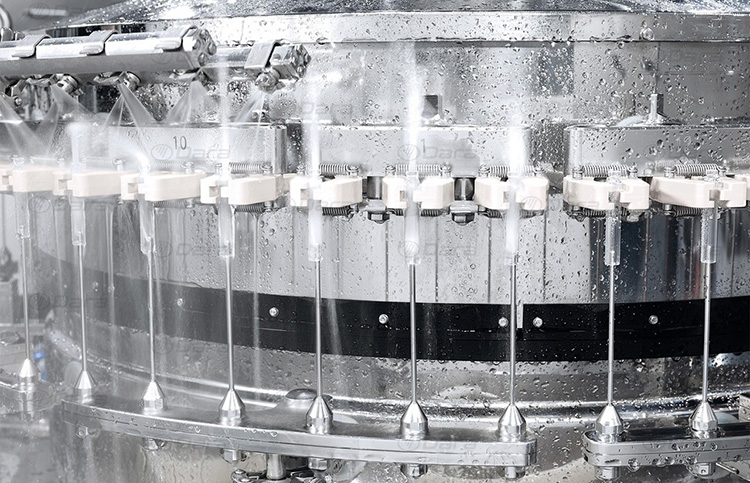

Plastic Bottle Washing Machine- Picture courtesy alibaba

A plastic bottle washing machine is a mechanical equipment that cleans and sanitizes the bottles by the action of various washing stages including pre-washing, rinsing, deep washing, and air-drying (optional) to offer contamination-free packaging material.

The machine has the ability to wipe not only the inner surface of the object but the exterior as well.

The washing action takes place by high nozzle sprays, water circulation systems, air filter blowers, and sensors. Plastic bottle washing machine is available in various types and sizes so it can be compliant with large and small production lines. The entire motive behind its development is to wipe off the presence and adherence of every minute particle that may progress an unwanted cause of contamination and affect the quality of your brand.

2.What are the Major Industrial Applications of Plastic Bottle Washing Machine?

When it comes to the uses of a plastic bottle washing machine; nevertheless you can find this robust machine everywhere in industrial manufacturing units. Some of the important applications are discussed below:

Chemical Industry

Picture Courtesy- Amazon

The chemical solution is always reactive in nature. One must keep in mind to use cleared and wiped plastic bottles prior to filling them. A plastic bottle washing machine is an essential tool used in this sector for cleanup bottles used to store products like alkali solvents, acidic solutions, buffers, salts, and organic and inorganic products.

Nutraceutical Industry

Picture Courtesy: SKS Bottles

Nutraceutical products include protein powders, probiotics, multivitamins, energy powders, supplements, etc. are available in solid, powders, or liquid form that must be stored in sanitized plastic bottles after being washed and dried by a plastic bottle washing machine.

Pharmaceutical Industry

Picture Courtesy- Tip Top Prop

A plastic bottle washing machine is used in this sector to clean plastic and glass bottles required for the filling and packaging of tablets, capsules, syrups, ointments, sterile preparations, and topical preparations like balms.

Food Industry

Picture Courtesy- Made in China

The filling of food products such as sauces, powders, kinds of ketchup, purees, dressing, topping, and spices, etc needs cleaned bottles which are achieved by using a plastic bottle washing machine.

Cosmetic Industry

Picture Courtesy- Primepac

Cosmetic formulations such as creams, lotions, face foundations, eye conclears, and other products are filled with high-grade sterile plastic bottles that must be passed from the plastic bottle washing machine.

Beverage Industry

Picture Courtesy- Medical News Today

Cleaning and washing plastic bottles prior to packaging and filling soda, juices, mineral water, and energy drinks must require this machine in the beverage industry.

Research and Development

Picture Courtesy CPLAB

This field of science is always looking for perfection. A plastic bottle washing machine is worth buying tool used in the research and development sector for storing sterile samples such as blood samples, plant extracts, biological samples, etc.,

Household Industry

Picture Courtesy Waster.com

Detergents, floor cleaners, floor disinfectants, powders, and shiners, are commonly used filling products used in this industry that are always treated with a plastic bottle washing machine.

Pesticide Industry

Picture Courtesy-Indiamart

Pesticidal filling products must be cleaned and washed as they’re prone to react with foreign particles and affect the potency. A plastic bottle washing machine is a must-have equipment in the pesticide industry production line.

3.What are Advantages of Plastic Bottle Washing Machine?

Plastic bottles washing machine has several advantages and checks all the boxes of hygiene, cleanliness and efficiency. Some common advantages that a plastic bottle washing machine offers are as follows.

Hygiene and cleanliness

Picture Courtesy- NPACK machine

Plastic bottle washing machine provides high level of hygiene and cleanliness by utilizing its multiple nozzles, directing water and soap at all possible angles ensuring a thorough wash in every cycle.

Labor saving and time effectiveness

All automatic plastic bottle washing machines usually require one operator to input machine parameters and perform the entire operations and as many as thousands of bottles can be washed in a given period. Thus cutting labor cost and providing clean bottles in just minutes.

Water saving

Picture Courtesy- Alibaba

Plastic bottle washing machines are designed in such a way that they utilize minimum water for each cycle i.e. water nozzles direct high pressure jets in preset quantities to wash every inch of bottles and save gallons of water which otherwise would have been wasted while cleaning.

Offering High Production Capacity

The quality of wash remains consistent for thousands of working hours provided that machine is looked after and maintained as recommended by manufacturer.

A trustworthy Choice

These machines are utilized in highly regulated industries such as food and pharmaceuticals therefore, these machines are designed to meet both local and international stringent regulatory requirements.

All rounder

Not only plastic bottle washing machine can wash bottles of different sizes or shapes, some models can be used to wash recyclable bottles. These special machines are provided with label removing unit that removes labels using water jets.

4.What is Step-by-Step Working of a Plastic Bottle Washing Machine?

The working principle of a plastic bottle washing machine is super easy. For your understanding, we’ve described them step by step.

STEP NO. 1: LOADING

The washing process began with the loading of upright and properly oriented bottles received from the conveyor belt which is usually connected to the bottle unscrambler. Here, presence of tipping cradle ensuring that bottles are loaded inverted toward the receptacles. This is an important mechanism that is offered with a safety switch which stops if any bottle is jammed between tipping cradle and conveyor so breakage of bottles can be avoided. The received set of plastic bottles is transferred toward the washing zone.

STEP NO. 2: WASHING

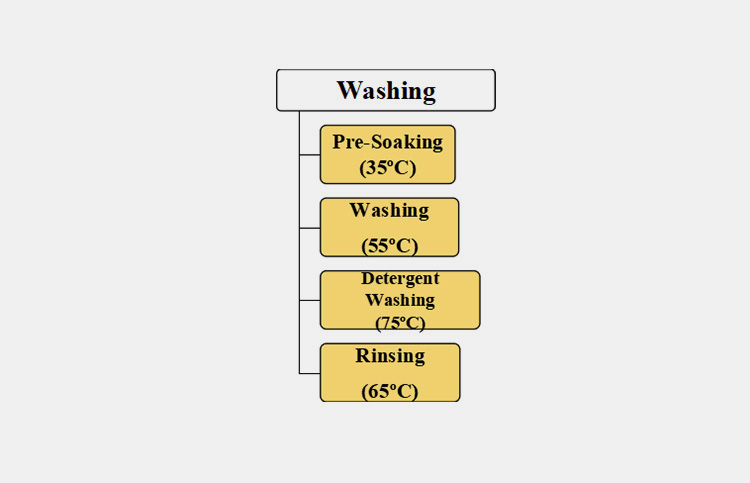

The washing step is the major stage where several washing sessions are taken place such as:

Picture Courtesy-Traktech

Pre-Soaking

With the help of conveyor chain plastic bottles are first introduced toward pre-soaking zone where warm water around 35ºC helps in removing of foreign particles., This step is essential before the final wash where plastic bottles are subjected to general wash in order to loosen the sticky residues on the inner and outer surface of the plastic bottle.

Washing

Next washing of bottle using jetting system of hot water around 55ºC is jetted inside and outside surface of bottles to remove if any particle left over surface. A high pressure nozzle sprays explode water on the plastic bottle with high intensity. This ensures plastic bottles are washed and cleaned with unwanted particles.

Detergent Soaking

Next conveyor chain brings plastic bottle in detergent soaking zone where hot detergent solution around 75ºC helps in the dissolving greasy, fat particles and flushed out the solution.

Rinsing

In this section rinsing of plastic bottles is involved with water jet system around 65ºC hot water. In order to assure that plastic bottles are cleaned; final rinsing can be done by spraying either water for injection which will eliminate the chances of any remaining or leftover particles inside or outside the plastic bottles. For cooling, water jet around 15ºC is passed through bottles to assure suitable temperature.

STEP NO 3: Air Drying

Picture courtesy- Solvair

Machines are designed with high air-jet heated blowers that simultaneously blow air with high temperatures (75ºC) that can dry the plastic material rapidly and then discharge through the system via a conveyor.

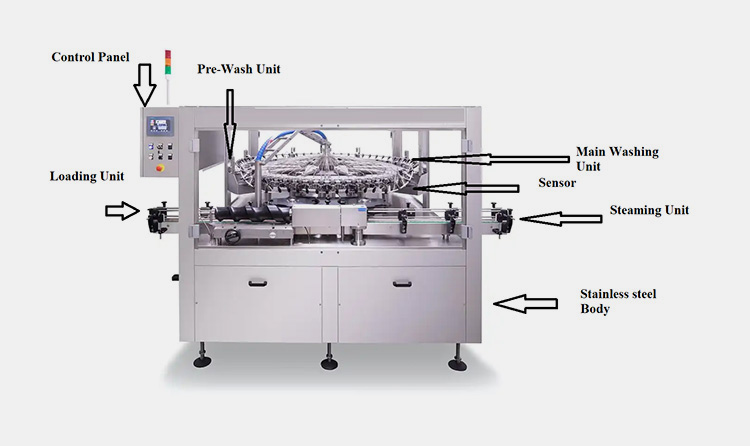

5.What are the Primary Parts of Plastic Bottle Washing Machine?

Parts of machine may vary from manufacturer to model to degree of automation that is why it is always advisable to consult manual provided with your machine. However, basic components of plastic bottle washing machine remain same and include following components.

| Parts | Description |

| Loading Unit

|

Depending on model a plastic bottle washing machine may be equipped with either infeed conveyer or both infeed as well as outfeed conveyer. The bottles for washing are loaded onto infeed conveyer and after the washing process the bottles are collected from outfeed conveyer. Operated by PLC control the conveyer system comprises of pulleys, conveyer belt etc. |

| Pre-wash unit

|

Many automatic and large plastic bottle washing machines contain a pre-wash unit where plastic bottles are washed before entering the main washing cycle. This pre-wash unit removes major chunks of debris and impurities and allow partially cleaned bottles to enter the washing cycle for a proper wash. |

| Sensor

|

The main function of bottle sorter is to remove damaged bottles from the main line allowing only the specified bottles to enter the washing cycle. Bottle sorter can be for different types and shapes of bottles. |

| Main washing unit | The main washing unit hold different multiple nozzles that spray water jet or soap thoroughly cleaning bottles from every angle, nook and corner. The machine first spray soap followed by multiple high pressure water jets for proper cleaning. The high pressure jet remove stubborn stains and dirt that might have escaped the pre-wash unit. |

| Steaming unit

|

In order to remove any chances of microbial contamination some machines have steaming unit where bottles are subjected to low temperature sterilization. Some models utilize hot water unit instead of a steaming unit for sterilization. |

| Drying unit

|

After washing the next phase in washing cycle is drying of bottles. This is carried out by using pressurized air jets for few minutes to remove water droplets. Alternatively, a low temperature heating unit can also be used that completely dries the bottles. |

| Control panel

|

Most machine these days have a digital control panel a part of human machine interface (HMI) which allows for entering required process parameters including machine speed, number of bottles, types of bottles, temperature of heating unit etc. Additionally, the control panel can also be used to switch on and off machine and abrupt halt of process in case of an emergency. |

| Stainless steel body

|

In order to limit contamination and reduce microbial growth main body of plastic bottle washing machine is made up of industrial grade steel as per regulatory guidelines. Steel not only reduces contamination, allows easy cleaning but also is sturdy and adds to working life of the machine. |

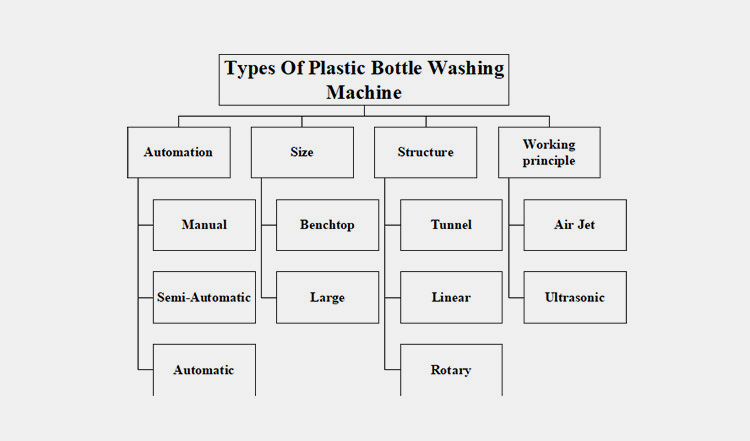

6.What is the Basic Classification of Plastic Bottle Washing Machine?

Today, a plastic bottle washing machine is offering various types of models and types for their consumers. The basic classification of plastic bottle machine is given below:

Manual hh

ACCORDING TO MACHINE AUTOMATION

Manual Plastic Bottle Washing Machine

Manual Plastic Bottle Washing Machine- Picture Courtesy Indiamart

A low cost machine suitable for small batches where bottles are fixed on washing molds present in the machine and water rinsing began upon opening the water valve. This is a simple machine commonly used in education sectors, protype developmental sector or production with astringent budget.

Semi Automatic Plastic Bottle Machine

Semi Automatic Plastic Bottle Machine- Picture Courtesy- Indiamart

This is good solution for running moderate to large production batches that require manual handling for loading and unloading the plastic bottles. The remaining task is performed by the machine itself. This machine offers rapid changeover so suitable for various shapes and size of bottles. Like, manual machine; it is also an affordable equipment involved with cleaning of large capacity output such as washing hundreds of plastic bottles in one hour.

Automatic Plastic Bottle Washing Machine

Automatic Plastic Bottle Washing Machine- Picture Courtesy Alibaba

This is fully automatic device requires no manual intervention. Loading of bottles can be achieved by conveyor that receives sorted bottles from unscrambler machine. A sophisticated step by step procedure is followed by automatic system fed by an operator using PLC system. This machine is super giant in the term of working as it can wash and dry hundreds of bottles in minutes and thousands of bottles in each hour.

ACCORDING TO MACHINE SIZE

Benchtop Plastic Bottle Washing Machine

Benchtop Plastic Bottle Washing Machine- Picture Courtesy Bottle washer

A small solution for those sectors that require super hygienic material for their practicals or production procedure with a limited space, limited budget, or small batches. A benchtop plastic bottle washing machine is available in semi-automatic feature that can manage moderate bottles washing in each session.

A Large Plastic Bottle Washing Machine

Large Plastic Bottle Washing Machine- Picture Credit Qpack

This is an ideal machine for big industries where day and night production processes are carried out automatically. The entire setup offers rapid change over time and flexibly can be integrated with other machines of the production. This machine requires a large installation space and gives you higher washing capacity with 100% robustness and accuracy each minute.

ACCORDING TO MACHINE STRUCTURE

Tunnel Plastic Bottle Washing Machine

Tunnel Plastic Bottle Washing Machine- Picture Courtesy Indiamart

A large industrial plastic bottle washing machine where machine design resembles tunnel like structure which is used to treat bulk quantities of unwashed bottles and discharge cleaned bottles after passing through various transition of stages. For example, pre-washing, washing, rinsing, etc., Machine can wash various size, shapes, and different material bottles rapidly and delicately.

Linear Plastic Bottle Washing Machine

Linear Plastic Bottle Washing Machine-Picture Courtesy Watersman Engineering

These machines are designed with simple linear structure with conveyor unit that is responsible for transporting plastic bottles into pre-washing, washing, and other zone of the machine in a linear fashion. This machine is suitable for medium to large production batches.

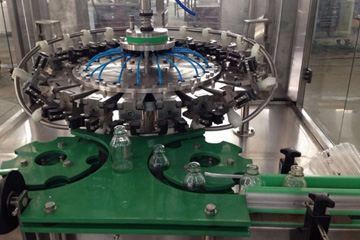

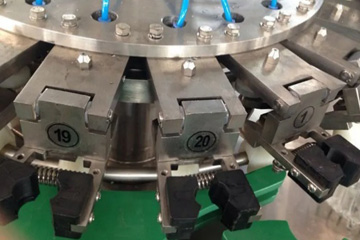

Rotary Plastic Bottle Washing Machine

Rotary Plastic Bottle Washing Machine-Picture Courtesy Alibaba

As it names show, a circular carousal or turntable is responsible for subjecting bottles for various stages/units of the machine for efficient washing procedure. As compared to linear this machine can encompass with large batches.

ACCORDING TO DIFFERENT WORKING PRINCPLE

Air Jet Plastic Bottle Washing Machine

Air Jet Plastic Bottle Washing Machine- Picture Courtesy- Indiamart

This system basically utilizes a powerful pressurizes water nozzles to spray water and compressed air to eliminate dirt and sticky particles adhere on inner and outer walls of the bottle.

Ultra-Sonic Plastic Bottle Washing Machine

Ultra-Sonic Plastic Bottle Washing Machine- Picture Courtesy- SPM

This is also known as a sonicator that works upon generation of high vibratory waves in the form of striking bubbles that gently implodes over walls of the bottles to wipe the unwanted particles. This is suitable for highly sensitive laboratories or healthcare industries.

7.What is the Complete Production Line of Plastic Bottle Washing Machine?

The following picture above demonstrates auxiliary equipment used in a production line of plastic bottle washing machine. The function of this complete unit is discussed below:

| Machine | Functions | Picture |

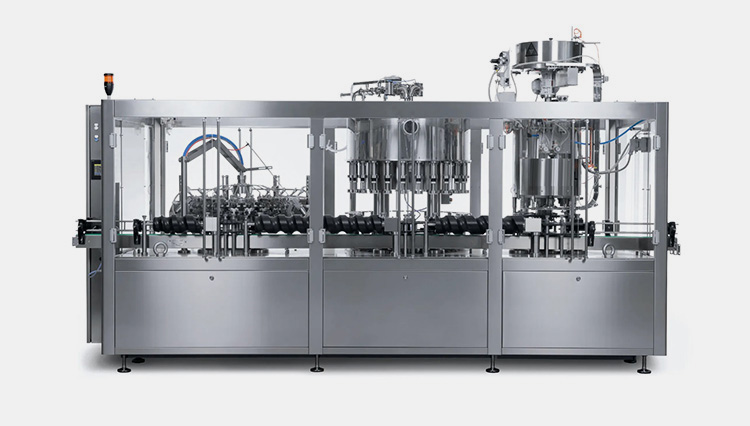

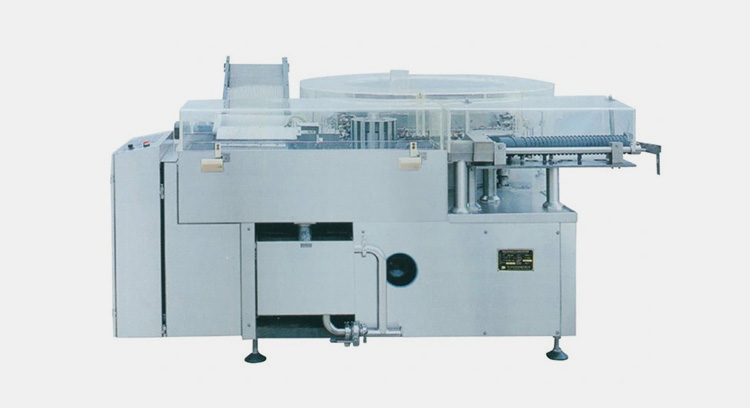

| Bottle Unscrambler | Before subjecting plastic bottles to washing machine it must be oriented in aligned and uniform pattern. Moreover, detection of damaged bottles also must be done. For this a bottle unscrambler machine is integrated with plastic bottle washing machine to receive bottles perfectly undamaged and in upright position. |  |

| Plastic Bottle Washing Machine | Upon receiving plastic bottles, they passes through the machine and cleaned bottles are discharged toward filling machine. |  |

| Tablet/Capsule Counting Machine | A cleaned set of plastic bottles are subjected for counting procedure using this machine. At this stage, one must assure that filling material is contamination free and product storage with no moisture content. |  |

| Capping Machine | Once plastic bottles are filled, they’re subjected to capping machine to secure insight product against leakage, spillage, and interacting with external environment. Machine has ability to twist caps around the next of bottles and discharge them for next machine of the facility. |  |

| Labelling Machine | This integrated machine offer significant job by printing and applies label over neat and cleaned external surface of the bottle. One must keep in mind, if external surface is uneven, labelling won’t be done properly. The labeling machine can stick label with mentioned information about the ingredients, date of manufacturing, expiry, dosage, batch number etc., |  |

| Cartoning Machine | A ready to market filled product is always subjected to cartoning machine for safe transportation. A cartoning machine can flip the carton and insert the bottle with leaflet automatically. |  |

8.What Other Things Plastic Bottle Washing Machine Can Wash?

Beside plastic bottles, a plastic bottle washing machine can wash several other things. For example,

| Type | Description | Picture |

| Ampoules | These are commonly used in medical, nutraceutical, cosmetics, and pharmaceutical section. Plastic bottle washing is of great benefits as it features ampoule washing as well. |  |

| Vials | Different sizes vials can be washed using plastic bottle washing machine which is required for sterile preparations such as antibiotics, vaccines, chemotherapeutic agents, optic solutions, and so on. |  |

| Beakers | Glassware and laboratory objects such as tubes, beakers, funnels can be washed using plastic bottle washing machine. |  |

| Cans | Cans of various sizes are commonly used for storing beverage, food products are washed with this machine. |  |

| Jars | Plastic bottle washing machine can be adapted for cleaning various jars used in broad applications. |  |

9.What are the Technical Challenges and Solutions of Plastic Bottle Washing Machine?

| Technical Problem | Possible Causes | Solution |

| Plastic Bottle Jamming

|

This mostly happens when bottle stuck between tipping cradle and conveyor | Reset machine setting.

Replace safety switch. Check and clear the passage between tipping cradle and conveyor. |

| Improper Bottle Cleaning |

This happens due to low jet pressure of water.

Clogging of pressure nozzles. |

Set the parameters to achieve required water jet pressure.

Check water temperature and unclog the nozzle sprays |

| Plastic bottle damage

|

This can be caused by excessive pressure during. The misalignment of grippers can also damage bottles by scratching the surface. | Adjust the speed of conveyor. Validate the positioning of bottle and readjust the alignment. |

| Bad Smell from Plastic Bottle Washing Machine

|

This can be due to low maintenance and improper cleaning. | This is recommended to clean and maintain machine on the regular basis to avoid development of mushy smell. |

Conclusion

A plastic bottle washing machine is an ideal addition in the packaging line that ensures your products safety and security by clearing unwanted materials inside and outside the bottle. Of course, this robust machine is significantly important to gain customer’s satisfaction and maintain competitive reputation in the marketplace. Before, purchasing the machine, we would suggest to please contact our team for more information and machinery details. Send us short message now!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide